Drainage ditch cleaning equipment for livestock breeding

A technology for cleaning equipment and drainage ditch, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as spending a lot of time and energy, limited cleaning range of breeders, and affecting work efficiency, etc. Achieve uniform moving speed, avoid loosening, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

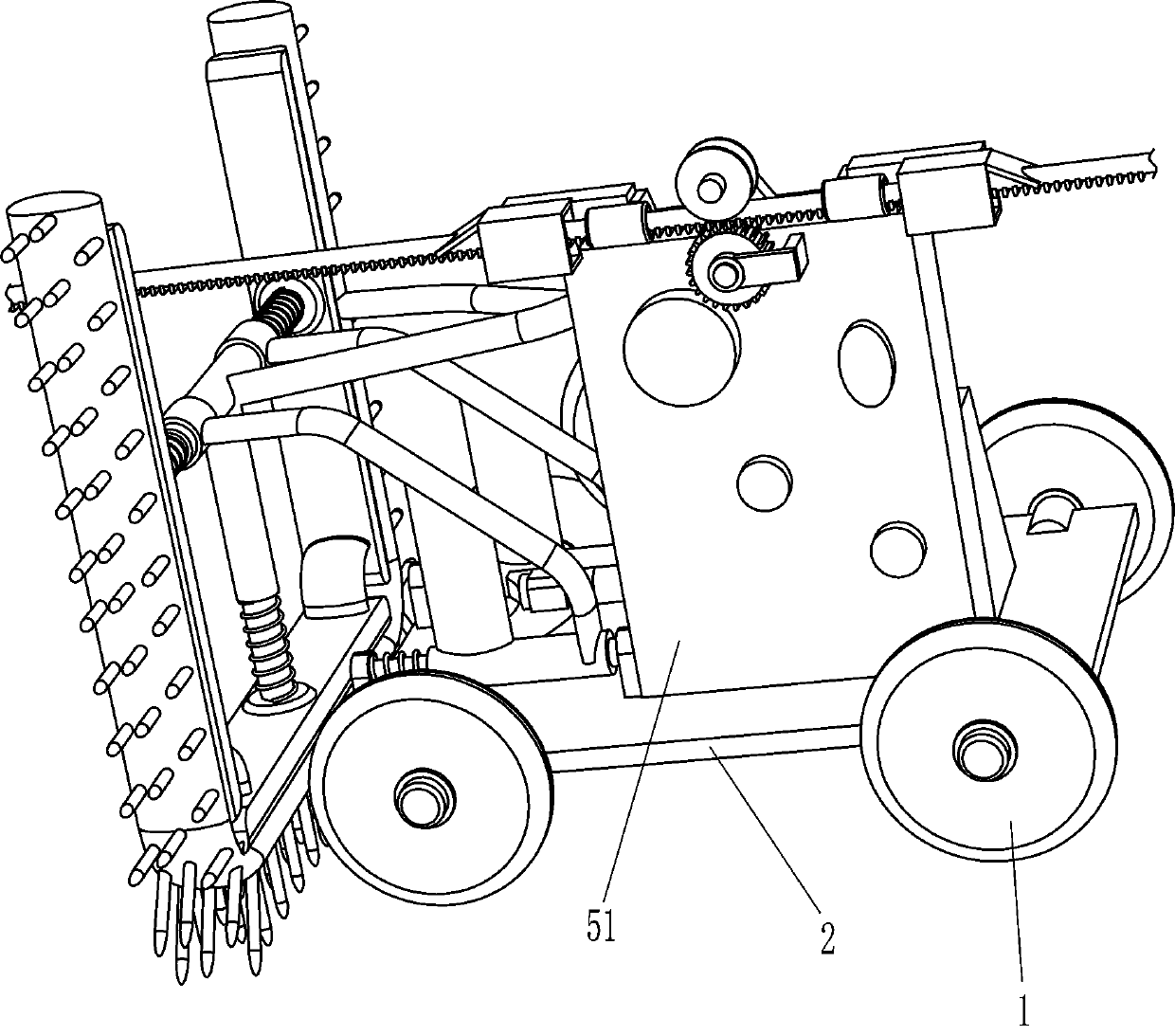

[0025] A kind of excrement ditch cleaning equipment for animal husbandry, see Figure 1-3 , including a roller 1, a mounting plate 2, a vibration mechanism 3 and a cleaning mechanism 4, two rollers 1 are installed on the front and rear sides of the mounting plate 2 through bolts, the rollers 1 on the front and rear sides are symmetrical, and the vibration mechanism is installed on the mounting plate 2 3. A cleaning mechanism 4 is installed on the vibrating mechanism 3 .

