Integral doffing device of ring spinning frame

A spinning frame and collective technology is applied in the field of improvement of the structure of the collective doffing device of the ring spinning frame, which can solve the complex action process, the limitation of the application range of the collective doffing device, and the difficulty of increasing the consistency control of the height of the doffing frame in and out. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

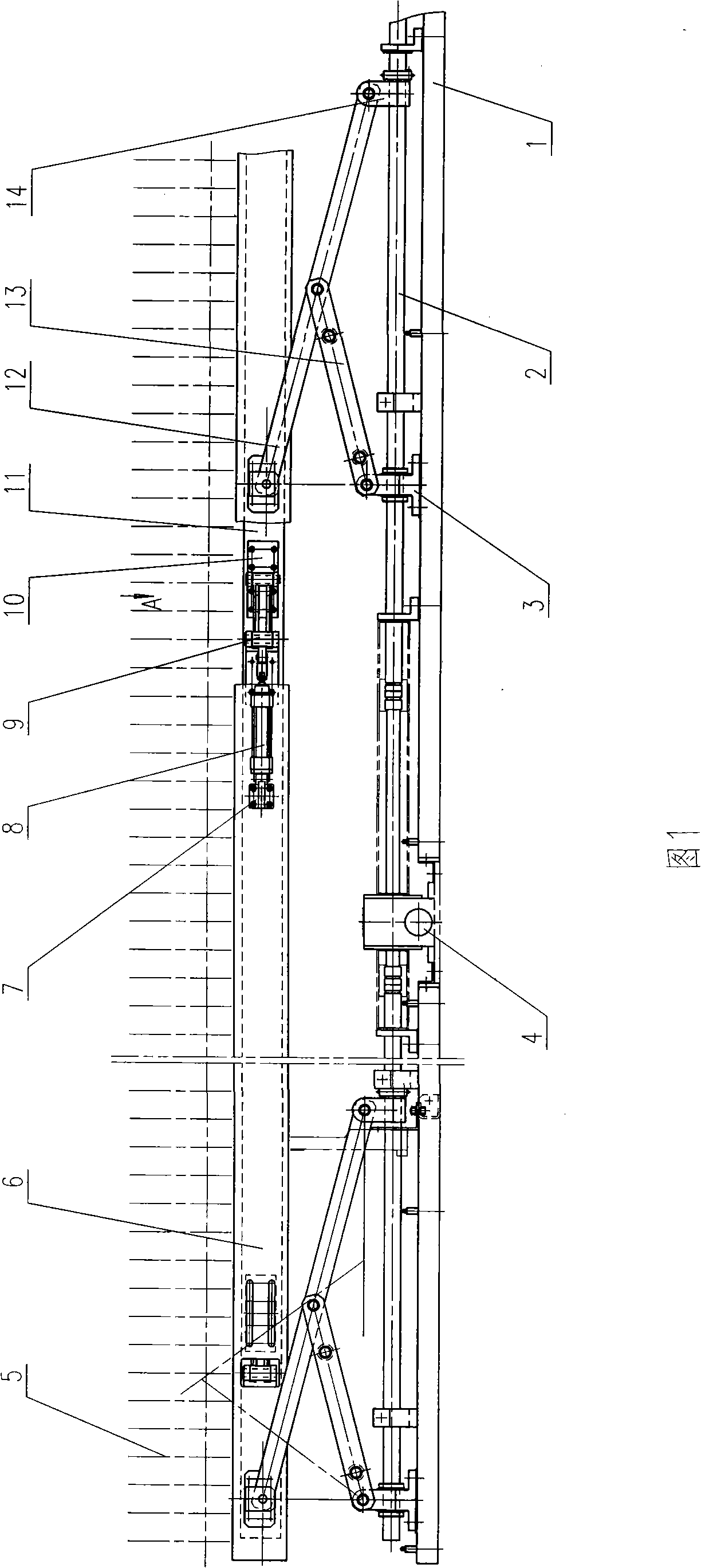

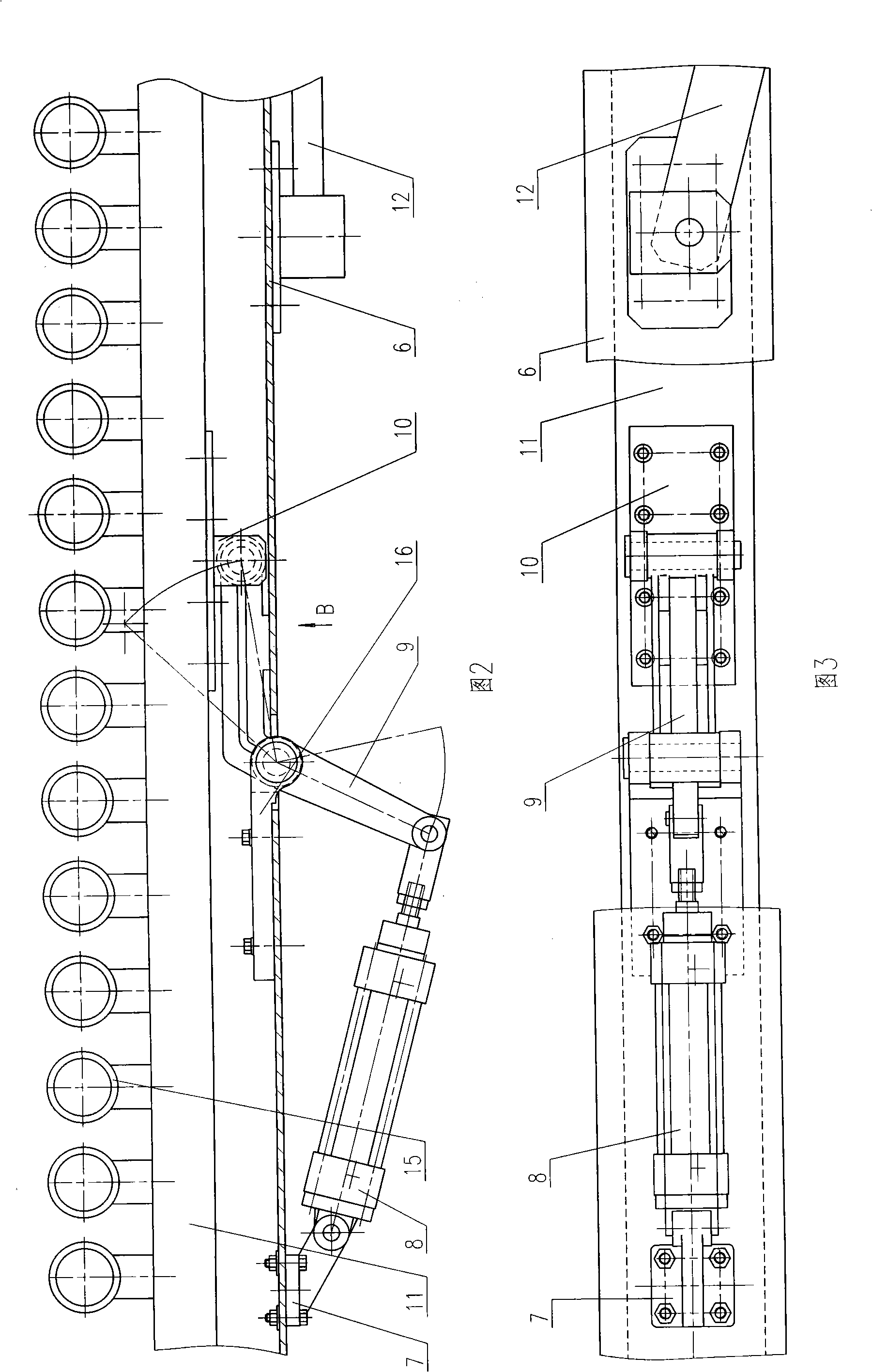

