A Modular Integrated Process Method Suitable for Treating Slaughterhouse Wastewater

A pretreatment module and modular technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, animal processing wastewater treatment, etc., can solve the problems of high concentration of wastewater, complex composition, difficult treatment, etc., and achieve low operating costs. , The effect of high modularity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

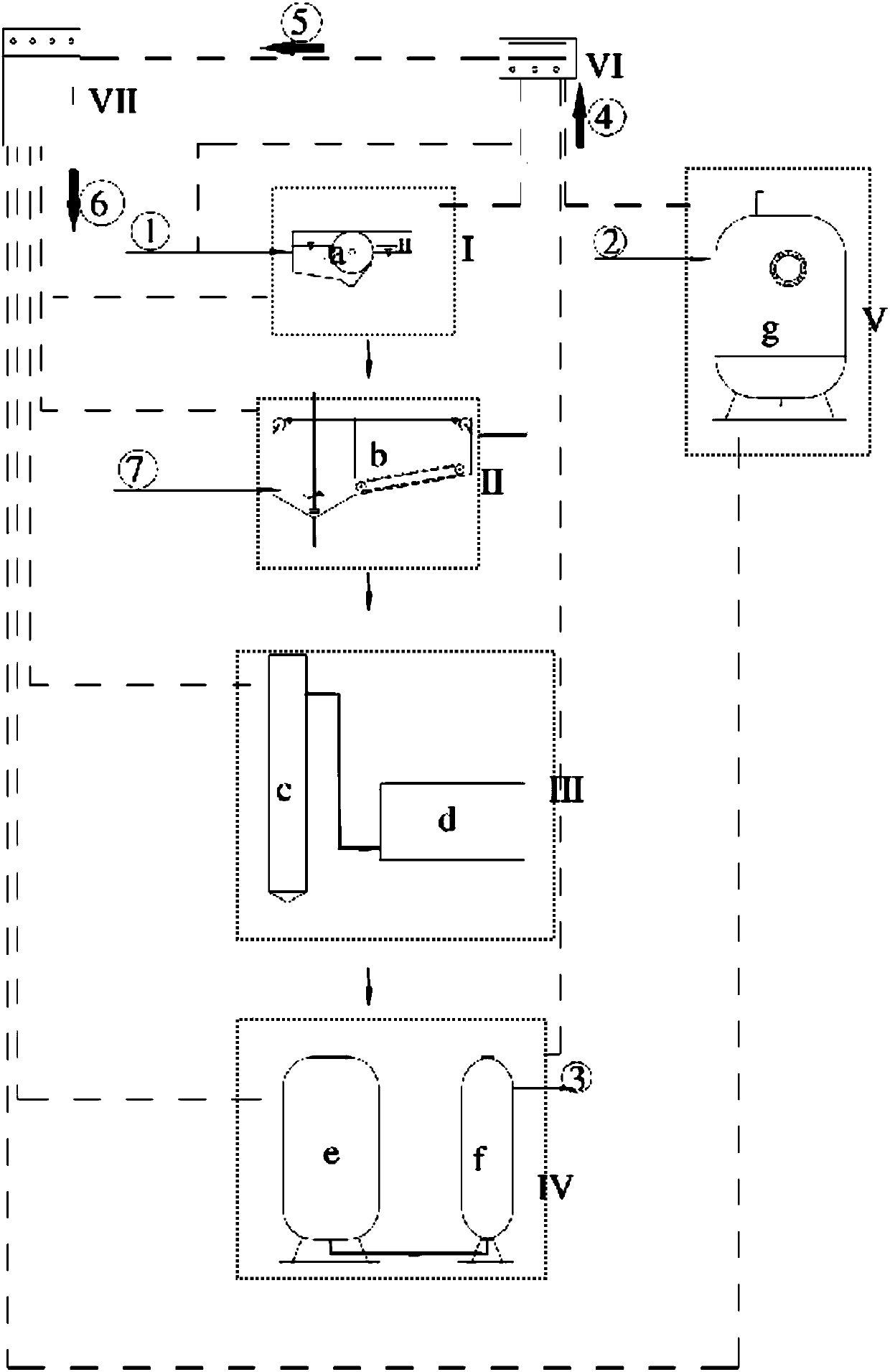

Image

Examples

Embodiment Construction

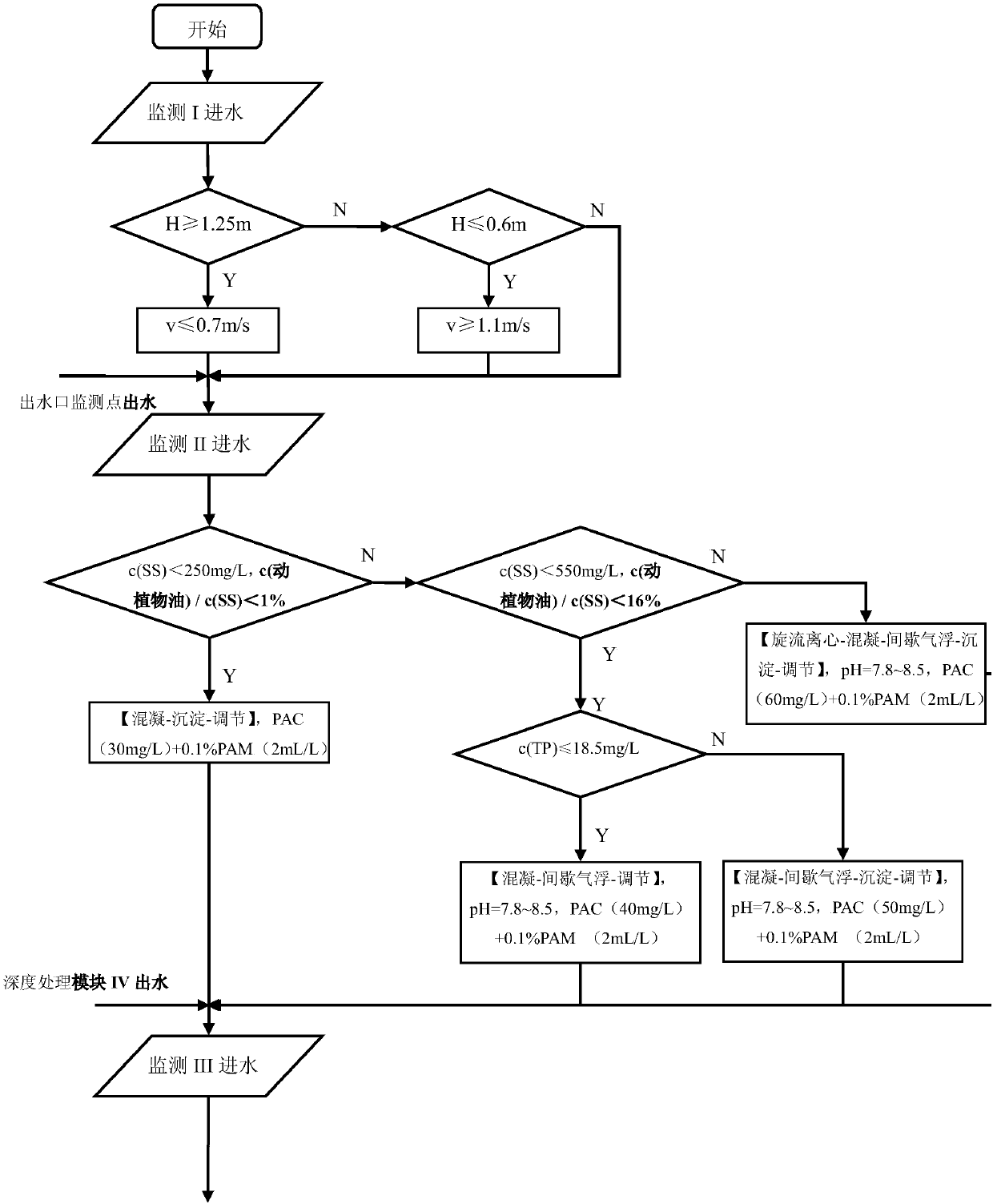

