Splitting machine cutter automatic adjusting device

A technology of automatic adjustment device and slitting machine, which is applied in metal processing and other directions, can solve the problems of reducing adjustment efficiency, complicated adjustment of cutter spacing, etc., and achieves the effect of simple adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

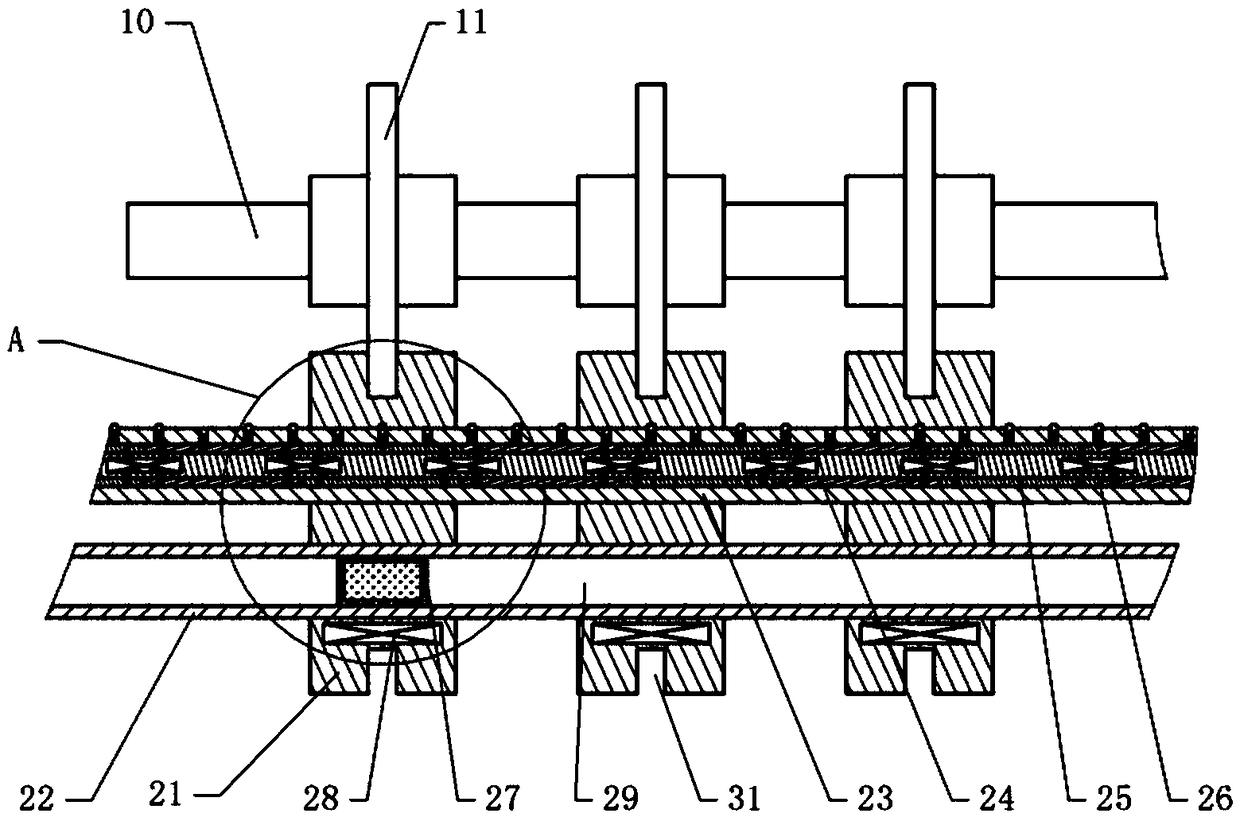

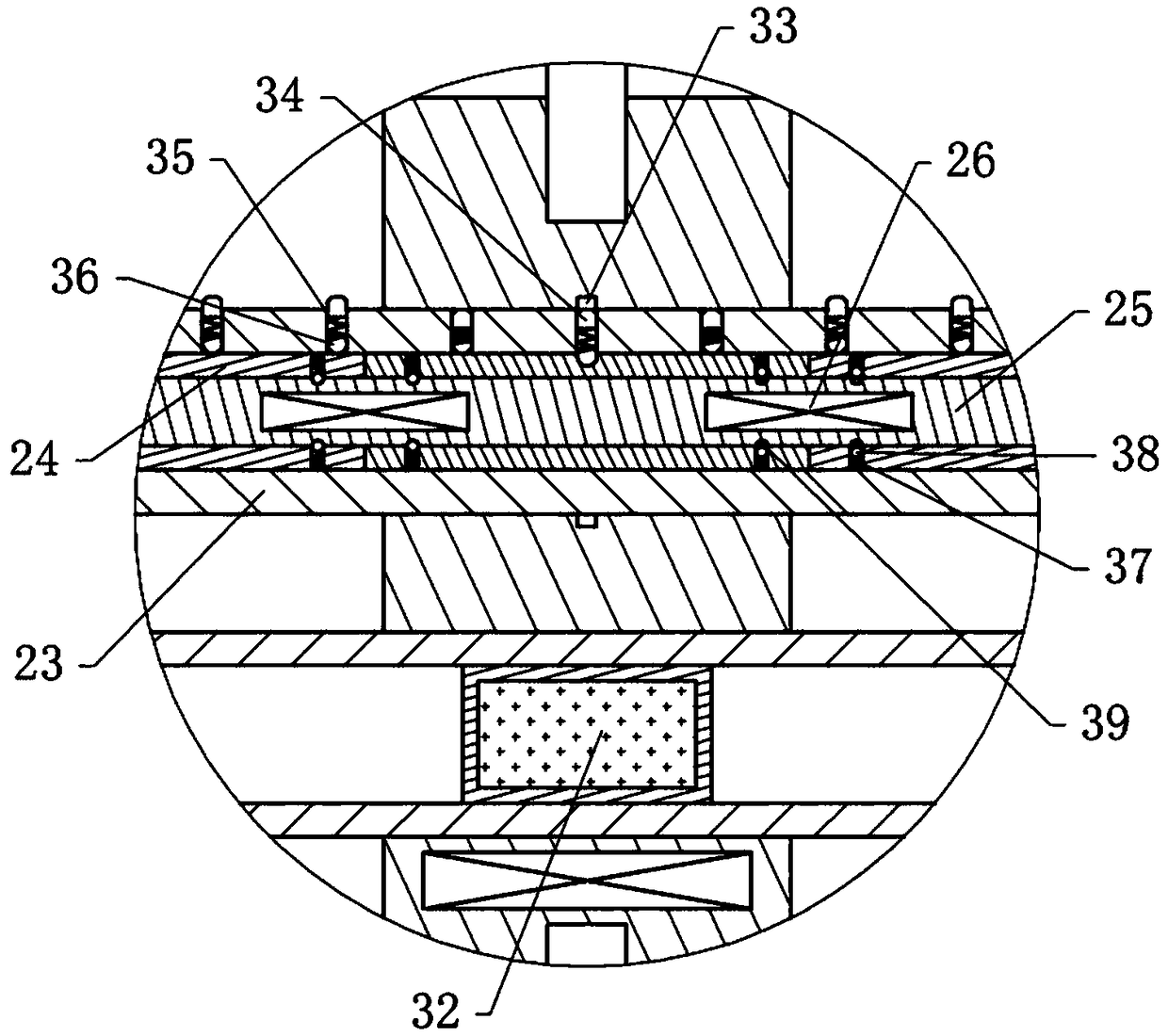

