Patents

Literature

50results about How to "Moving at a uniform speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

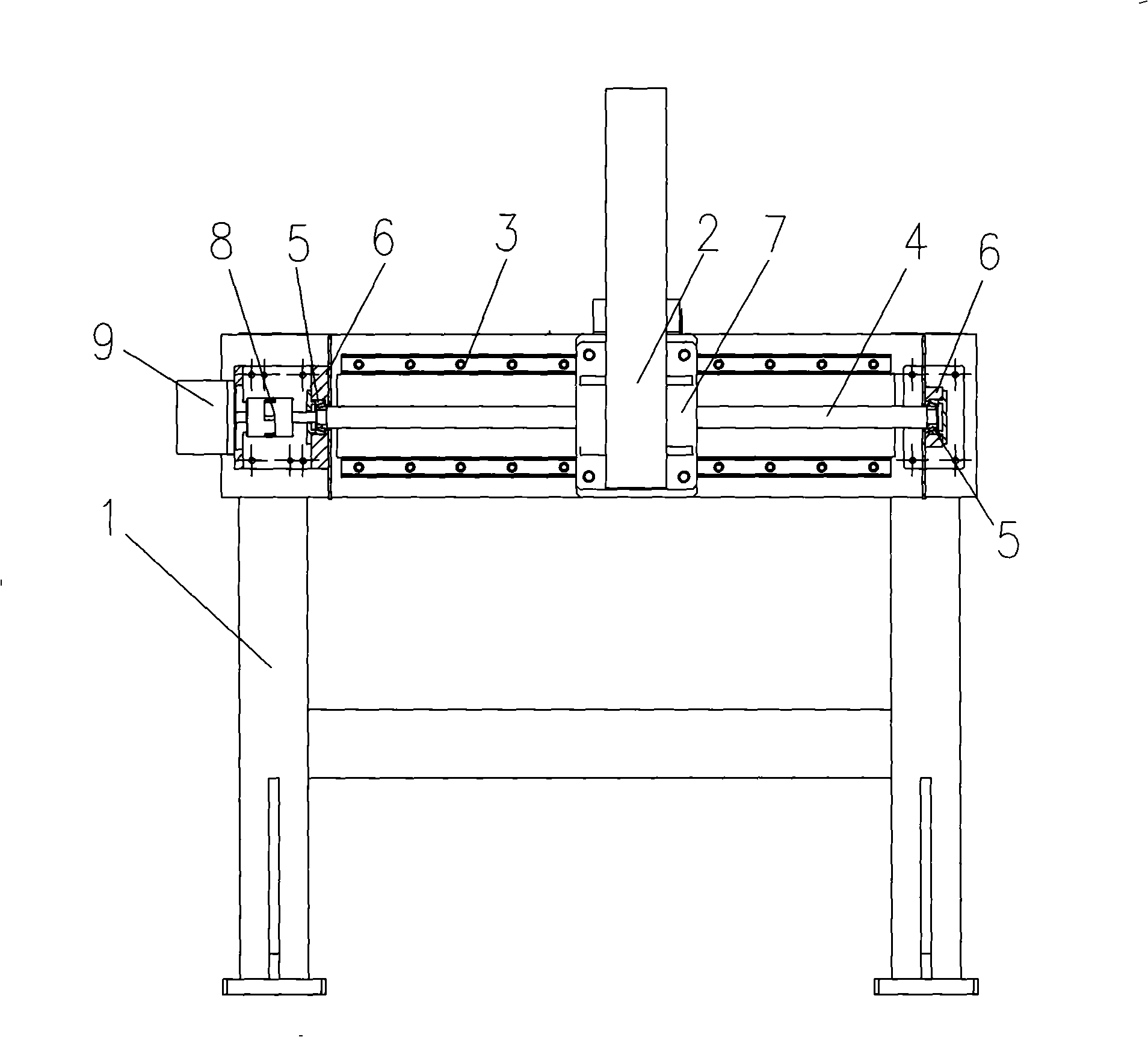

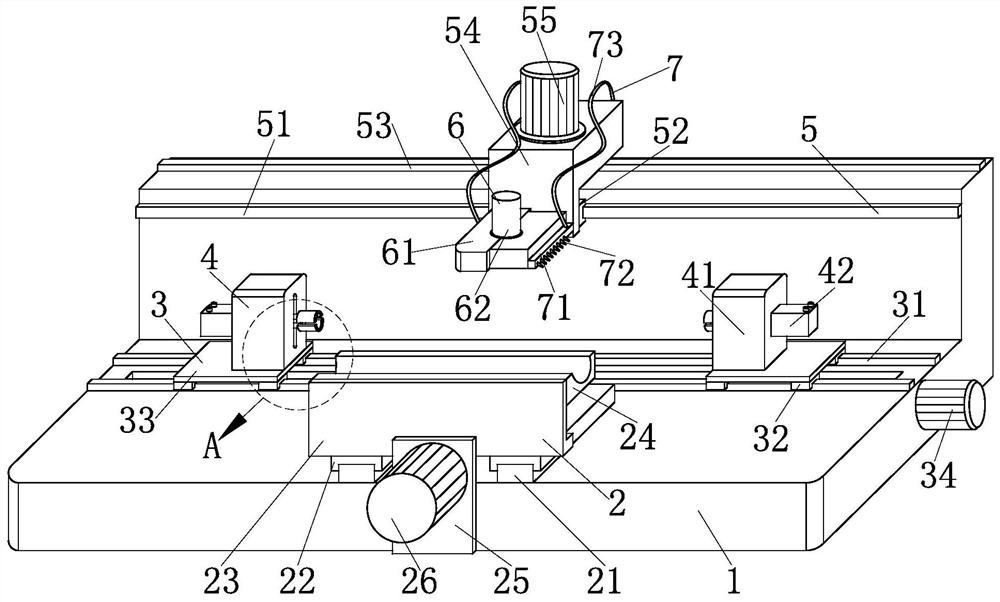

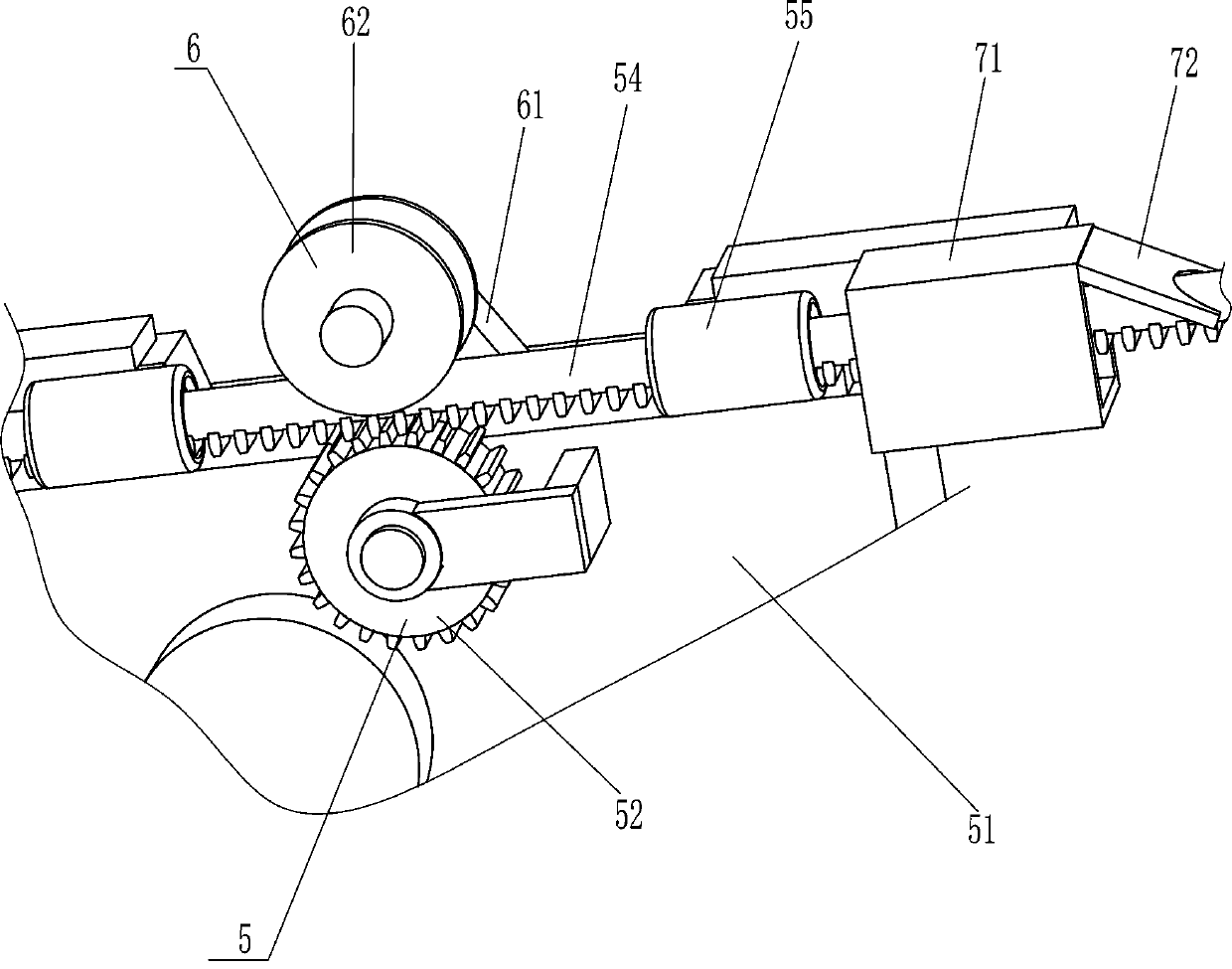

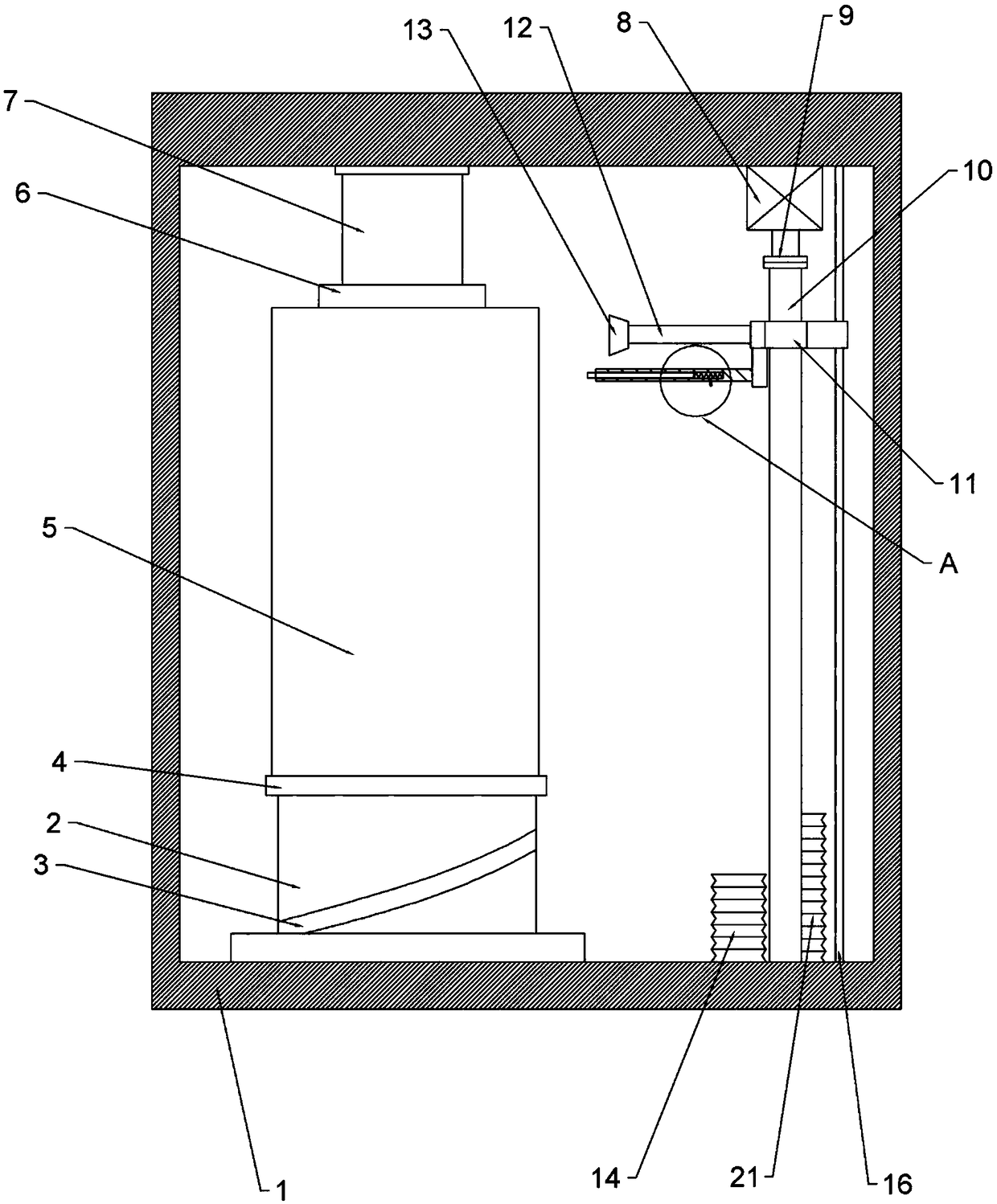

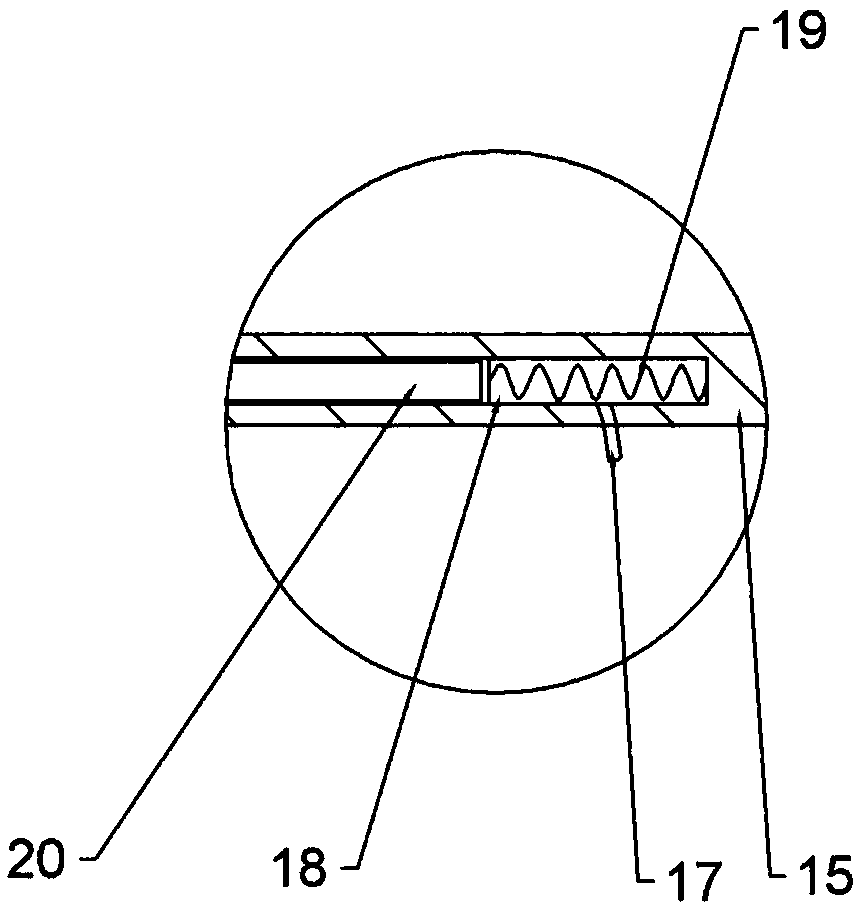

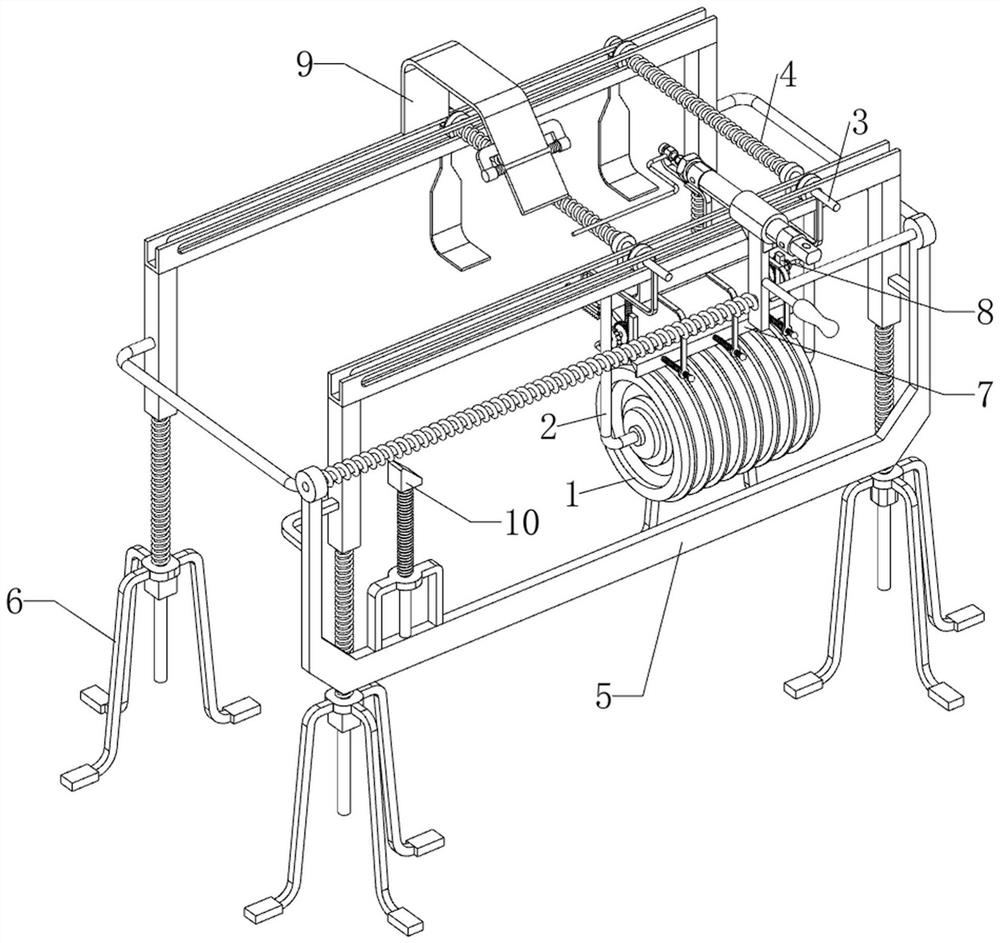

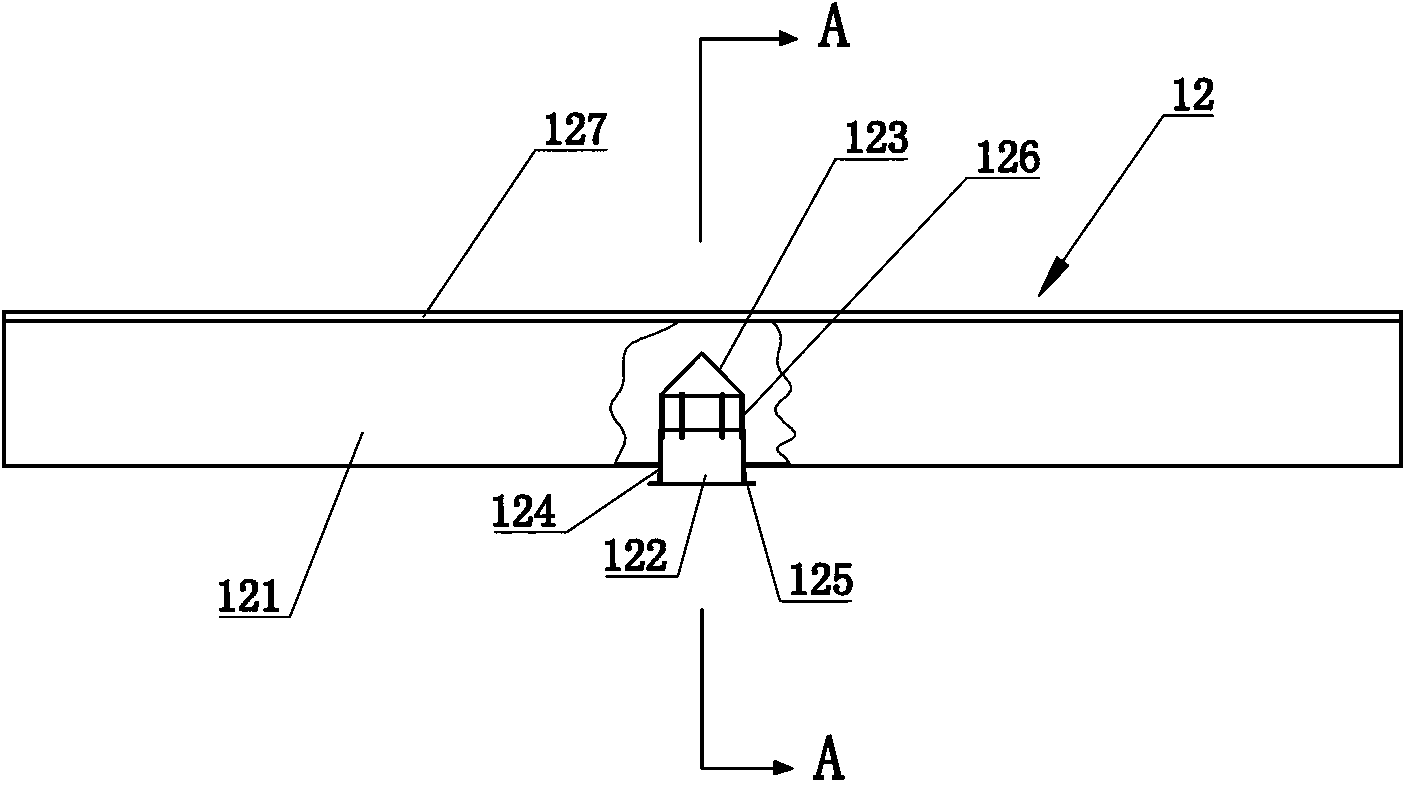

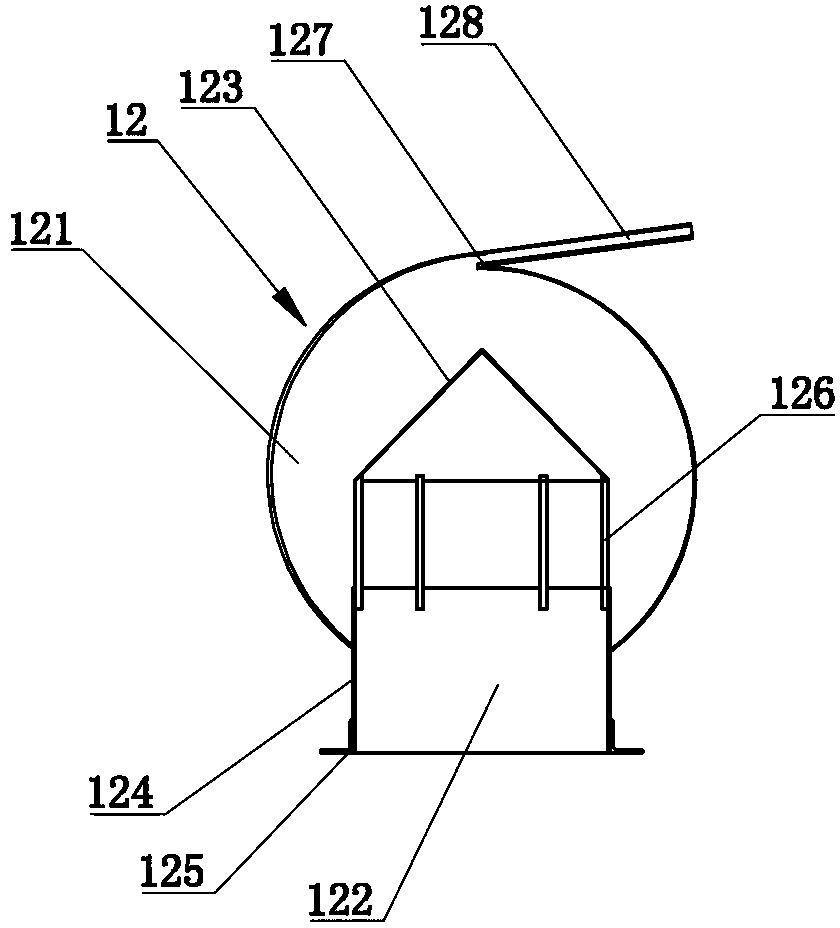

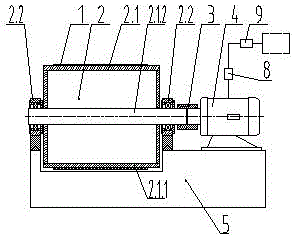

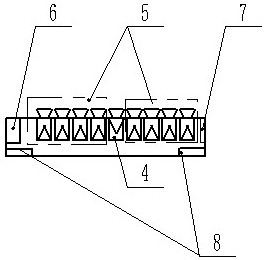

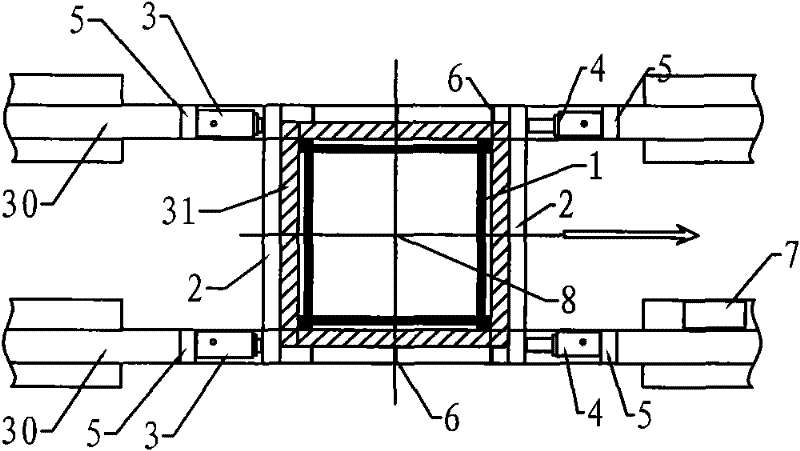

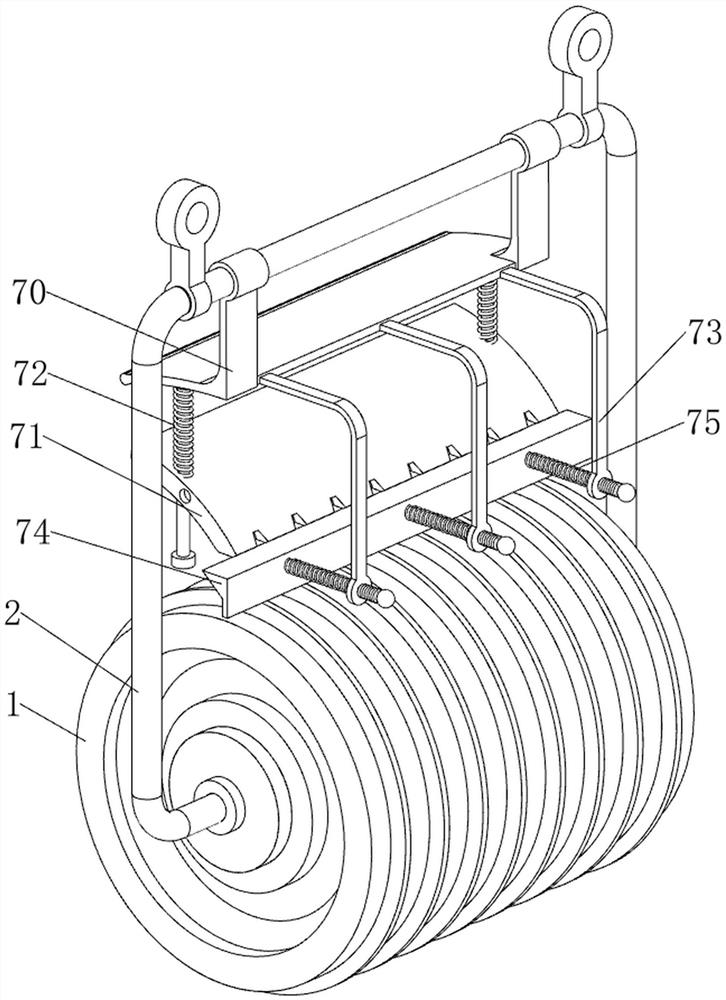

Welding gun moving apparatus of jackrod abrasion-proof belt welding machine

InactiveCN101293309AEasy to weldUniform thicknessWelding/cutting auxillary devicesAuxillary welding devicesCouplingBall screw