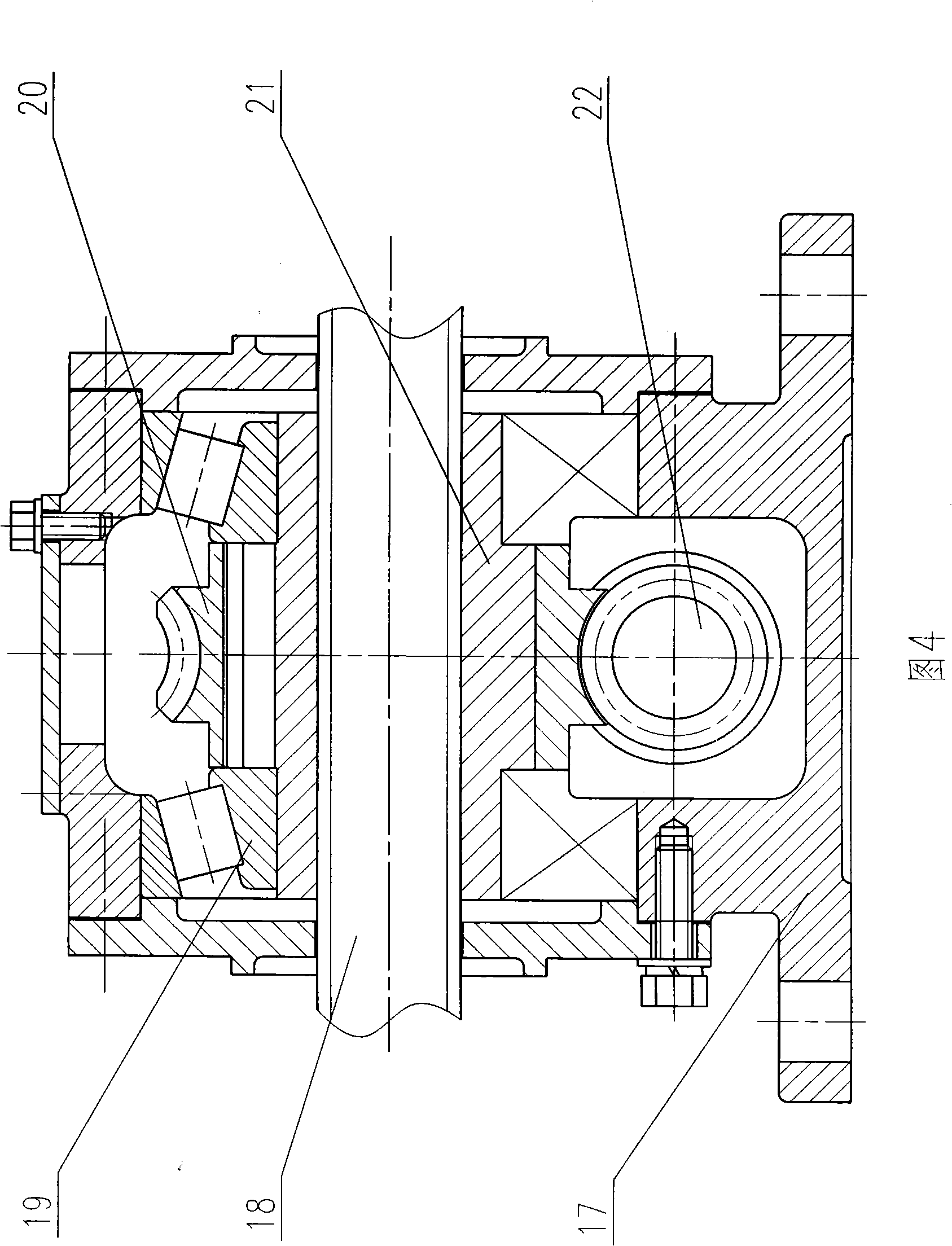

[0014] In the collective doffing device of the ring spinning frame shown in Figure 1, the horizontally arranged elevating beam 6 extends from the head position of the spinning frame to the rear of the spinning frame, and the length of the elevating beam 6 corresponds to the spinning frame spindle on one side of the spinning frame 5. The lower hinge of the elevating crossbeam 6 has an elevating link mechanism. The other end of the hinge is supported on the pull bar slide seat 3. One end of the lifting link 12 is hinged on the lifting crossbeam 6, and the other end is hinged with the lifting rod 2 through the connecting rod hinge seat 14. The lifting rod 2 is slidably supported on the base 1 through a plurality of rod sliders 3 along the direction of its axis, and the lifting rod 2 is driven by a rod driving device installed on the base 1 . As shown in Figure 4, the pull rod driving device includes a transmission box 17, a worm wheel 20 and a worm 22 located in the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com