Method for recovering gold from roasting-cyaniding tailings

A technology for cyanidation tailings and gold recovery, applied in the field of gold recovery, can solve the problems of long water leaching time of roasting materials, generating a large amount of toxic gas, unfriendly roasting environment, etc., and achieves short cycle, small investment, simple and smooth process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

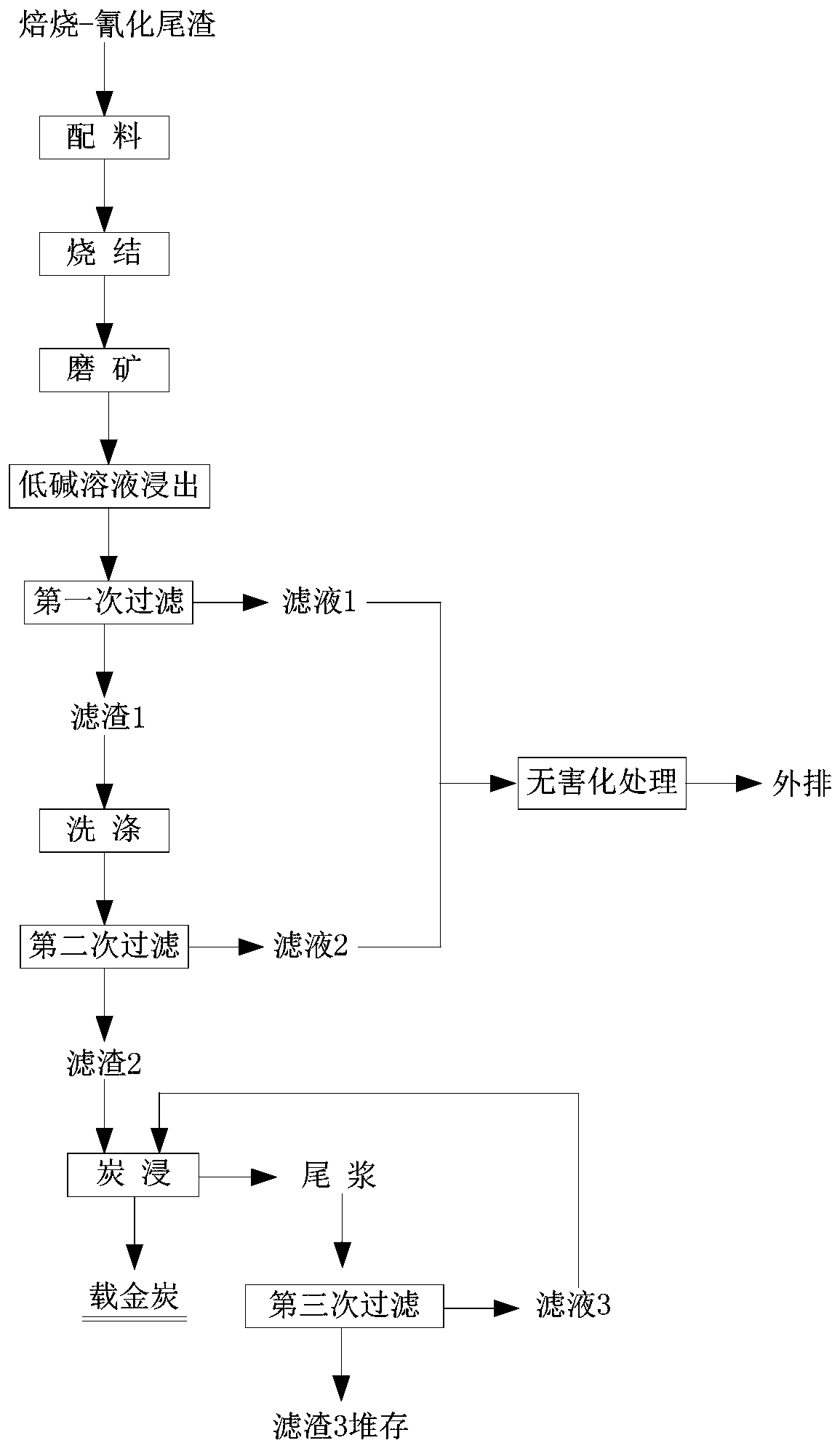

Image

Examples

Embodiment 1

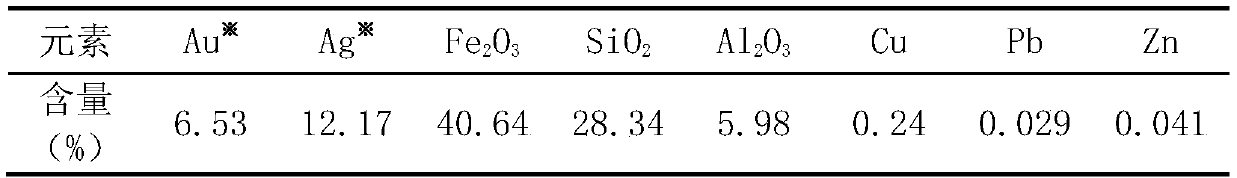

[0036] Table 1 shows the analysis results of the main elements of the roasting-cyanidation tailings from a gold smelting company in Fujian.

[0037] Table 1 Analysis results of main elements of a roasting-cyanidation tailings in Fujian

[0038]

[0039] Note: "※" unit is g / t, the same below.

[0040] The method for recovering gold from roasting-cyanidation tailings comprises the following steps in sequence.

[0041] The first step ingredients: according to Na 2 O molar mass: (Fe 2 o 3 Molar mass+Al 2 o 3 Molar mass+SiO 2 Molar mass)=1.3, add sodium hydroxide to the roasting-cyanidation tailings and mix to obtain a mixture, then add water to adjust the mixture into mud block material.

[0042]The second step of sintering: send the clay lump material obtained in the first step to a high-temperature furnace, and carry out sintering at a sintering temperature of 950° C. for 60 minutes to obtain sintered clinker.

[0043] The third step is low-alkali solution leaching: f...

Embodiment 2

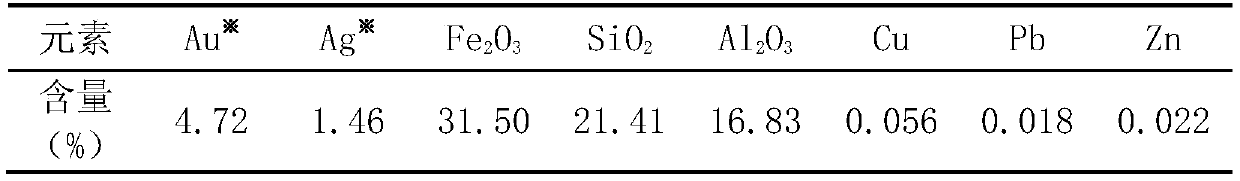

[0048] Table 2 shows the main element analysis results of roasting-cyanidation tailings from a gold smelting company in Shandong.

[0049] Table 2 Analytical results of main elements in a roasting-cyanidation tailing residue in Shandong

