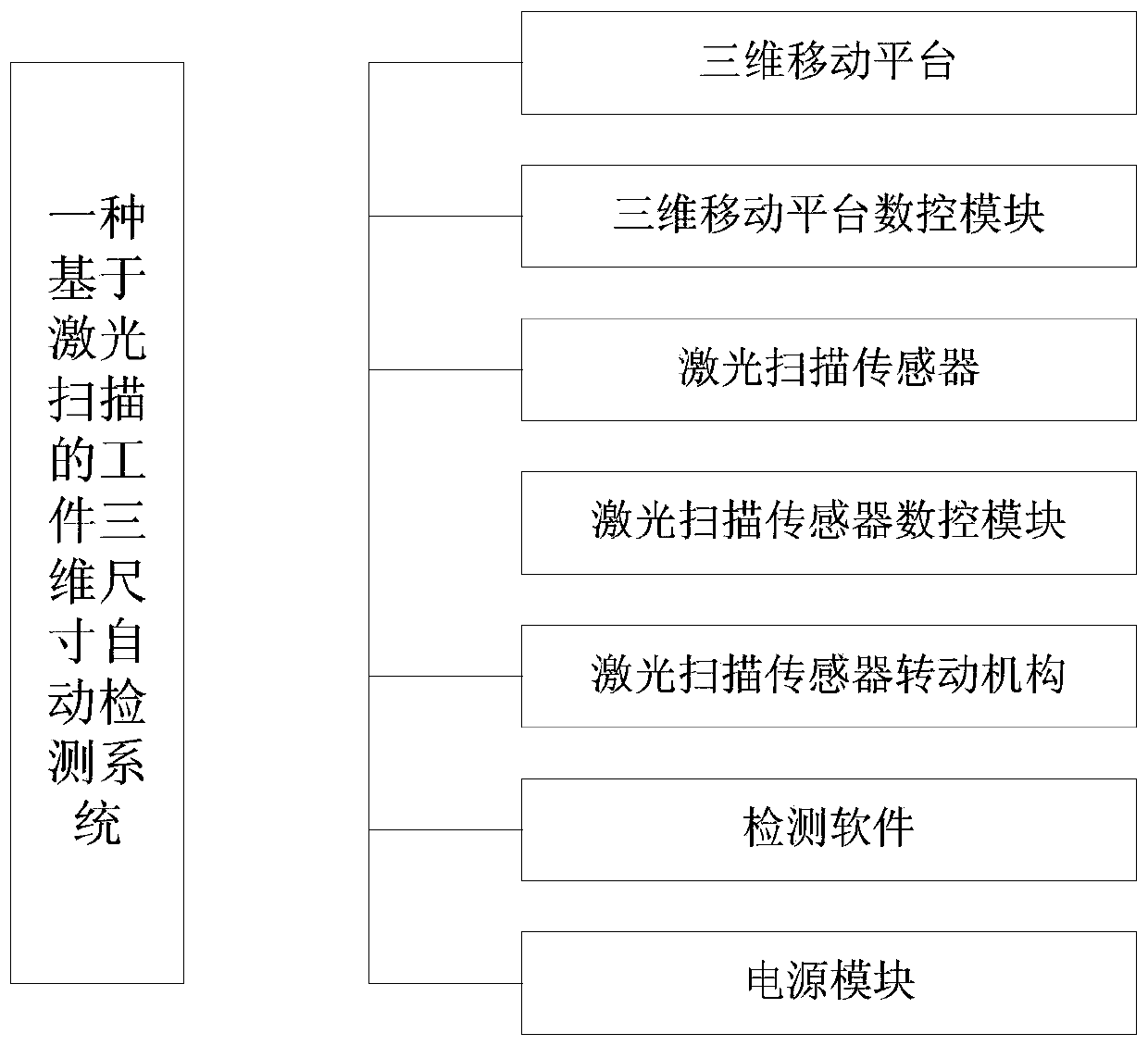

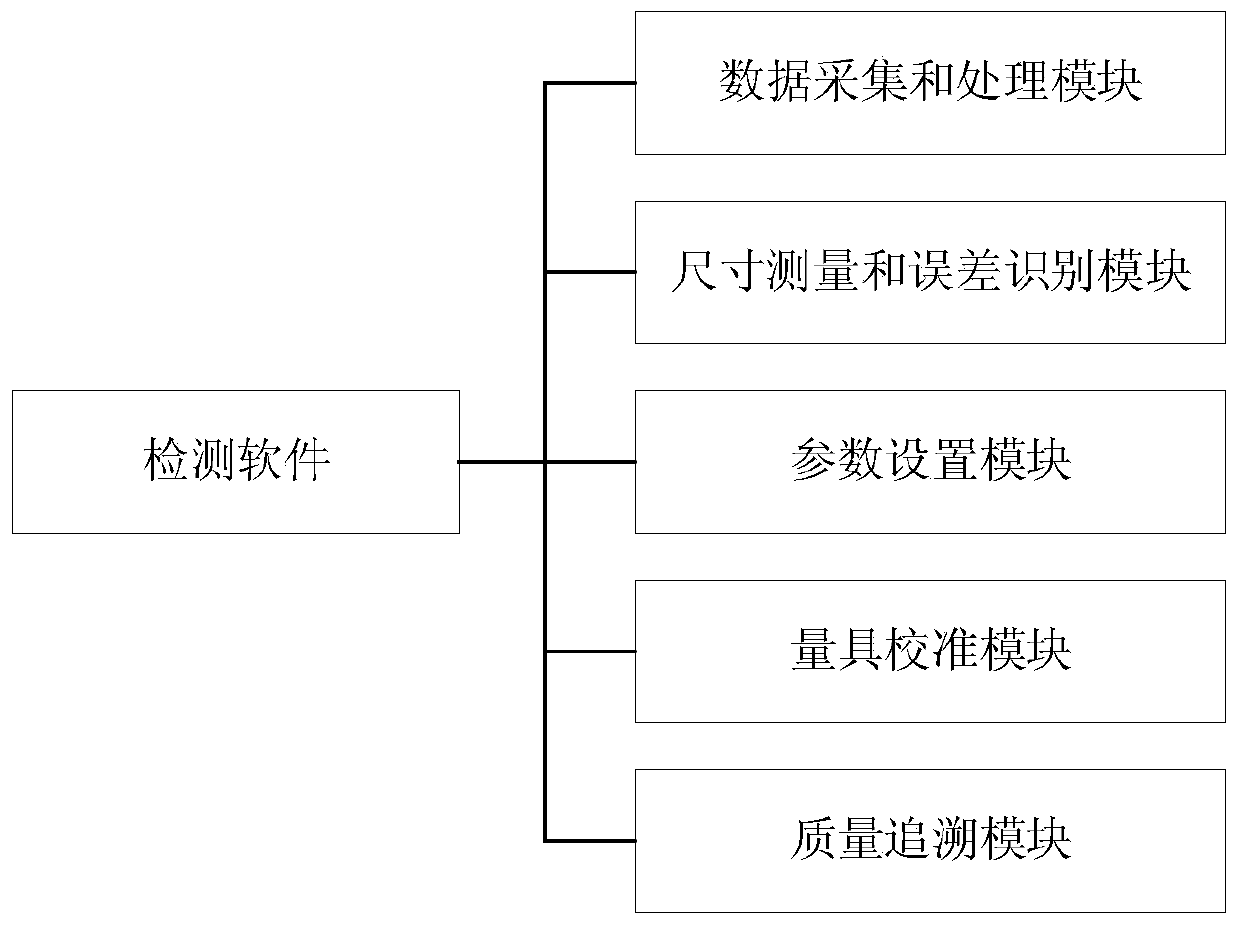

Workpiece three-dimensional dimensions automatic detection system and method based on laser scanning

A laser scanning and automatic detection technology, applied in the field of three-dimensional scanning and digital analysis, can solve the problems of low detection efficiency and low automation level, achieve strong anti-interference ability, high measurement accuracy, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

