Production process of petroleum pipe

A production process, oil pipe technology, applied in the direction of metal rolling, etc., can solve the problems of large project investment, uncompact process, large floor area, etc., achieve low project investment, reduce production energy consumption, and small floor area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

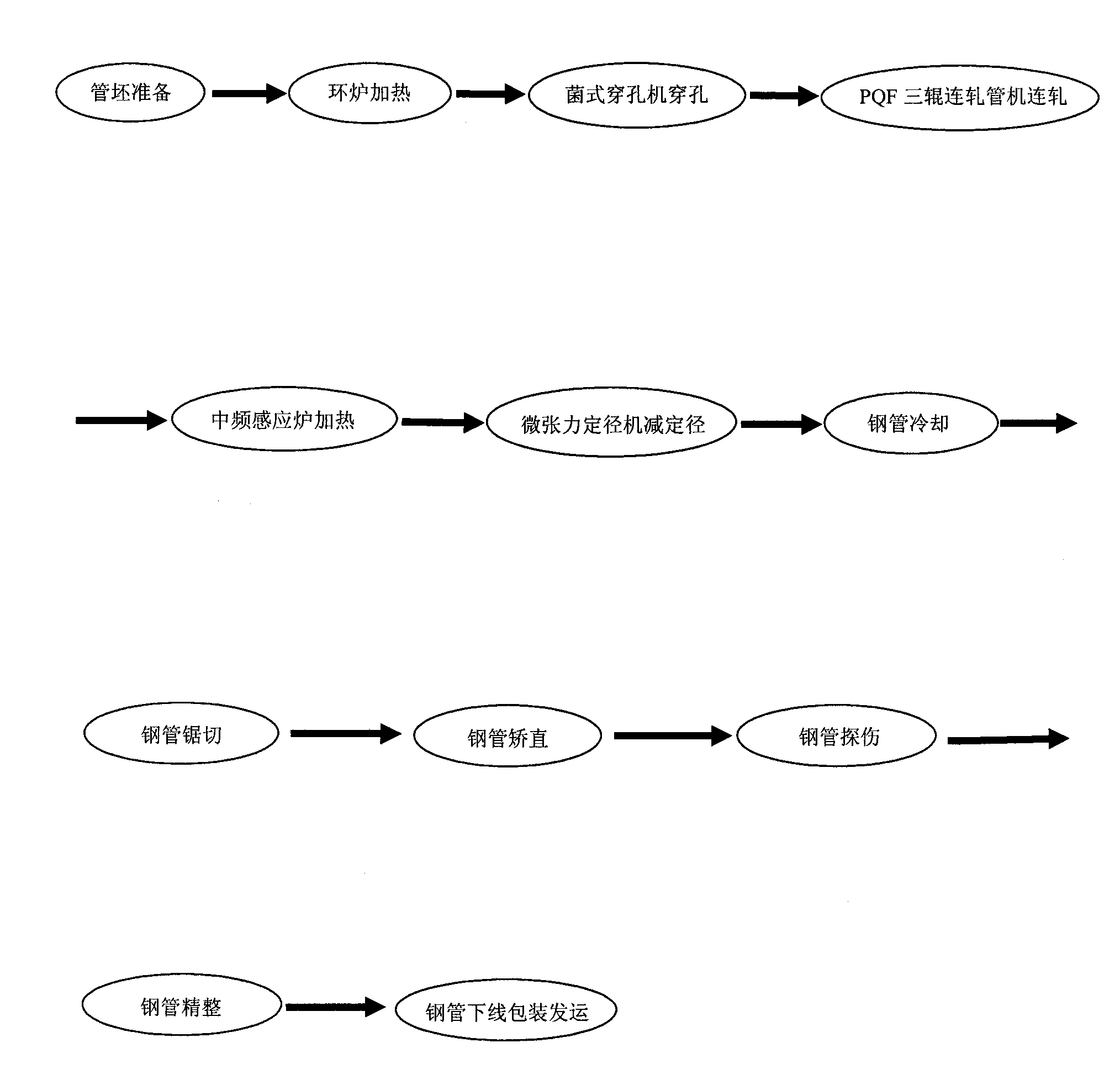

[0020] Such as figure 1 As shown, a petroleum pipe production process, the main process includes pipe blank preparation, ring furnace heating, piercing machine piercing, continuous rolling mill continuous rolling, waste pipe secondary heating, reducing and sizing, steel pipe cooling, sawing, straightening , flaw detection, and finishing, characterized in that: the perforation process uses a bacteria-type piercer, the continuous rolling process uses a PQF three-roller continuous rolling mill, the second heating process of the waste tube uses an intermediate frequency induction furnace, and the sizing process uses a micro Tension sizing machine. This process is not only suitable for the production of thin-walled pipes, but also for the production of medium-thick-walled pipes.