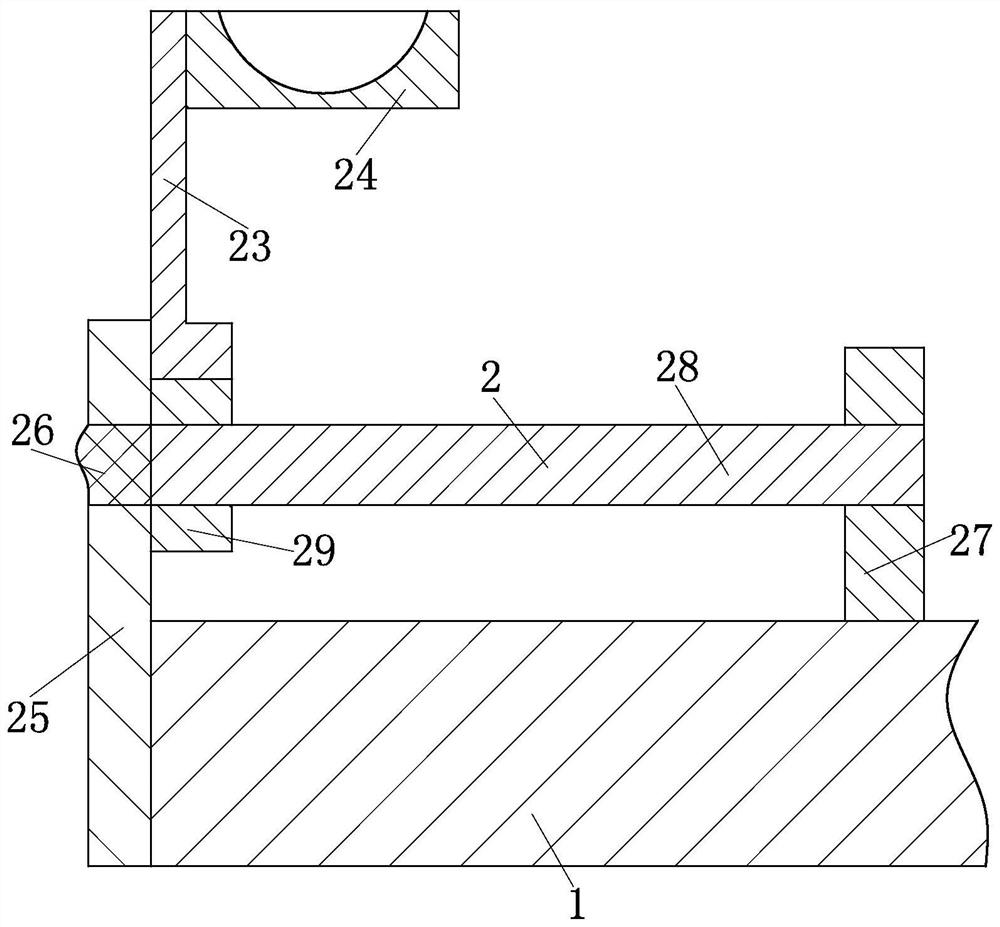

The invention relates to a welding torch moving device for a welding machine with a drill stem wear-resistance belt, which comprises a mounting frame, a ball screw rod and a tubular moving column; a slide rail is arranged on the mounting frame; the screw rod in the ball screw rod is fixedly connected on the mounting frame by a bearing and a bearing seat; the tubular moving column is fixedly connected with a nut in the ball screw rod by a slide block fixedly connected with the tubular moving column; the slide block is connected with the slide rail arranged on the mounting frame; a welding torch is connected on the tubular moving column; one end of the screw rod in the ball screw rod is connected with a stepping motor by a coupling; the stepping motor is fixedly connected on the mounting frame; when in use, the welding torch is connected on the tubular moving column; automatic adjusting is carried out by the stepping motor according to welding width when the wear-resistance belt is welded; the welding torch moving device of the invention is very convenient to be used; besides, the welding of the drill stem wear-resistance belt can be conveniently carried out aiming at the drill stems with different diameters.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

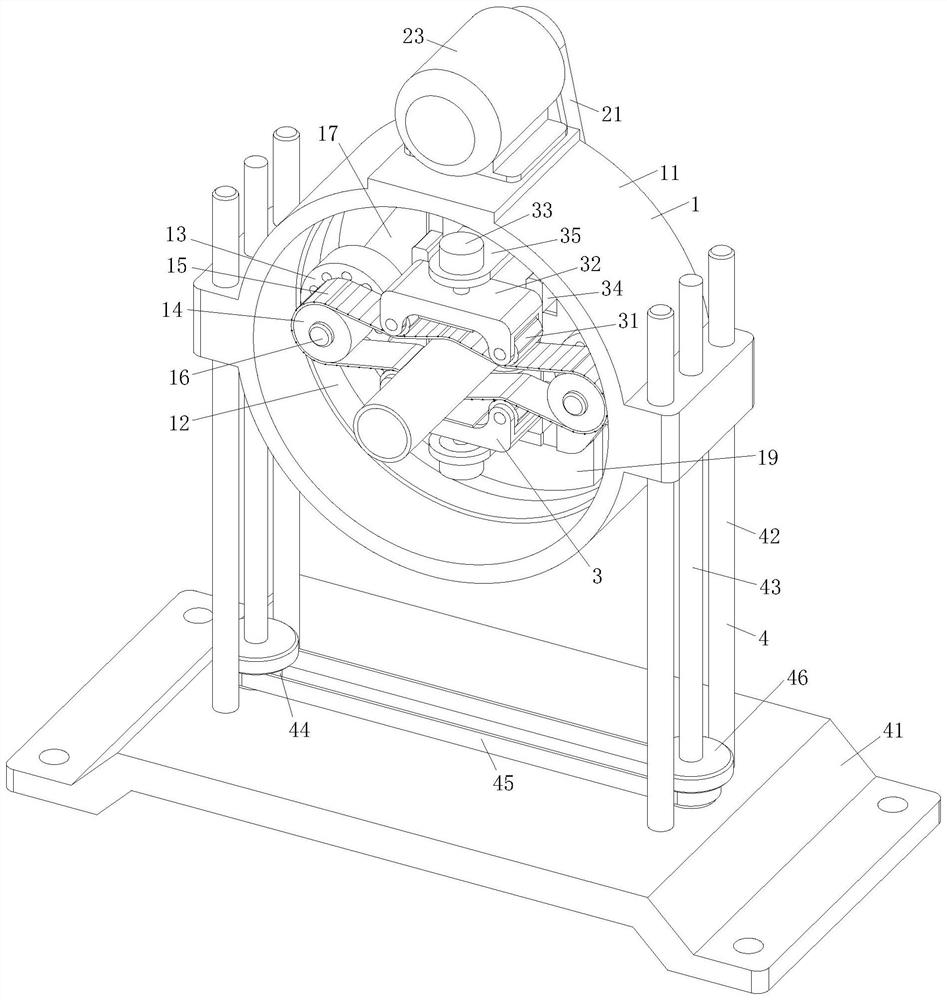

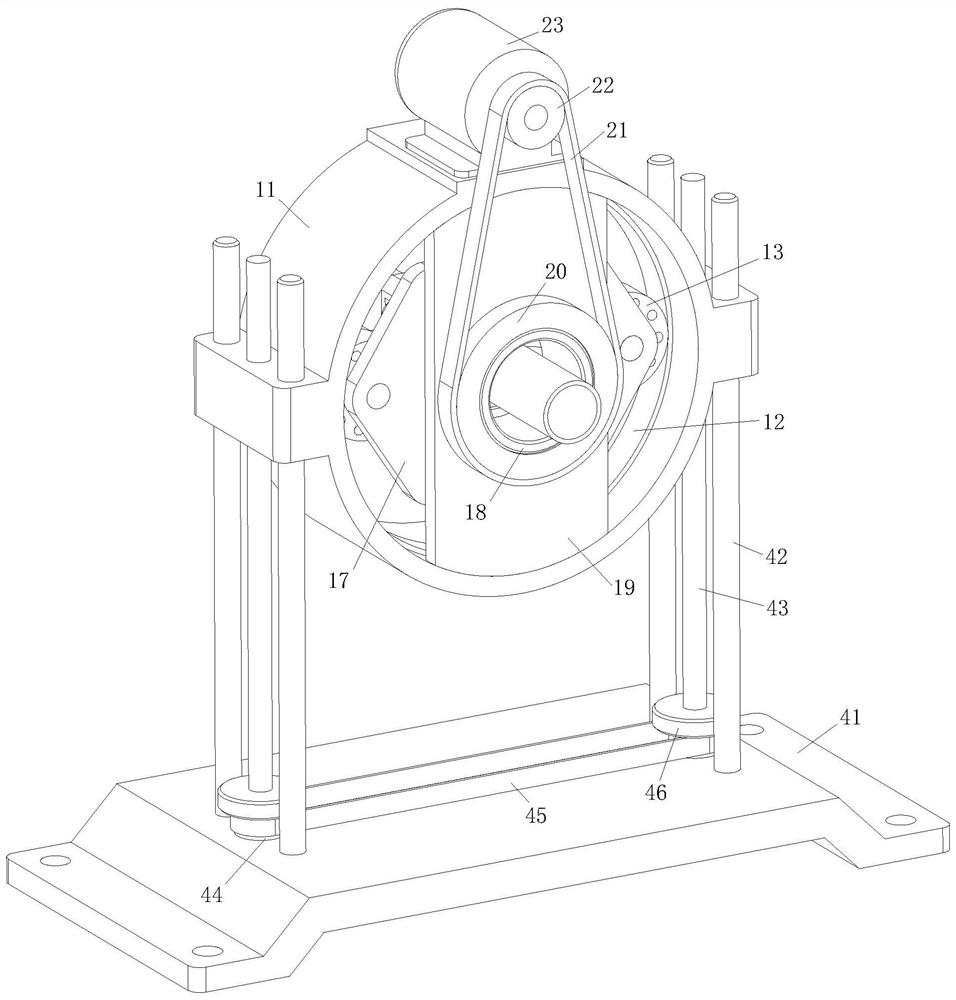

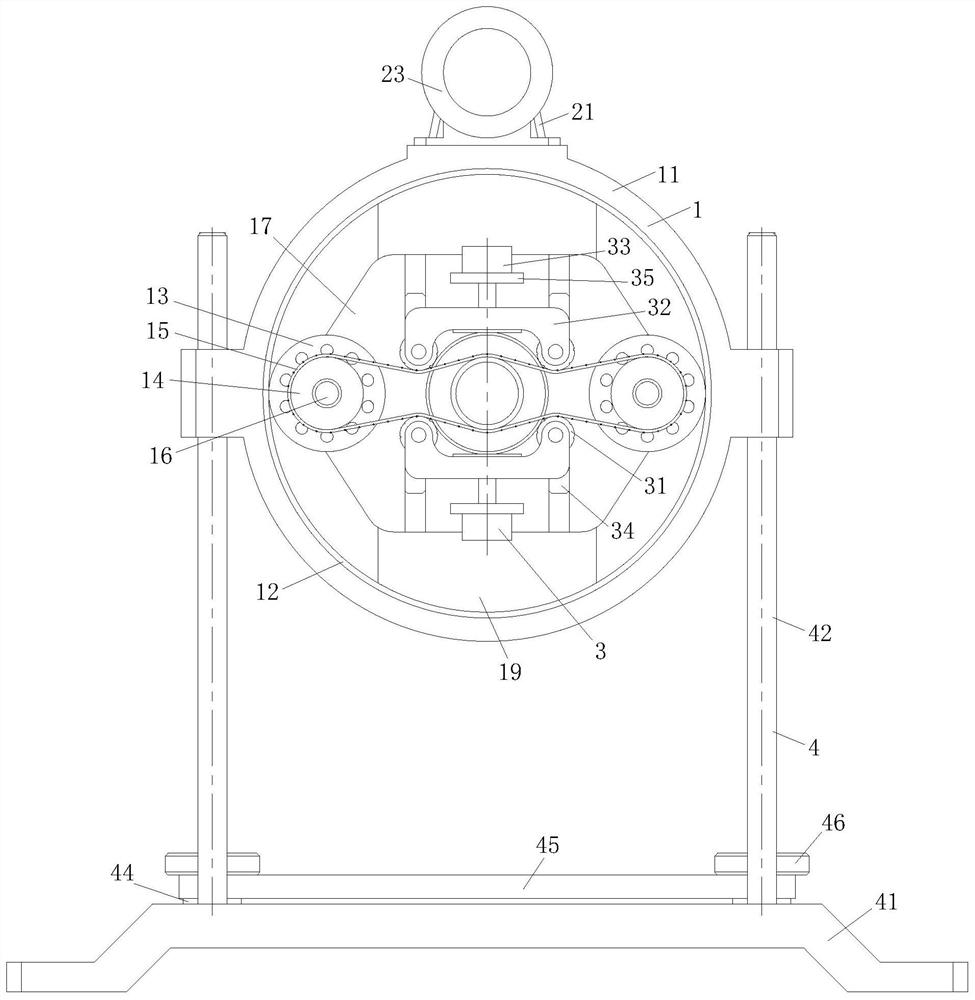

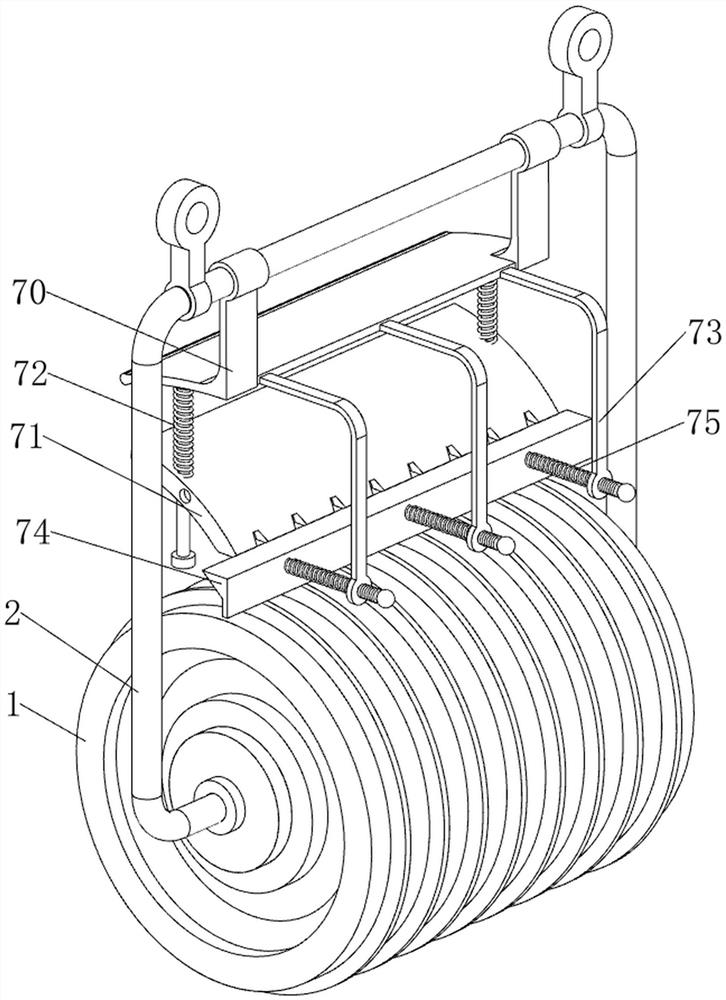

Portable uniform grinding device for welds of stainless steel tube

ActiveCN112247772AExtended service lifeGuaranteed grinding efficiencyBelt grinding machinesGrinding/polishing safety devicesGear wheelElectric machinery

The invention belongs to the technical field of grinding equipment, and particularly relates to a portable uniform grinding device for welds of a stainless steel tube. The portable uniform grinding device comprises a planet grinding component, a tensioning feeding component and a height adjusting component. The planetary grinding part comprises a cylindrical base, an annular gear ring, a planetarygear, a grinding belt wheel, a grinding belt, a first rotating shaft, a rotating plate, a hollow rotating shaft, a supporting plate, a first belt wheel, a first belt, a second belt wheel and a driving motor. According to the invention, the rotating plate is driven by the hollow rotating shaft to rotate, and the rotating plate drives the planetary gear and the grinding belt wheel to rotate aroundthe hollow rotating shaft through the first rotating shaft; meanwhile, the planetary gear meshes with the annular gear ring, so that the grinding belt wheel drives the grinding belt to rotate; and thegrinding belt driven by the grinding belt wheel rotates around the hollow rotating shaft at the same time, so that polishing points, which are in contact with the surface of the stainless steel tube,of the polishing belt can cover the surface of the whole stainless steel tube, and the moving speeds of the polishing points are uniform, thereby realizing uniform grinding for the welds on the surface of the stainless steel tube.

Owner:佛山市维通金属制品有限公司

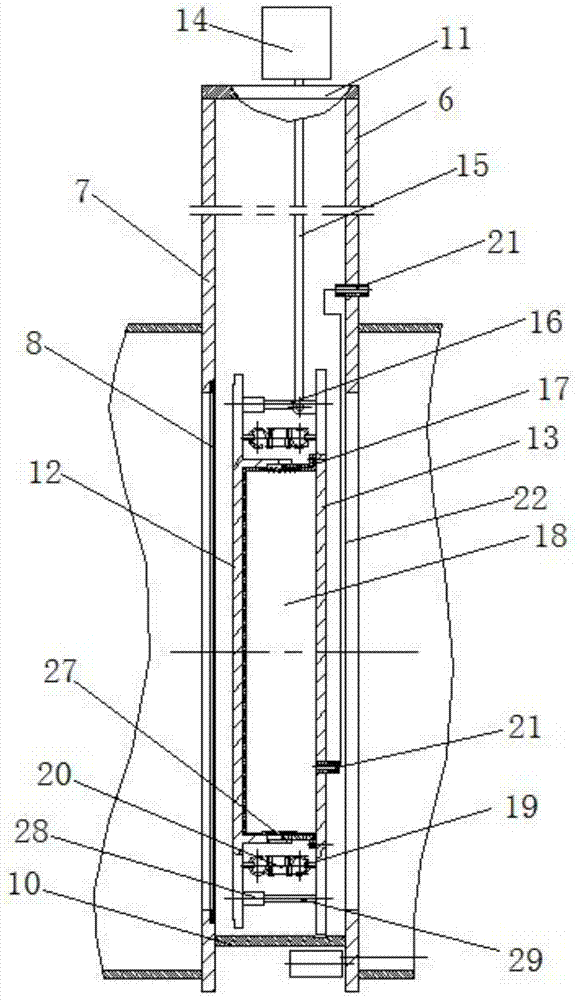

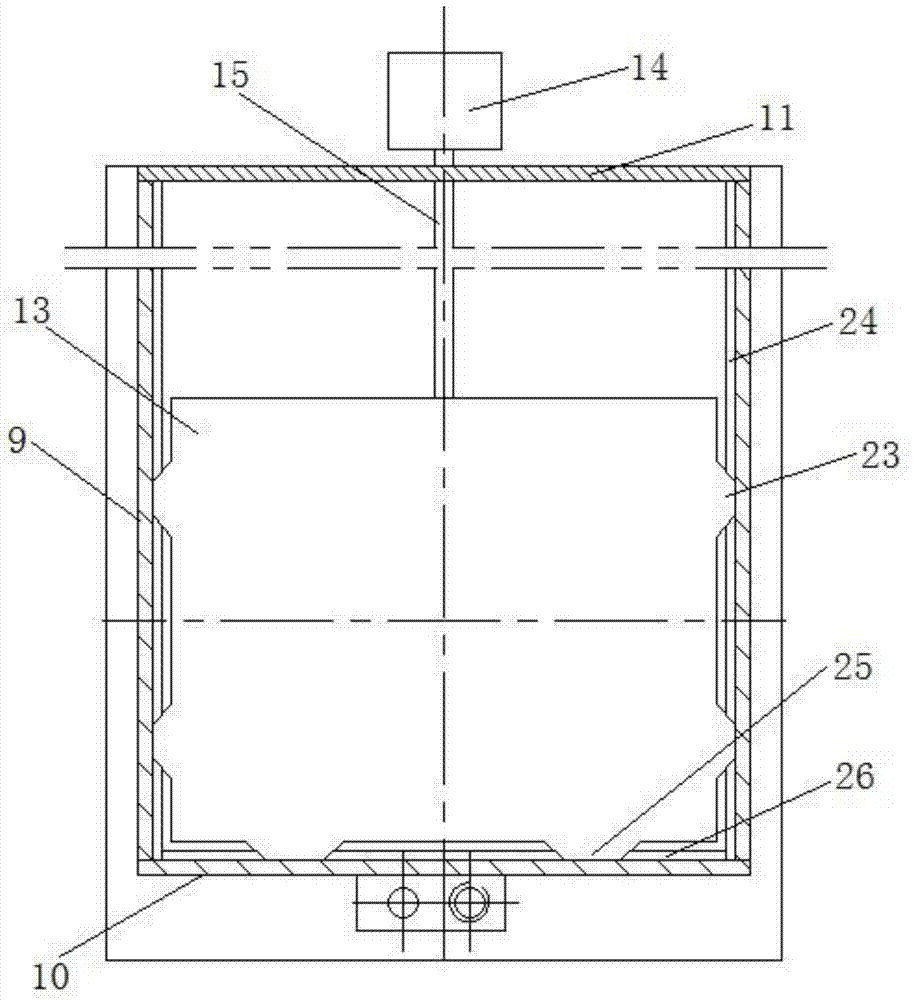

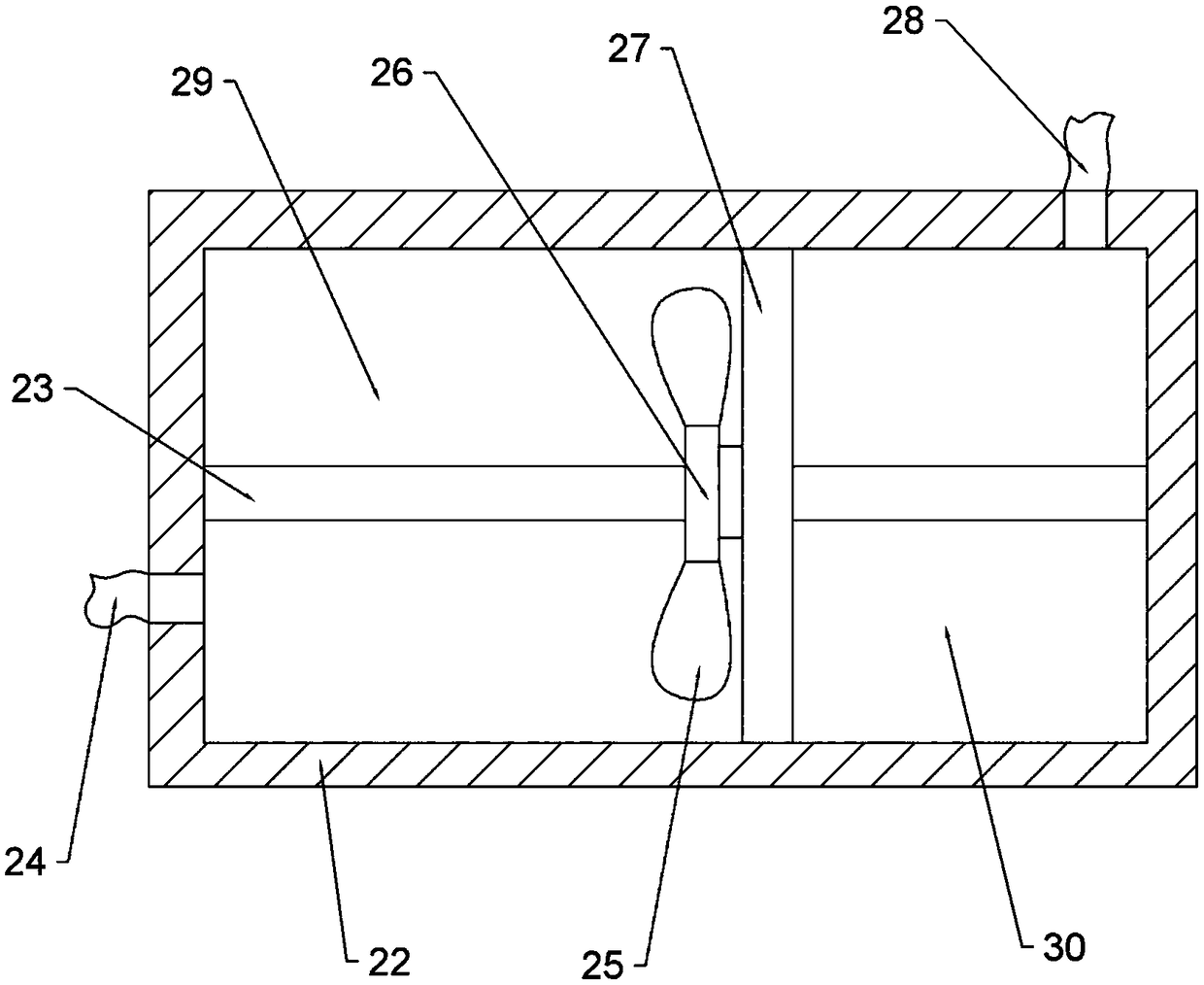

Continuous pressure steaming machine air bag sealing method

InactiveCN104728452AMoving at a uniform speedGuaranteed uptimeEngine sealsFood preparationHydraulic cylinderExpansion joint

The invention discloses a continuous pressure steaming machine air bag sealing method. Under the action of hydraulic cylinders, piston rods push sealing flange cover plate supporting plates through lifting lugs and carry the sealing flange cover plate supporting plates, sealing flange cover plates, hooks, tension springs, air bags and air bag sleeves to move downwards together; after the sealing flange cover plate supporting plates move downwards to a position, pre-heated compressed air enters the air bags from flexible air pipes and connectors, along with increasing of pressure in the air bags, expansion joints arranged on the air bags expand to push the sealing flange cover plates to tightly press sealing gaskets arranged on sealing flanges, and therefore sealing is formed. In the sealing process, the sealing flange cover plates are uniform in moving speed and stable in operation, the stressed area on the sealing flange cover plates from the air bags is large, the sealing flange cover plates are evenly stressed and small in deformation, finally the sealing gaskets are evenly stressed and deformed, the sealing effect is improved, and the key problems that the sealing effect among all bins is poor, and work reliability is poor are solved.

