A fuel nozzle atomization angle automatic measurement mechanism and automatic measurement method

An automatic measurement and fuel nozzle technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of poor consistency of measurement results, inconsistent probe moving speed, low measurement accuracy, etc., and achieve responsiveness The time is fast and accurate, the probability of explosion is reduced, and the effect of high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

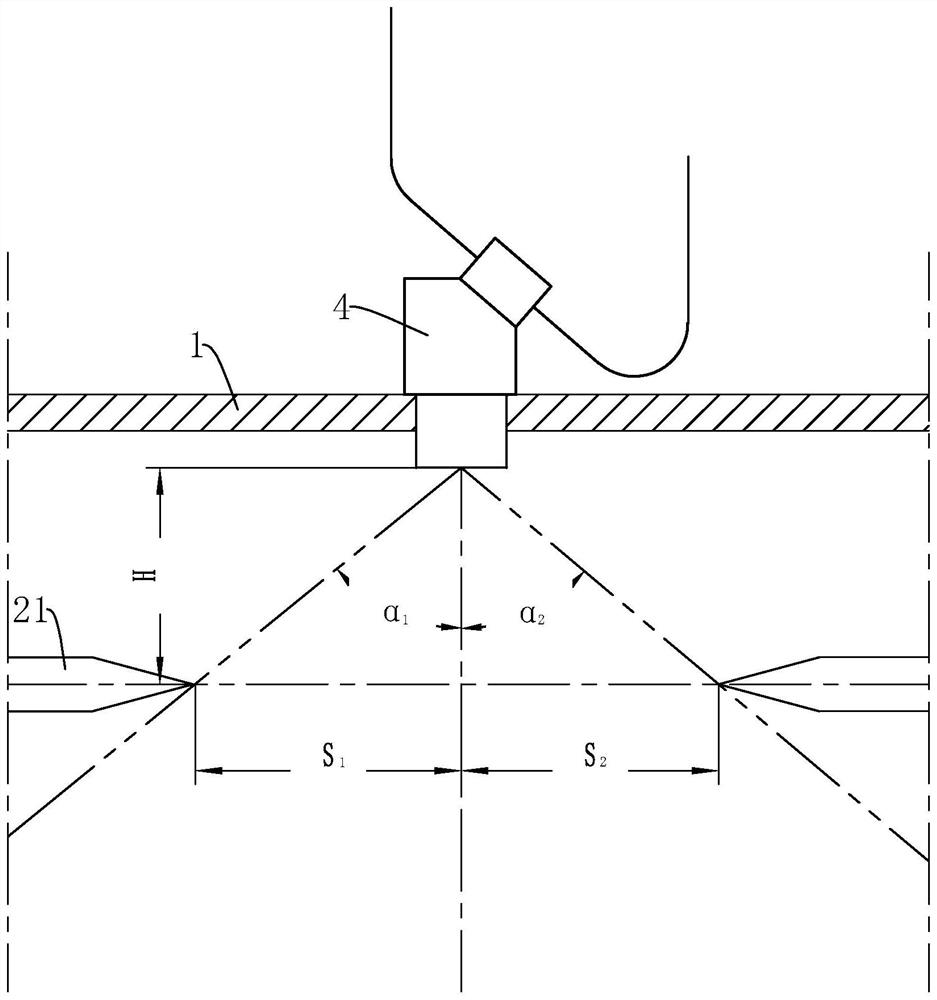

[0042] The following is attached Figure 1-4 The application is described in further detail.

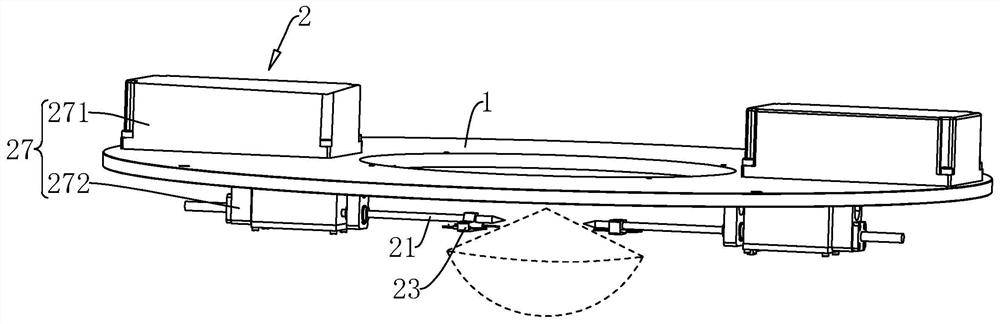

[0043] The embodiment of the present application discloses an automatic measurement mechanism for the atomization angle of a fuel nozzle. refer to figure 1 A fuel nozzle atomization angle automatic measurement mechanism includes a test installation panel 1 for installing a nozzle 4 and a measuring device 2 installed on the test installation panel 1 for measuring the atomization angle of the nozzle 4 . Wherein, two sets of measuring devices 2 are provided, and the two sets of measuring devices 2 are respectively located on opposite sides of the nozzle 4 .

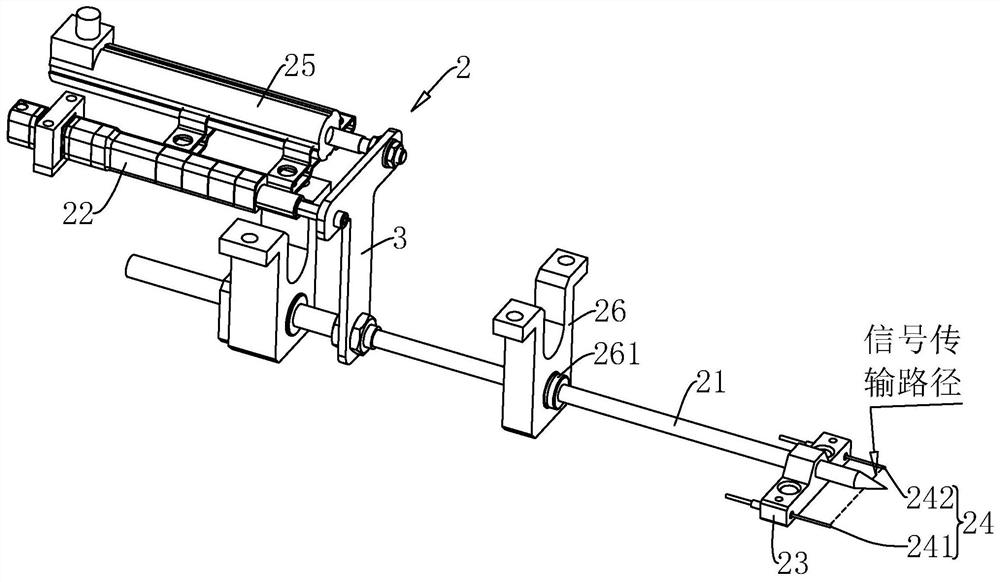

[0044] refer to figure 1 and figure 2The measuring device 2 includes a probe 21 slidably connected to the test installation panel 1 and a driving device 22 that drives the probe 21 to move toward the nozzle 4 or away from the nozzle 4 . Among them, the drive device 22 can be a device that can directly output linear power such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com