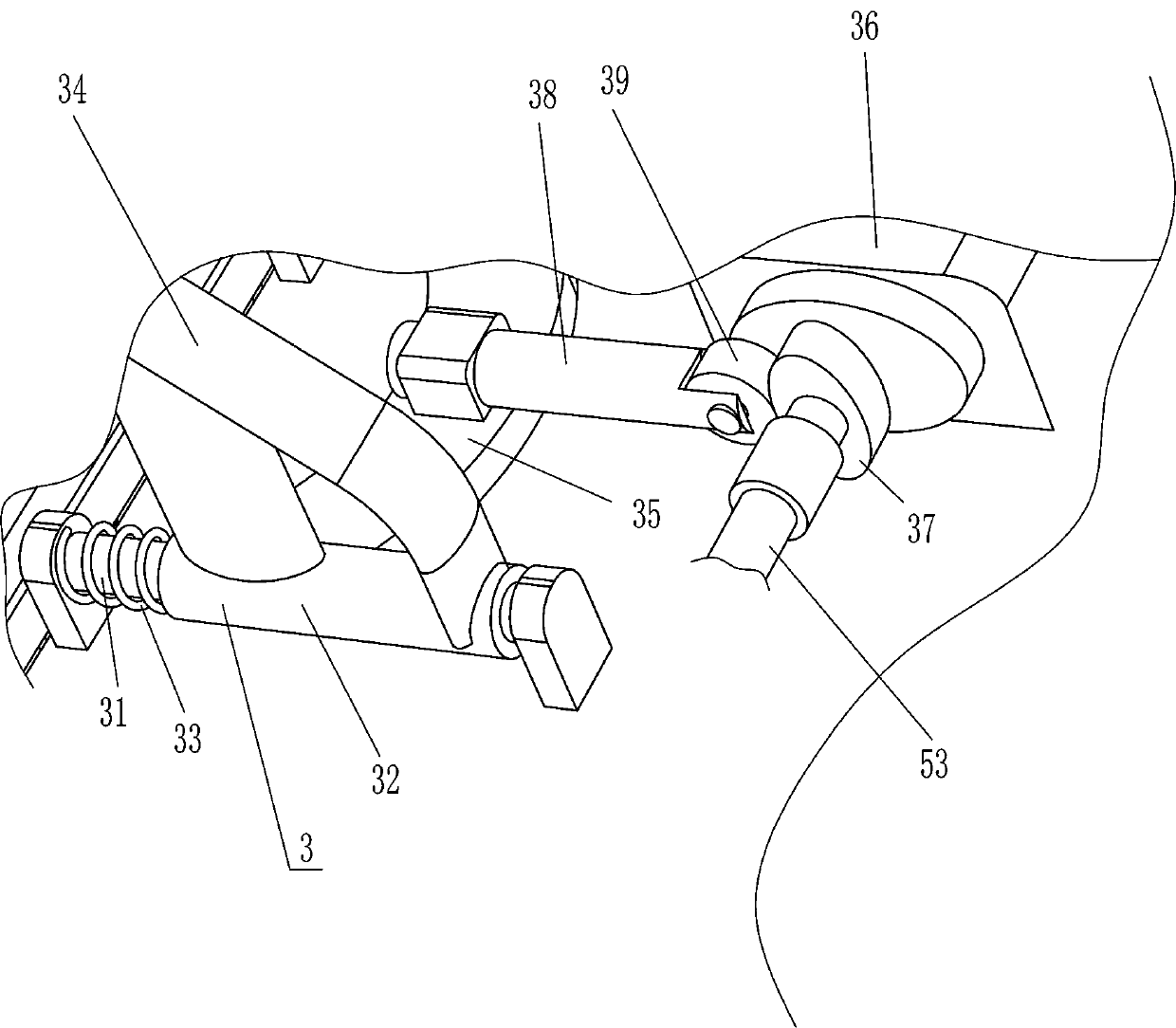

[0026] Vibration mechanism 3 includes guide rod 31, guide sleeve 32, first spring 33, mounting frame 34, connecting plate 35, drive motor 36, cam 37, drive shaft 38 and contact wheel 39, two front and rear sides on the left side of mounting plate 2 tops. Both sides are equipped with guide rods 31 by bolts, and the guide rods 31 on the front and rear sides are all slidably provided with guide sleeves 32. The guide rods 31 are wound with a first spring 33, and the right end of the first spring 33 is connected w...