Owner:SHAANXI UNIV OF SCI & TECH

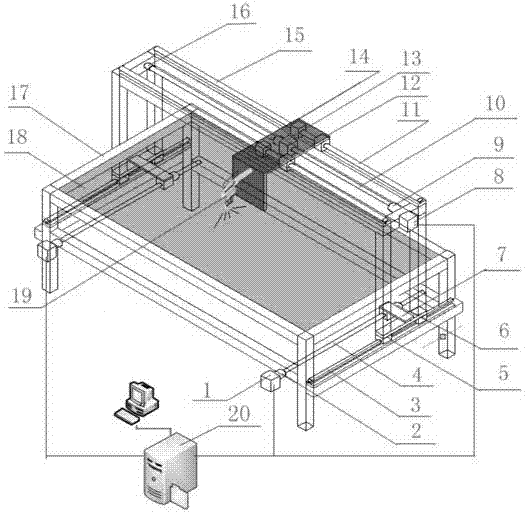

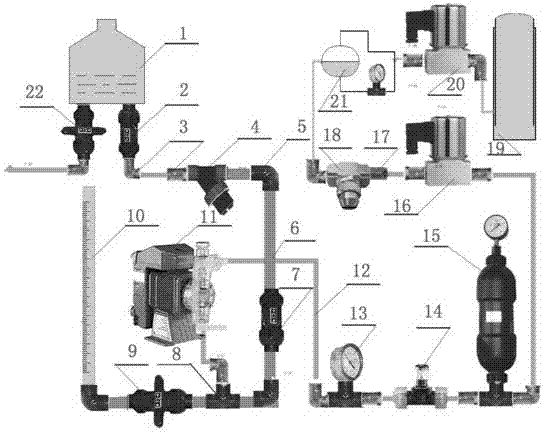

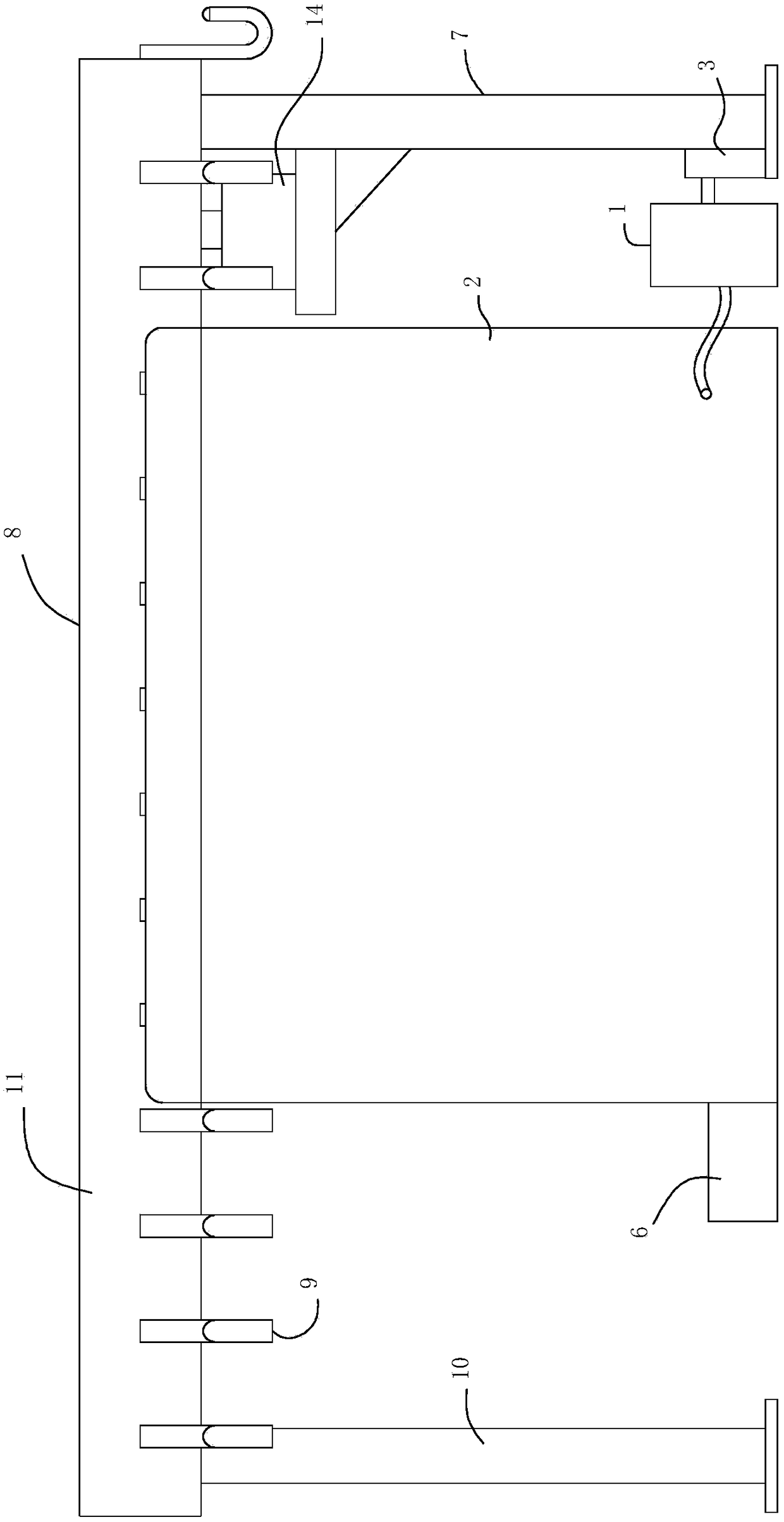

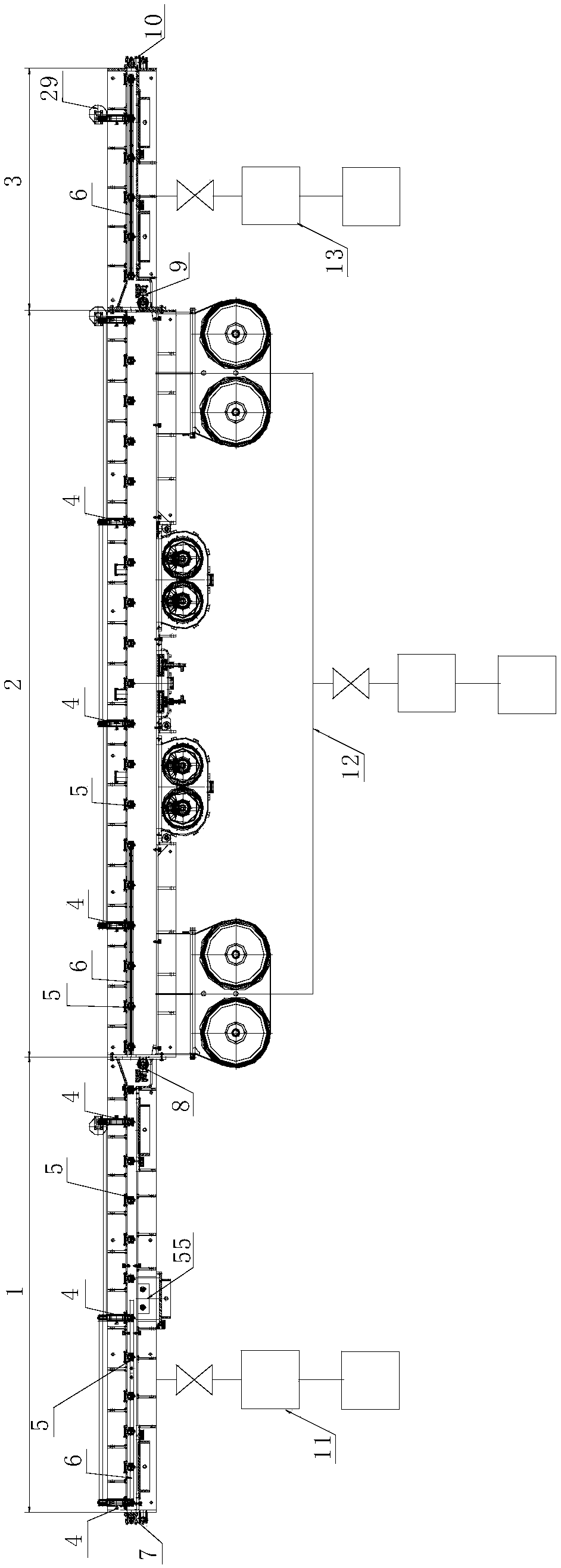

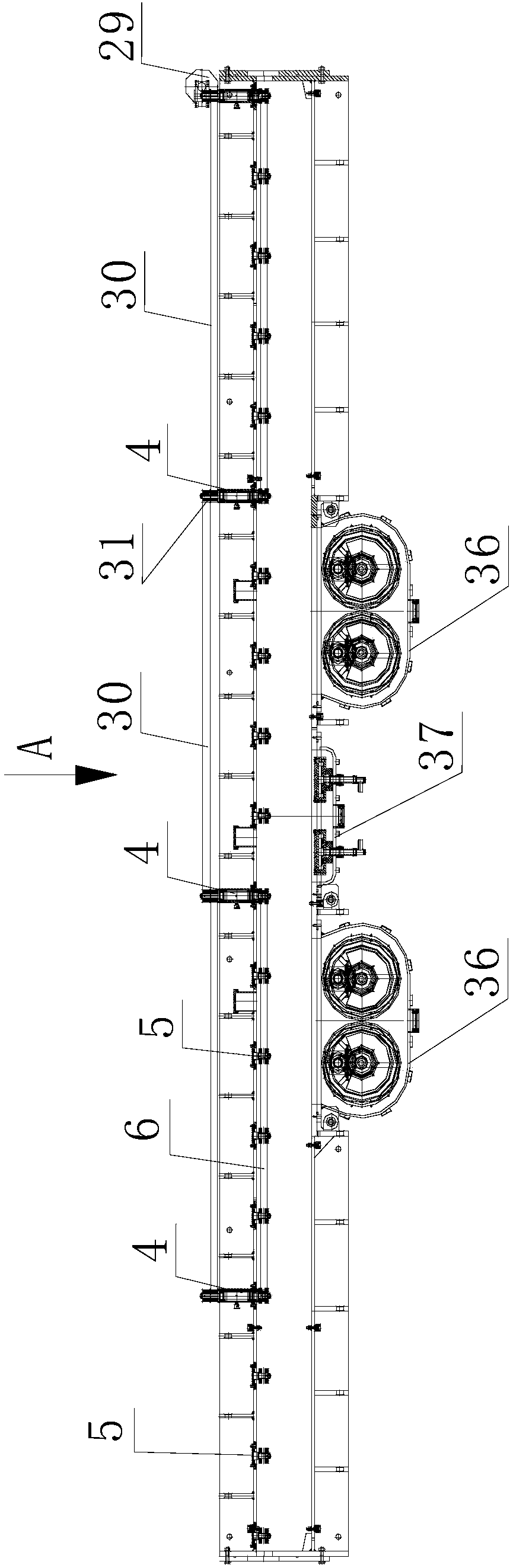

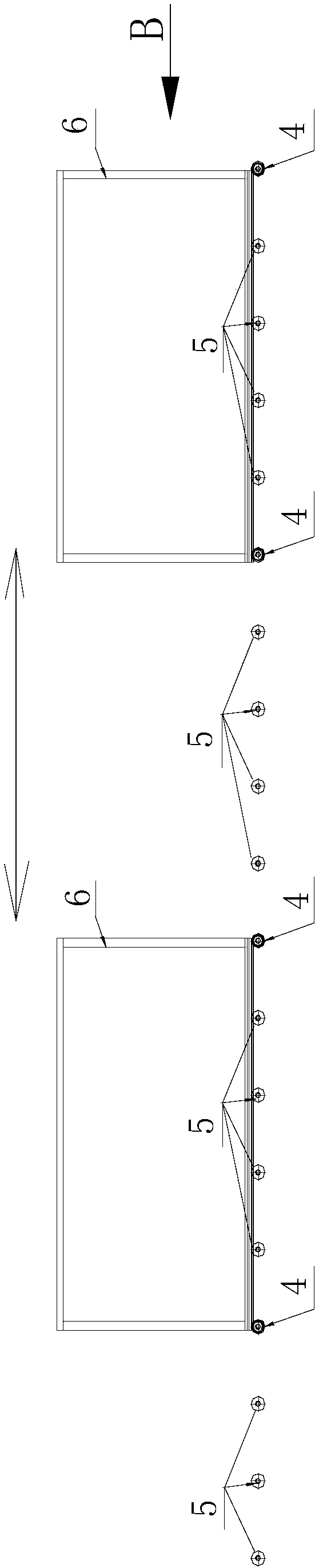

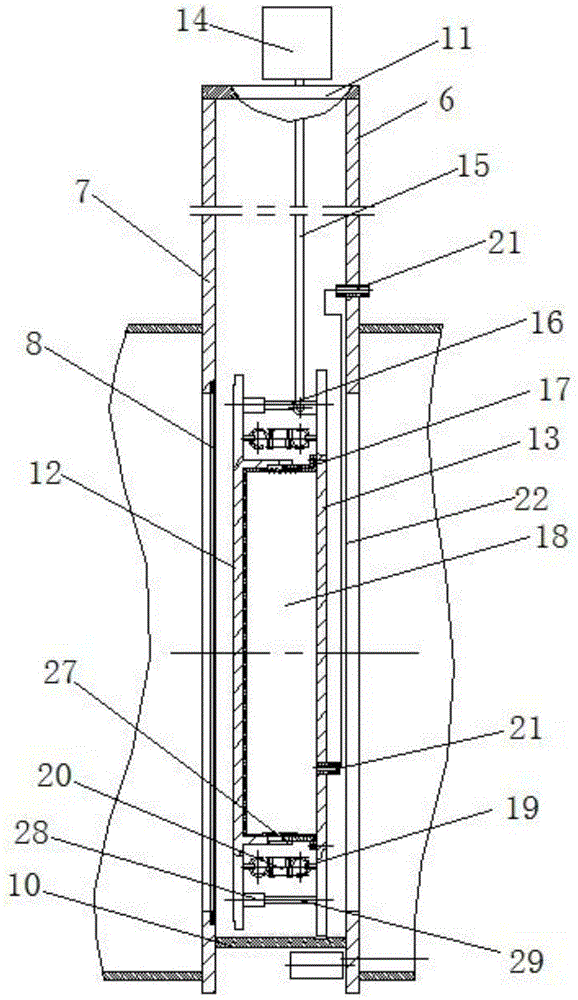

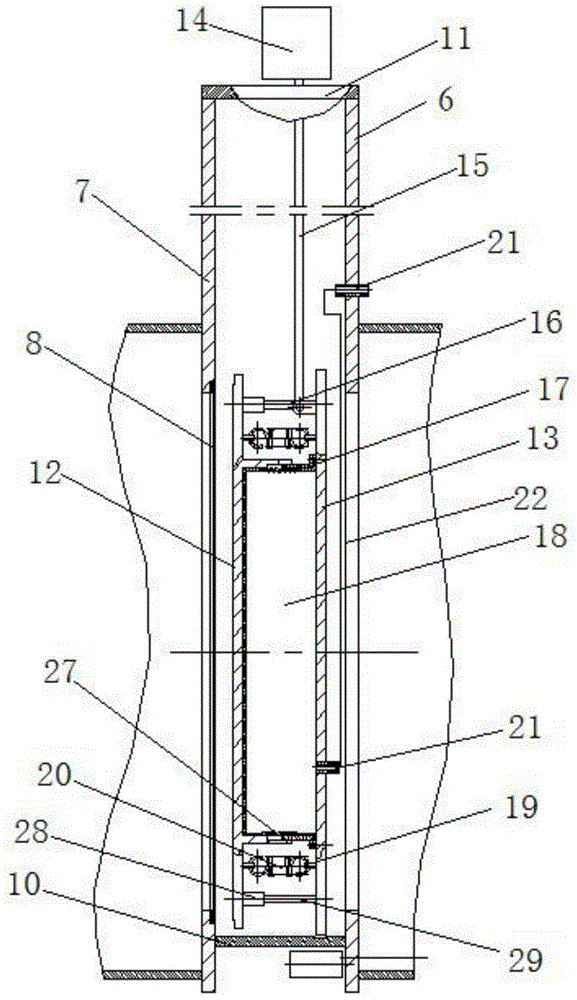

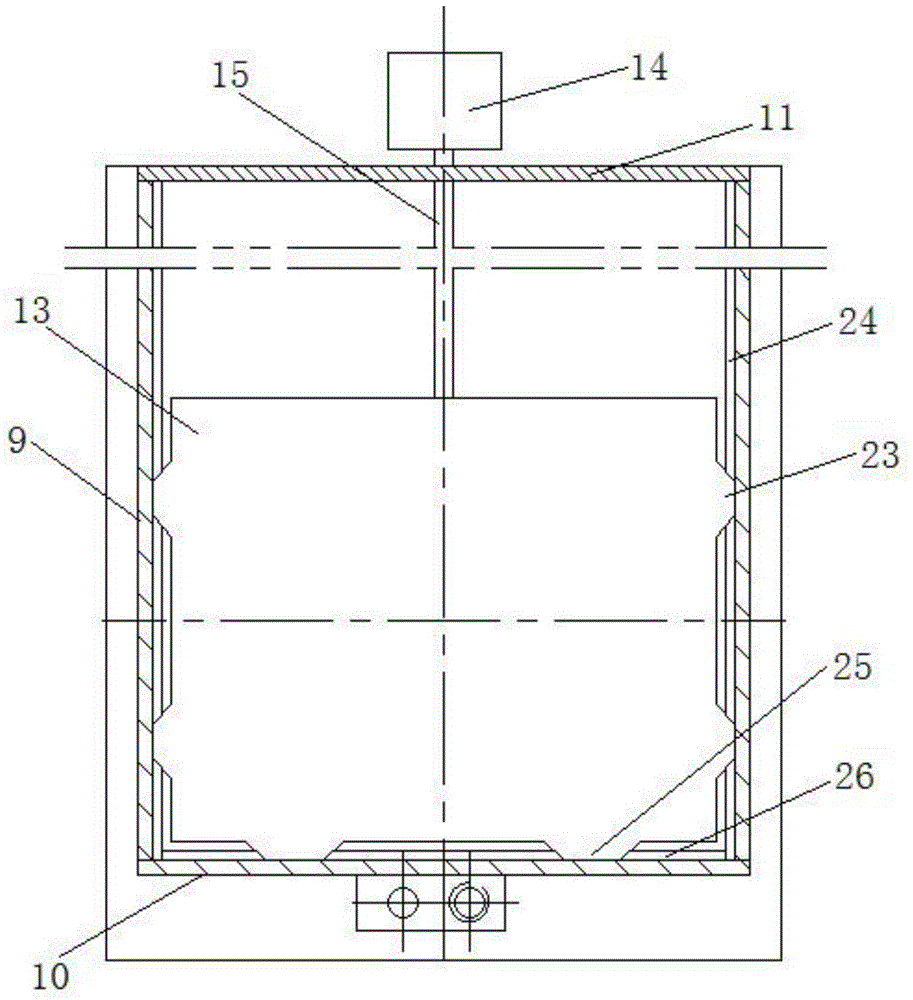

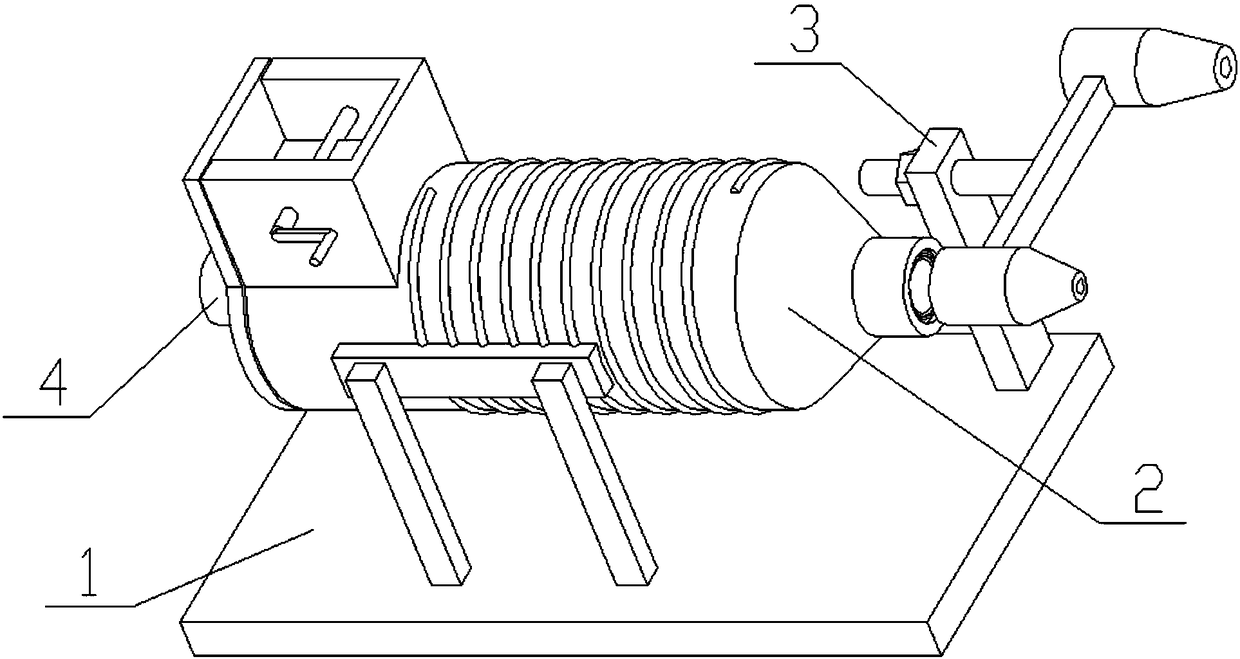

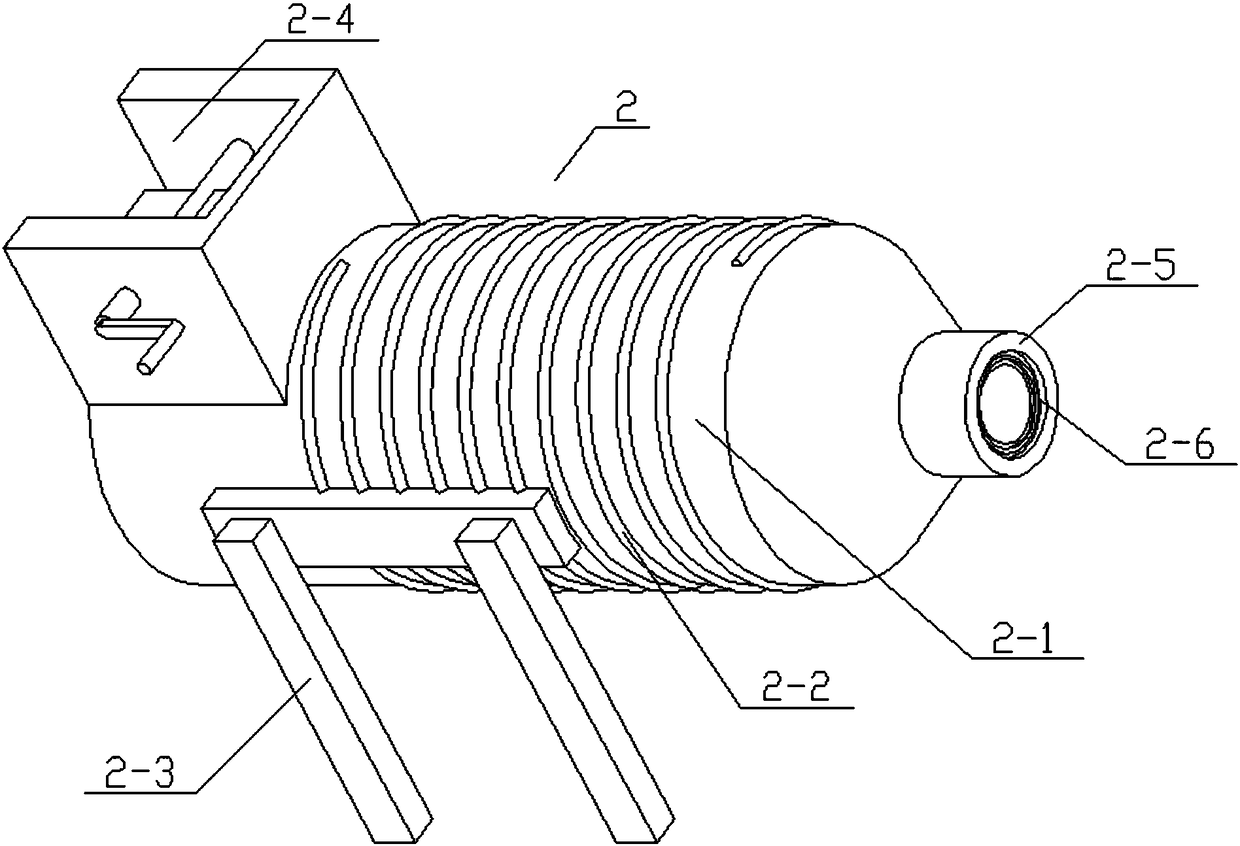

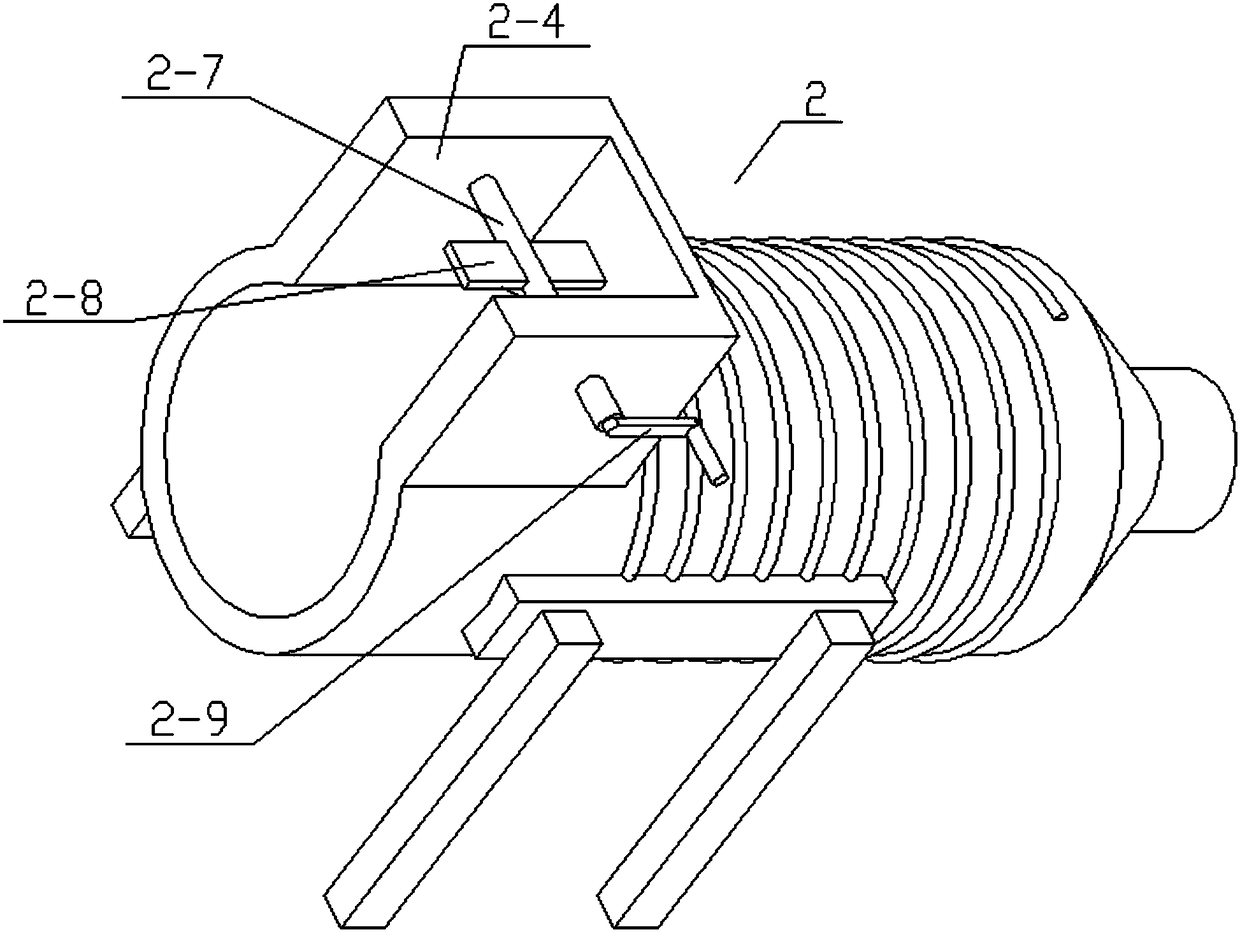

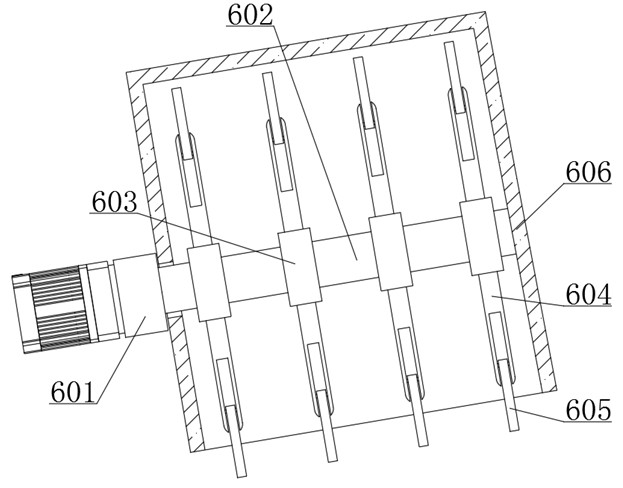

Intelligent nano anti-pollution coating spraying system

InactiveCN103801470ASpray evenlyMoving at a uniform speedLiquid spraying apparatusEngineeringAir compressor

The invention relates to an intelligent nano anti-pollution coating spraying system. A quantitative liquid spraying system of the intelligent nano anti-pollution coating spraying system is formed by sequentially connecting a liquid accumulating tank, a filter, a meter pump, a pressure meter, a back pressure valve, stop valves, a damper, an electromagnetic valve, a calibrating tube, an air compressor, a pressure regulating valve, a check valve, a gas spray nozzle, a pluggable movable joint, a tee and an elbow through stainless steel water tubes and plastic hoses; an intelligent motion control system comprises screw rods, screw rod nuts, sliding tracks, sliding blocks, connecting rods, a support, a bearing seat, a bearing, stepping motors, couplers and a rack which are arranged in the longitudinal direction and the horizontal direction; a longitudinal connecting rod is fixed on a longitudinal screw rod nut and a sliding block of a longitudinal sliding track simultaneously, and a horizontal connecting rod is fixed on a horizontal screw rod nut and a sliding block of a horizontal sliding track simultaneously; one end of each of a longitudinal screw rod and a horizontal screw rod is fixed on the rack through the bearing and the bearing seat, and the other ends of the longitudinal screw rod and the horizontal screw rod are connected with the stepping motors fixed on the rack through the couplers; and two ends of each of the sliding tracks are fixed on the rack through the support.

Owner:章晨曦

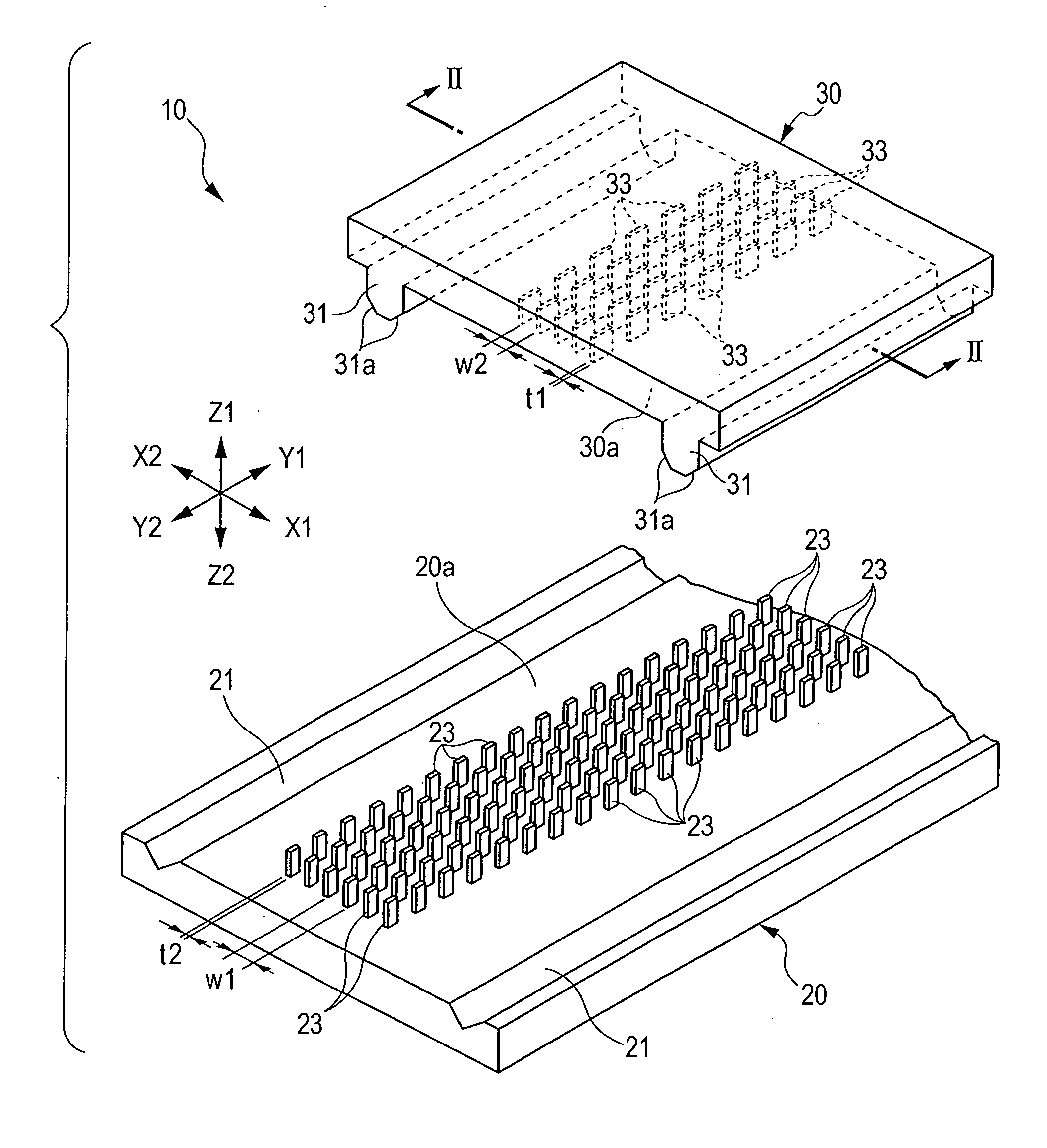

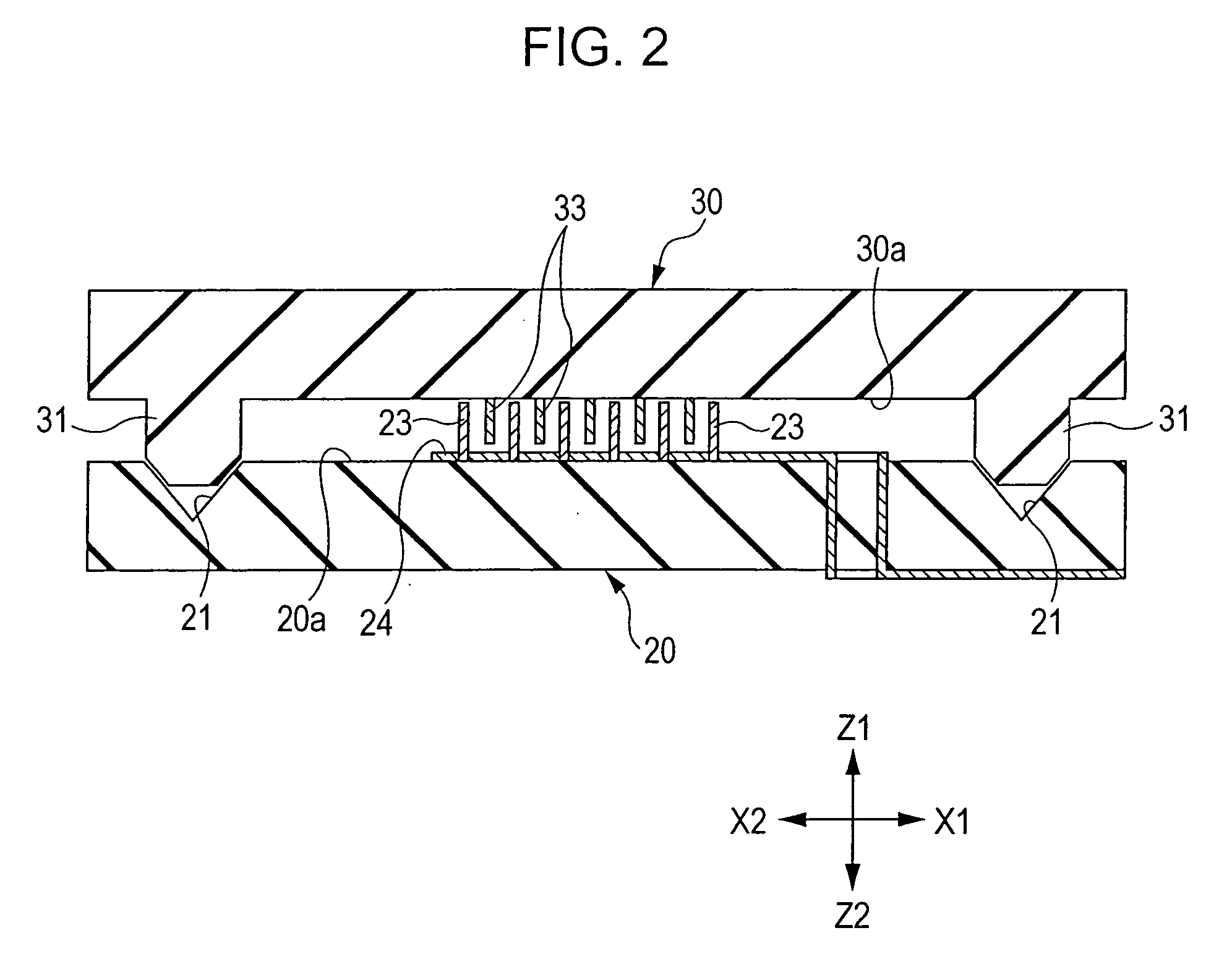

Electrostatic actuator