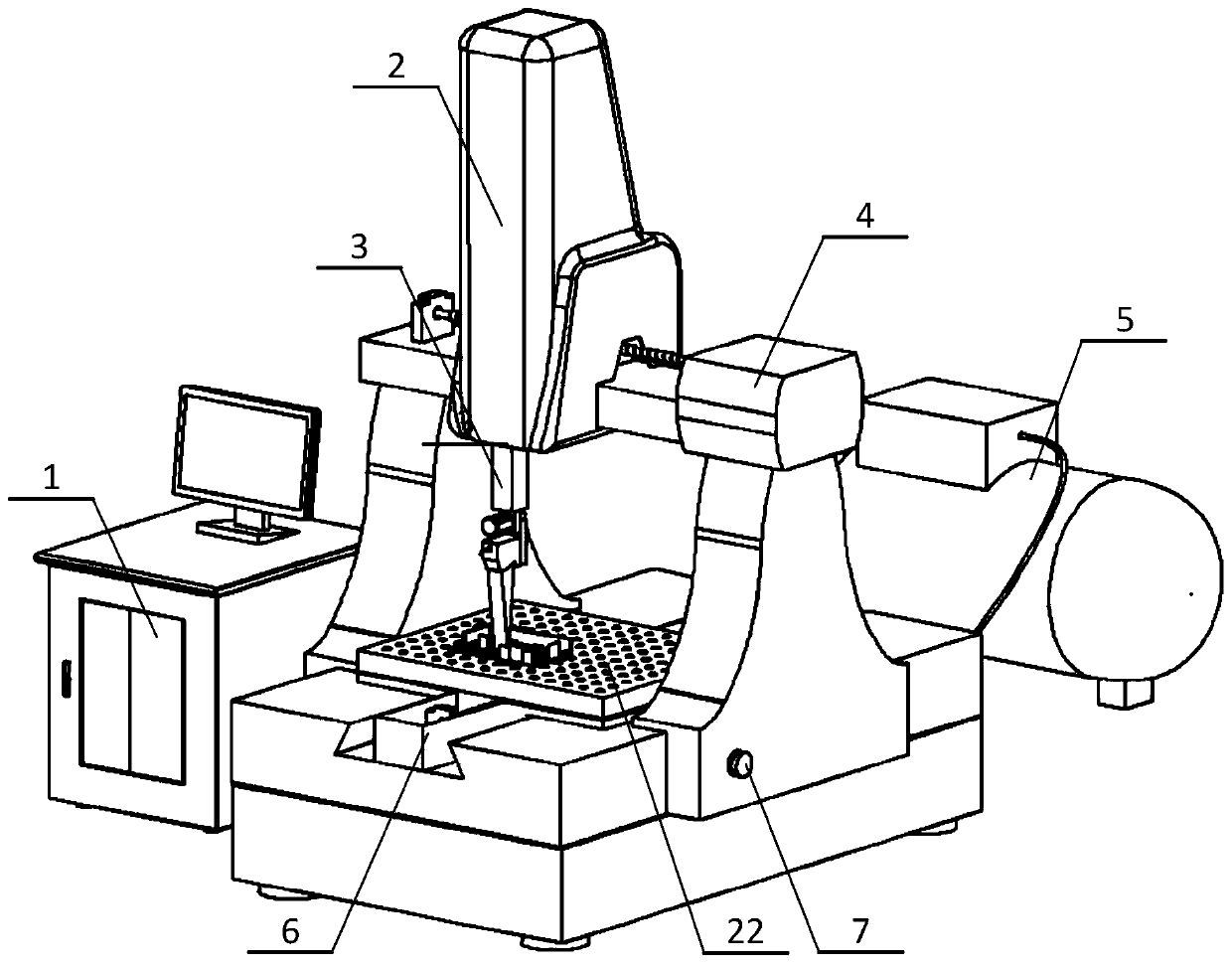

Examples

Embodiment

[0096] In a specific embodiment of the present invention, the laser scanning sensor scans the workpiece to obtain point cloud data including its key dimensions and position parameters, and the measurement error of the three-dimensional mobile platform is controlled within ±5 μm. The measurement error of the selected laser scanning sensor is better than ±0.02mm. The detection software denoises, simplifies, and merges the massive point cloud data obtained by the laser scanning sensor to obtain the key dimensions and position parameters of the workpiece. In the process of data processing, the lack of data, the generation of singular points and other factors will affect the accuracy of the detection results, and the error introduced by data processing is controlled within ±10 μm. During the detection process, changes in environmental factors such as temperature, humidity, air pressure, etc. will cause expansion and contraction of the measured object and the measuring device, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com