Electric railway overhead contact system cantilever preassembled automatic production line

An automated production line and electrified railway technology, applied in the direction of overhead lines, etc., can solve the problems of inability to pre-assemble steel and aluminum wrist-arm pipe fittings, insufficient safeguard measures, poor pre-allocation accuracy, etc., to achieve good adaptability, automation and intelligence The effect of high degree, assembly precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

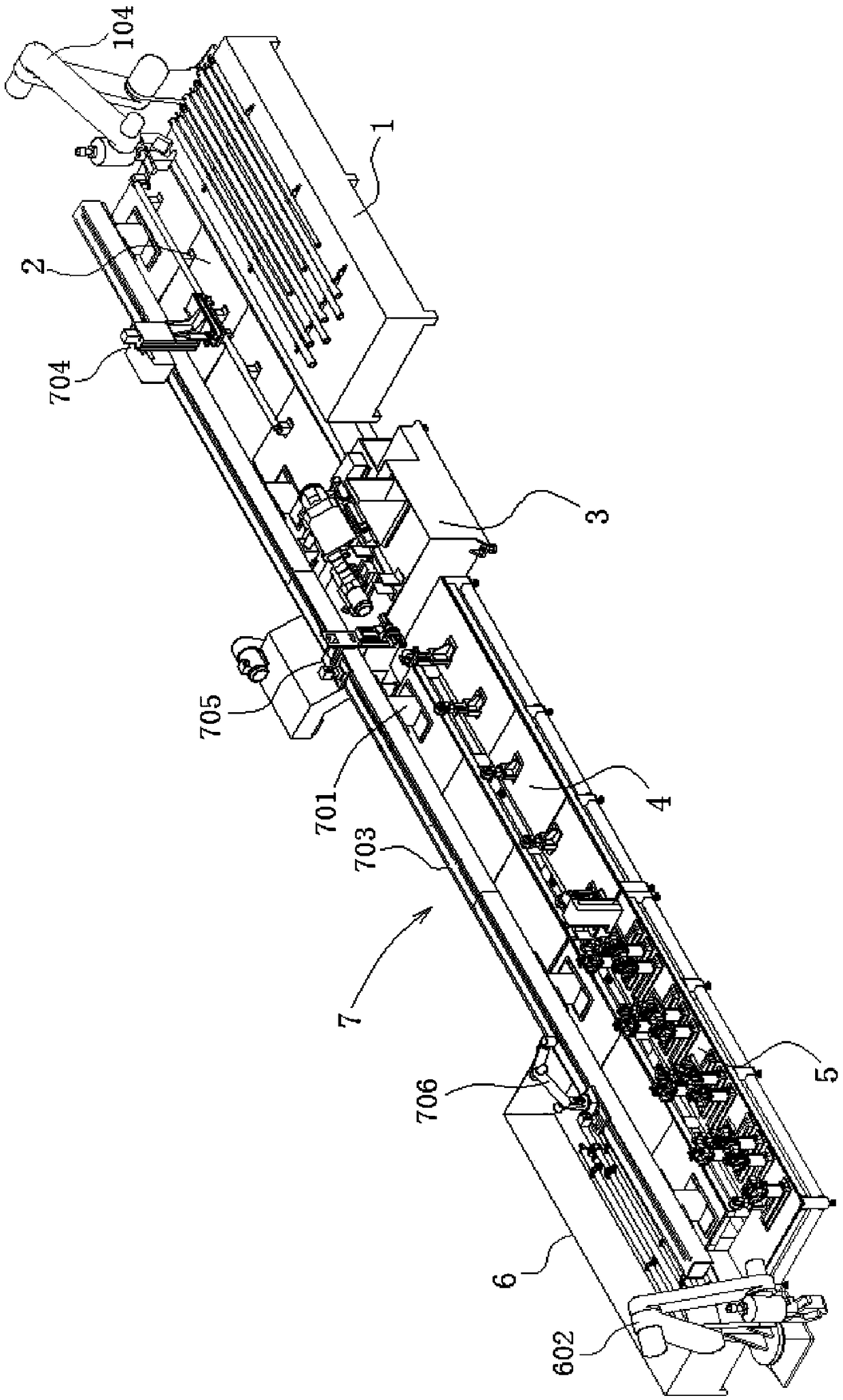