InactiveUS20060108893A1Great driving forceReduce variationProjector focusing arrangementCamera focusing arrangementEngineeringElectrostatic actuator

An electrostatic actuator includes a stator that includes a stator-side electrode group including a plurality of electrodes, a mover that includes a mover-side electrode group including a plurality of electrodes and that can move in a predetermined movement direction, this plurality of electrodes opposing the electrodes in the stator-side electrode group, a guide instrument that guides the mover, and a driving signal supply unit that generates driving signals and applies the driving signals between the stator-side electrode group and the mover-side electrode group. In one electrode group of these electrode groups, the electrodes and gaps have the same length and are alternately disposed in the movement direction, and the other electrode group includes a first group and a second group alternately disposed in the movement direction, each of the first and second groups including an electrode and a gap.

Owner:ALPS ALPINE CO LTD

Zone sintering method for long and porous ceramics

The invention relates a method for ceramics burn, concretely, relates to an area burn method for ceramic switch long size and multiple holes applied in high temperature gas filtration pipe, bubble generator and burner used in chemical industry and heat exchanger. Place the substance to be burnt on the unfixed support plate by which they can be moved into or out from the furnace, they are moved into vertically from the bottom, with their lengths; longer than that of the part of furnace with the highest temperature. The invention has lots of beneficial effect: since it uses area furnace, the price and energy are both decreased, besides, the time for burn is much shorter. The invention uses area burn and has balanced moving speed, so that the substance to be burnt will be broken and deformation, the ceramics material burnt is wholly average.

Owner:QINGHAI UNIVERSITY +2

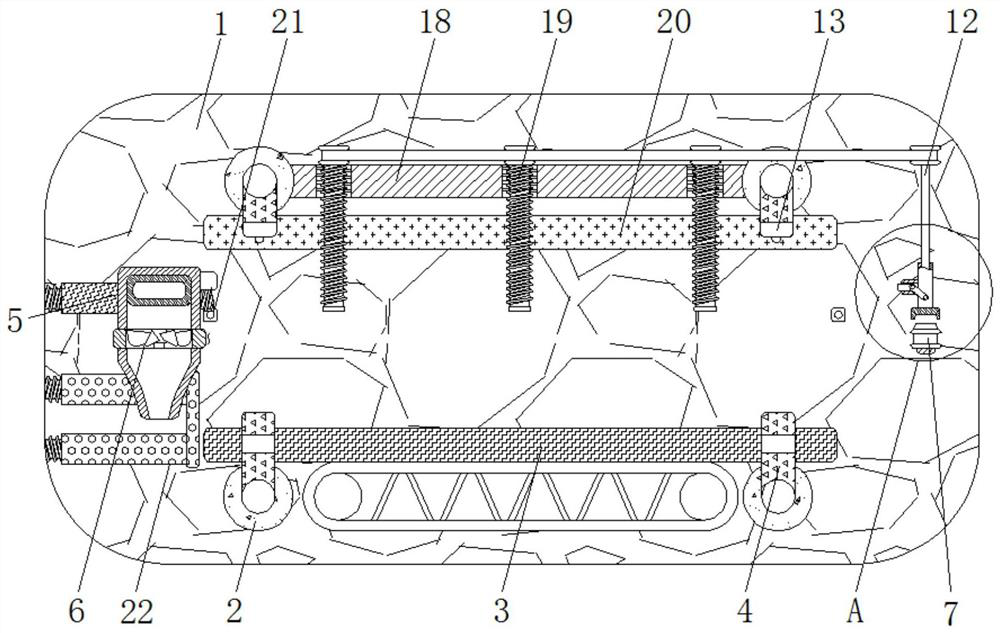

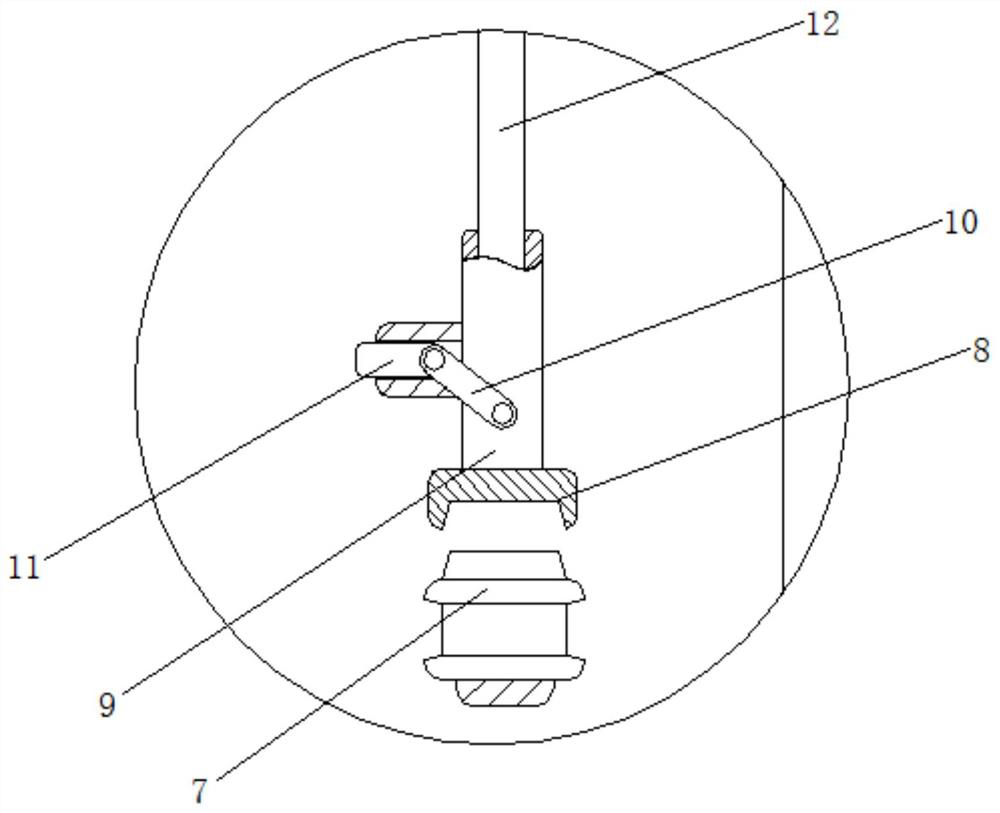

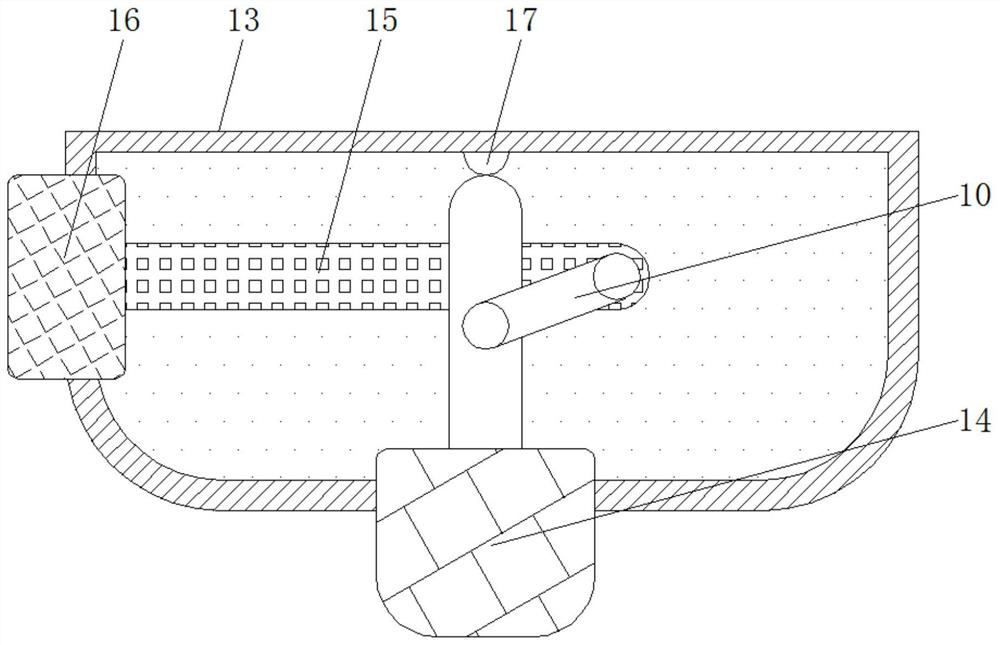

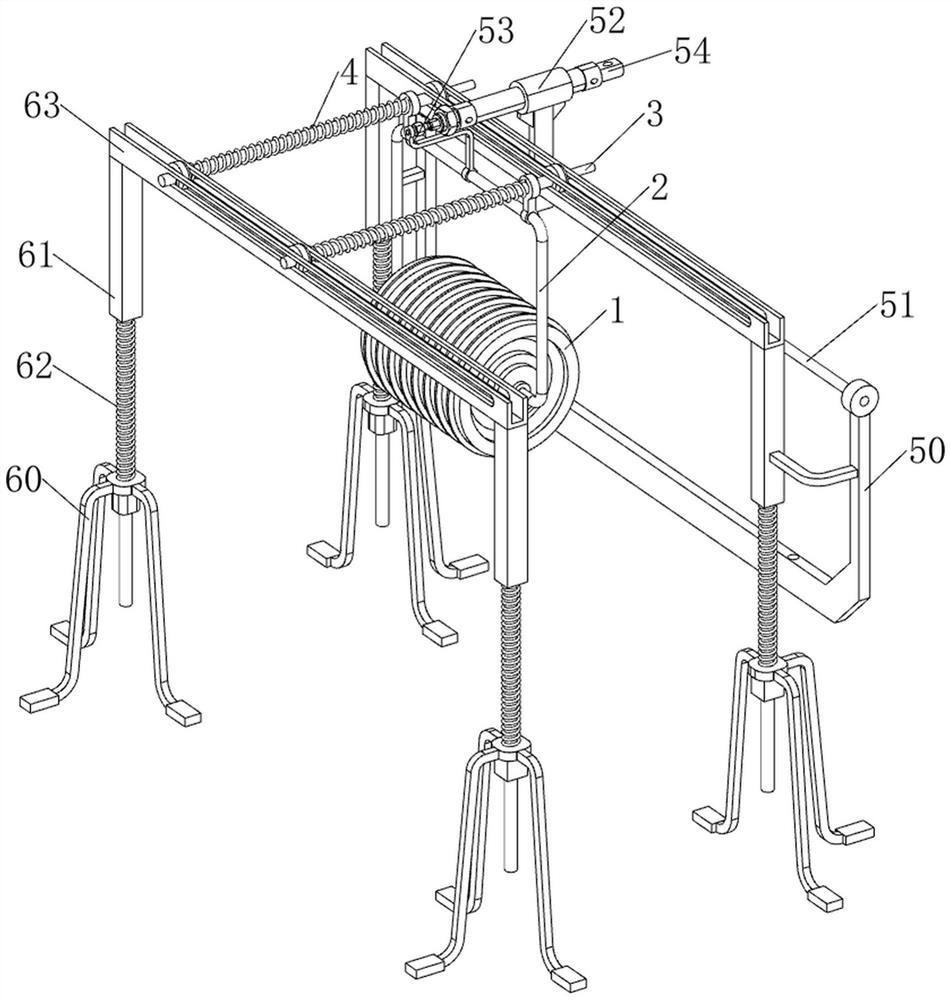

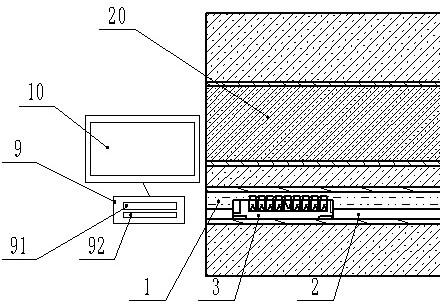

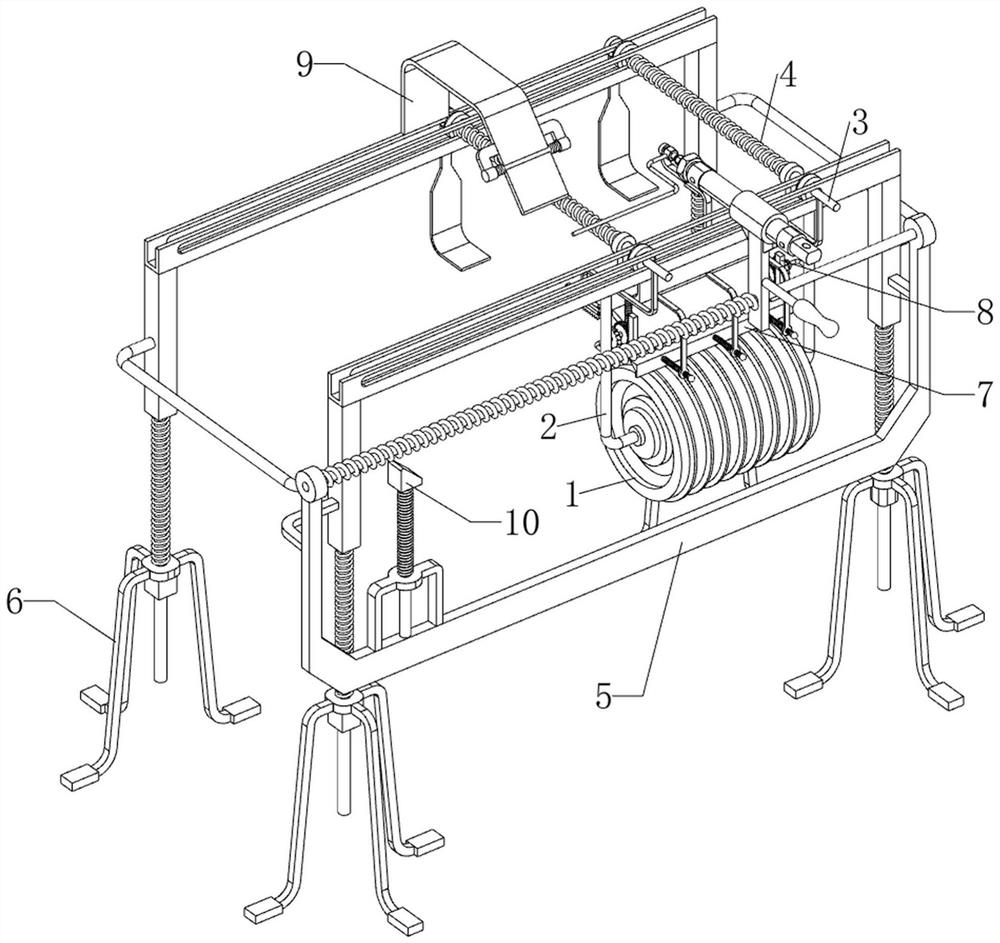

Portable metal surface defect laser scanning detection device

PendingCN111781207AHigh precisionEasy to clamp and fixOptically investigating flaws/contaminationLaser scanningPipe

