Method for making large-scale vault split mounting type asphalt storage tank

A production method and assembled technology, which is applied in the production field of large-scale vaulted assembled asphalt storage tanks, can solve the problems that affect the normal progress of the construction period, affect the installation of asphalt storage tanks, and the accuracy of bolt hole positions is not enough, so as to achieve installation efficiency And the effect of high pass rate, simple and smooth process, and strong reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

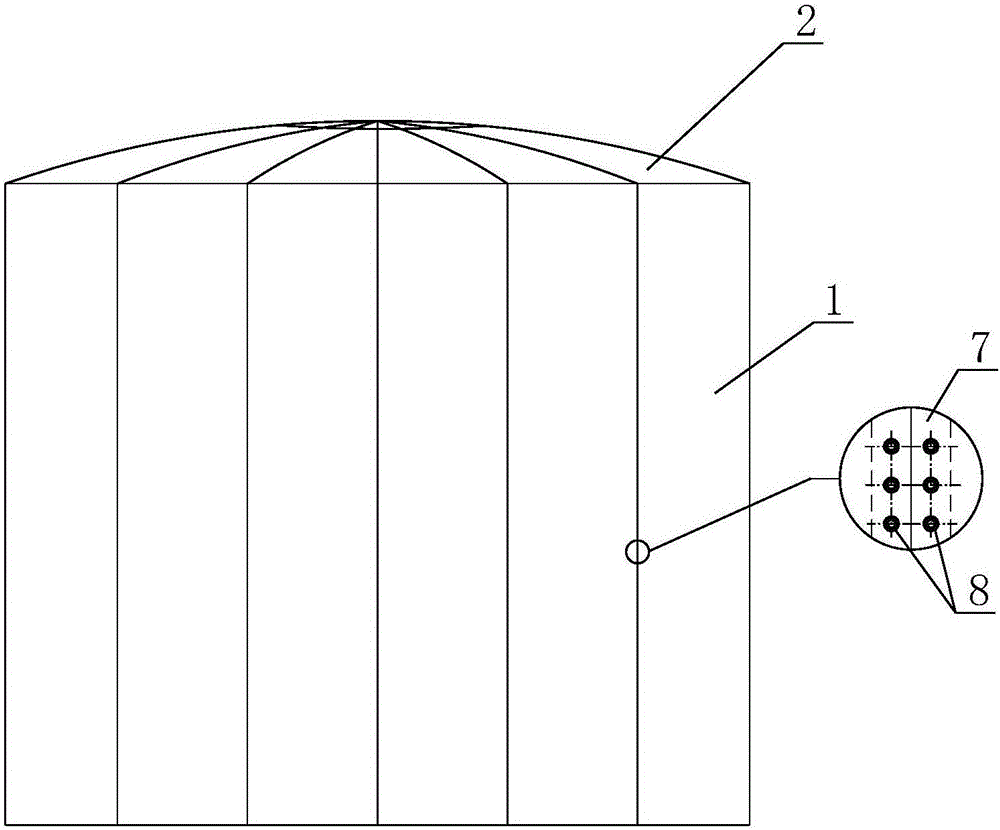

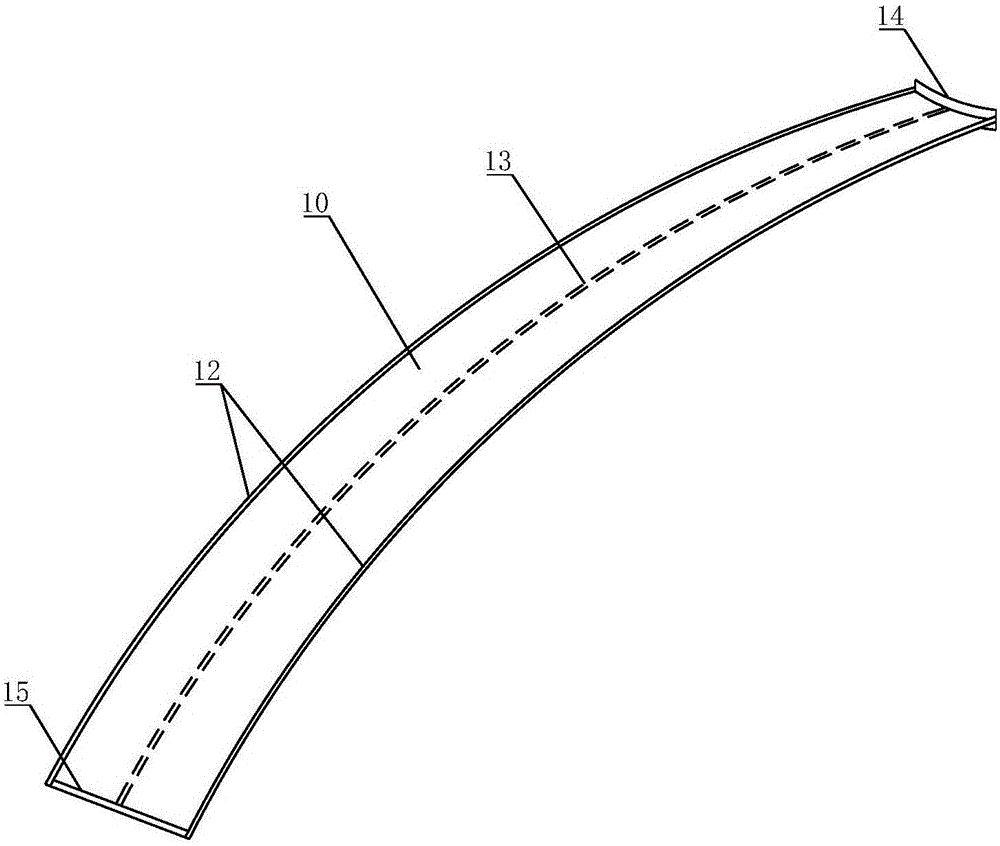

[0047] Such as figure 1 As shown, the manufacturing method of a large-scale vaulted asphalt storage tank described in the present invention includes two parts: making the tank body 1 and making the tank top 2, wherein:

[0048] 1. Tank production process:

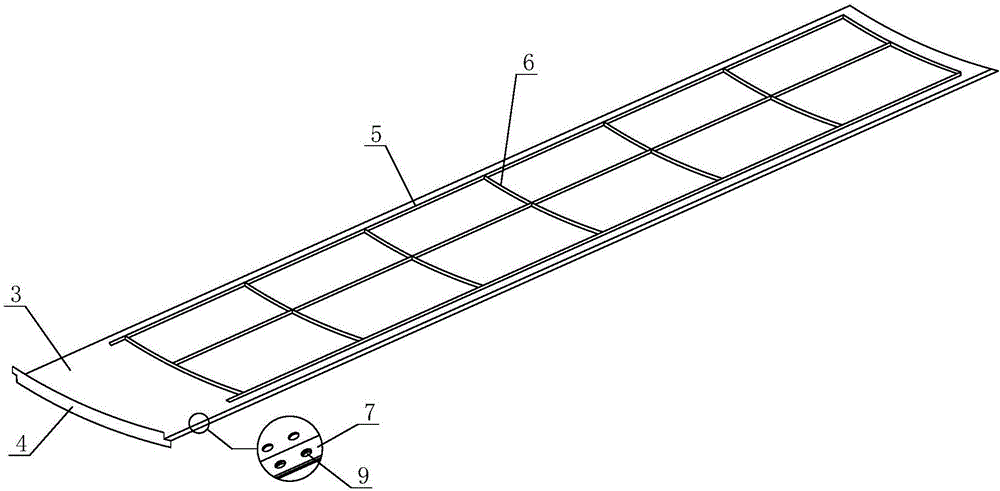

[0049] The tank body 1 is a cylindrical structure enclosed by a plurality of tank wall panels of the same structure and size. The seams between the tank wall panels are overlapped, and the lap joints are connected by high-strength bolts 8; figure 2 As shown, each tank wall panel is composed of a curved panel 3, a tank bottom flange 4, a straight rib 5 and an arc rib 6, wherein the curved panel 3 is composed of multiple steel plates, and its longitudinal direction corresponds to the tank body 1. In the height direction, a liner 7 is provided on one side of the lap of the arc-shaped panel 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com