Two-sided automatic polishing machine

A polishing machine and automatic technology, applied in the direction of grinding/polishing equipment, grinding machines, machine tools suitable for grinding workpiece planes, etc., can solve problems such as low production efficiency, unstable product quality, and weak market competitiveness, and achieve Solve the effects of low production efficiency, high-quality polishing work, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below according to the drawings and embodiments.

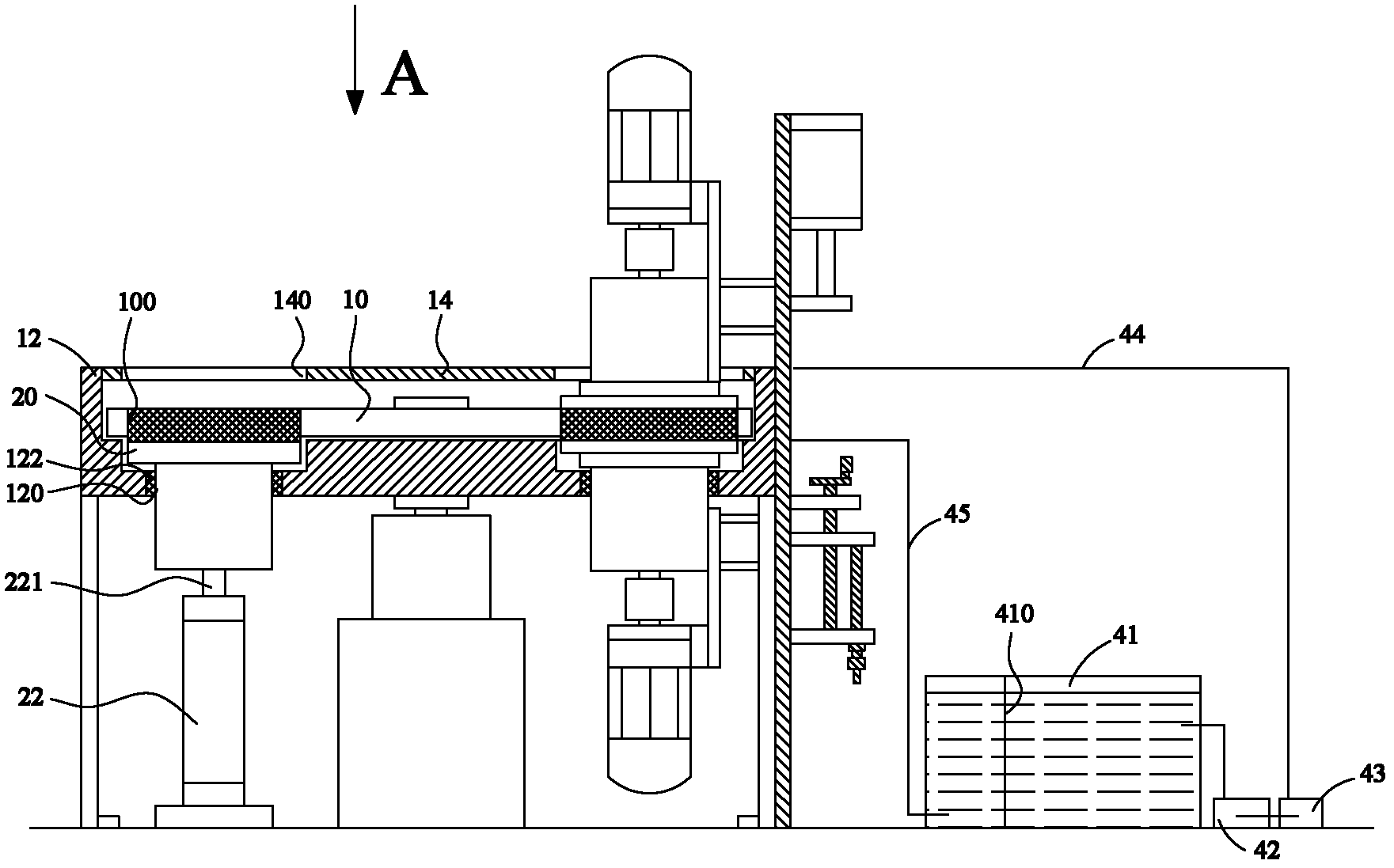

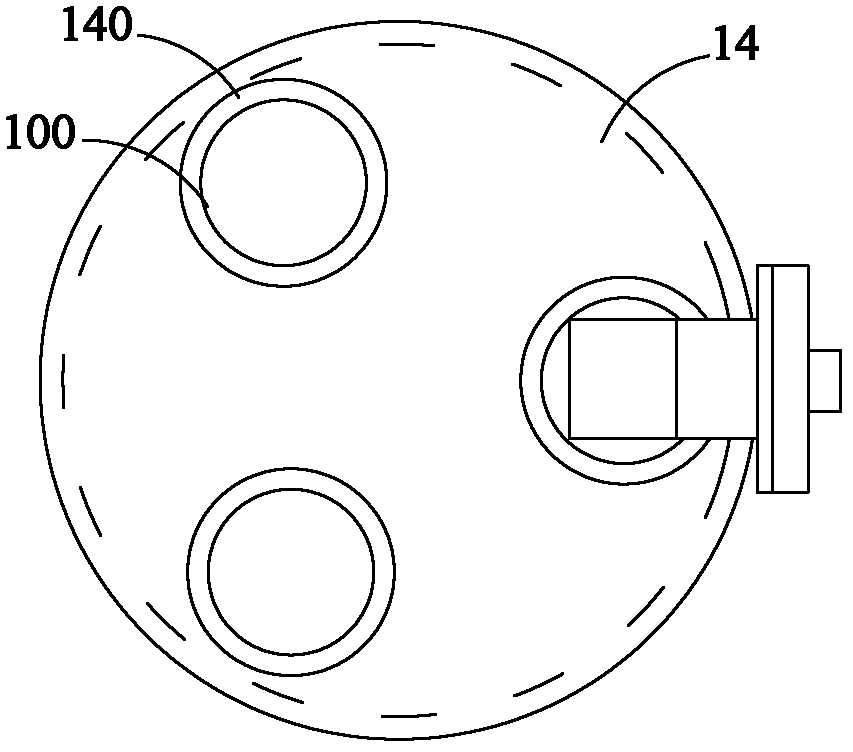

[0028] figure 1 It is the structural representation of the double-sided automatic polishing machine of the present invention, figure 2 for figure 1 Schematic diagram of the angle of view in direction A, refer to figure 1 , figure 2 , the present invention, a double-sided automatic grinder, includes a turntable 10 and various devices surrounding the turntable 10 . The turntable 10 is arranged horizontally, and the turntable 10 has at least two through holes as station holes 100. In this embodiment, the turntable 10 has three station holes 100, and the three station holes 100 are 120° from each other. The distance from each station hole 100 to the center of the turntable 10 is the same. The turntable 10 transmits workpieces to be processed through each station hole 100 through rotation.

[0029] Outer box 12 is arranged on the periphery of turntable 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com