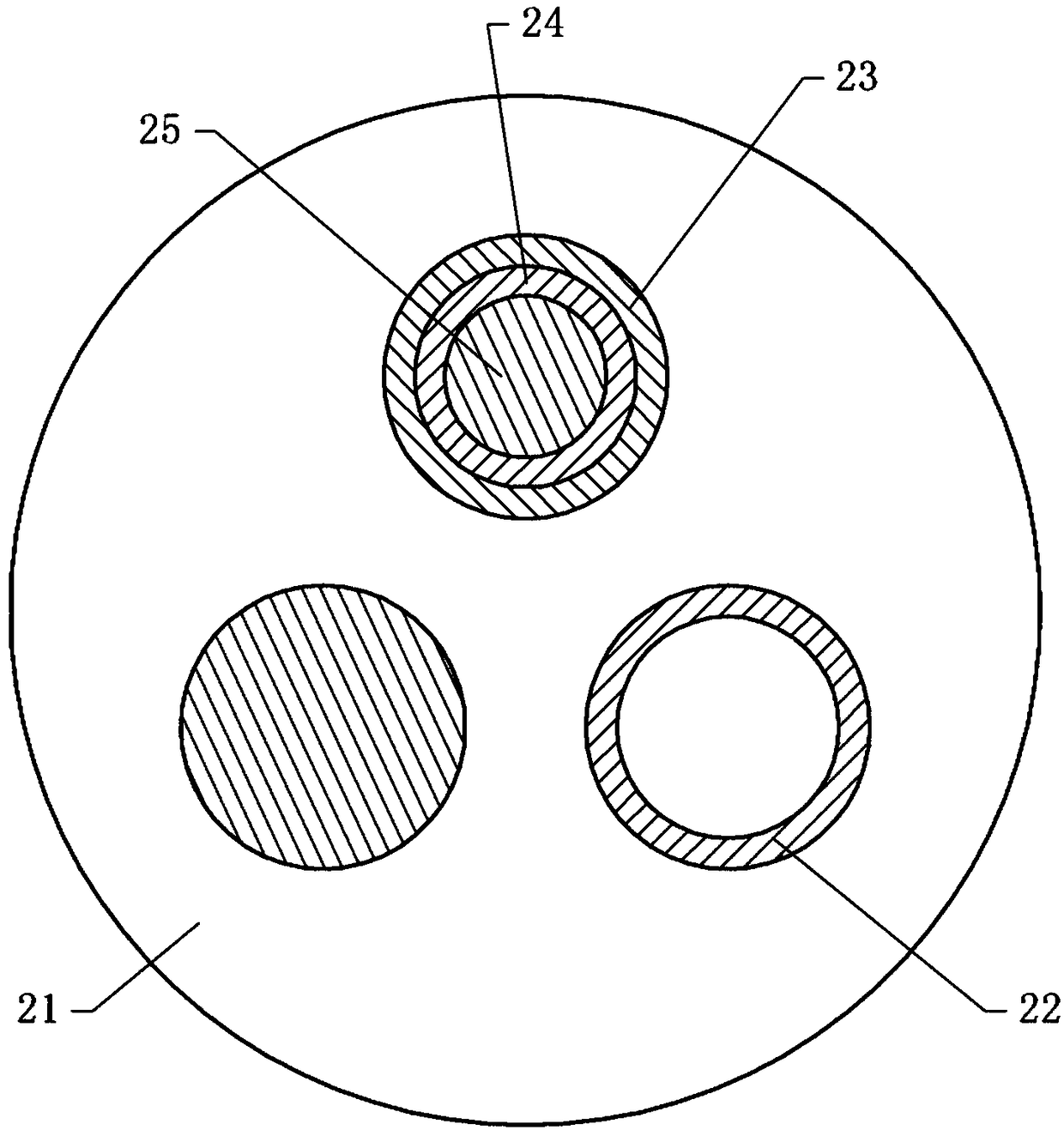

[0021] The reference signs in the drawings of the description include: cutting shaft 10, cutter 11, positioning block 21, hydraulic rod 22, outer jacket 23, ring body 24, inner rod 25, second electromagnet 26, piston 27, first electromagnetic Iron 28, hydraulic chamber 29, annular groove 31, permanent magnet 32, positioning groove 33, positioning column 34, stage clip 35, ball 36, extension spring 37, steel ball 38, driving groove 39.

[0022] The embodiment is basically as figure 1 , figure 2 with image 3 Shown:

[0023] The cutter automatic adjustment device of the slitting machine of the present embodiment comprises a slitting shaft 10 and a positioning shaft, ten cutting knives 11 are slidably connected on the slitting shaft 10, and a positioning block 21 cooperating with the cutting knives 11 is provided on the positioning shaft, and the positioning The block 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com