A method for synthesizing sapo-34 molecular sieves by utilizing industrial phosphate fertilizer by-product fluosilicic acid and its application

A technology of SAPO-34 and molecular sieve, which is applied in the field of comprehensive utilization of resources, can solve the problems of high price, high cost, and restrictions on wide application, and achieve the effects of strong reproducibility, high crystallinity, and overcoming process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Add 25g of distilled water to the polytetrafluoroethylene lining, add 5.07g of 85% phosphoric acid and 2.4g of pseudo-boehmite in sequence under stirring conditions, and then add 9.51g of triethylamine after thorough mixing, and stir for 2h each time. , stir until the body phase is uniform to obtain solution I;

[0034] 2) Add 2.88g of 30wt% industrial fluorosilicic acid to 3g of triethylamine and stir well to obtain solution II, add solution II to solution I, and stir at room temperature for 2h to obtain a precursor solution. At this time, the molar composition ratio of each substance in the precursor solution is Al 2 O 3 : SiO 2 :P 2 O 5 :H 2 O:TEA=1:0.3:1.1:70:6.2;

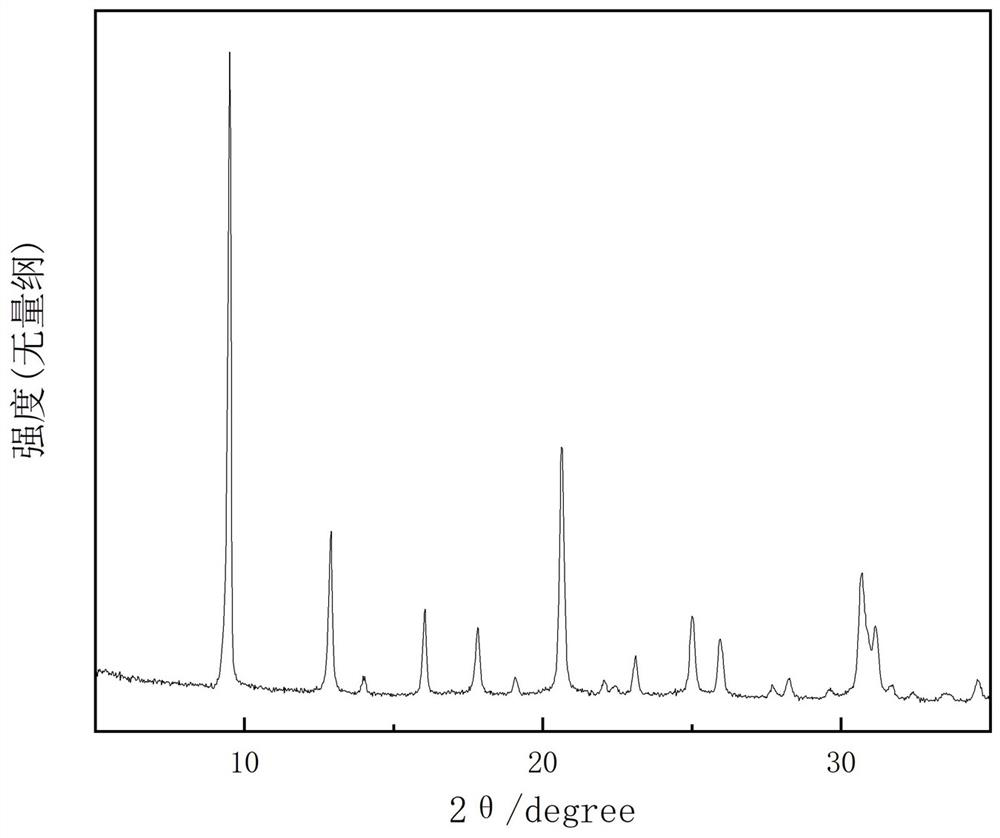

[0035] 3) Put the polytetrafluoroethylene liner with the precursor liquid in it into a high temperature and high pressure reaction kettle, and statically crystallize it in an oven at 200°C for 1 day; the obtained mother liquor is recovered, and the solid product is washed with deionized water un...

Embodiment 2

[0046] 1) Add 25g of distilled water to the polytetrafluoroethylene lining, add 5.07g of 85% phosphoric acid and 2.4g of pseudo-boehmite in sequence under stirring at room temperature, and then add 9.51g of triethylamine after mixing thoroughly, and stir for 2h each time. , stir until the body phase is uniform to obtain solution I;