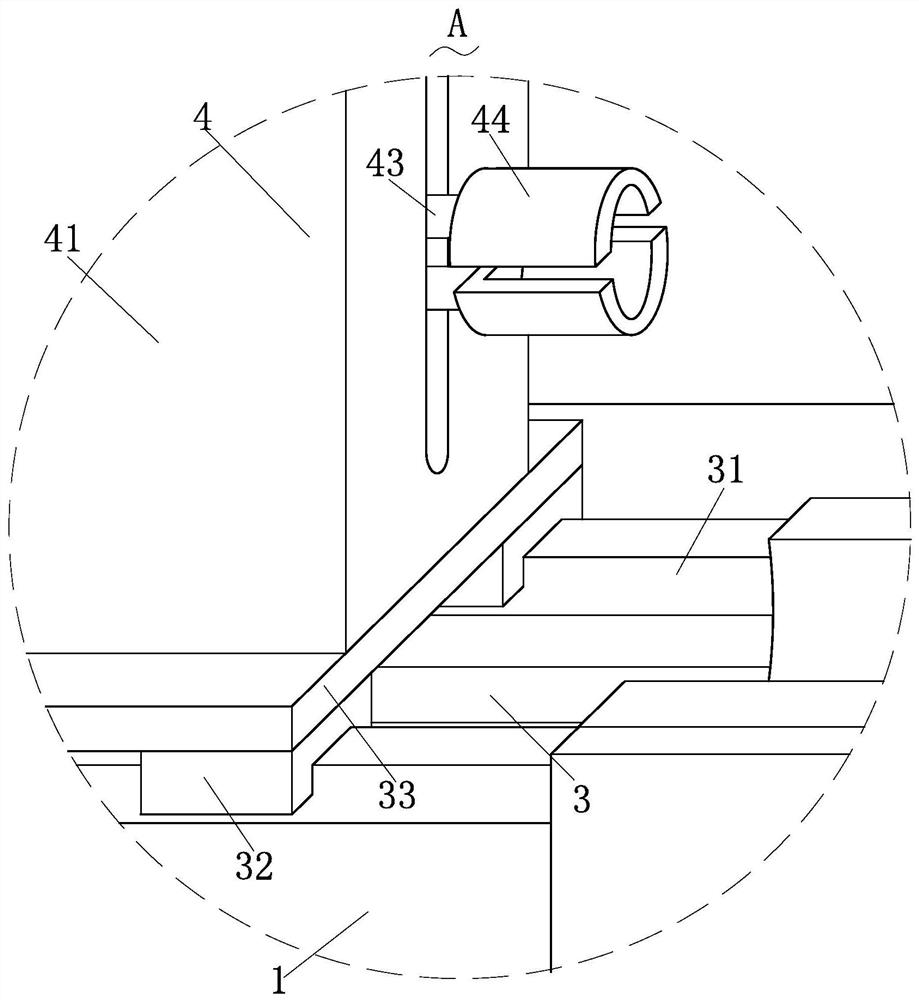

The invention relates to the field of metal surface defect detection devices, in particular to a portable metal surface defect laser scanning detection device which comprises a fixing seat, a feedingstructure, a clamping structure, a fixing structure, a moving structure, a mounting structure and an ash removal structure. Through arranging the mobile structure, reciprocating comprehensive detection work can be carried out on the surface of the steel pipe, detection is more convenient and accurate, the moving speed is more uniform, and the requirement of improving the detection precision can bemet. Cooperating with the arrangement of the mounting structure, the scanning assembly can be conveniently clamped and disassembled. The device is convenient to install and replace. The ash removal structure can be synchronously driven to work while the moving structure works. Through work of the ash removal structure, dust outside a steel pipe can be removed while the steel pipe is detected, andtherefore the situation that the detection result of the steel pipe is affected by the dust on the surface of the steel pipe can be avoided.

Owner:王亚军

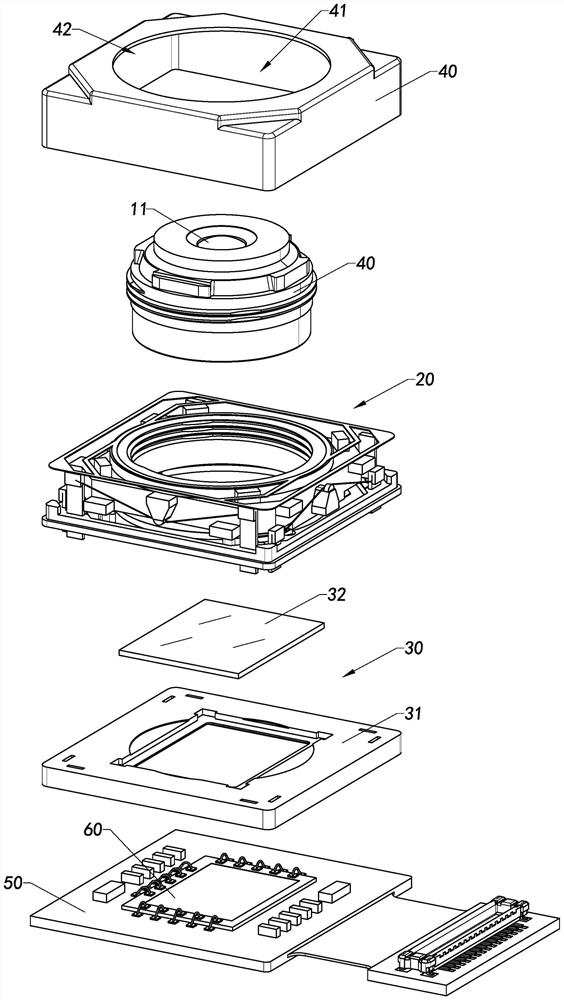

Imaging device, SMA driving equipment, manufacturing method of SMA driving equipment and driving method of SMA driving equipment

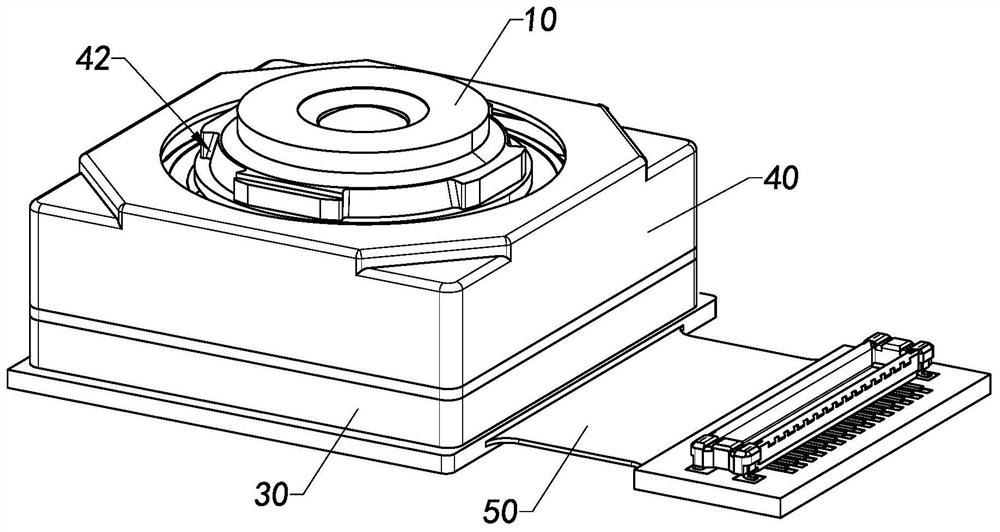

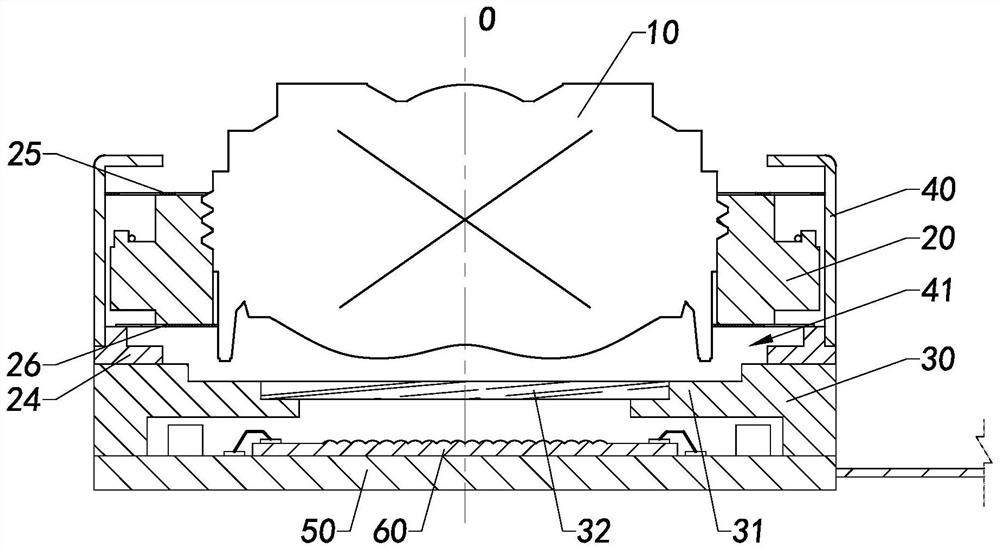

PendingCN111629125AQuick responseMaximum stroke halvedTelevision system detailsColor television detailsControl engineeringDriving mode

The invention provides a camera device, SMA driving equipment, a manufacturing method of the SMA driving equipment and a driving method of the SMA driving equipment. The camera device comprises at least one circuit board, a photosensitive chip, at least one lens, a lens base and at least one SMA driving equipment. The SMA driving equipment further comprises a lens carrier, at least one uplink driver and at least one downlink driver. The lens carrier is connected to the uplink driver in a driving manner. The uplink driver supports the lens carrier upwards in a thermal driving manner, and lifting the lens carrier to move upwards, wherein the lens carrier is drivingly connected to the downlink driver, wherein the downlink driver pulls the lens carrier downwards in a thermal driving mode and pulls the lens carrier to move downwards, the lens is arranged on the lens carrier of the SMA driving equipment, and the SMA driving equipment drives the lens to move up and down.

Owner:NINGBO SUNNY OPOTECH CO LTD

Sausage casing dryer

PendingCN108870941AEven contactExpedited drying processDrying gas arrangementsSausage casingsAir pumpEngineering

The invention relates to sausage casing processing equipment, in particular to a sausage casing dryer and belongs to the field of sausage casing processing. The sausage casing dryer is reasonable in structure design and convenient to operate by an operator. According to the sausage casing dryer, an air heating chamber heats air pumped by an air pump, the heated air enters a drying chamber and is blown to a drying channel through a blowhole, the sausage casings pass through the drying channel under the action of a swing mechanism, the air flow exhausted by the blowhole dries the sausage casingsrapidly, and the sausage casing drying efficiency is improved. Hooks are arranged on the swing mechanism and used for hanging the sausage casings, during actual operation, the operator only needs tohang the undried sausage casings on the hooks, then the dried sausage casings are taken down from the hooks, the labour intensity of the operator is reduced, and the sausage casing drying operation isconvenient.

Owner:浙江亚泰生物科技有限公司

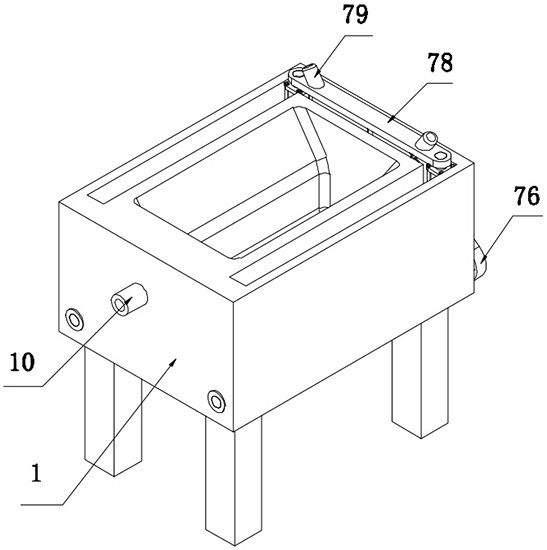

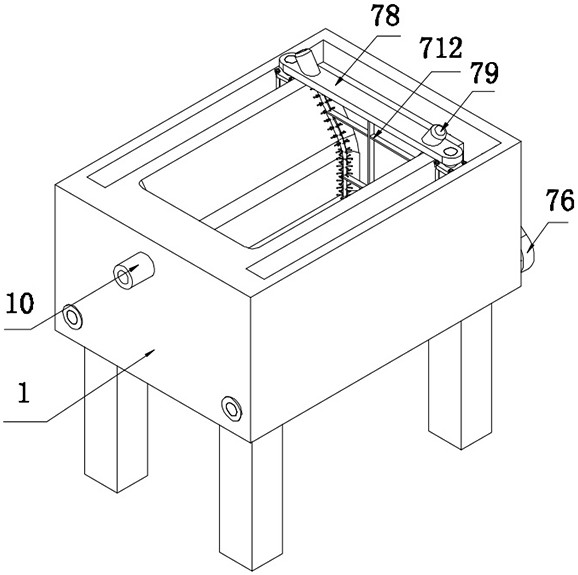

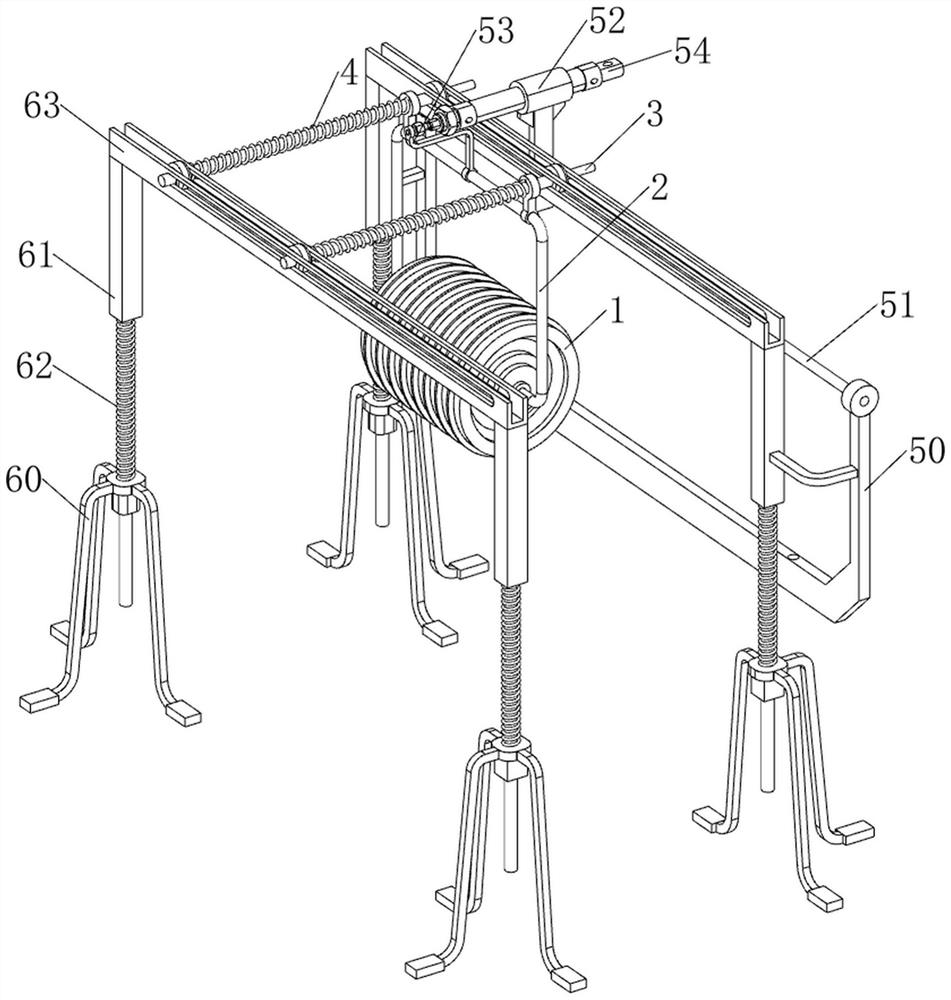

Semiconductor wafer groove type cleaning machine

ActiveCN114602873AHigh movement accuracyFast shippingFinal product manufactureHollow article cleaningEngineeringMachine

The invention belongs to the technical field of semiconductor production and manufacturing, and particularly relates to a semiconductor wafer groove type cleaning machine which comprises a cleaning groove and a mechanical arm used for taking a flower basket into the cleaning groove. The mechanical arm comprises a mechanical claw, the flower basket is taken into the cleaning tank through the mechanical claw to be cleaned, and a guiding and positioning mechanism is arranged above the mechanical arm. According to the groove type cleaning machine for the semiconductor wafer, by arranging the speed change mechanism, when the moving speed of the mechanical arm needs to be adjusted, meshing teeth are driven by stretching out and drawing back of the first air cylinder to make meshing movement with the synchronous belt, the synchronous belt is driven, and the moving speed of the synchronous belt and the mechanical arm is adjusted at the same time; and the moving speed of the manipulator is controlled, and the manipulator after speed regulation has the effect of uniform and stable moving speed.

Owner:ZHICHENG SEMICON EQUIP TECH (KUNSHAN) CO LTD

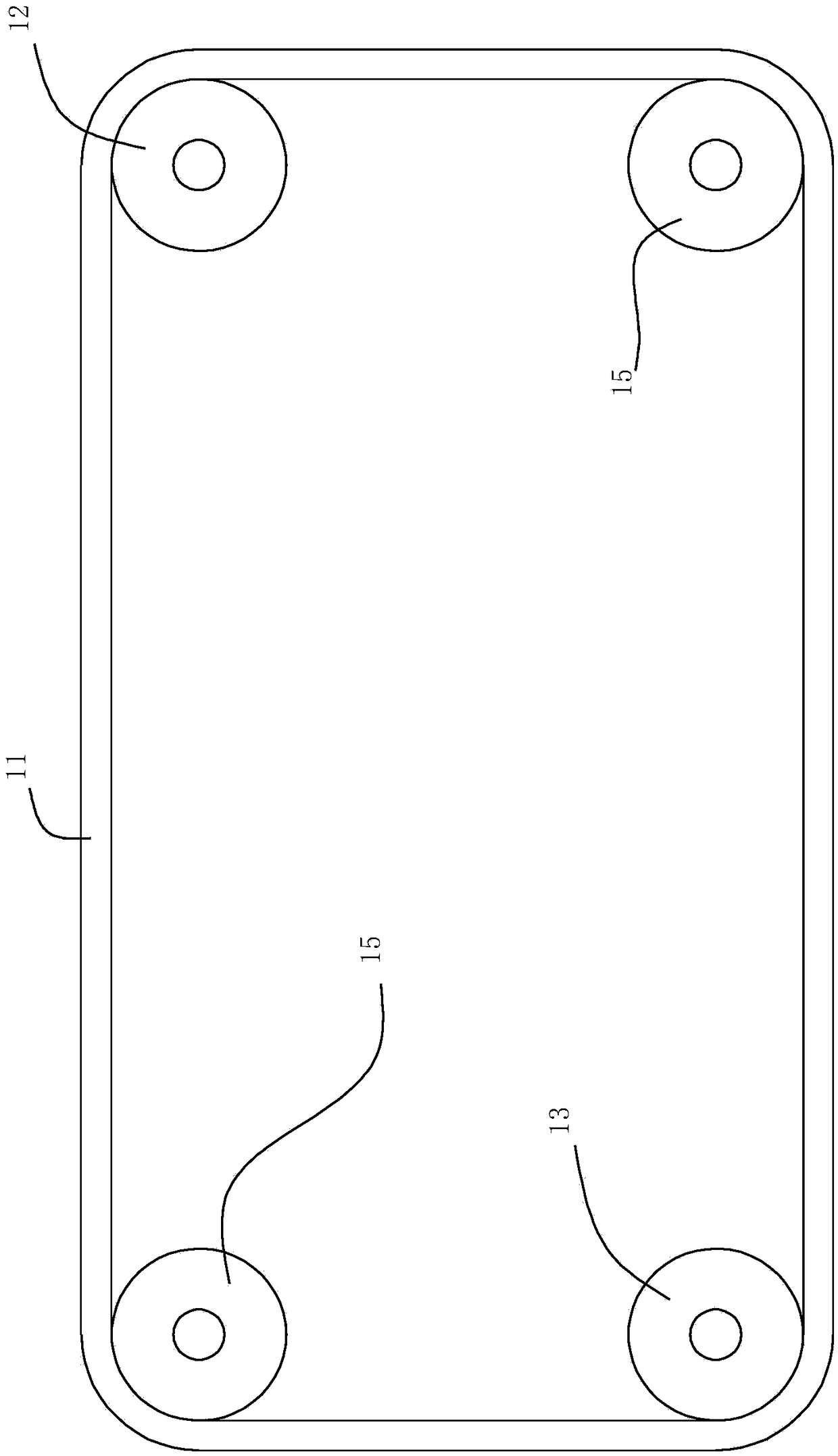

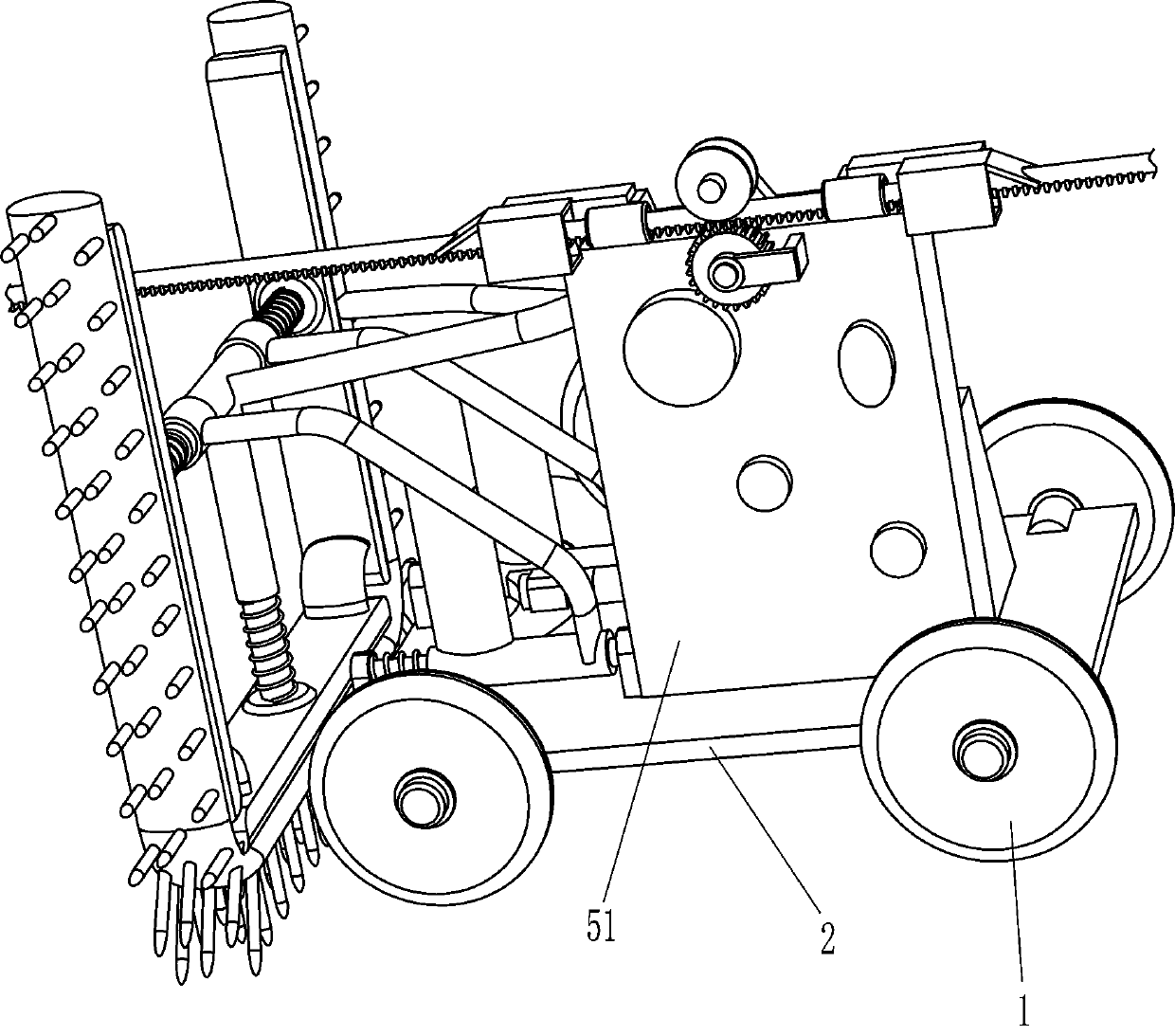

Drainage ditch cleaning equipment for livestock breeding

InactiveCN111085476AImprove work efficiencyMoving at a uniform speedCleaning using toolsBiologyManual handling

The invention relates to cleaning equipment, in particular to drainage ditch cleaning equipment for livestock breeding. The technical purpose is to provide the drainage ditch cleaning equipment for livestock breeding which can improve the work efficiency. The drainage ditch cleaning equipment for livestock breeding comprises idler wheels, a mounting plate and the like. The two or more idler wheelsare installed on the two sides of the mounting plate. According to the drainage ditch cleaning equipment for livestock breeding, a vibration mechanism can make a cleaning mechanism vibrate to clean the inner wall of a drainage ditch, and since the cleaning mechanism is in contact with the inner wall of the drainage ditch, the three faces of the drainage ditch can be cleaned at a time, and accordingly the work efficiency can be improved. The equipment can move leftwards through a movement mechanism, in this way, machinery is used for replacing manual operation, the movement speed of the equipment is more uniform, and each area of the inner wall of the drainage ditch can be thoroughly cleaned.