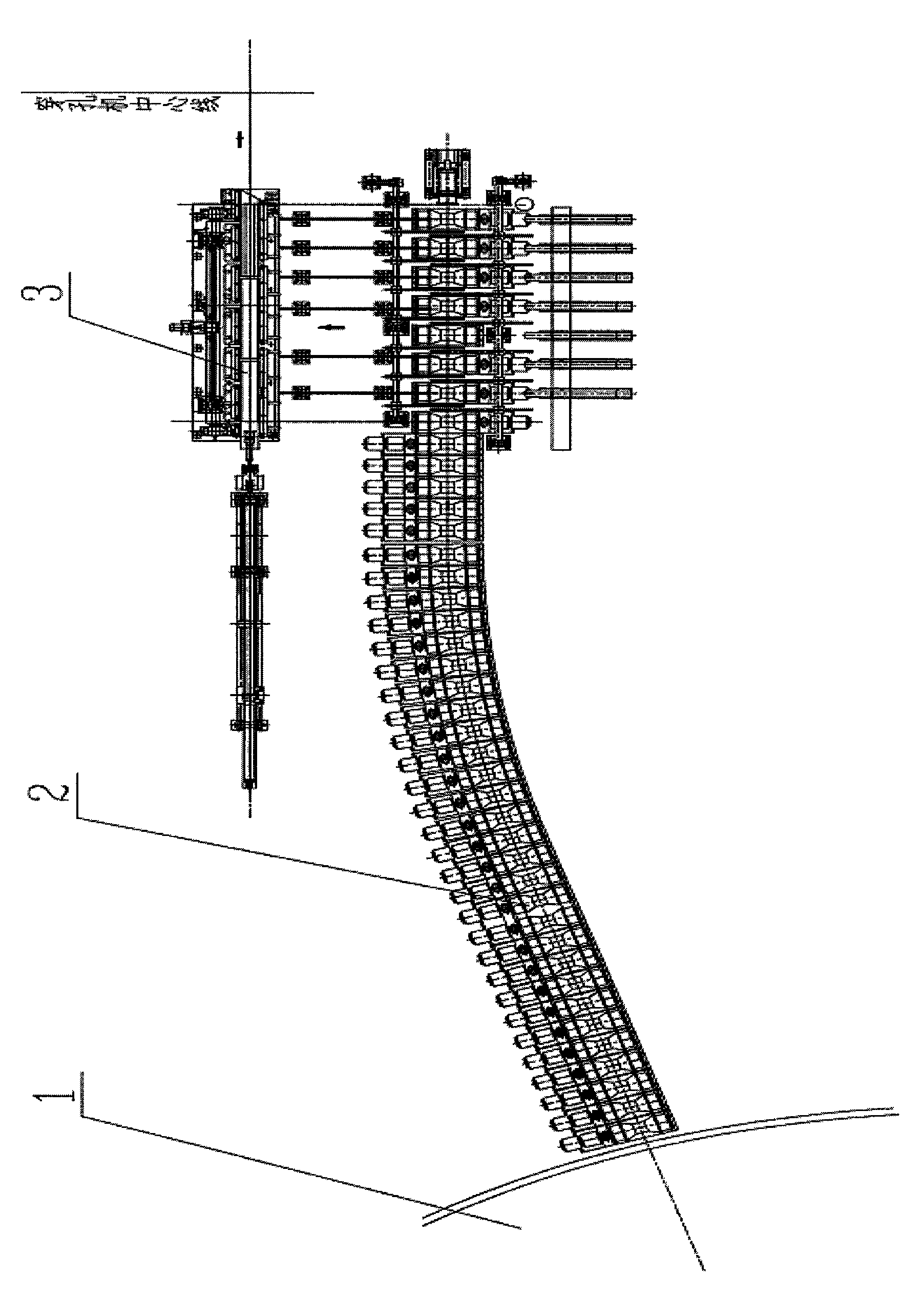

[0021] Such as image 3 As shown, in order to reduce the temperature drop of the tube blank, the tube blank is directly transported from the exit 1 of the ring furnace to the front desk 3 of the piercin...