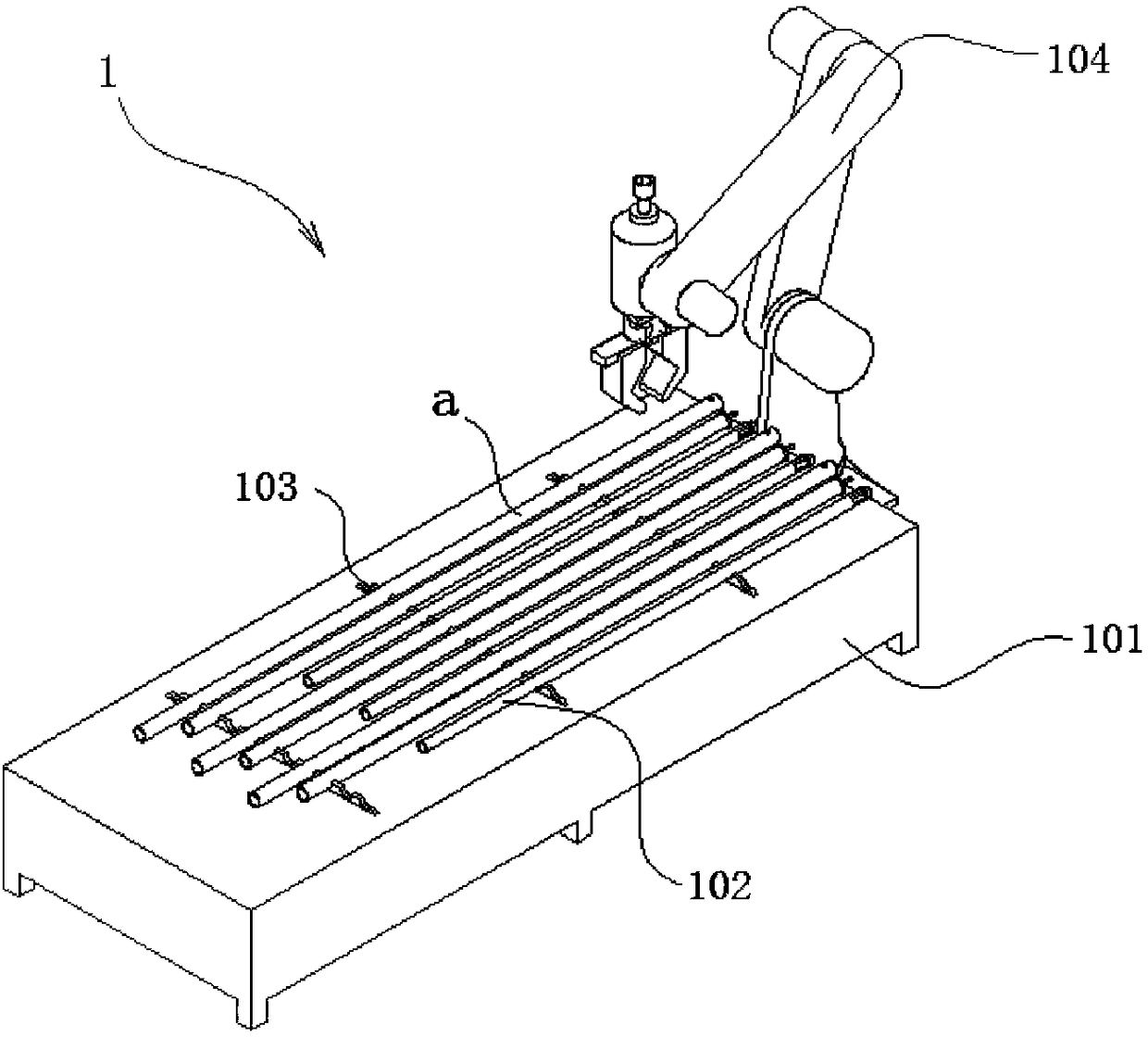

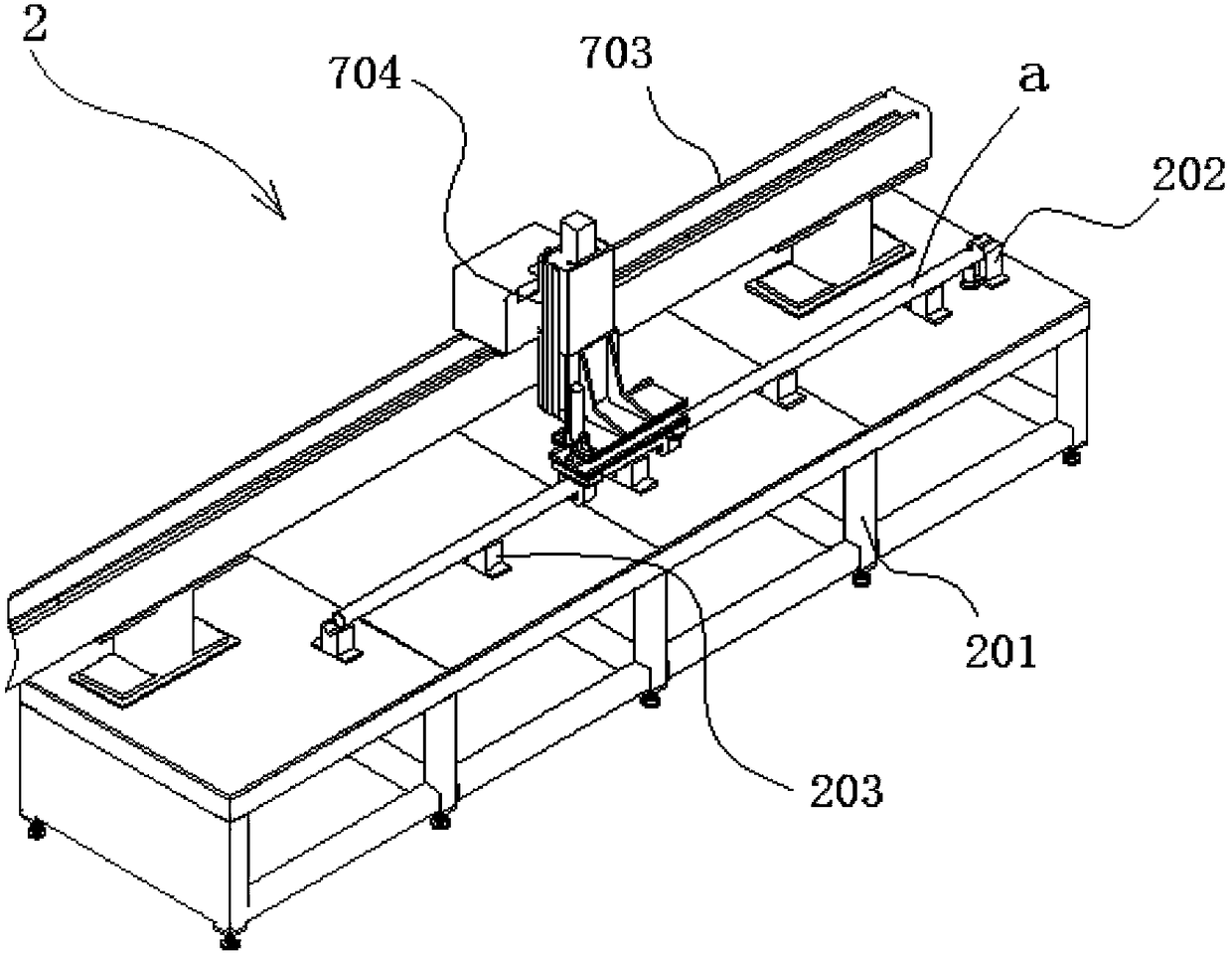

[0050] See figure 1 , the electrified railway catenary arm pre-configuration automated production line provided by the present invention includes a feeding unit 1, a propulsion unit 2, a processing unit 3, a spraying unit 4, an assembly unit 5, a blanking unit 6 and a transfer unit 7, the propulsion The unit 2, the processing unit 3, the spraying unit 4, and the assembly unit 5 are arranged in a line from front to back, and the feeding unit 1 and the unloading unit 6 are arranged next to the propulsion unit 2 and the assembly unit 5 respectively. The transfer unit 7 is vertically arranged on the propulsion unit 2, the processing unit 3, the spraying unit 4, and the assembly unit 5; the feeding unit 1 is provided with a pipe manipulator 104 connected with the propulsion unit 2; the propulsion unit 2, processing Unit 3 , spraying unit 4 , and assembly unit 5 are connected through the transfer unit 7 ;

[0051] See figure 2 , the feeding unit 1 includes a feeding frame 101, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com