Electric spark processing equipment

A kind of processing equipment and EDM technology, applied in the field of mold processing equipment, can solve the problems of easy wear of mechanical transmission mechanism, difficulty in ensuring the movement accuracy of transmission mechanism, and poor processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

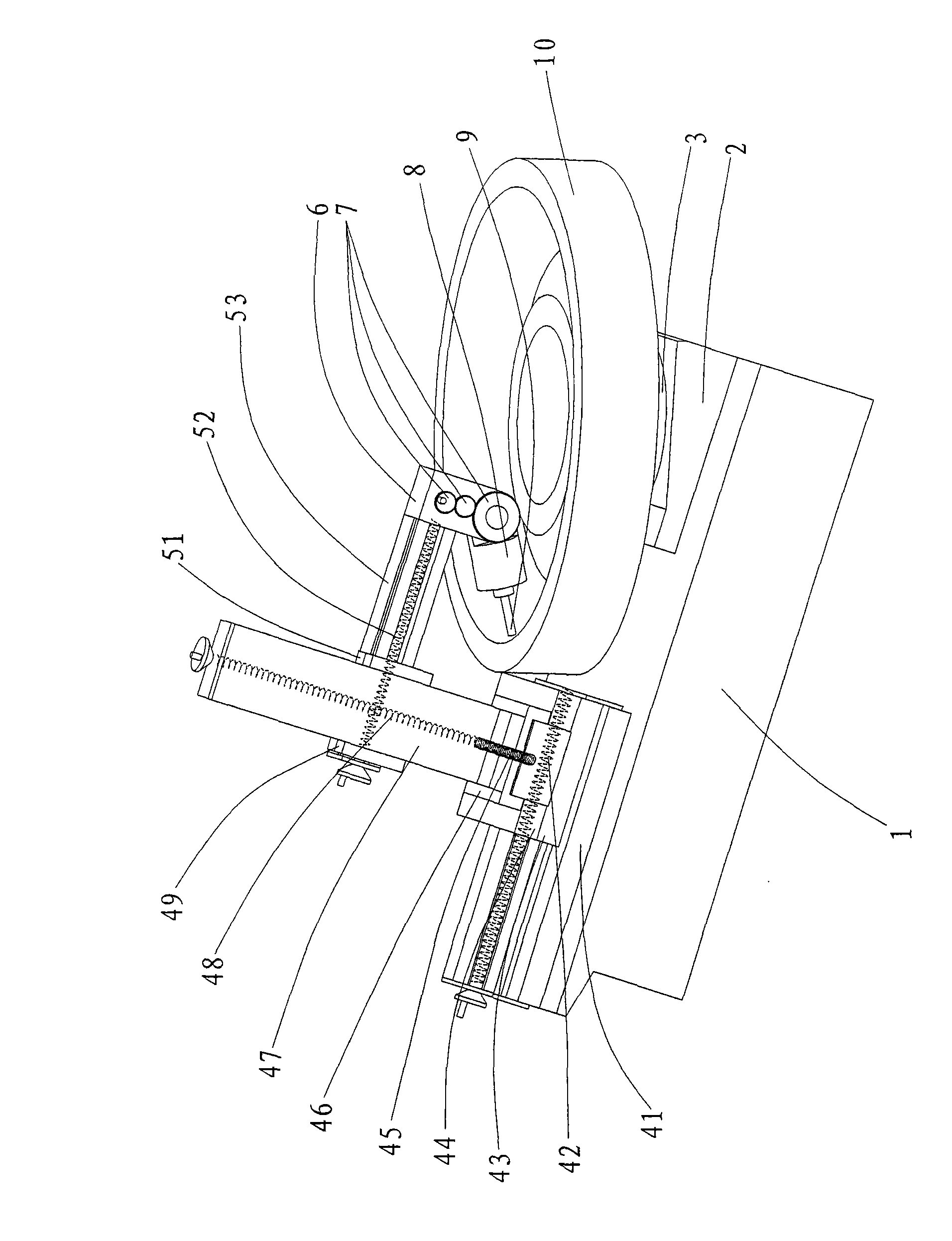

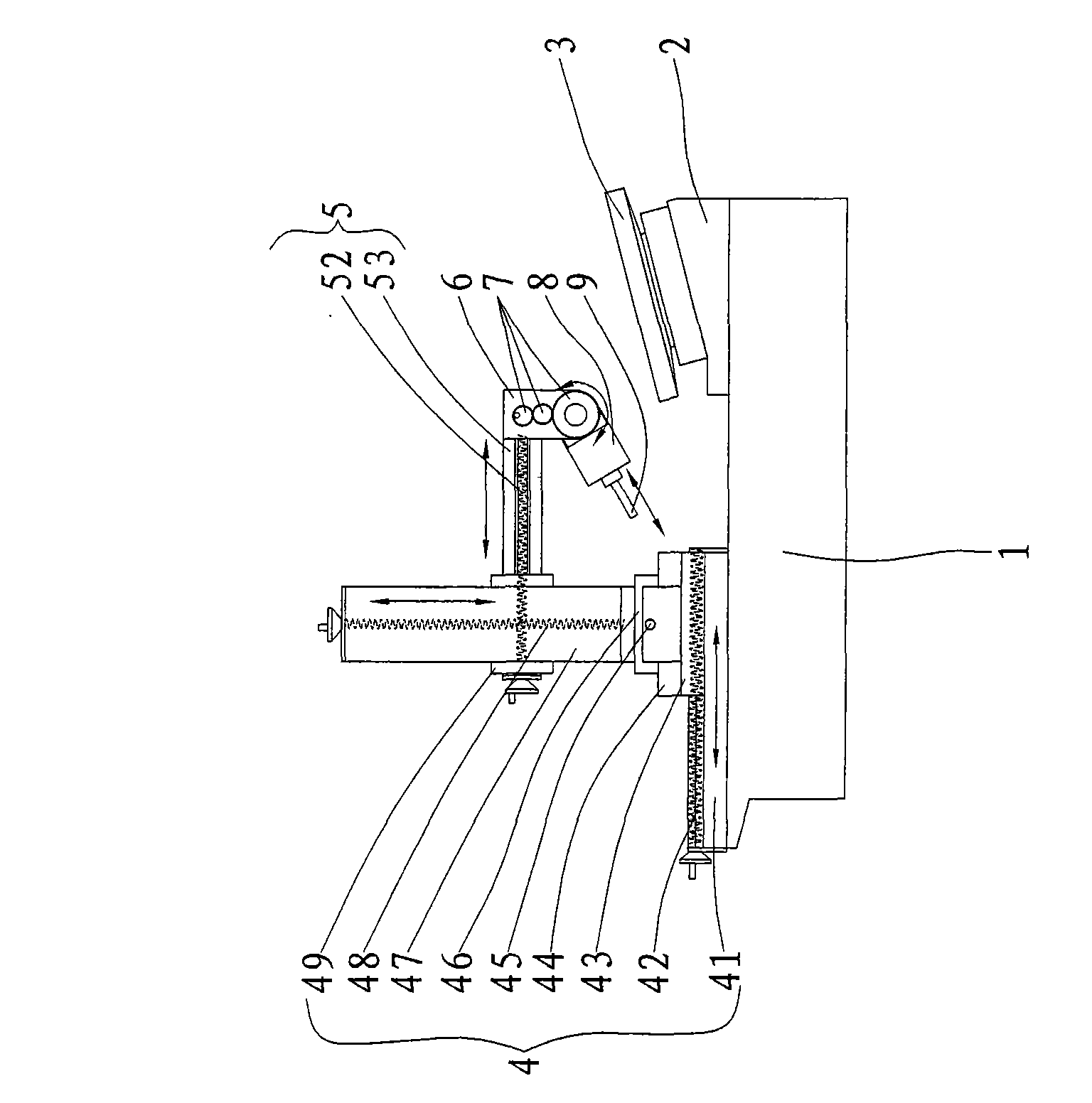

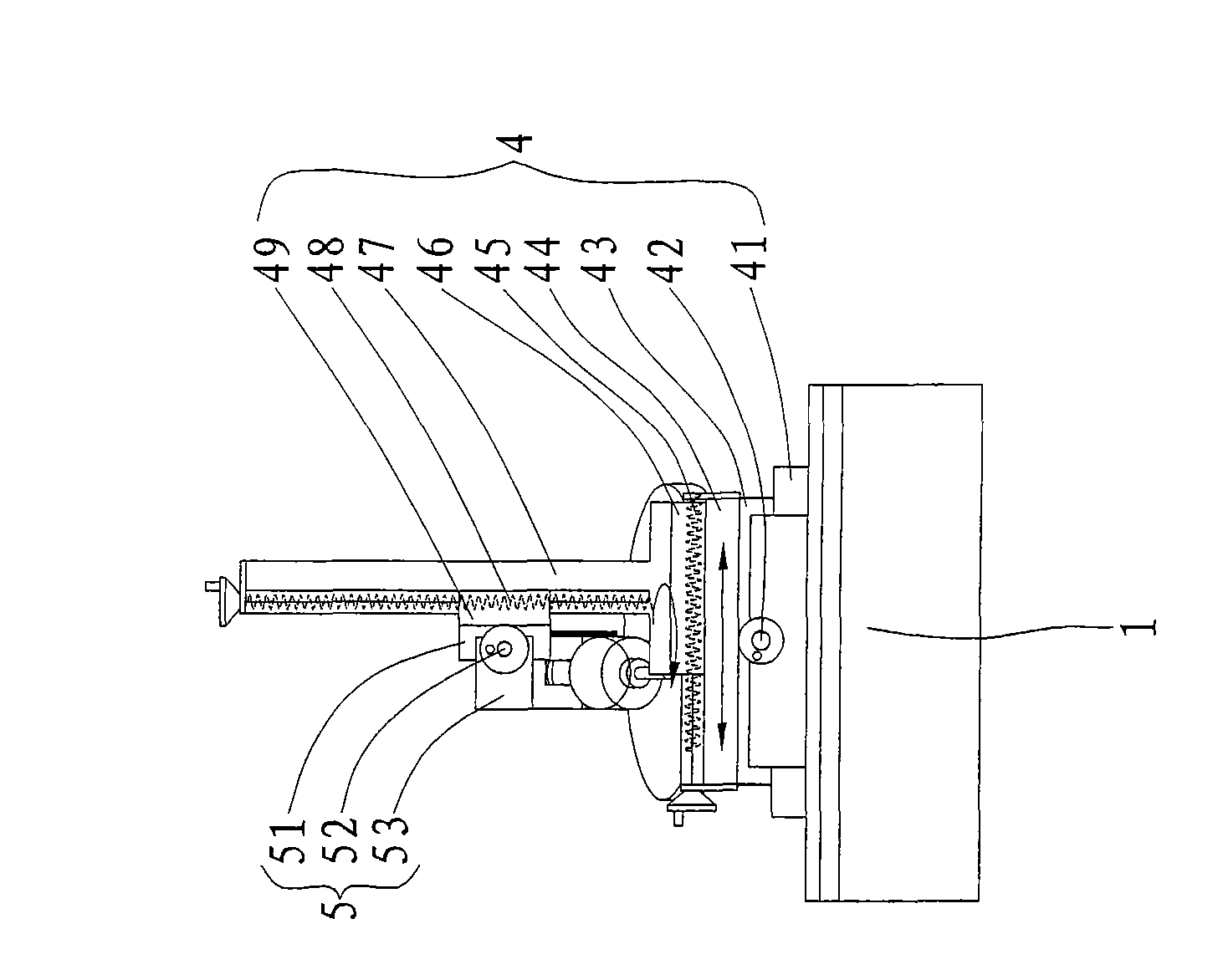

[0013] Such as figure 1 refer to Figure 4 As shown, the present invention is a kind of EDM equipment, which mainly consists of a base 1, a slope block 2, a turntable 3, a three-dimensional moving mechanism 4, a beam mechanism 5, a steering block 6, a discharge head steering gear 7, a discharge head 8, Electrode 9 composition.

[0014] Described three-dimensional moving mechanism 4 comprises X-axis guide rail 41, X-axis screw mandrel 42, X-axis slide block 43, Y-axis guide rail 44, Y-axis screw mandrel 45, Y-axis slide block 46, the column 47 that is provided with Z-axis guide rail , Z-axis screw mandrel 48, Z-axis slide block 49. The beam mechanism 5 includes a beam slider 51, a beam screw rod 52, and a beam 53. The X-axis guide rail 41 is fixed on the base, and the two ends of the X-axis screw rod 42 are rotatably connected to the X-axis guide rail 41. The two ends of the X-axis slider 43 are slid on the X-axis guide rail 41 and the middle part is screwed with the X-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com