A method for integrating the net ring side filter water supply pump group and the net ring water supply pump group

A technology for water supply pumps and ring water purification, applied in water supply devices, water supply devices, water supply main pipelines, etc., can solve the problems of high equipment failure rate, large floor area, and many equipment, so as to achieve stable operation, save land occupation, and The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

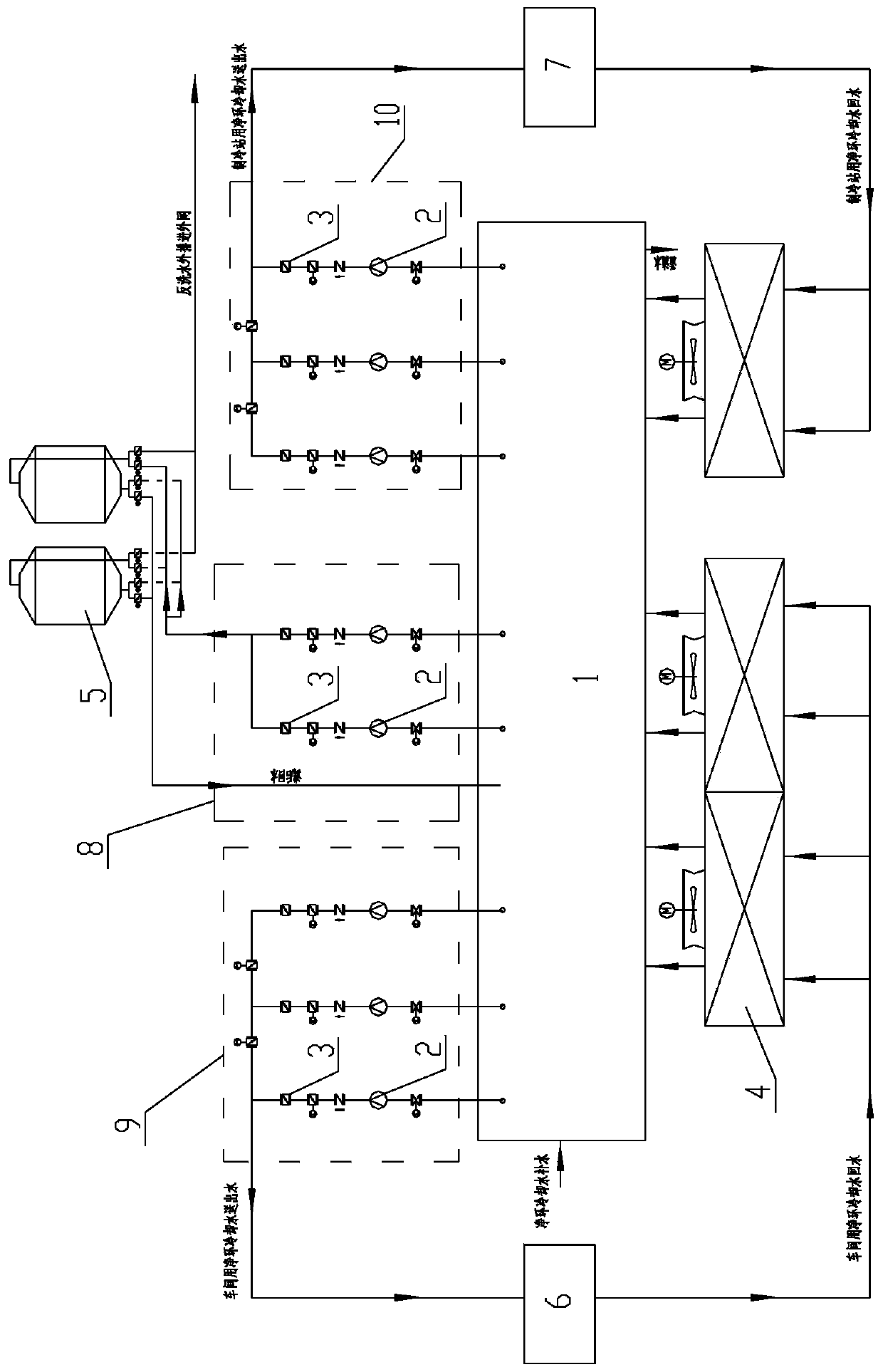

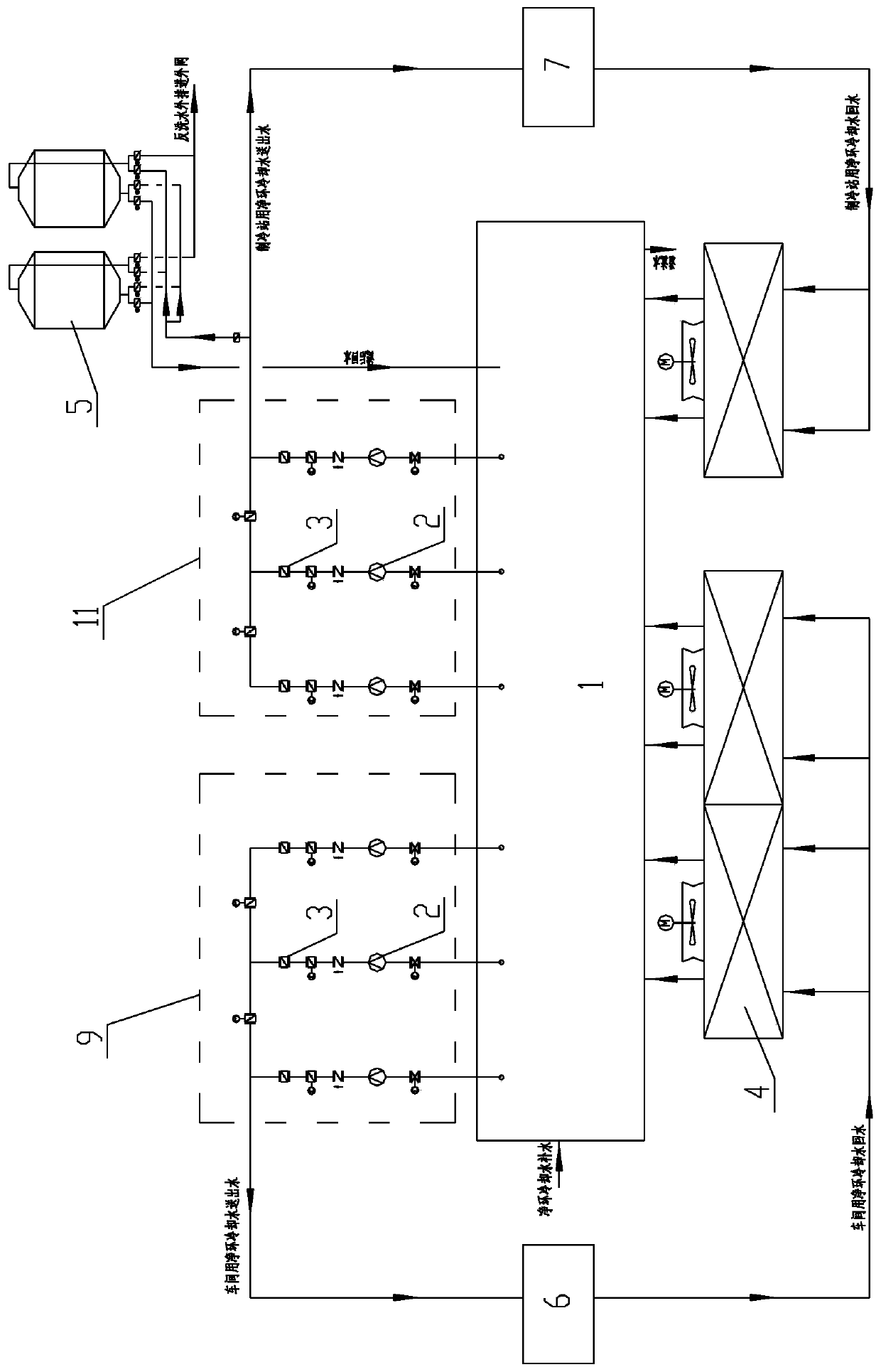

[0017] Such as figure 2 As shown in the present invention, a method for integrating the net ring side filter water supply pump group and the net ring water supply pump group includes the following steps:

[0018] 1) The clean ring cooling water system includes a clean ring cooling water suction well 1, a plurality of clean ring water supply pump sets 9, 10 (only with figure 2 For example, the same below), bypass filter 5 and net ring cooling tower 4; net ring water supply pumps 9, 10 are connected to net ring water users 6, 7 through the net ring cooling water supply pipe, and the water temperature rises after the circulating cooling water is used High, the return water uses the residual pressure to directly enter the net ring cooling tower 4 through the net ring cooling water return pipe for cooling, then flows into the net ring water suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com