Positional error evaluation method for mobile device and movement accuracy improving method based on evaluation result

A technology of a mobile device and an evaluation method, which is applied in the field of position error evaluation of mobile devices and improvement of moving accuracy according to the evaluation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

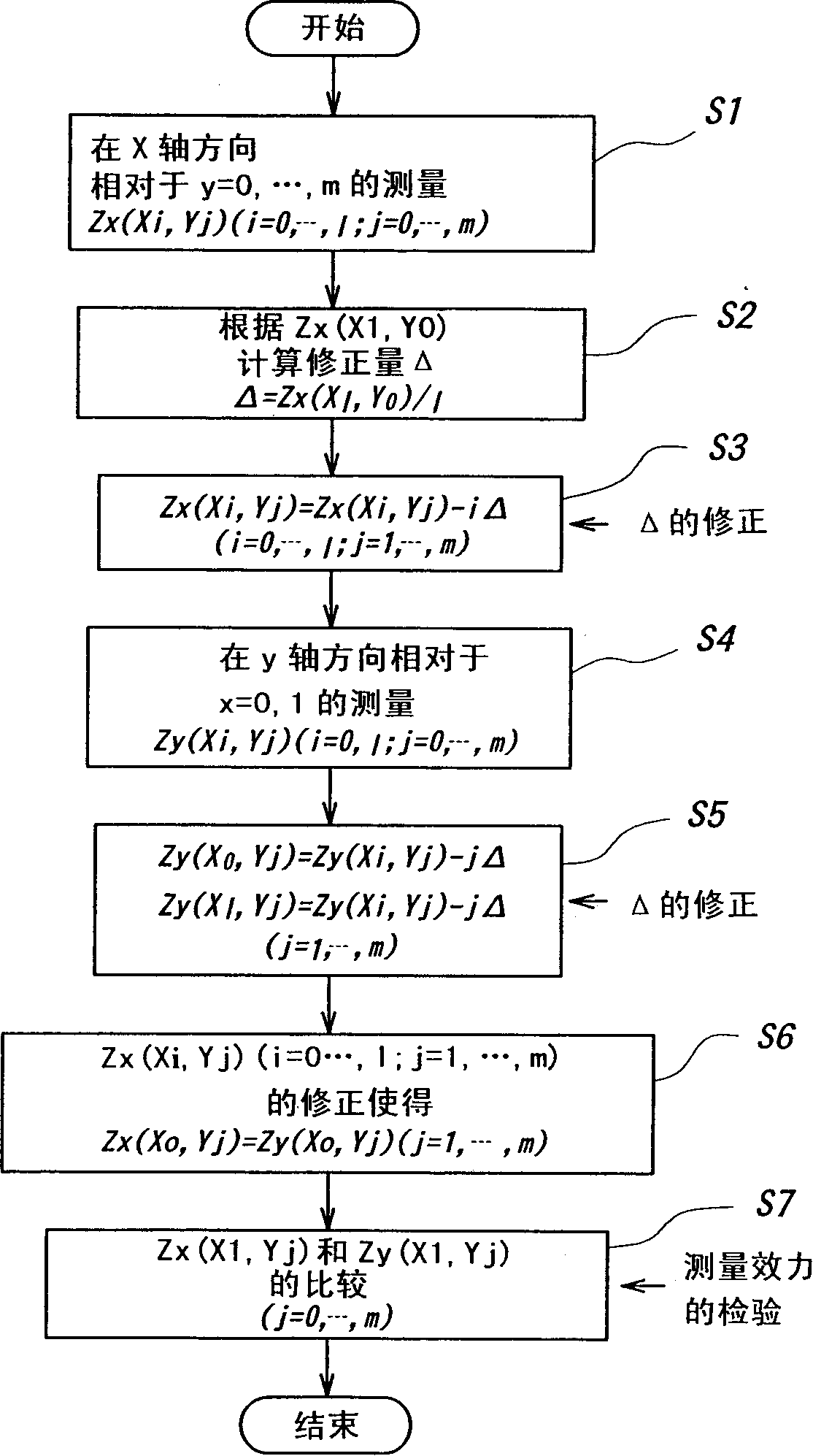

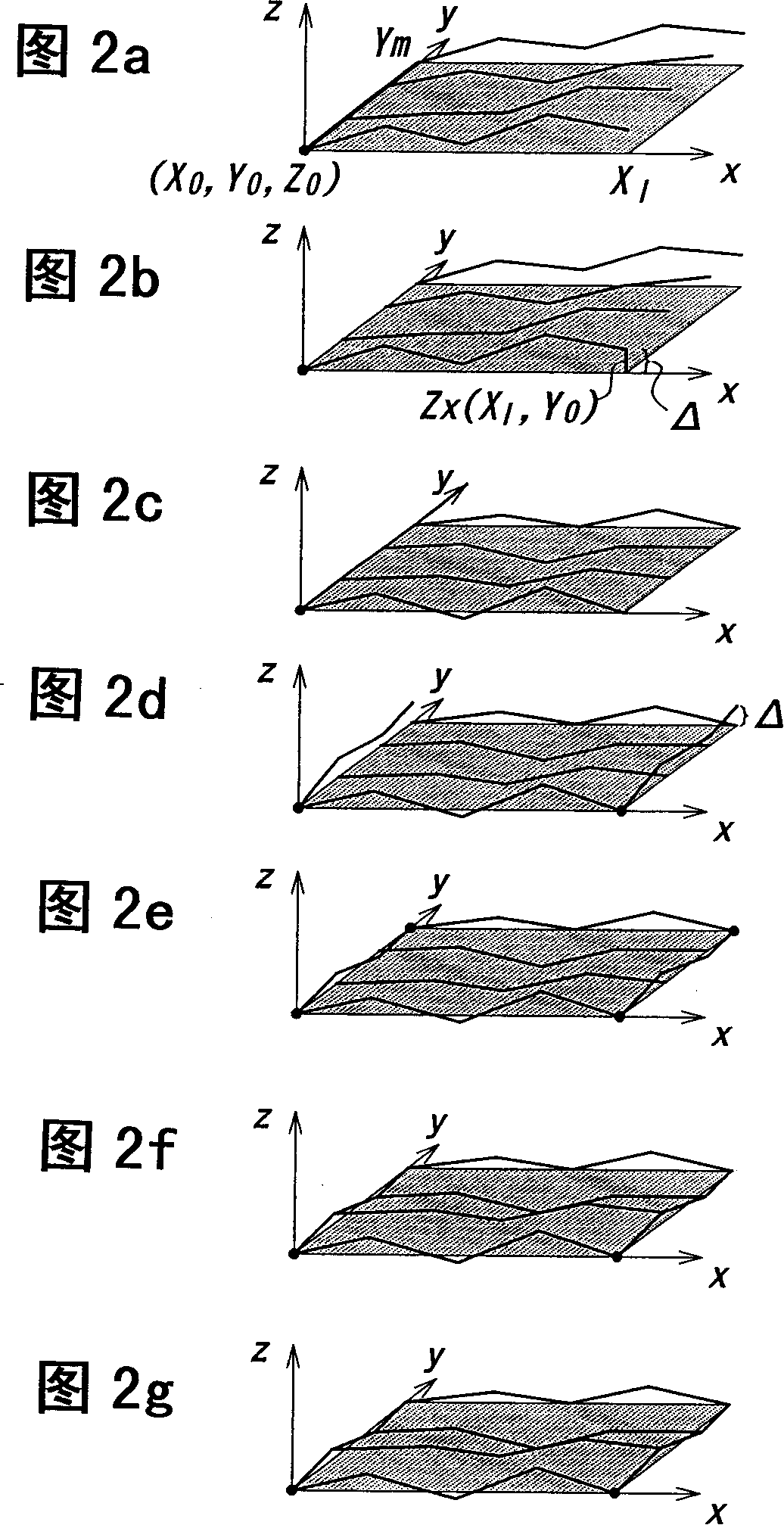

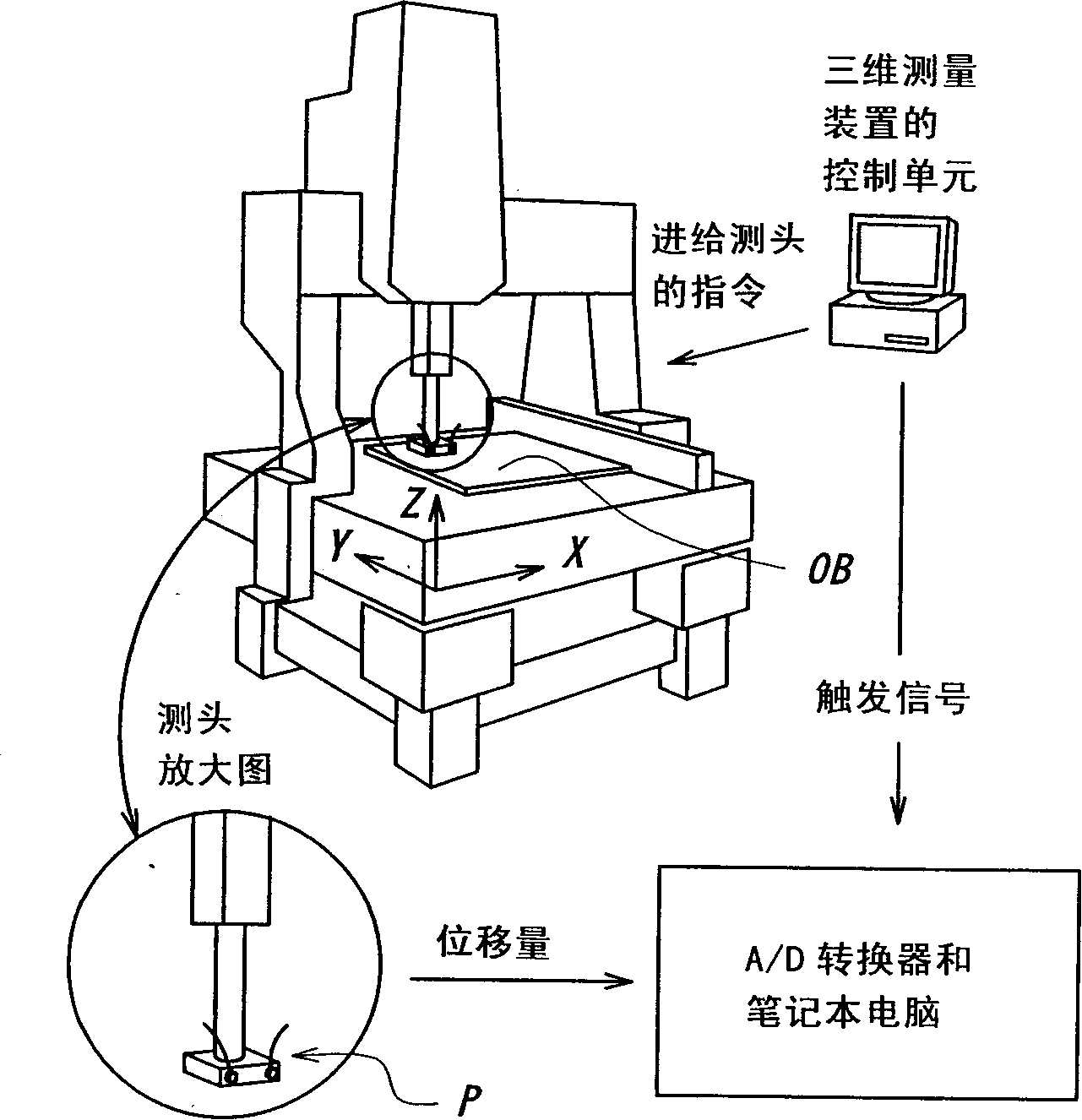

[0041] Hereinafter, a preferred embodiment of the present invention will be described in detail based on an example with reference to the accompanying drawings. it's here, figure 1 is a flow chart showing the flow in a position error evaluation method of a three-dimensional coordinate measuring device as an example of a position error evaluation method of a mobile device according to the present invention. Figures 2(a) to 2(g) are representations of figure 1 Illustrative diagram of the process shown. image 3 is a perspective view showing an example of a three-dimensional coordinate measuring apparatus to which the above example is applied.

[0042] In the example method, first set as image 3 Shown is a coordinate space with three axes of x, y, and z for a three-dimensional coordinate measuring device, wherein the extension direction of the portal frame is set as the X axis as shown in the figure. Here, instead of the probe is the Figure 4 The above-mentioned three-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com