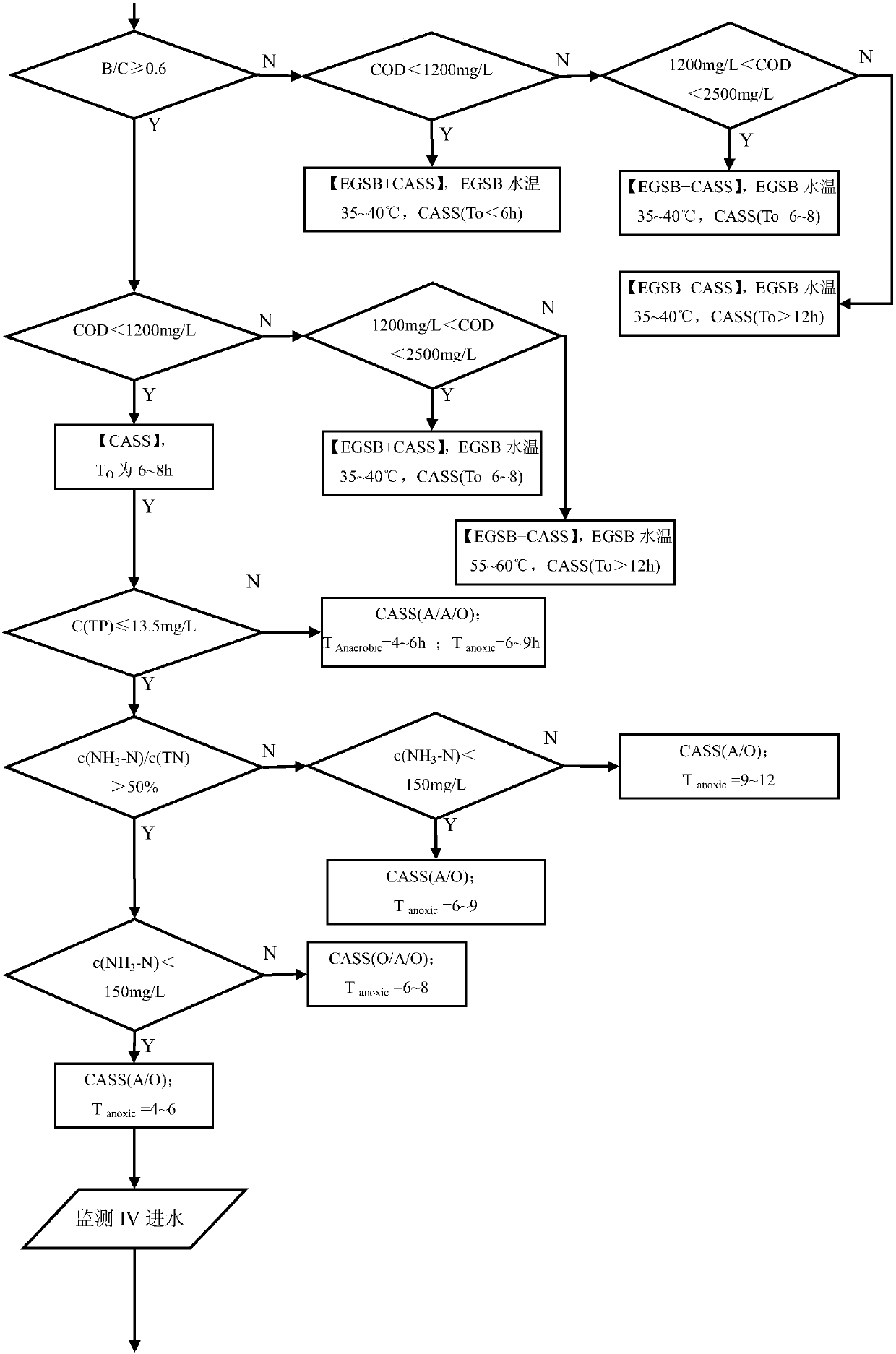

[0034] The water quality of the influent is monitored in real time through the online water quality monitoring system, and relevant information is fed back to the computer automatic control system, and the module combination and operating parameters that should be selected under the water quality conditions are determined according to the set computer program.

[0035] When the water level difference before and after the grid of the pretreatment module I is H≥1.25m, adjust the water inlet flow pump, and adjust the flow velocity v to be below 0.7 m / s; when the water level difference before and after the grid is H≤0.6m, adjust the water inlet flow pump, and pass the grid The flow velocity v is adjusted to above 1.1 m / s.

[0036] When the primary physical and chemical module II enters water: c(SS)18.5mg / L, run [coagulation-intermittent air flotation-sedimentation-regulation] module, adjust pH=7.8~8.5, add agent PAC (50mg / L )+0.1%PAM (2mL / L); In addition to the above conditions, run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com