Automatic treatment equipment for PE pipe machining

A technology for processing equipment and mobile devices, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of uneven and smooth surface, affect the electric melting process, and small caliber of the scraper, so as to ensure smoothness , mobile stability, improve the effect of funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

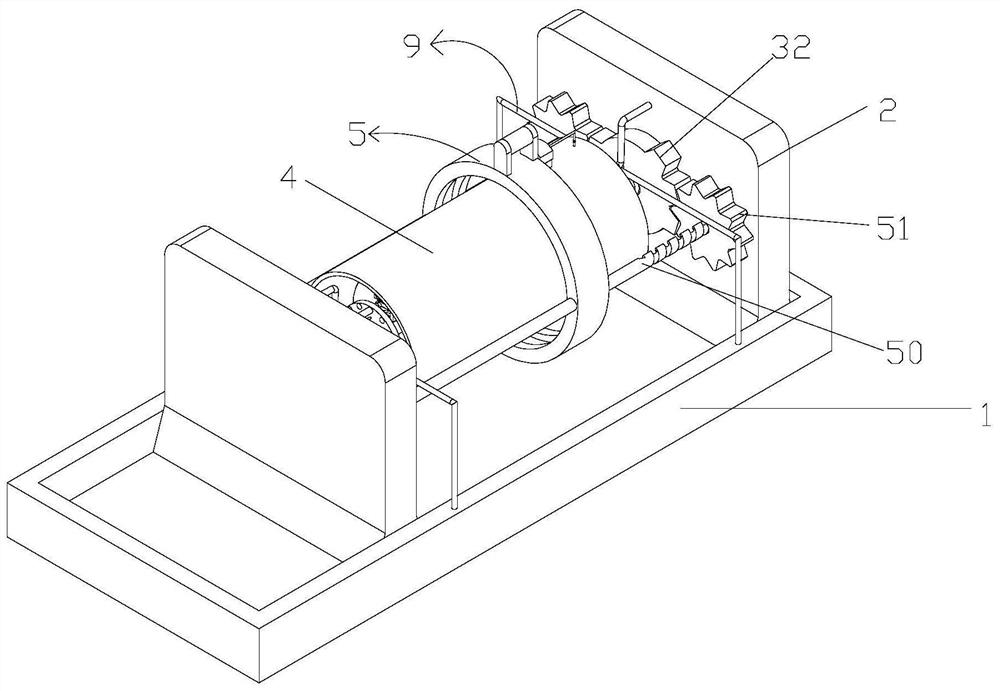

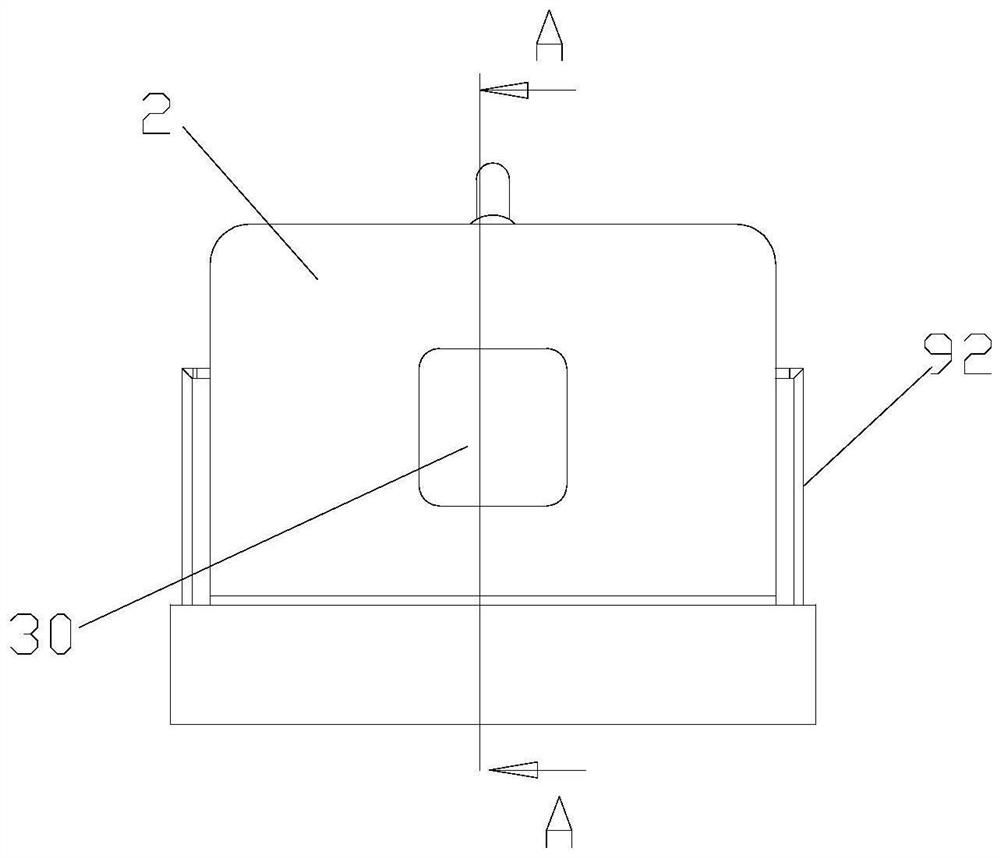

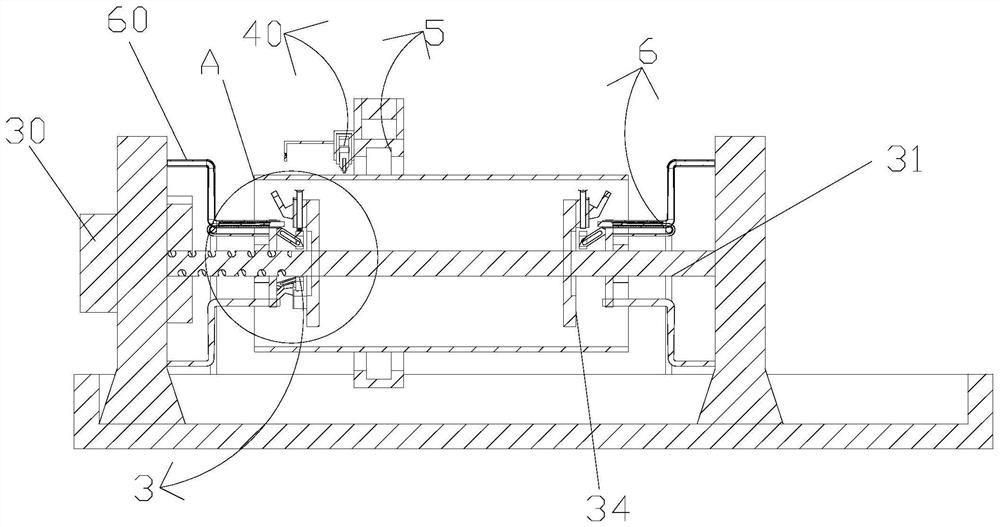

[0033] Such as Figure 1-14 As shown, an automatic processing equipment for PE pipe processing includes a tank body 1, a support frame 2, a moving device 3, a PE pipe 4 and a scraping mechanism 5; The left and right sides of 1; the moving device 3 is respectively set on the support frame 2; the PE pipe is set on the moving device 3; the scraping mechanism 5 is set on the PE pipe.

[0034] Such as Figure 3-8 As shown, the moving device 3 includes a motor 30, a screw rod 31, a missing gear 32, a nut 33, a rotating disk 34, a guide hole 35, a guide device 6 and a support device 7; the motor 30 is fixed on the left side of a single support frame 2 Connection; one end of the screw rod 31 is fixedly connected to the right side of the motor 30, and penetrates inside the support frame 2, and the other end is fixedly connected to the right side of the support frame 2; the missing gear 32 is sleeved outside the screw rod 31; the The nut 33 is sleeved on the outside of the screw rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com