Spiral flow mixer for positive pressure metering injection type proportionally-mixing device

A proportional mixing device and mixer technology, which is applied in fire rescue and other directions, can solve problems such as affecting the fire extinguishing effect, unstable mixing, and unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

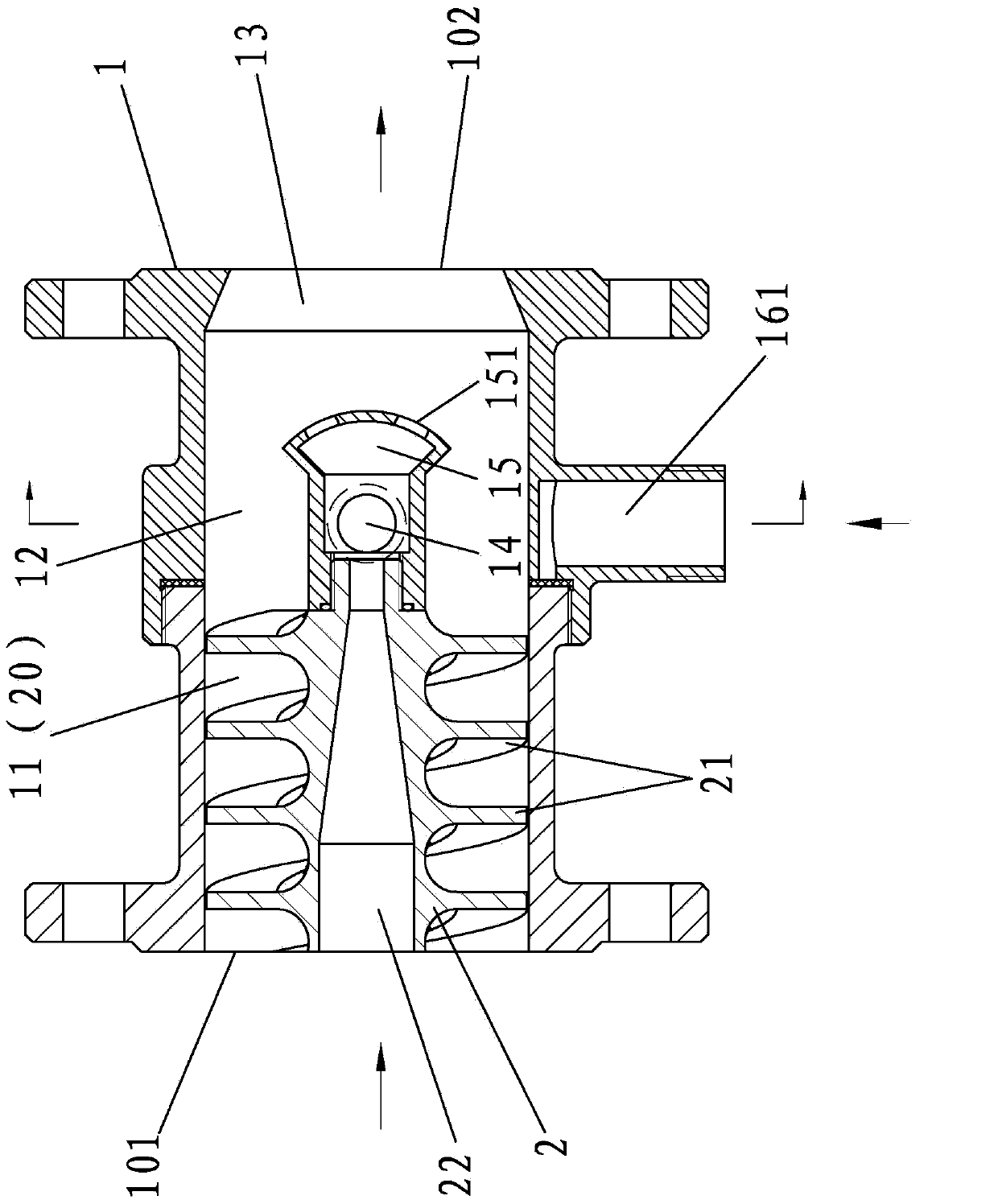

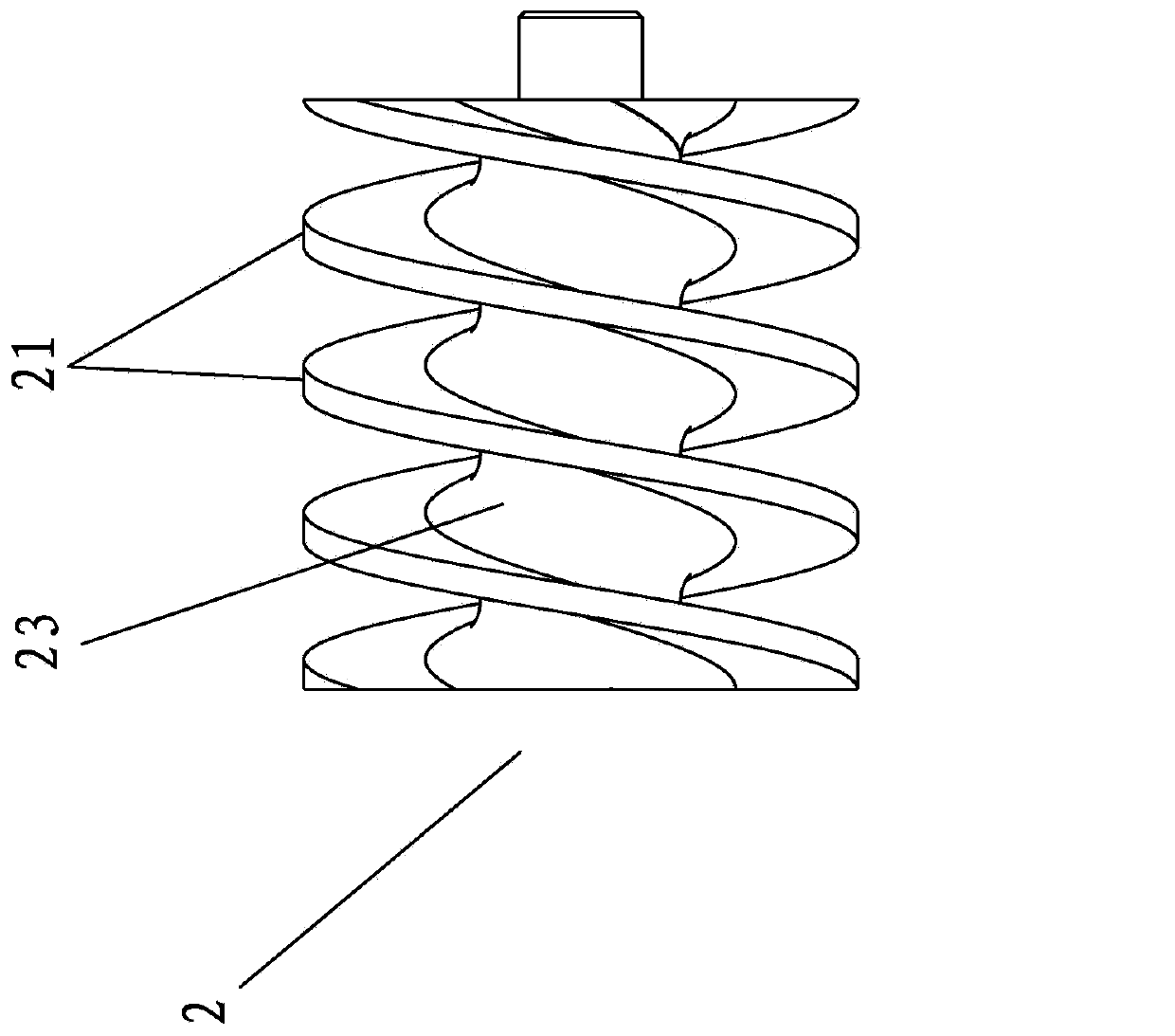

[0025] This case involves a spiral flow mixer for positive pressure metering injection proportional mixing device, such as Figure 1-3 As shown, it mainly includes a mixer body 1 and a continuous spiral deflector 2 .

[0026] The mixer body 1 is preferably assembled from a front circular tube wall and a rear circular tube wall. The mixer body 1 is provided with a body chamber through which both ends are connected. The two ends of the body chamber are opened as a water inlet 101 and a liquid outlet 102, and the direction from the water inlet 101 to the liquid outlet 102 is defined as the axial direction. The body chamber is divided into a spiral baffle chamber 11 and a swirl chamber 12 which are connected in the axial direction.

