Modular integration process method for kitchen waste filtrate

A technology of food waste and process methods, which is applied in the direction of chemical instruments and methods, filtration treatment, anaerobic digestion treatment, etc., can solve the problems of difficult wastewater treatment, and achieve the effects of low operating costs, high modularization, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

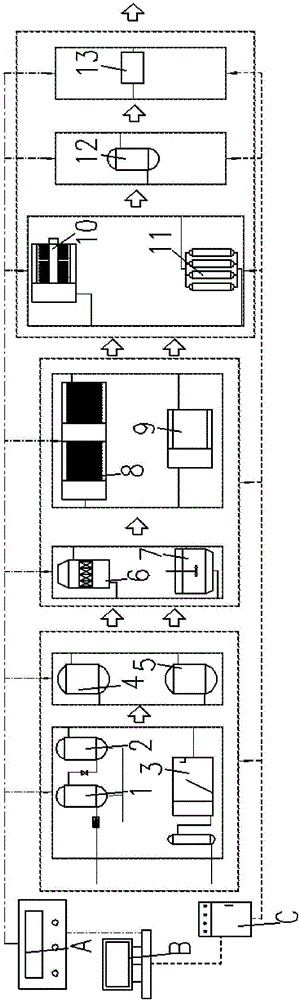

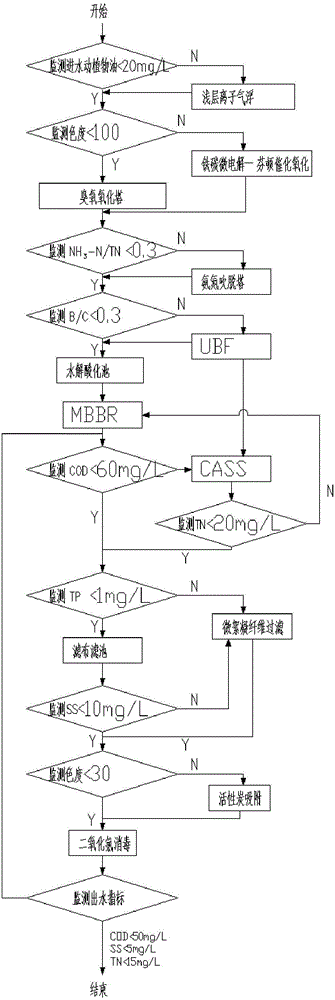

[0035] Such as figure 1 As shown, a modular integrated process method for food waste filtrate, specifically adopts the following modules: a physical and chemical module, a biochemical module and an advanced treatment module; the physical and chemical module includes a primary physical and chemical sub-module and a secondary physical and chemical sub-module module, the first-level physicochemical module includes iron-carbon micro-electrolysis-Fenton catalytic oxidation and shallow ion air flotation, the second-level physicochemical module includes an ozone oxidation tower and an ammonia nitrogen stripping tower; the biochemical module includes anaerobic sub-modules and good Oxygen sub-module, the anaerobic sub-module includes upflow sludge bed filter (UBF) and hydrolytic acidification, the aerobic sub-module includes multi-stage suspended packing biological bed reactor (MBBR) and circulating activated sludge process reaction (CASS), the anaerobic sub-module and the aerobic sub-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com