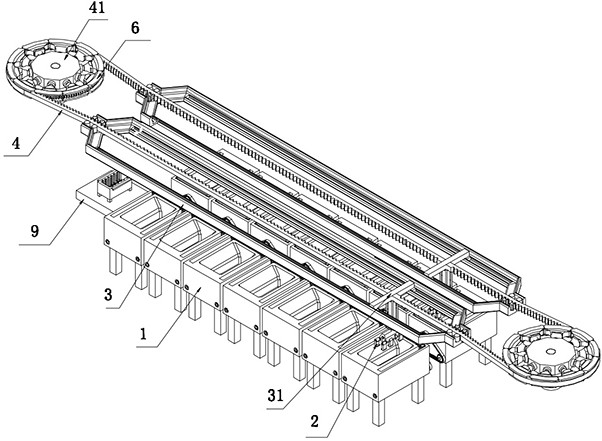

Semiconductor wafer groove type cleaning machine

A technology for semiconductors and cleaning machines, applied in semiconductor/solid-state device manufacturing, liquid cleaning methods, conveyor objects, etc., to achieve uniform moving speed, increase transportation speed, and avoid cleaning liquid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

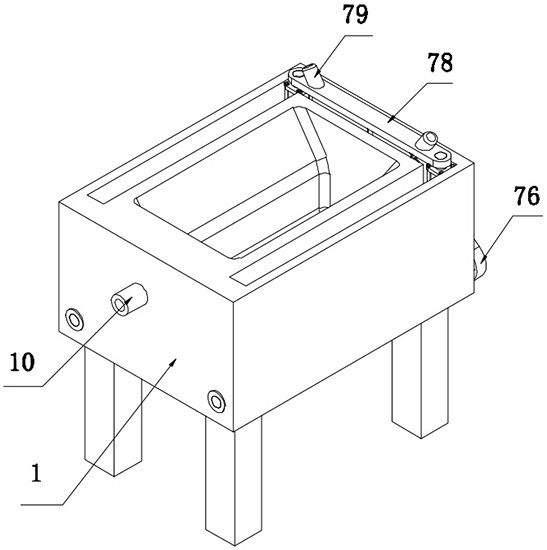

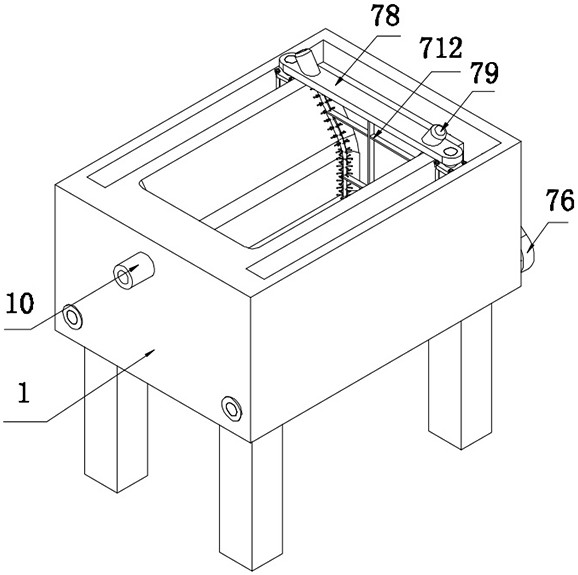

Embodiment Construction

[0037] like Figure 4 and Figure 7 As shown, in order to realize the adjustment of the moving speed of the manipulator, specifically, the speed change mechanism also includes a rotating disc 41 driven by a motor, and the two rotating discs 41 are mirror-symmetrically distributed in the length direction of the synchronous belt 4, and the first cylinder 5 Fixedly installed on the radial direction of the outer surface of the rotating disk 41, the meshing teeth 6 are fixedly installed on the piston rod outer end of the first cylinder 5 to realize radial expansion and contraction. into a gear with a fixed diameter, when the speed of the synchronous belt 4 needs to be adjusted, the first cylinder 5 only needs to drive the meshing teeth 6 to expand and contract to change the diameter of the gear, and the purpose of speed regulation of the synchronous belt 4 can be realized. A plurality of first cylinders 5 are distributed in a circular array with the axis of the rotating disc 41 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com