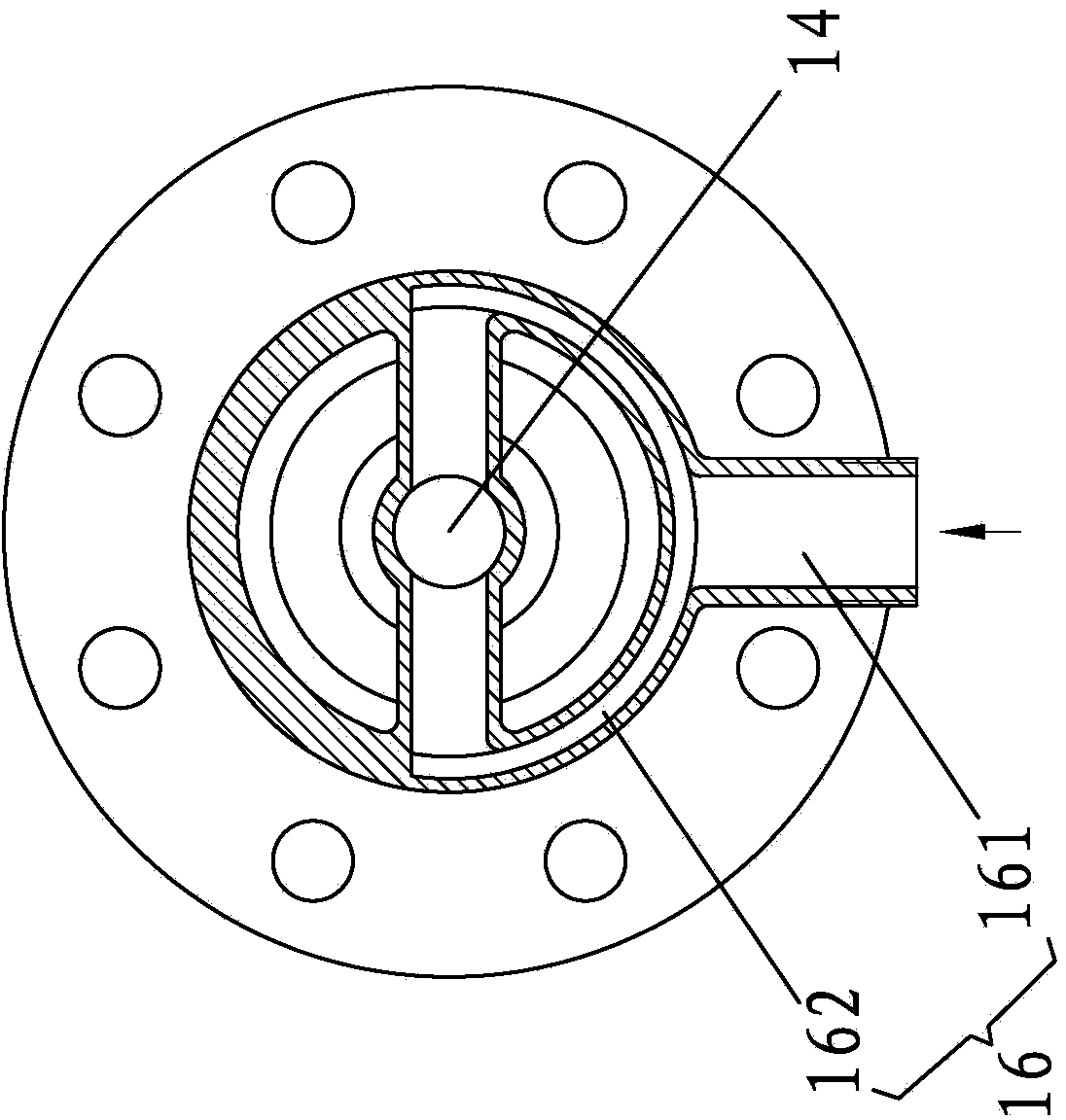

[0027] A core body is arranged inside the swirl chamber 12, and a crushing chamber 14 and an injection chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com