Owner:曾凡信

Wind power generation power distribution cabinet surface paint spraying device

ActiveCN109351517AAvoid affecting the painting effectUniform paint effectSpraying apparatusSprayerEngineering

The invention belongs to the field of paint spraying devices, and particularly discloses a wind power generation power distribution cabinet surface paint spraying device. The wind power generation power distribution cabinet surface paint spraying device comprises a shell, a rotation barrel, a one-way bearing and a rotation disc. The lower end of the rotation barrel is rotationally connected with the bottom of the shell, and the upper end of the rotation barrel is connected with the rotation disc through the one-way bearing. The shell is internally provided with a paint spraying structure and amoving structure. The paint spraying structure comprises a paint storage bin, a communication pipe and a sprayer, and the two ends of the communication pipe are connected with the paint storage bin and the sprayer correspondingly. The moving structure comprises a power source, a screw and a threaded piece, wherein the power source is fixedly connected with the shell, the screw is vertically arranged, an output shaft of the power source is connected with one end of the screw, the other end of the screw is rotationally connected with the shell, the threaded piece and the screw are in threaded fit, a guide rod parallel to the screw is arranged in the shell, and the guide rod is in sliding fit with the threaded piece. The sprayer is fixedly connected with the threaded piece. The 1 / 4 circumference face of the rotation barrel is provided with a chute, and the threaded piece is provided with a lifting lever capable of being inserted in the chute. The device can achieve automatic power distribution cabinet paint spraying, and paint spraying is uniform.

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

Uniform gluing and clamping device for processing aluminum-plastic plate

InactiveCN112317235AGlue evenlyUniform coatingLiquid surface applicatorsMaterial gluingStructural engineeringMechanical engineering

The invention relates to the technical field of aluminum-plastic equipment, and discloses a uniform gluing and clamping device for processing an aluminum-plastic plate. The uniform gluing and clampingdevice comprises a fixing plate, a pressing wheel is rotatably connected to the surface of the fixing plate, an aluminum plate is arranged on the surface of the pressing wheel, a limiting device is arranged on the surface of the pressing wheel, and a gluing head is arranged at the left end of the fixing plate. And a counting wheel is rotatably connected to the interior of the gluing head, a powerwheel is rotatably connected to the right end of the fixing plate, and a matching wheel is arranged on the upper side of the power wheel. According to the uniform gluing and clamping device for processing the aluminum-plastic plate, through cooperative use of the pressing wheel, the aluminum plate, the limiting device, the gluing head, the counting wheel, the power wheel, the matching wheel, a hollowed column, a connecting rod, a touch rod, a fixing shaft, a gluing switch, a pushing plate and the like, uniform glue discharging and coating during gluing are achieved, and the pressing wheel isused for pressing the aluminum plate and the plastic plate after gluing. The effects of tight fitting and no possibility of bulging in the later period are achieved.

Owner:潘小胜

Multi-film continuous coating device and method

InactiveCN108517504AReduce coating production costsReduce manufacturing costVacuum evaporation coatingSputtering coatingEngineeringFilm coating

The invention discloses a multi-film continuous coating device and method. The device comprises a surface treatment chamber, a multi-film coating chamber and a substrate outlet vacuum chamber which are connected in sequence; each chamber is provided with a workpiece reciprocating moving mechanism; and the workpiece reciprocating moving mechanisms are arranged below a substrate frame, a magnetic steering mechanism is arranged above the substrate frame, active drive supporting wheels and driven bearing wheels in the workpiece reciprocating moving mechanisms are arranged on a mounting support inthe vacuum chamber, the multiple driven bearing wheels are distributed between two adjacent active drive supporting wheels, and under driving of the active drive supporting wheels, the substrate framedoes reciprocated moving along the driven bearing wheels and the magnetic steering mechanism. The method comprises the steps that the workpiece reciprocating moving mechanisms drive the substrate frame and a workpiece to do reciprocated moving in the surface treatment chamber, and repeated surface roughening and cleaning treatment are achieved; reciprocated moving in the multi-film coating chamber is carried out, and multi-film coating is achieved; and finally, the workpiece is conveyed out from the substrate outlet vacuum chamber. The equipment structure can be effectively simplified, and the coating efficiency and the coating uniformity are improved.

Owner:ZHAOQING KERUN VACUUM EQUIP

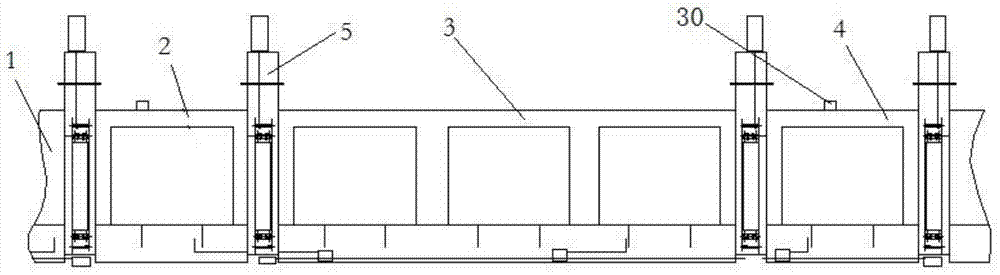

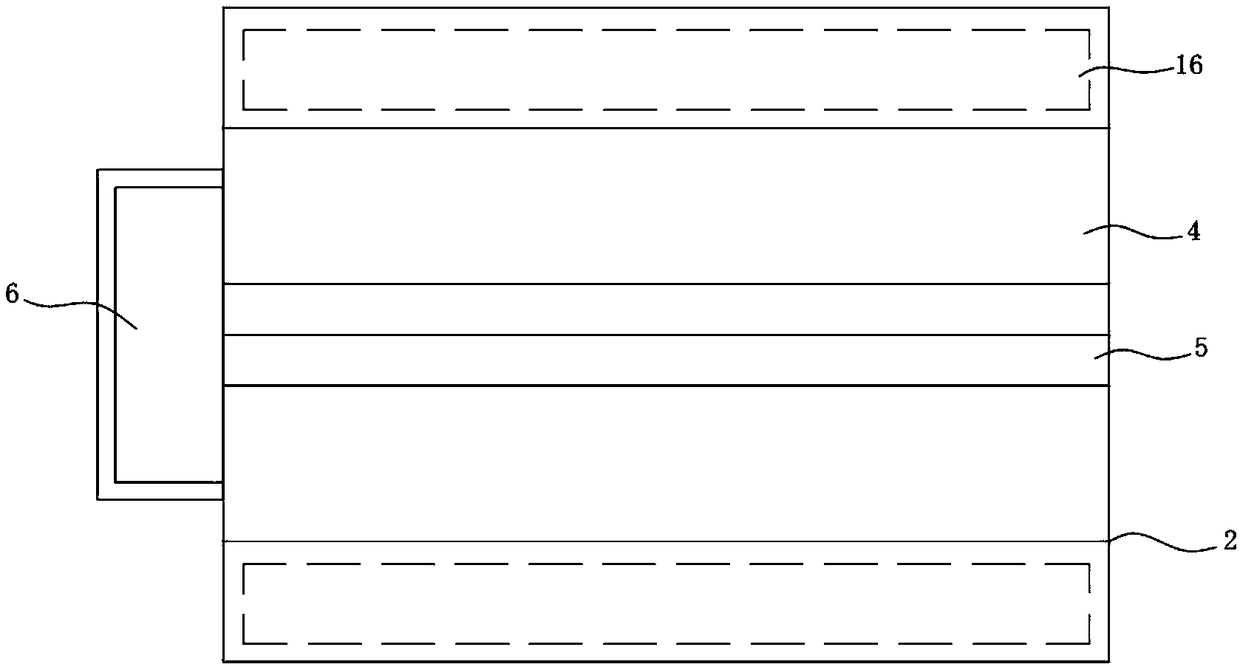

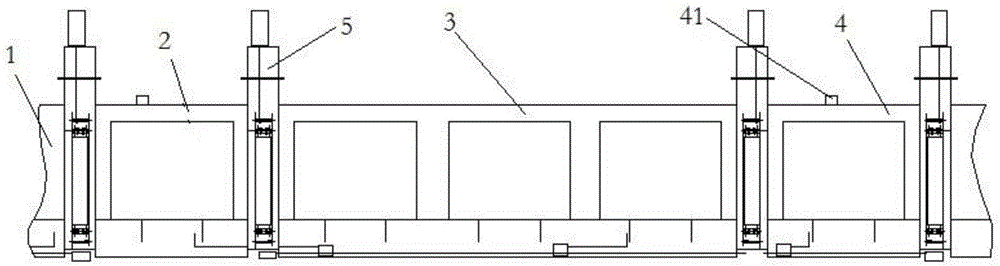

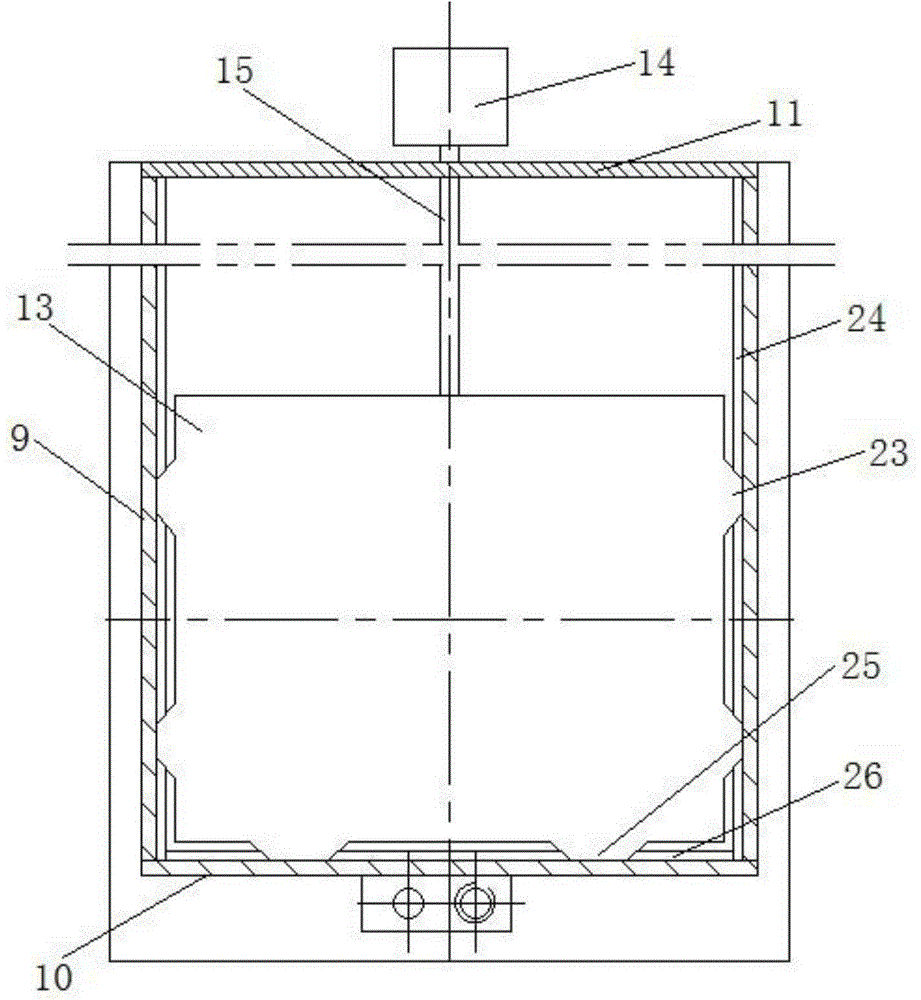

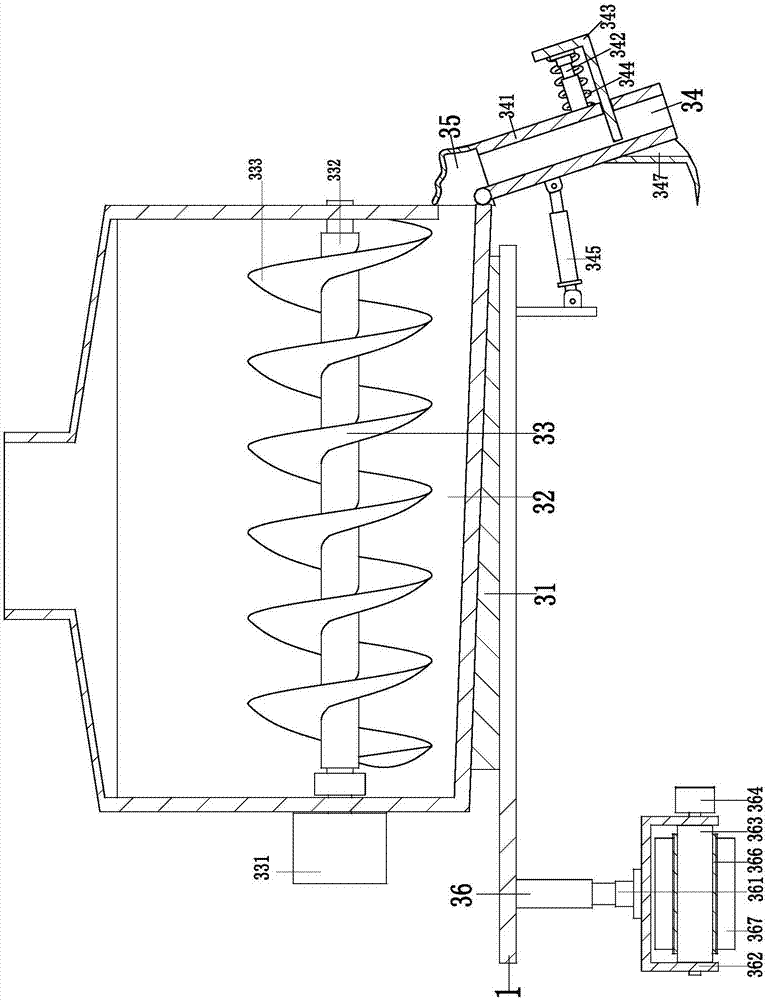

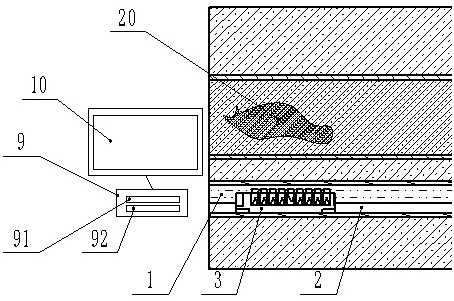

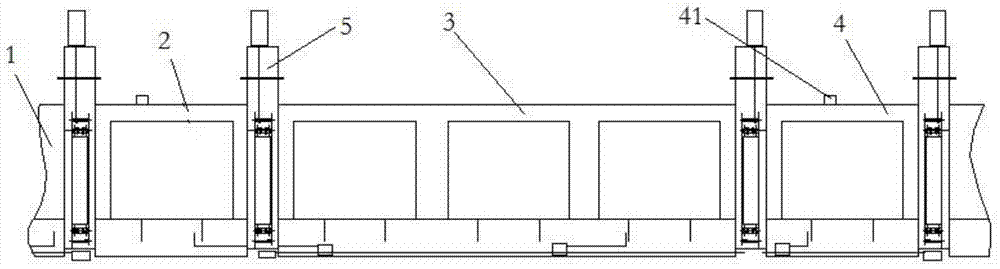

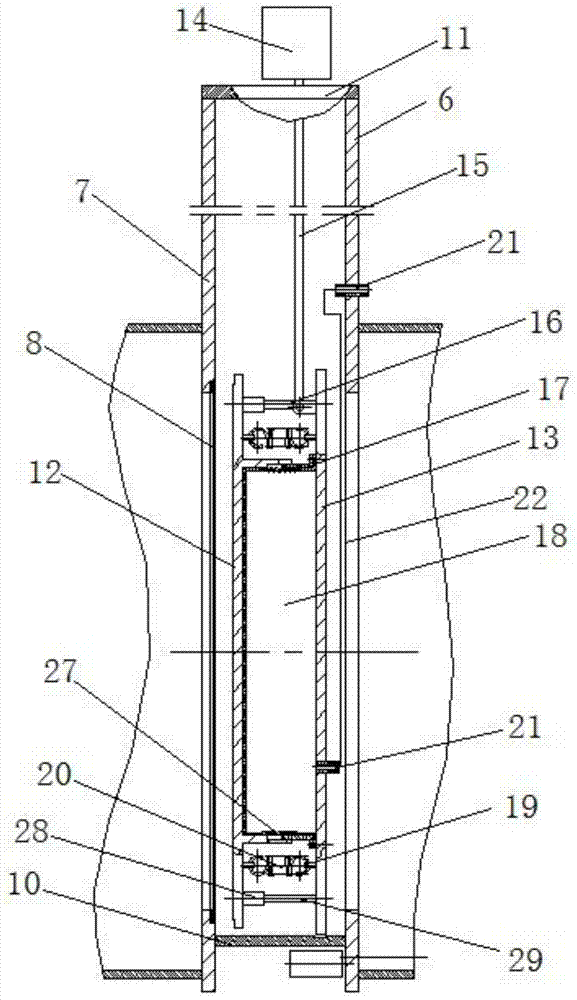

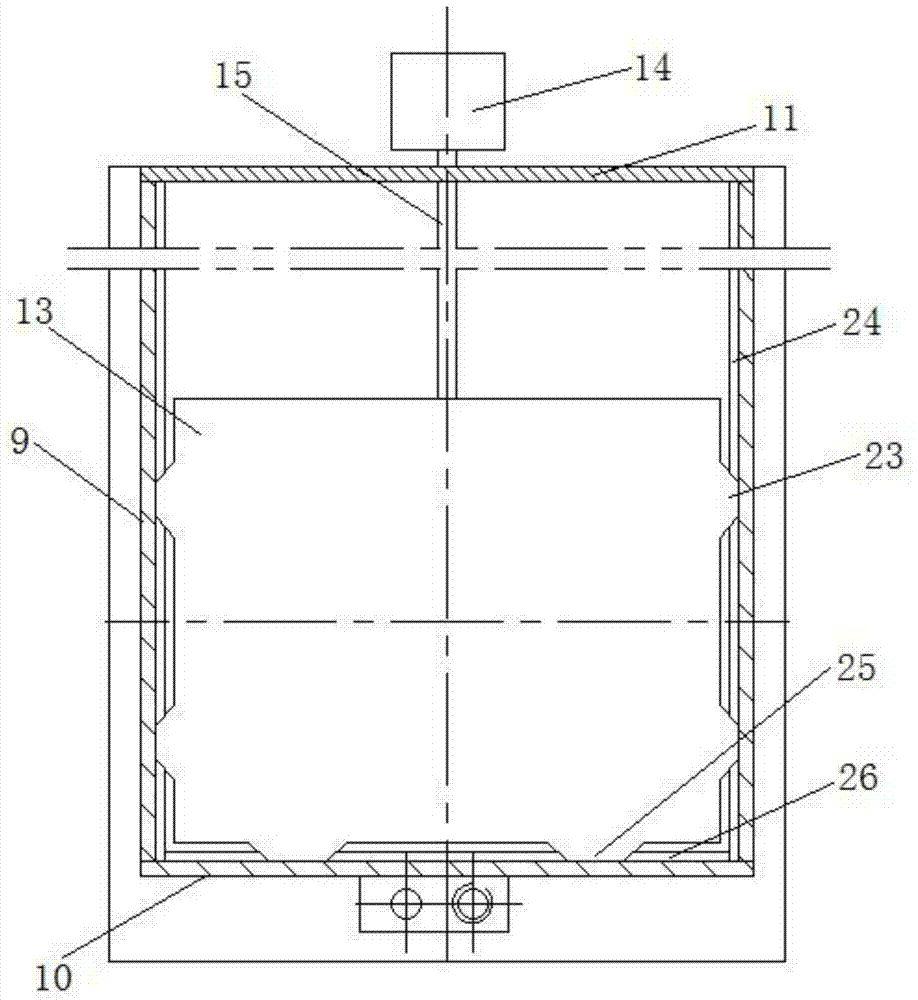

Continuous pressure steaming machine

ActiveCN104642827AMoving at a uniform speedEven by forceFood preparationEngineeringPressure reduction

The invention discloses a continuous pressure steaming machine. The continuous pressure steaming machine comprises a preheating bin barrel body, a pressurizing bin barrel body, a steaming bin barrel body and a pressure reduction bin barrel body, wherein air bag sealing devices are arranged between each two of the preheating bin barrel body, the pressurizing bin barrel body, the steaming bin barrel body and the pressure reduction bin barrel body, tray pushing devices are arranged at the outlet positions of the preheating bin barrel body, the steaming bin barrel body and the pressure reduction bin barrel body respectively, and a tray pulling device is arranged at the inlet position of the steaming bin barrel body. The air bag sealing device is adopted, a sealing flange cover board is moved uniformly and stably in a sealing process, the stress area of the air bag on the sealing flange cover board is large, the sealing flange cover board is stressed uniformly, the deformation of the sealing flange cover board is small, a sealing gasket is stressed uniformly and deformed uniformly, and the sealing effect is improved; and a servo motor and a screw rod are used as power, pulling and pushing mechanical arms by use of guide rods for guiding are adopted, the operation is stable and reliable, and the control operation can be realized easily.

