Four-shaft machine tool calibration method based on multi-station measurement of laser tracker

A technology of laser tracker and calibration method, which is applied in the direction of measuring devices, instruments, and optical devices, and can solve the problems of being unable to meet the requirements of fast and efficient, multiple optical components, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

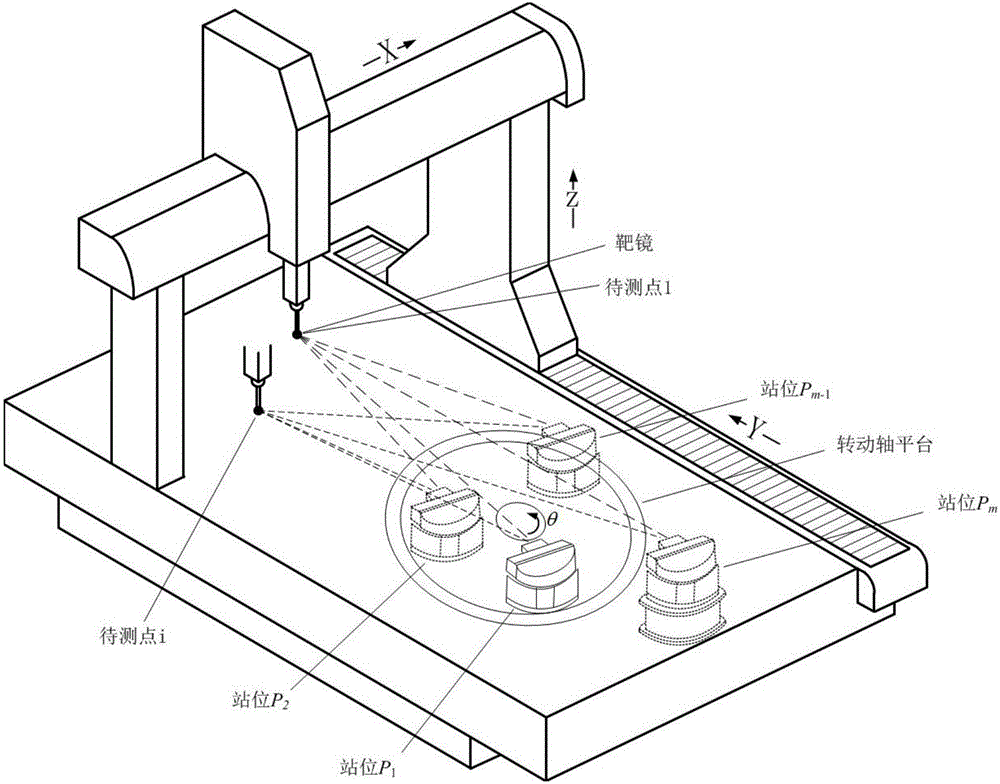

[0096] In the simulation experiment, the figure 1 The multi-station measurement system of the four-axis machine tool shown is used to measure the relative interference length measurement value, so the analysis is carried out through the following steps:

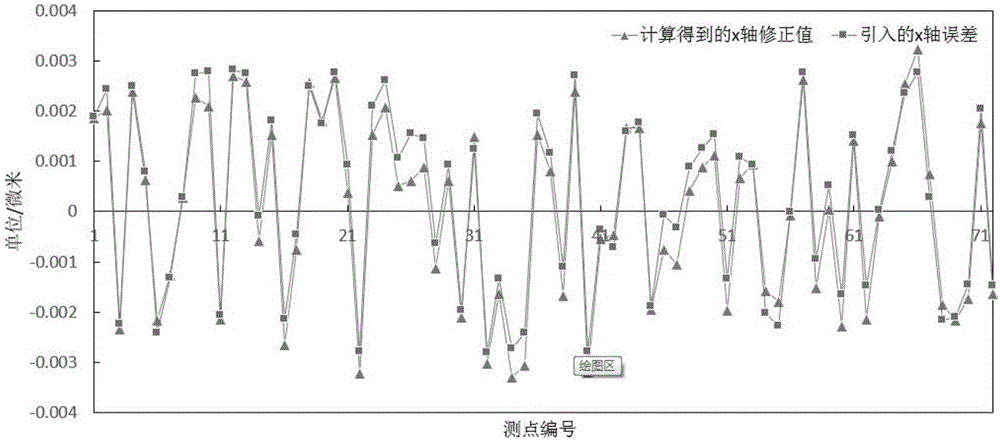

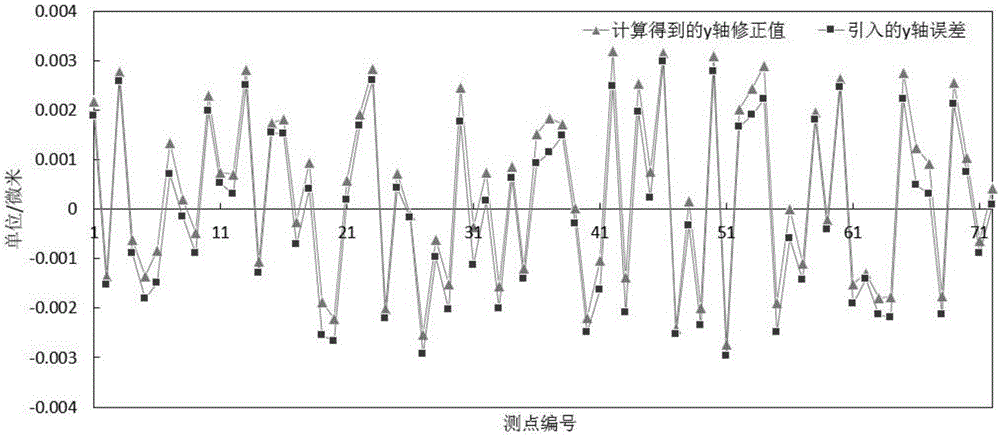

[0097] Step 1: Construct a multi-station measurement model of a four-axis machine tool laser tracker. Considering the measurement accuracy and the time required for the experiment, the number of laser tracker stations is determined to be 13, of which 12 stations are the stations where the laser tracker is fixed on the rotating shaft platform and the stations obtained after rotating 11 times. The 13th station is a station with a height difference from the 12th station. The number of space points to be measured in the four-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com