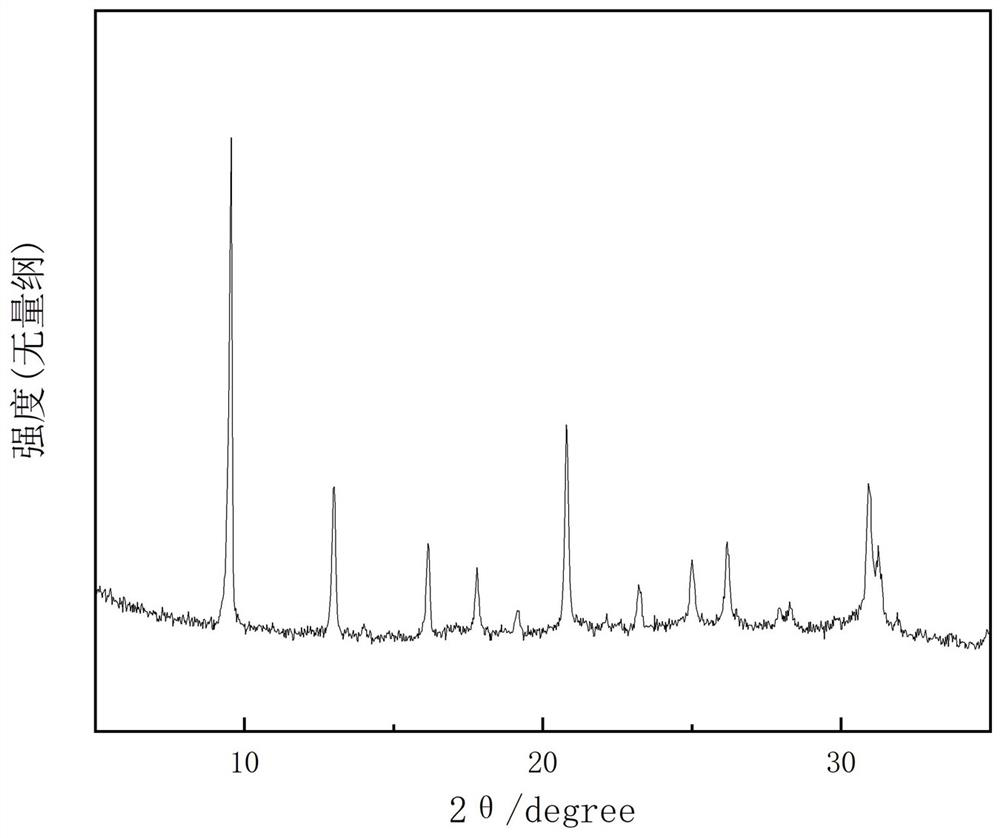

[0047] 2) Add 3.46g of 25wt% industrial fluorosilicic acid to 3g of triethylamine and stir to obtain solution II, and add the solution II to the solution I and stir to obtain a precursor solution, and add the solution to the precursor solution according to the method of Example 1 The prepared SAPO-34 seed crystal was used as a crystal guide agent and stirred for 1 h. The addition amount of the crystal guide agent was 2% of the mass of the precursor solution. At this time, the molar composition ratio of each substance in the precursor solution was Al 2 O 3 : SiO 2 :P 2 O 5 :H 2 O:TEA:seed=1:0.3:1.1:90:5.7;

[0048] 3) Put the polytetrafluoroe...

Embodiment 3

[0052] 1) Add 25g of distilled water to the polytetrafluoroethylene lining, add 5.07g of 85% phosphoric acid and 2.4g of pseudo-boehmite in sequence under stirring conditions, and then add 9.51g of triethylamine after thorough mixing, and stir for 2h each time. , stir until the body phase is uniform to obtain solution I;

[0053] 2) Add 3.09g of 28wt% industrial fluorosilicic acid to 3g of triethylamine and fully stir to obtain solution II, add solution II to solution I, and stir at room temperature for 2h to obtain a precursor solution. At this time, the molar composition ratio of each substance in the precursor solution is Al 2 O 3 : SiO 2 :P 2 O 5 :H 2 O:TEA=1:0.3:1.1:70:6.2;

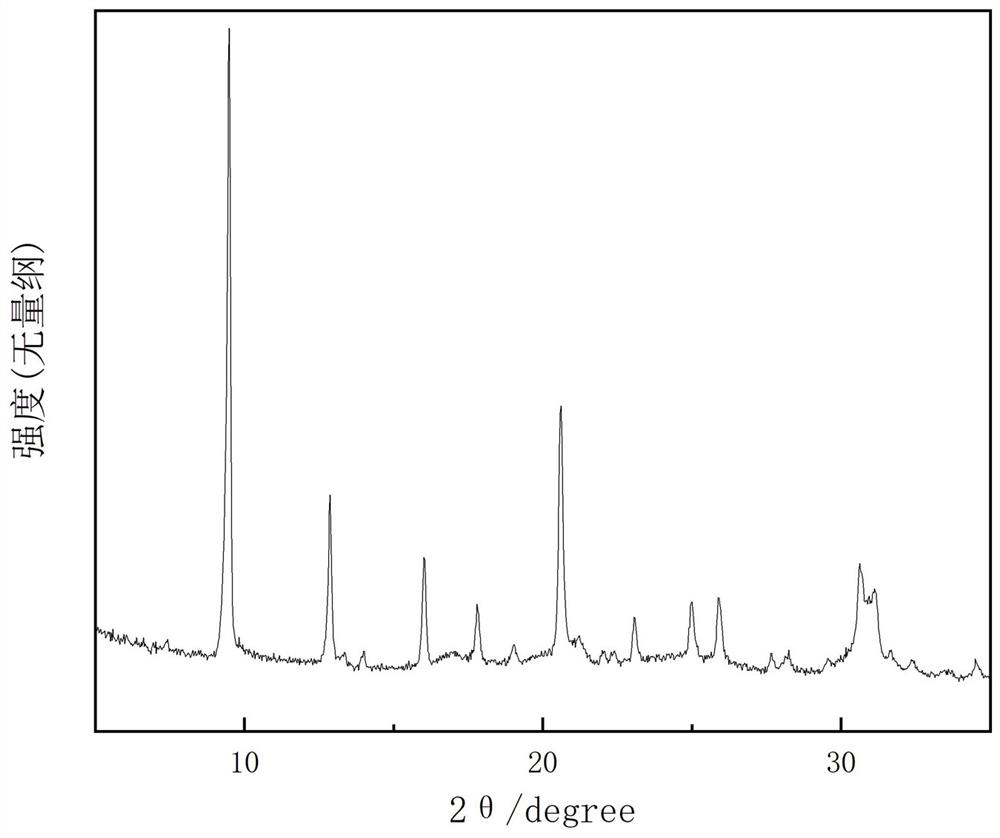

[0054] 3) Put the polytetrafluoroethylene lining with the precursor liquid in it into a high temperature and high pressure reaction kettle, and statically crystallize it in an oven at 220 ° C for 2 hours; the obtained mother liquor is recovered, and the solid product is washed with deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com