Embodiment 2

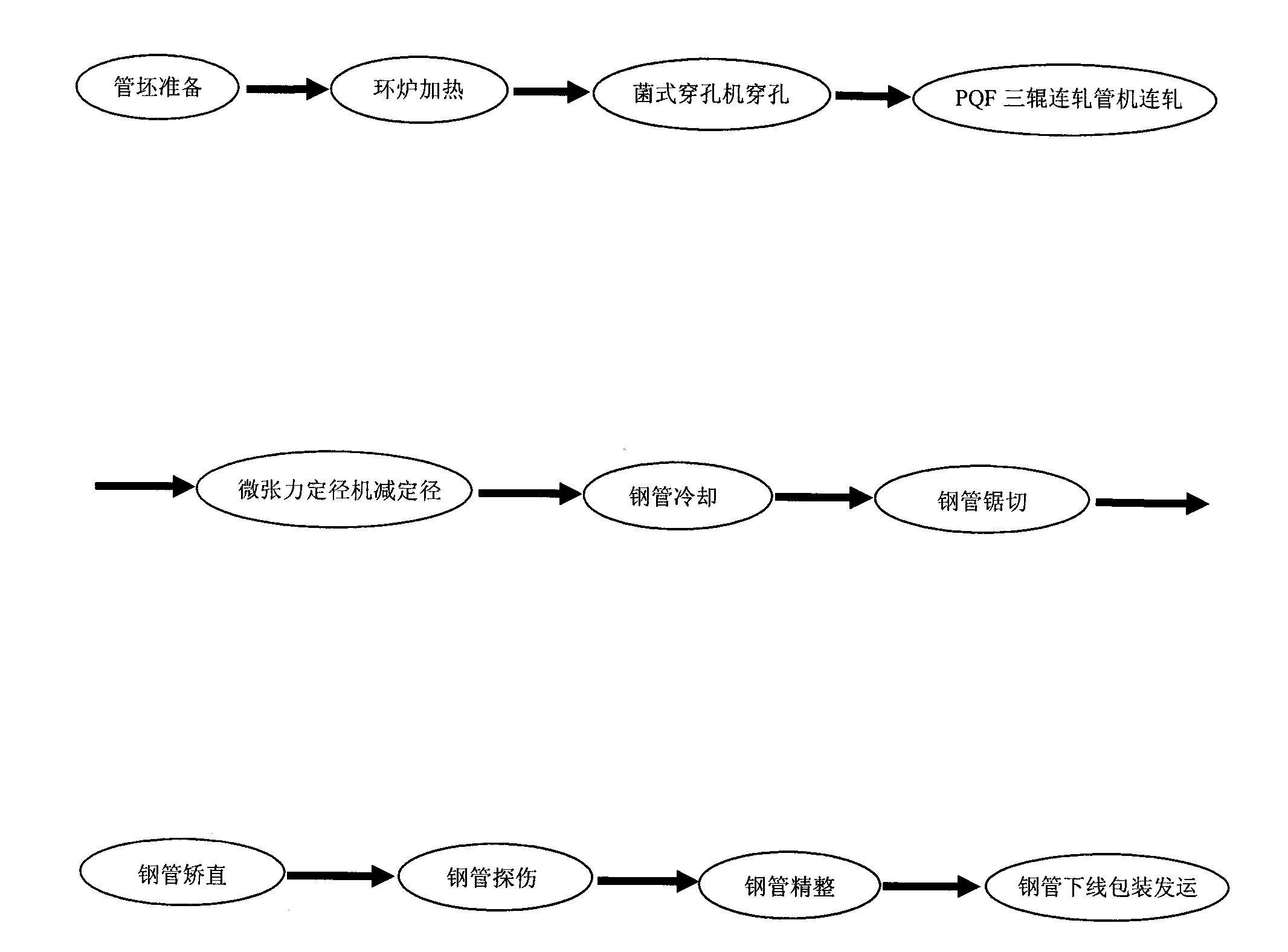

[0023] Such as figure 2 As shown, for the production of medium and thick-walled oil pipes, the present invention can also produce oil pipes by eliminating the secondary heating of waste pipes. The main steps of the process include pipe blank preparation, ring furnace heating, piercing by piercing machine, and continuous rolling of pipes. Machine continuous rolling, reducing and sizing, steel pipe cooling, sawing, straightening, flaw detection, finishing, the described piercing process adopts fungal piercing machine, continuous rolling process adopts PQF three-roller continuous rolling mill, reducing and sizing process adopts Micro tension sizing machine.

[0024] Such as image 3 As shown, in order to reduce the temperature drop of the tube blank, in the process of producing medium and thick-walled oil pipes, the tube blank can also be directly transported from the ring furnace outlet 1 to the front desk 3 of the piercing machine through the arc-shaped roller table 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com