Owner:SHAANXI UNIV OF SCI & TECH

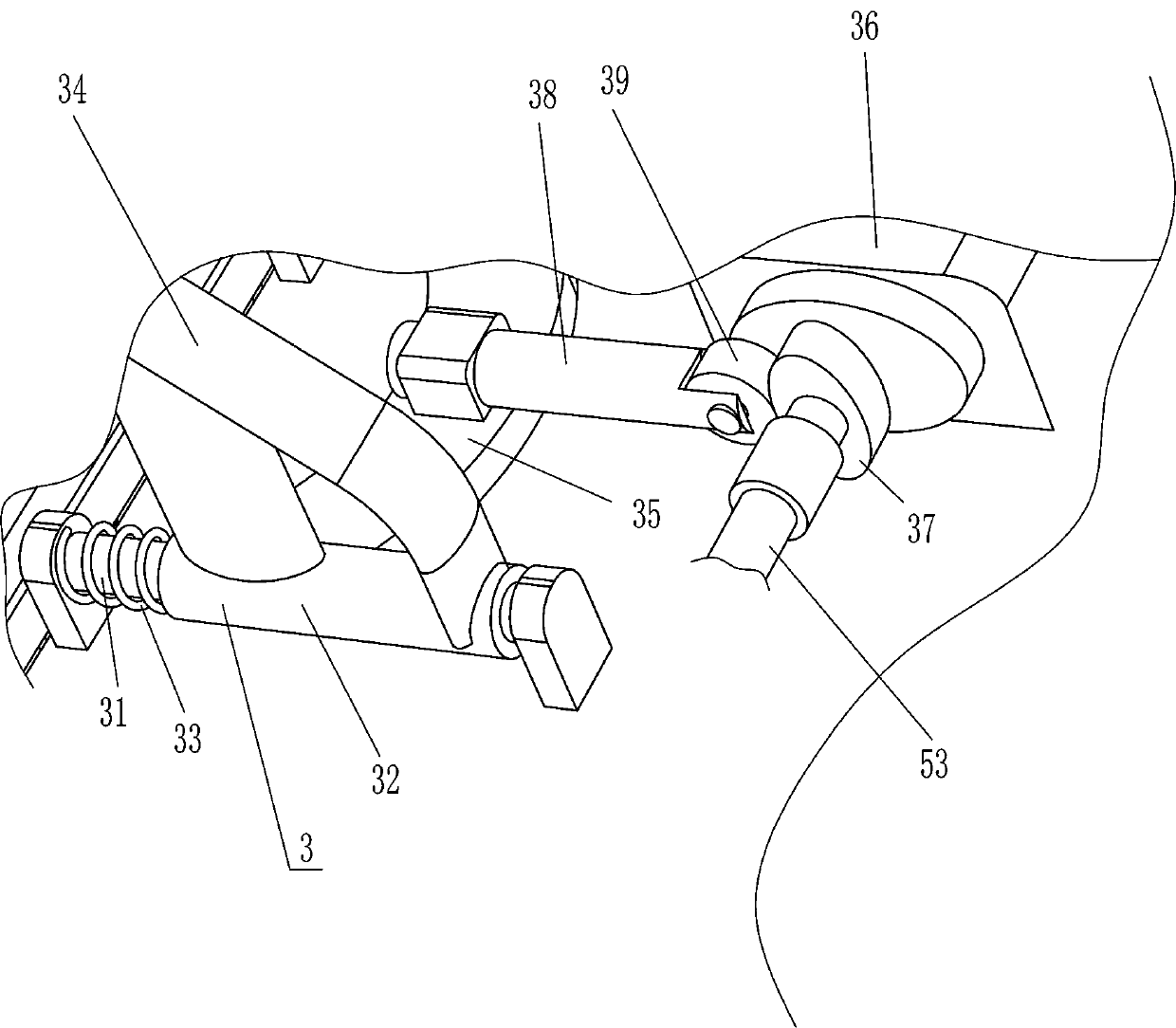

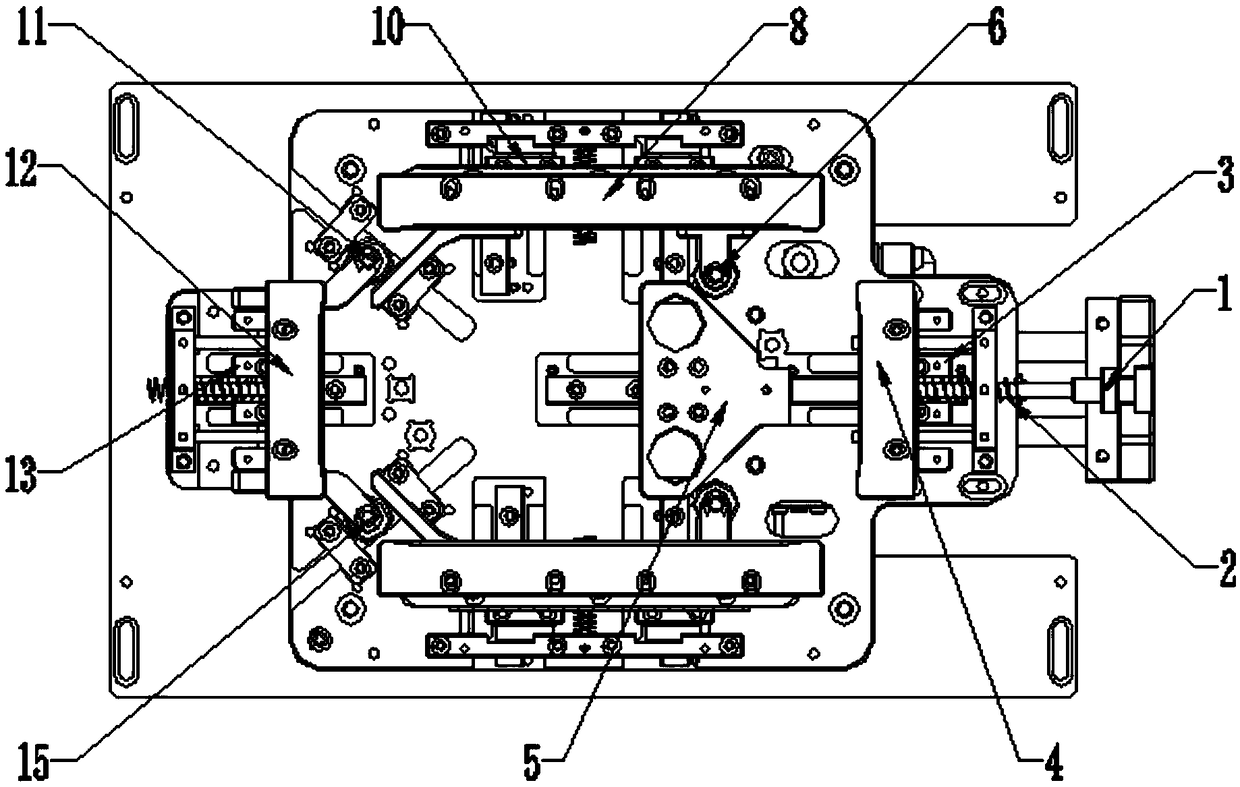

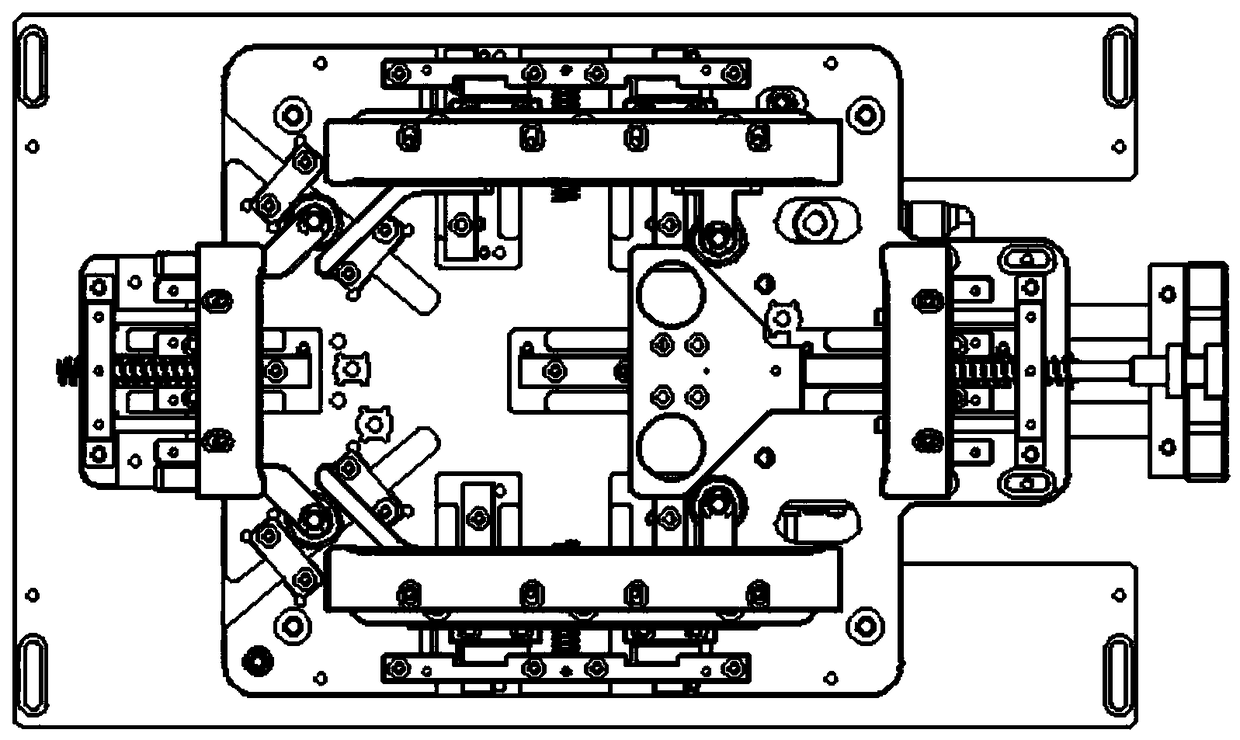

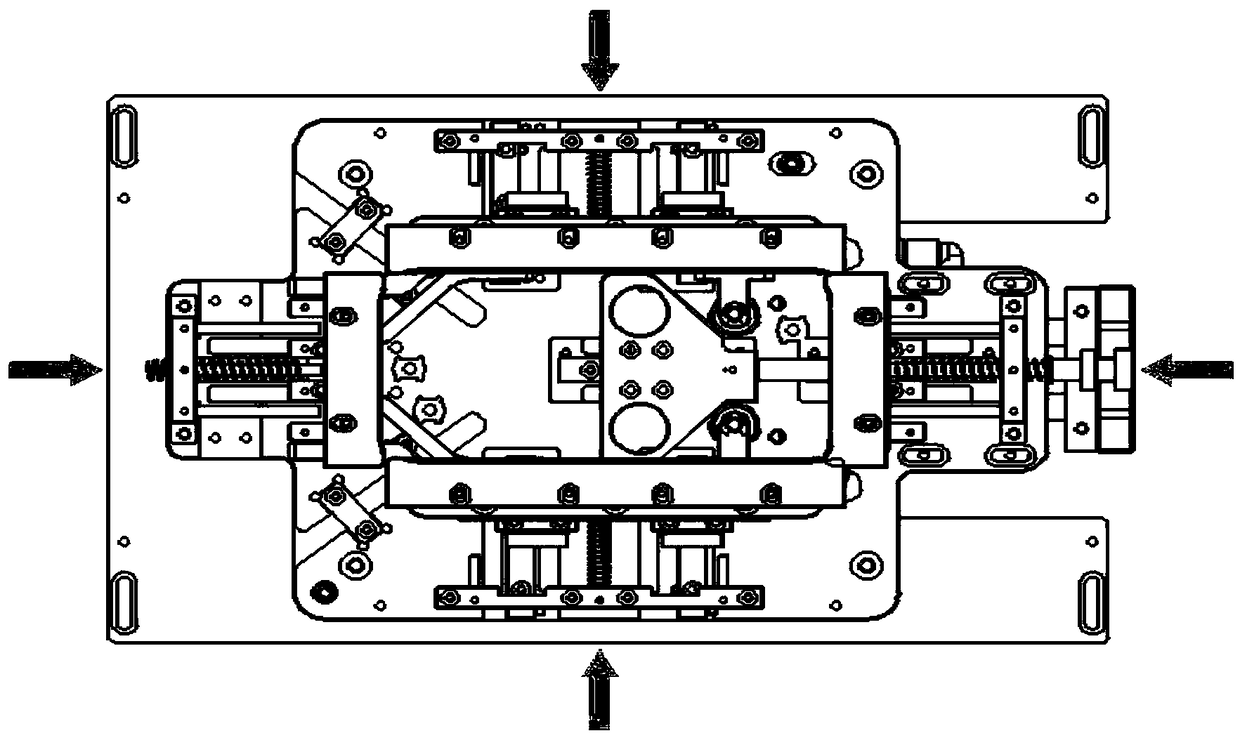

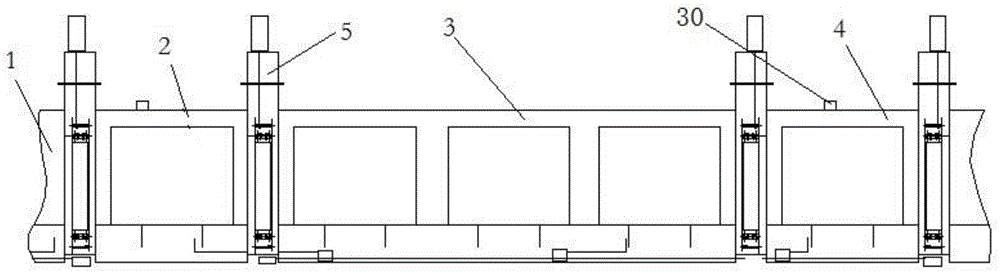

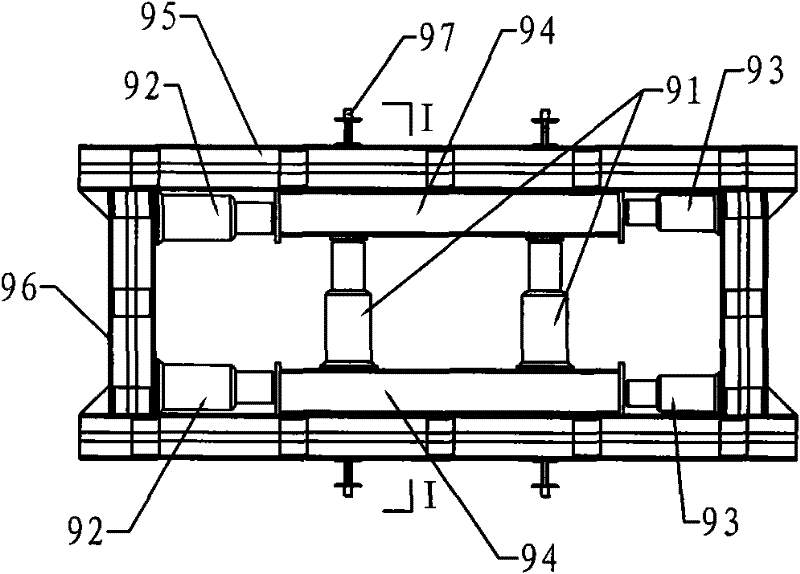

Peripheral clamping mechanism and operation method

ActiveCN109048418ARunning at the same speedEasy to operate and controlPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a peripheral clamping mechanism and an operation method. The peripheral clamping mechanism comprises a die holder and a driving mechanism, wherein the driving mechanism is horizontally arranged at the top edge position of the die holder and is fixedly connected to the die holder through a screw; a sliding block A is arranged at the bottom of the driving mechanism; the sliding block A is horizontally arranged in the middle of the bottom of the driving mechanism and is fixedly connected to the driving mechanism through the screw; a clamping block A is arranged at the topof the sliding block A; the clamping block A is horizontally arranged in the middle of the top of the sliding block A and is fixedly connected to the sliding block A through the screw; a transmissionblock is arranged on one side of the clamping block A; the transmission block is horizontally arranged at one end of the driving mechanism and is fixedly connected to the driving mechanism through thescrew; a sliding block B and a sliding block C which are parallel to each other are arranged at the top of the die holder; and the sliding block B and the sliding block C are horizontally arranged atthe top edge position of the die holder and are fixedly connected to the die holder through the screws. The peripheral clamping mechanism has the advantages of simple operation control, identical peripheral clamping force and consistent running speed of the clamping blocks.

Owner:上海莘翔自动化科技有限公司

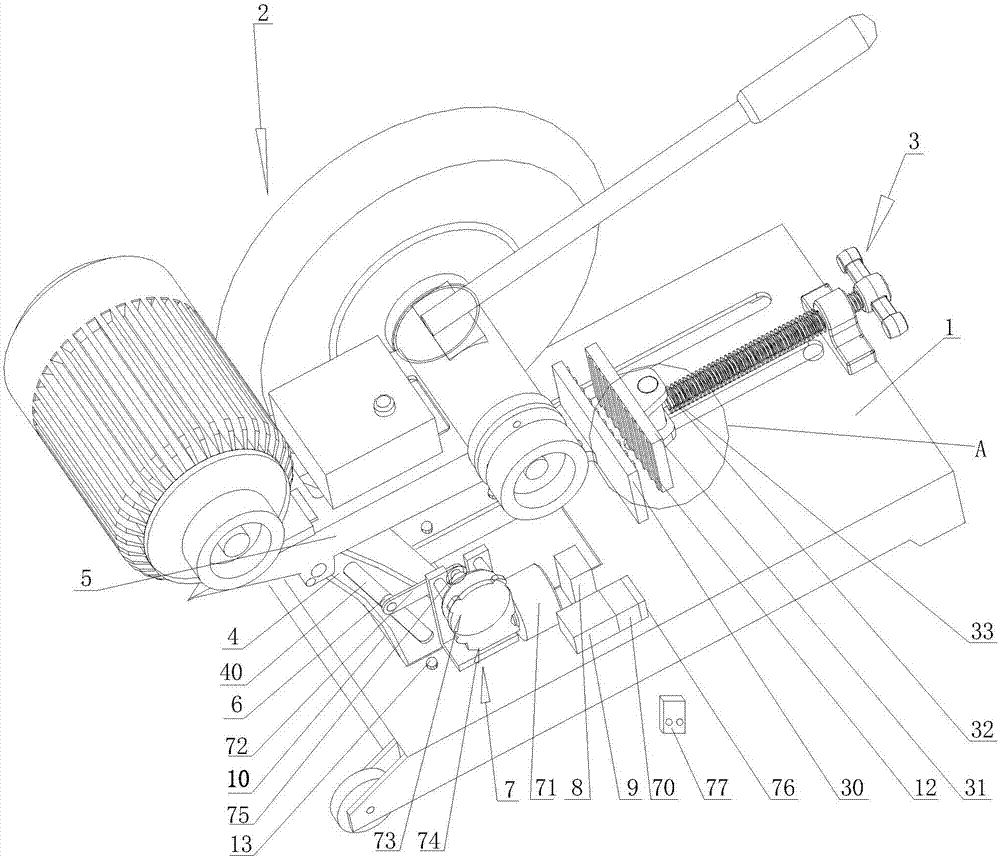

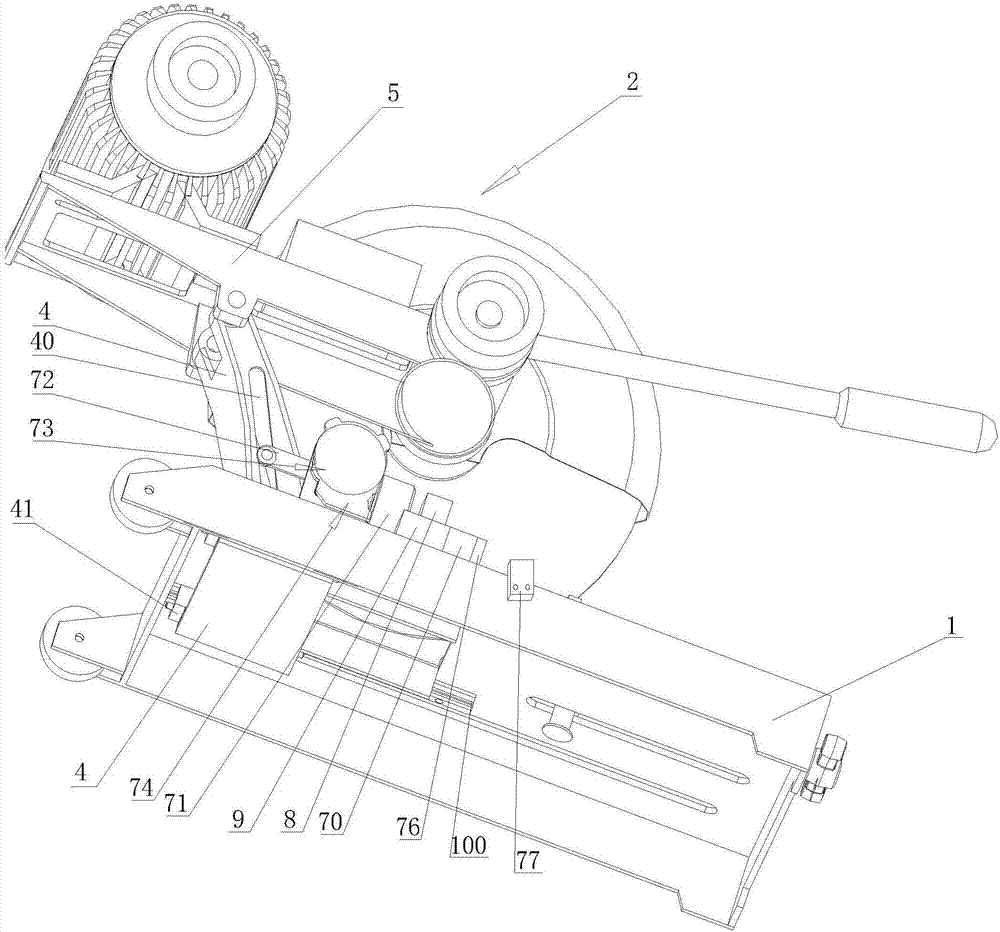

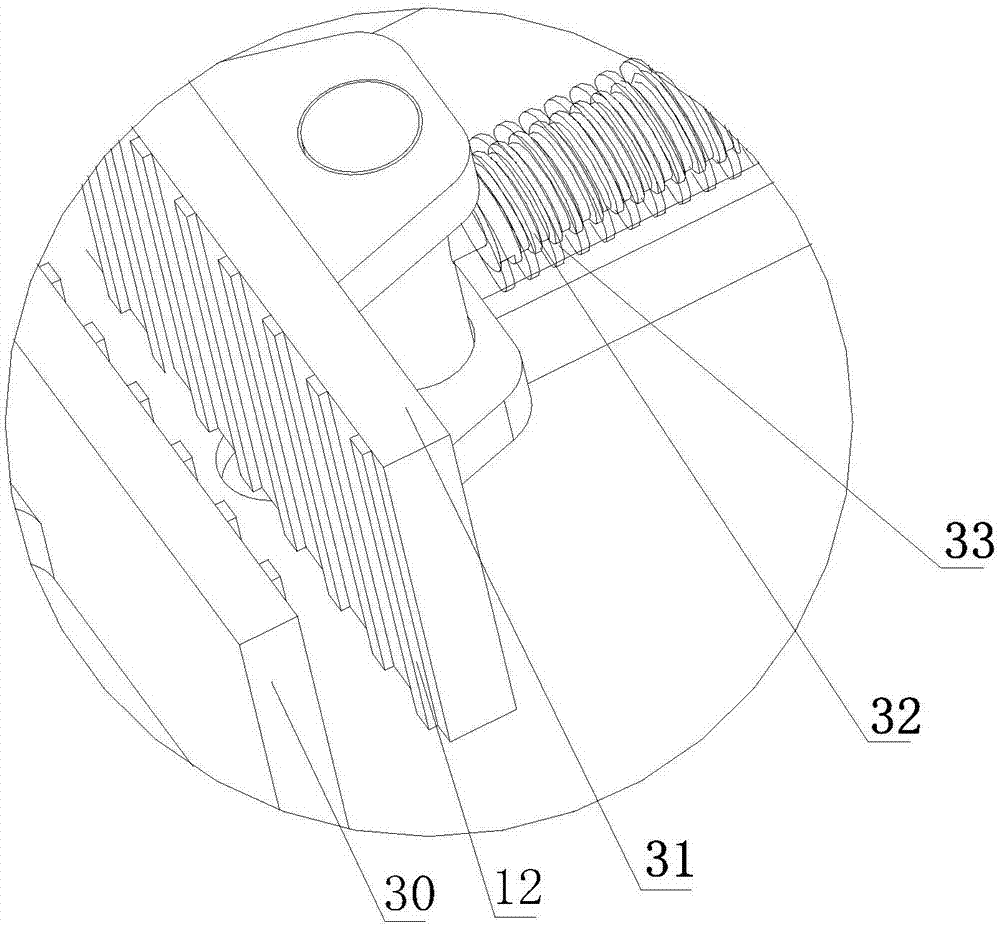

Automatic moving dovetail type grinding wheel cutting machine

InactiveCN107127668AEasy to moveControl movement speedGrinding carriagesGrinding feed controlTurbineGrinding wheel

The invention discloses an automatic moving dovetail type grinding wheel cutting machine. The machine comprises a base, a cutting assembly used for cutting workpieces and a fixture used for fixing the workpieces. A dovetail groove is formed in the base. The dovetail groove is internally provided with a dovetail support frame. The dovetail support frame is provided with a cutting bracket. The cutting assembly is connected with the cutting bracket. A sliding groove is formed in the dovetail support frame. The sliding groove is internally provided with a sliding block. The sliding block is connected with an automatic moving device. The automatic moving device drives the dovetail support frame to move in the dovetail groove. The automatic moving device comprises a controlling device, a motor, a connecting rod, a worm, a rotating shaft and a turbine. The controlling device is in circuit connection with the motor. The motor is connected with the worm. The turbine and the worm are connected with each other in a meshed mode. The turbine is connected with the connecting rod through the rotating shaft. The connecting rod is rotatably connected with the sliding block. According to the automatic moving dovetail type grinding wheel cutting machine, users can use the machine conveniently, time and labor are saved, the uniform moving speed is ensured, the cutting efficiency is improved, and the cutting quality is ensured.

Owner:安徽铸星机械制造有限公司

Pavement marking equipment for constructional engineering

ActiveCN113308976AMoving at a uniform speedNo leakageRoads maintainenceWire wheelStructural engineering

The invention relates to scribing equipment, in particular to pavement marking equipment for constructional engineering. The technical problem to be solved is to provide the pavement marking equipment for constructional engineering, which is simple to operate and does not have the phenomenon of paint accumulation or missing coating. The pavement marking equipment for constructional engineering comprises: a moving mechanism and a lifting mechanism, wherein the moving mechanism is arranged on the lifting mechanism; two guide rods which are arranged on the lifting mechanism in a sliding manner; a connecting rod which is arranged between one sides of the connecting rod and the guide rod in a sliding manner; a wire wheel, wherein the lower part of the connecting rod is rotatably provided with the wire wheel; and first springs which are arranged between one side of the upper part of the connecting rod and the two guide rods. Through cooperation of the wire wheel, the moving mechanism and the lifting mechanism, the equipment can automatically complete line marking operation on a road surface, is small in occupied area and easy to operate, the moving speed of the wire wheel is uniform, and the phenomena of missed coating and accumulation of paint are avoided.

Owner:江西华翔建筑有限责任公司

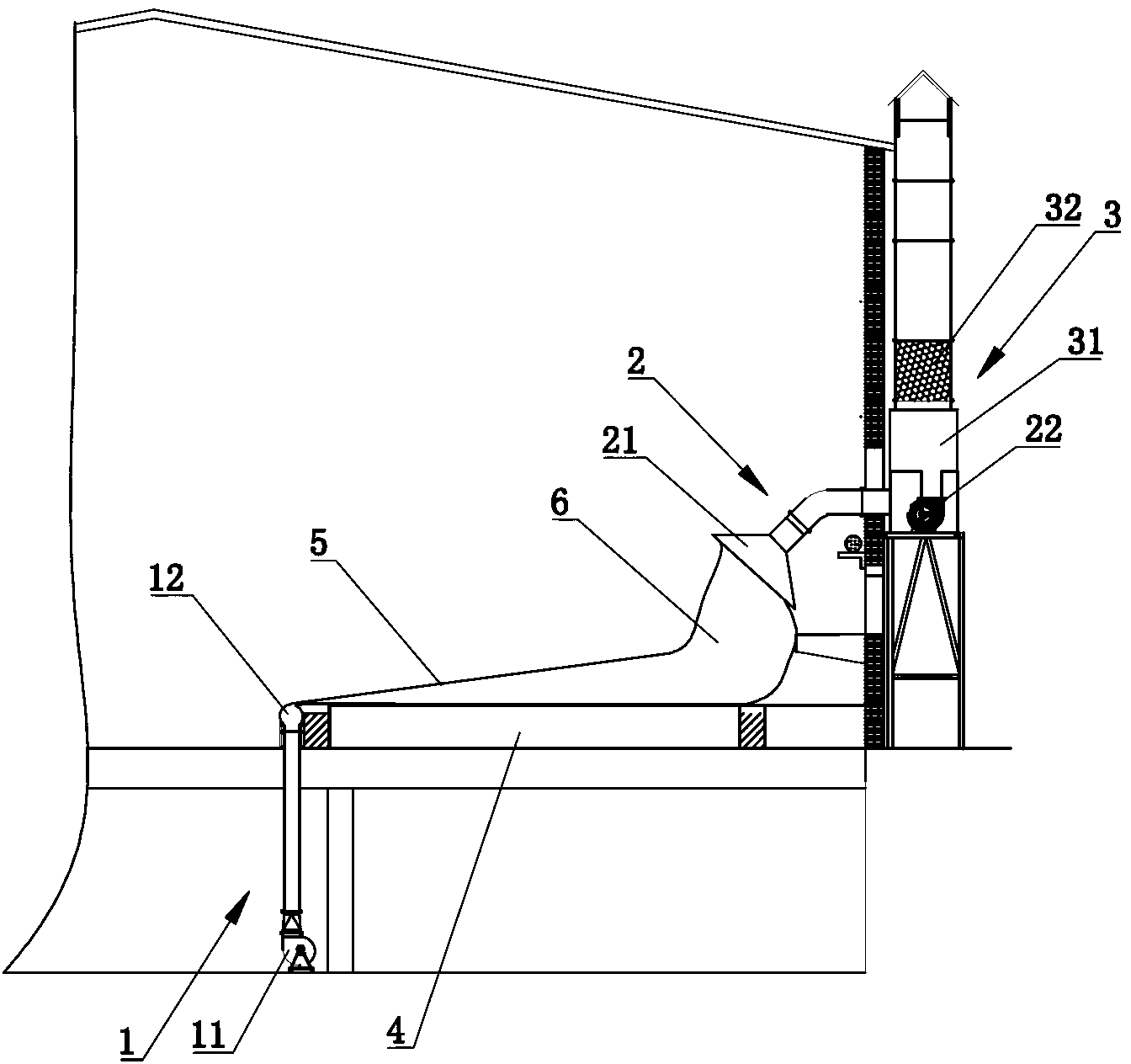

Workshop poisonous harmful gas processing device

ActiveCN103264033ASolve problems that are not easily collected for processingEfficient collectionDirt cleaningProduct gasPlenum chamber

The invention discloses a workshop poisonous harmful gas processing device which comprises an air supply system, an air suction system and a processing exhaust system, wherein the air supply system, the air suction system and the processing exhaust system are sequentially arranged. The air supply system comprises a new air forced draught blower and an air curtain pipe, the air outlet end of the new air forced draught blower is connected with an air inlet of the air curtain pipe, and an air outlet of the air curtain pipe stretches in the axial direction of the air curtain pipe to be arranged and is located above a poisonous harmful gas area. The air suction system comprises an air collection cover, wherein the air inlet end face of the air collection cover faces the poisonous harmful gas area and is arranged opposite to the air outlet of the air curtain pipe, and the air outlet end of the air collection cover is connected with an induced draft fan. The processing exhaust system comprises a plenum chamber, wherein the inlet end of the plenum chamber is connected with the air outlet end of the induced draft fan, the outlet end of the plenum chamber is connected with a gas harmless processing device. The workshop poisonous harmful gas processing device can effectively collect and process poisonous harmful gas in a workshop.