[0050]

[0051] The method for recovering gold from roasting-cyanidation tailings comprises the following steps in sequence.

[0052] The first step ingredients: according to Na 2 O molar mass: (Fe 2 o 3 Molar mass+Al 2 o 3 Molar mass+SiO 2 Molar mass)=1.5, add sodium carbonate to the roasting-cyanidation tailings and mix to obtain a mixture, then add water to adjust the mixture into mud block material.

[0053] The second step of sintering: send the clay lump material obtained in the first step to a high-temperature furnace, and carry out sintering for 40 minutes at a sintering temperature of 1000° C. to obtain sintered clinker.

[0054] The third step is low-alkali solution leaching: finely grind the clinker obtained in the second...

Embodiment 3

[0059] Table 3 shows the main element analysis results of roasting-cyanidation tailings from a gold smelting company in Hunan.

[0060] Table 3 Analytical results of main elements in a roasting-cyanidation tailing residue in Hunan

[0061]

[0062] The method for recovering gold from roasting-cyanidation tailings comprises the following steps in sequence.

[0063] The first step ingredients: according to Na 2 O molar mass: (Fe 2 o 3 Molar mass+Al 2 o 3 Molar mass+SiO 2 Molar mass)=1.0, add sodium bicarbonate to the roasting-cyanidation tailings and mix to obtain a mixture, then add water to adjust the mixture into a mud block material.

[0064] The second step of sintering: send the clay lump material obtained in the first step to a high-temperature furnace, and sinter for 30 minutes at a sintering temperature of 1100° C. to obtain sintered clinker.

[0065] The third step is low-alkali solution leaching: finely grind the clinker obtained in the second step to -0.074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com