Embodiment 2

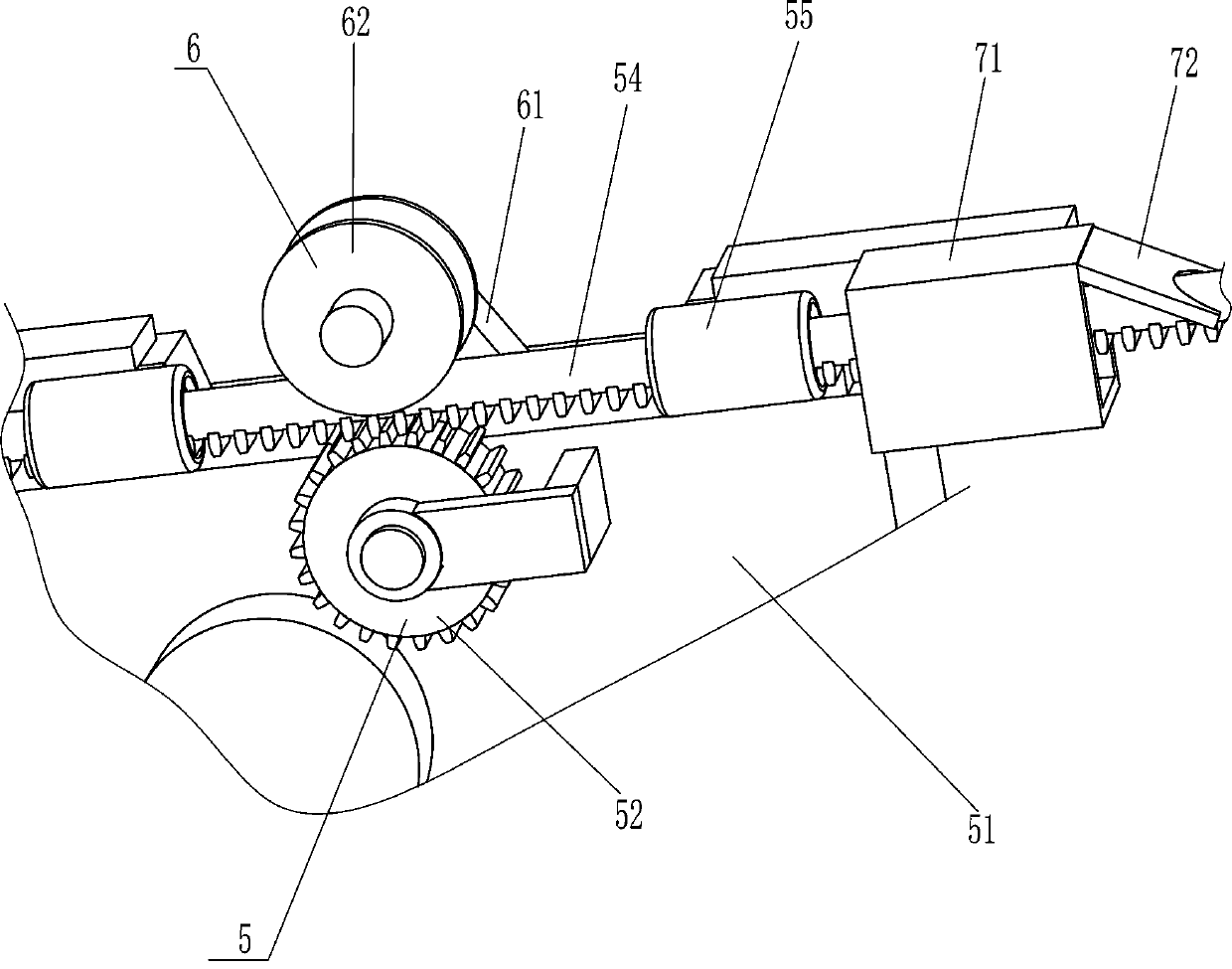

[0032] On the basis of embodiment 1, refer to figure 1 , image 3 , Figure 4 with Figure 5 , also includes moving mechanism 5, and moving mechanism 5 includes gearbox 51, gear 52, shaft coupling 53, toothed belt 54 and fixed sleeve 55, and the front side of mounting plate 2 top is equipped with gearbox 51 by bolt, and drive motor 36 The output shaft of the gearbox 51 is connected to the input end of the gearbox 51 through a coupling 53, and a gear 52 is installed on the output end of the gearbox 51. The left and right sides of the top of the gearbox 51 are connected with fixed sleeves 55, and the two fixed sleeves 55 are equipped with There is a toothed belt 54, and the toothed belt 54 can be made of rubber, and the toothed belt 54 is meshed with the gear 52.

[0033] Also includes engagement mechanism 6, and engagement mechanism 6 comprises mounting seat 61 and sheave 62, is connected with mounting seat 61 in the middle of gearbox 51 top, and mounting seat 61 is triangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com