Owner:SHANDONG TAIBEI ENVIRONMENTAL PROTECTION EQUIP

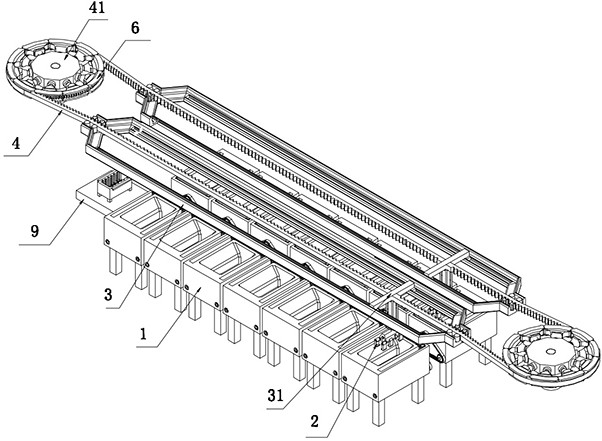

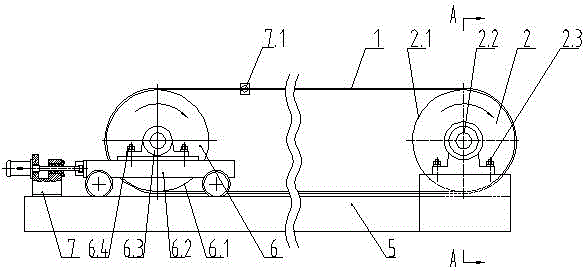

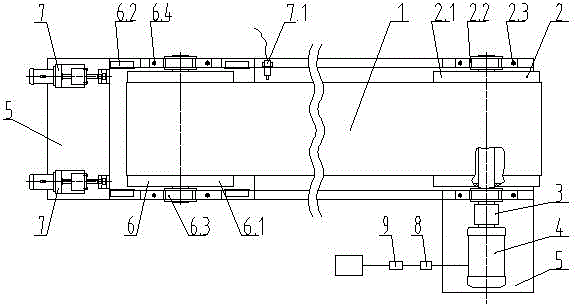

Steel strip variable-frequency transmission system of steel strip type reduction furnace

InactiveCN105935765ASimple structureImprove transmission efficiencyTransportation and packagingMetal-working apparatusFrequency changerCoupling

The invention discloses a steel strip variable-frequency transmission system of a steel strip type reduction furnace, which is arranged in the steel strip type reduction furnace. The steel strip variable-frequency transmission system comprises a steel strip, a driving roller part, a driven roller part, a bracket part and a variable-frequency speed adjusting motor; the driving roller part is provided with a driving roller, and is fixedly connected to the upper plane of one end of the bracket part; the driven roller part includes a driven roller and a movable roller frame, and is supported on the upper plane of the other end of the bracket part in a rolling manner; the steel strip surrounds the outer walls of the driving roller and the driven roller; the variable-frequency speed adjusting motor drives the driving roller to move forwards at uniform speed; one end of the driving roller is coaxially connected with the variable-frequency speed adjusting motor through a coupling; a control loop of the variable-frequency speed adjusting motor is provided with a frequency converter and a program controller, and is electrically connected with a control system of the reduction furnace; and steel strip rectifying devices are respectively arranged in two positions symmetrical corresponding to conveying center axis on the left side of the driven roller part. The steel strip variable-frequency transmission system adopts the frequency converter to adjust the speed in a stepless manner, and is simple in transmission structure, stable in operation and excellent in protecting performance.

Owner:孙颖

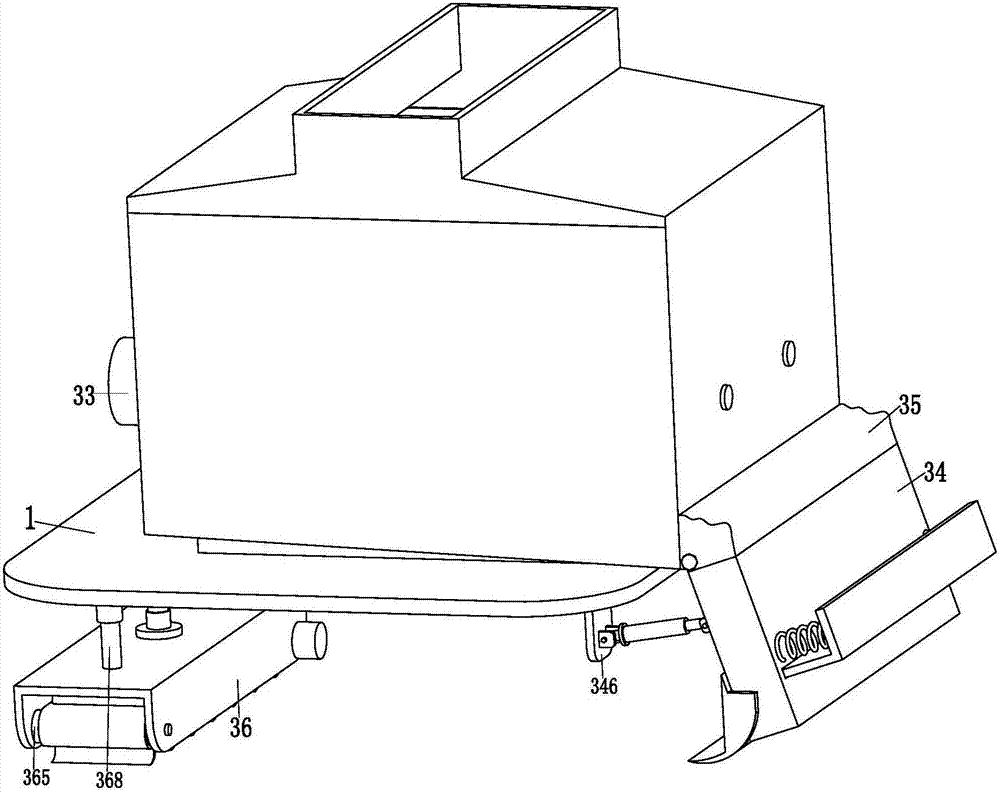

High-efficiency spreading machine for anti-ultraviolet polyurethane material plastic track

The invention relates to a high-efficiency rubber scraper for an ultraviolet-resistant polyurethane material plastic track, which comprises a base plate, a support block is installed on the base plate, a stirring frame is installed on the upper end of the support block, and two stirring mechanisms are symmetrically arranged on the stirring frame. The front end of the frame is provided with an adjusting limit mechanism, and the rear end of the bottom plate is equipped with a horizontal troweling mechanism. The mixing mechanism, the adjusting limit mechanism and the horizontal troweling mechanism cooperate with each other to complete the high-efficiency scraping process of the hybrid plastic track. The invention can solve the problem that the glue liquid and the rubber particles need to be manually stirred into the base glue in the construction process of the existing mixed plastic track scraping glue, the glue liquid has a fast coagulation speed, needs to be manually stirred at regular intervals, and the distribution of the artificially stirred base glue is uneven. It is necessary to manually use a leveling tool to level the primer spread on the ground. Manually leveling the uneven primer, complicated operation, high labor intensity and low work efficiency, etc., can realize the function of high-efficiency scraping of mixed plastic runways. .

Owner:丁建丽

A kind of continuous pressure steamer air bag sealing method

InactiveCN104728452BMoving at a uniform speedGuaranteed uptimeEngine sealsFood scienceHydraulic cylinderEngineering

The invention discloses a continuous pressure steaming machine air bag sealing method. Under the action of hydraulic cylinders, piston rods push sealing flange cover plate supporting plates through lifting lugs and carry the sealing flange cover plate supporting plates, sealing flange cover plates, hooks, tension springs, air bags and air bag sleeves to move downwards together; after the sealing flange cover plate supporting plates move downwards to a position, pre-heated compressed air enters the air bags from flexible air pipes and connectors, along with increasing of pressure in the air bags, expansion joints arranged on the air bags expand to push the sealing flange cover plates to tightly press sealing gaskets arranged on sealing flanges, and therefore sealing is formed. In the sealing process, the sealing flange cover plates are uniform in moving speed and stable in operation, the stressed area on the sealing flange cover plates from the air bags is large, the sealing flange cover plates are evenly stressed and small in deformation, finally the sealing gaskets are evenly stressed and deformed, the sealing effect is improved, and the key problems that the sealing effect among all bins is poor, and work reliability is poor are solved.

Owner:SHAANXI UNIV OF SCI & TECH

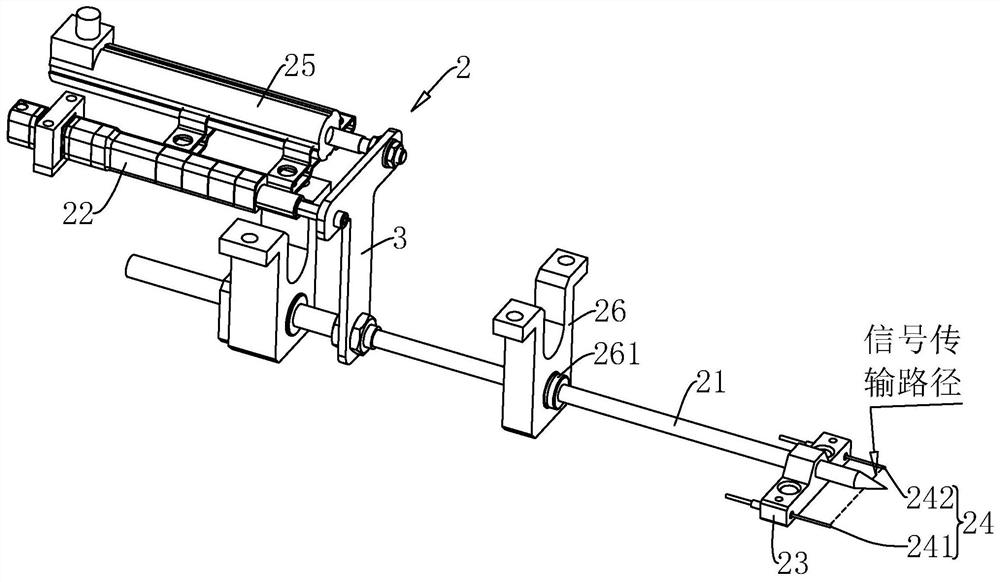

A detection system based on ultrasonic transducer

ActiveCN113252774BMoving at a uniform speedEasy accessAnalysing fluids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalData displayWireless transceiver

The invention relates to a detection system based on ultrasonic energy conversion, which includes a channel, a track, a base, an ultrasonic generator, an ultrasonic receiver, a displacement sensor, an acoustic wave analysis device, and a data display screen. The analysis device is equipped with a second wireless transceiver and a central control module. The central control module is used to analyze the sound waves. The detection system is used to detect the initial stage. The base is located at the beginning of the channel. The central control module controls the ultrasonic generator to emit ultrasonic waves. The receiver receives the reflected ultrasonic signal and transmits the received signal to the acoustic wave analysis device through the first wireless transceiver, and the base moves along the track at a constant speed while the ultrasonic generator emits ultrasonic waves. The invention receives the reflected ultrasonic signal in real time through the ultrasonic receiver, and the central control module determines whether the grouting bellows grouting is qualified by analyzing the sound wave intensity, thereby ensuring the quality of the project and providing powerful data support for bridge repair and maintenance.

Owner:北京唯恩传感技术有限公司

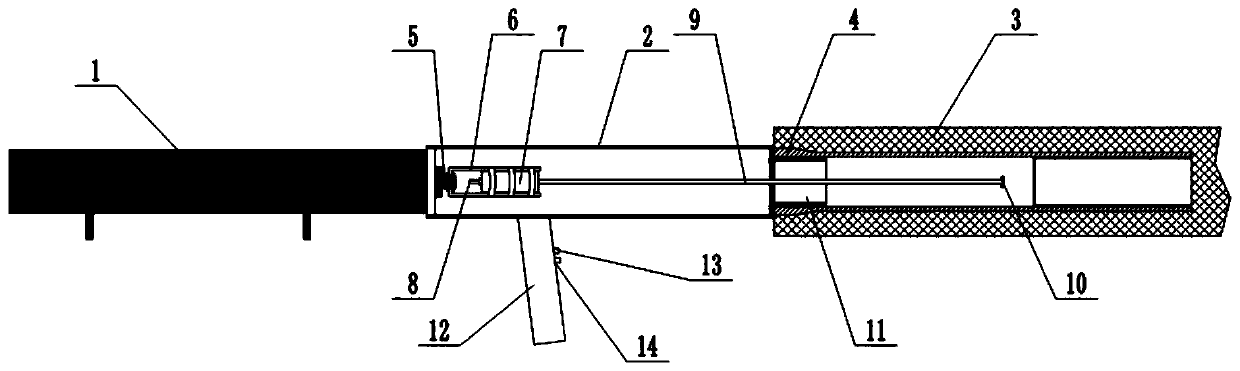

Anti-corrosion oil jetting tool for inner cavity of wind power pre-buried screw sleeve

PendingCN110394262AMove at the same speedCauses uneven sprayingSpraying apparatusElectricitySpray nozzle

The invention belongs to the technical field of wind power equipment, and particularly discloses an anti-corrosion oil jetting tool for an inner cavity of a wind power pre-buried screw sleeve. The tool comprises a driving part, a main frame, a spray gun, a positioning block and a control assembly, wherein the spray gun is horizontally and slidably connected inside the main frame, and the driving part is used for driving the spray gun to horizontally move; a gun nozzle of the spray gun is in horizontal sliding connection with the positioning block, the gun nozzle of the spray gun is located atthe center of the positioning block, the nozzle on the gun nozzle is located on one side, away from the main body frame, of the positioning block, the diameter of the nozzle is larger than that of thegun nozzle, the positioning block can enter the pre-buried screw sleeve and is contact with the inner cavity of the pre-buried screw sleeve, and the opening area of the pre-buried screw sleeve is smaller than the bottom area of the main frame; and the control assembly simultaneously controls opening and closing of the driving part and the spray gun. According to the tool with the structure, the problems of uneven spraying, multi-coating or leakage-coating and low efficiency caused by manual operation of the spray gun in the prior art can be solved.

Owner:重通成飞风电设备江苏有限公司

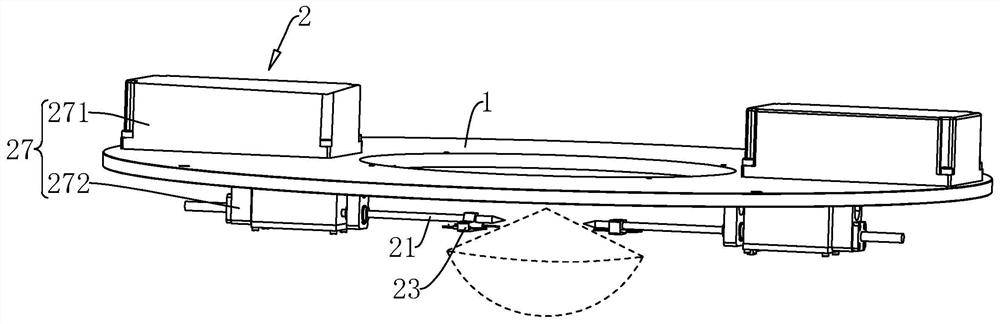

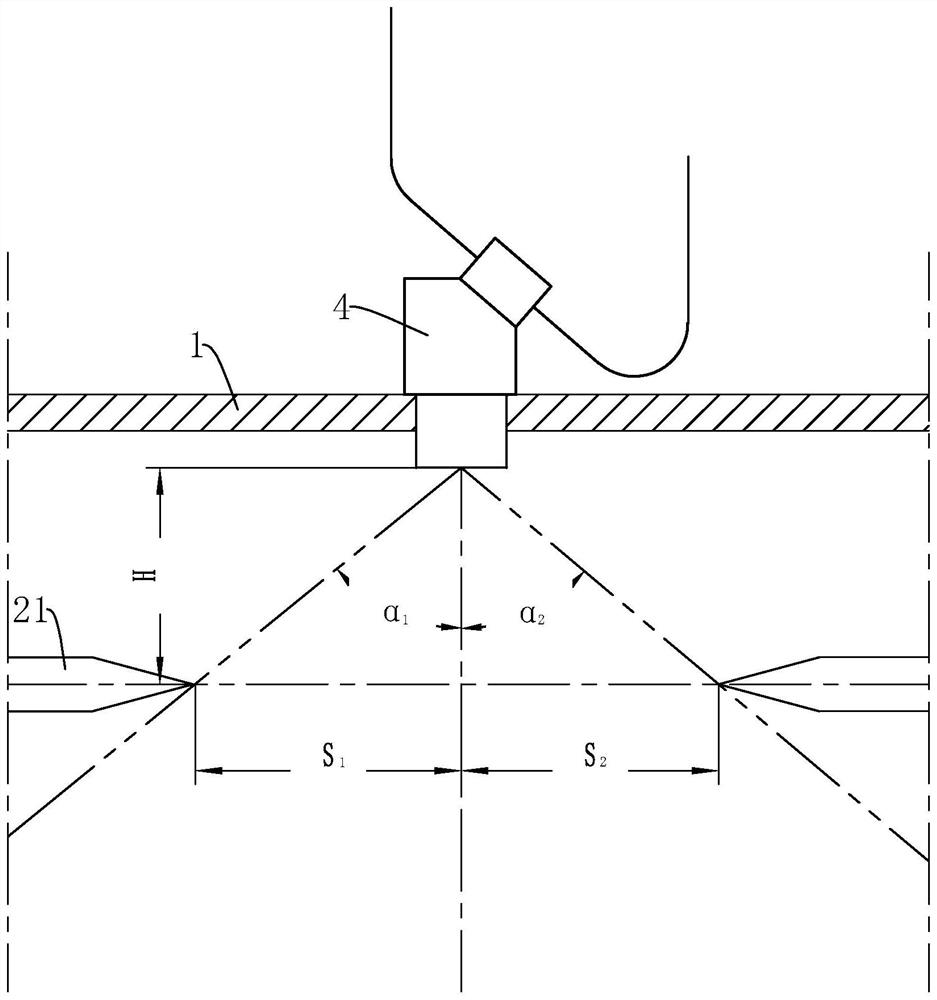

A fuel nozzle atomization angle automatic measurement mechanism and automatic measurement method

ActiveCN113720277BImprove consistencyMoving at a uniform speedMachine part testingUsing optical meansEngineeringOil droplet

This application relates to the field of nozzle atomization angle detection, in particular to a fuel nozzle atomization angle automatic measurement mechanism and an automatic measurement method, the fuel nozzle atomization angle automatic measurement mechanism includes a test installation panel for installing the nozzle and installed on the The measuring device used to measure the atomization angle of the nozzle on the test installation panel, the measuring device is provided with two groups, and the measuring devices of the two groups are respectively located on the opposite sides of the nozzle, and the measuring device includes a sliding connection A probe on the test mounting panel and a driving device that drives the probe toward or away from the nozzle, the driving device being configured to stop when an oil drop falls on the probe. The present application has the effects of increasing the measurement accuracy and improving the consistency of the detection results when detecting the atomization angle of the nozzle.

Owner:BEIJING CRONDA NEW TECH CO LTD

A continuous pressure steamer

ActiveCN104642827BMoving at a uniform speedEven by forceSteam cooking vesselsFood scienceAirbagFlange

The invention discloses a continuous pressure steaming machine, which comprises a preheating chamber cylinder body, a pressurized chamber cylinder body, a steaming chamber cylinder body and a decompression chamber cylinder body, and the preheating chamber cylinder body, the pressurized chamber cylinder body, An air bag sealing device is installed between the cylinder body of the steaming chamber and the cylinder body of the decompression chamber, and a tray pushing device is installed at the outlets of the cylinder body of the preheating chamber, the cylinder body of the steaming chamber and the cylinder body of the decompression chamber, and the steaming There is a pallet pulling device at the entrance of the silo body. The first one of the present invention adopts the airbag sealing device, the moving speed of the sealing flange cover plate is uniform during the sealing process, and the operation is stable. The result is that the gasket is evenly stressed and deformed, and the sealing effect is improved. The second is to use the servo motor and the lead screw as the power, and the pulling and pushing manipulator guided by the guide rod operates smoothly, is easy to realize control, and operates reliably.

Owner:SHAANXI UNIV OF SCI & TECH

Material extruder capable of rotatably replacing head and application method thereof

The invention discloses a material extruder capable of rotatably replacing a head and an application method thereof. The material extruder capable of rotatably replacing the head comprises a bottom plate, an extruding barrel assembly, a head replacing assembly and a motor assembly, wherein the extruding barrel assembly comprises an extruding barrel, a spiral electric heating wire, supporting columns, a feeding port, a discharging port, an extruding head groove, a rotating shaft, a rectangular blade and a manual rotating device; the extruding barrel is of a hollow cylindrical structure; the discharging port is formed in the right end of the extruding barrel; the extruding head groove is formed in the discharging port; the feeding port is formed in the upper end of the left side of the extruding barrel and is rotatably connected to the rotating shaft; the rectangular blade is fixedly connected to the rotating shaft; the manual rotating device is fixedly connected to the front end of therotating shaft; four supporting columns are symmetrically fixedly connected to the extruding barrel; the spiral electric heating wire is fixedly connected to the extruding barrel through a screw; theleft end of the extruding barrel is of an opening structure.

Owner:俞云飞

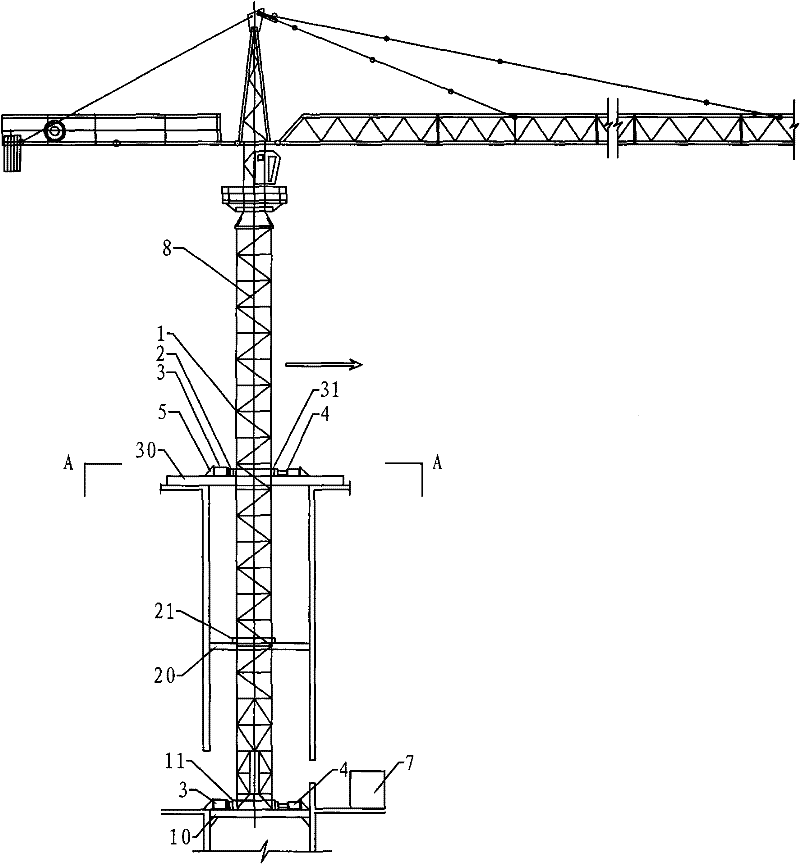

Integral translation device and method for internal climbing tower crane

Owner:中国华西企业股份有限公司 +1

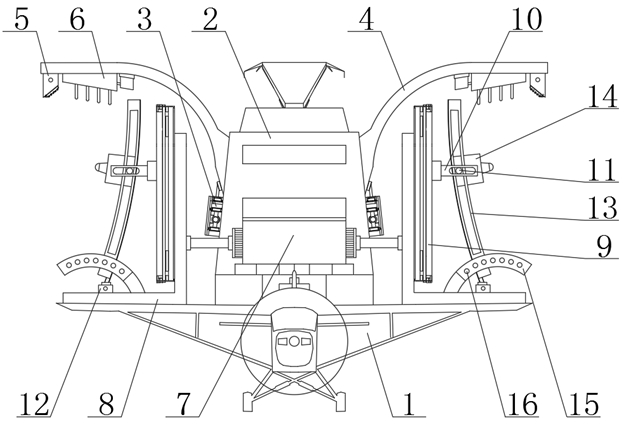

Agricultural plant protection equipment and use method thereof

InactiveCN114557332AMoving at a uniform speedUniform spraying methodClimate change adaptationSpraying apparatusAgricultural engineeringPesticide application

The invention discloses agricultural plant protection equipment and a using method thereof.The agricultural plant protection equipment comprises a walking module, a pesticide supply module, an upper leaf surface sweeping module and a simulated manual pesticide spraying module, the pesticide supply module is installed above the walking module, lifting mechanisms are installed on the two sides of the pesticide supply module, and the tops of the lifting mechanisms are connected with the upper leaf surface sweeping module; a translation driving mechanism mounted above the walking module is arranged on the front side of the pesticide supply module, two main shafts of the translation driving mechanism are connected with an L-shaped sliding plate, and a simulation manual pesticide spraying module is mounted in the L-shaped sliding plate; a reciprocating mechanism drives a moving plate to move up and down in a reciprocating mode, meanwhile, a crank connecting rod mechanism in a second pesticide spraying device drives an atomizing nozzle to rotate back and forth, pesticide liquid is radiated to the back faces of grape leaves in a corrugated mode under the combined action of the two moving tracks, pesticide application is more uniform, the situation that the pesticide liquid drips is not likely to occur, and pesticide spraying efficiency is improved. The state that the leaf surface is wet but not dripped is conveniently achieved.

Owner:朱秀苗

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com