Steel strip variable-frequency transmission system of steel strip type reduction furnace

A technology of frequency conversion drive and reduction furnace, which is applied in the direction of furnace, furnace type, transportation and packaging, etc., can solve the problems affecting iron powder reduction quality and work efficiency, uneven operation of steel belt, complex transmission structure, etc., to achieve photoelectric integration Control, uniform moving speed, high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

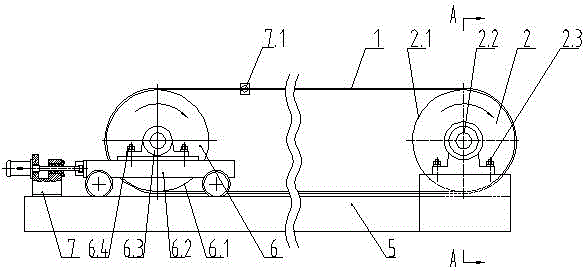

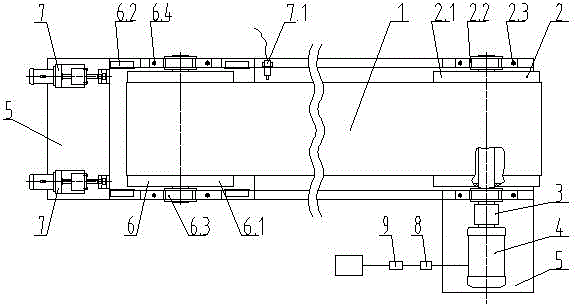

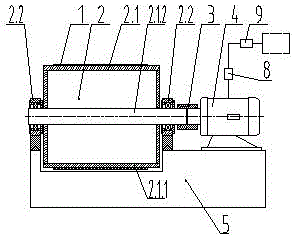

[0016] The steel belt frequency conversion transmission system of the steel belt reduction furnace shown in the attached figure is set in the steel belt reduction furnace, including the steel belt 1, the driving roller part 2, the driven roller part 6, the bracket part 5, and the frequency conversion speed regulating motor 4 , coupling 3; the driving roller part 2 is fixed on the plane at one end of the bracket part 5, and the driven roller part 6 is rollingly supported on the plane at the other end of the bracket part 5; the driving roller part 2 includes the driving roller 2.1, the bearing seat I2.2, Bolt fastener I 2.3; driving roller 2.1 includes roller 2.1.1, driving shaft 2.1.2, driving shaft 2.1.2 runs through the two end plates of roller 2.1.1 and is welded to the two end plates of roller 2.1.1 The driving roller 2.1 is fixed; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com