Workshop poisonous harmful gas processing device

A harmful gas and processing equipment technology, applied in the direction of smoke removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of large workshop space, processing, environmental pollution, etc., to prevent occupational diseases, prevent physical health, and prevent environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

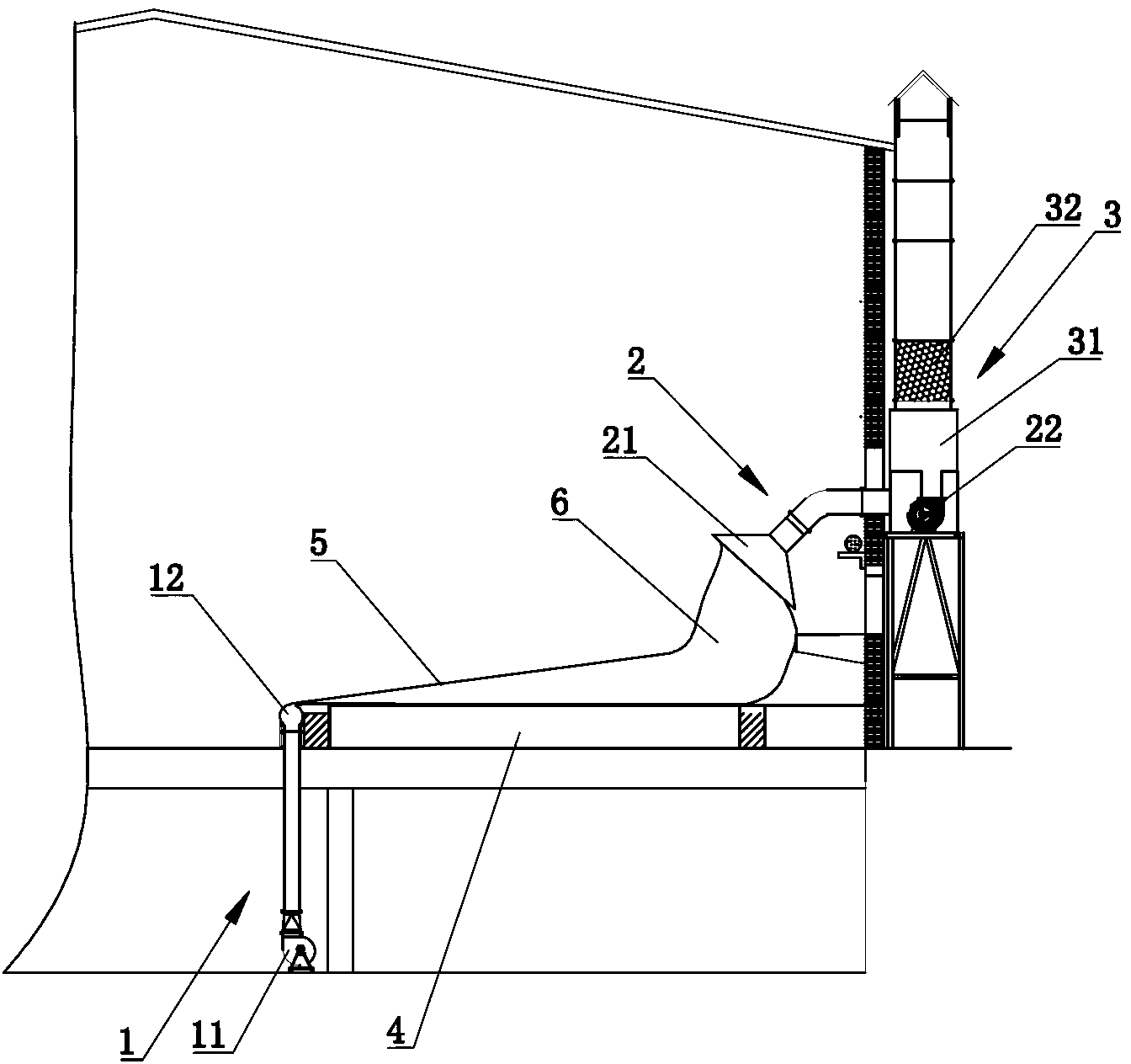

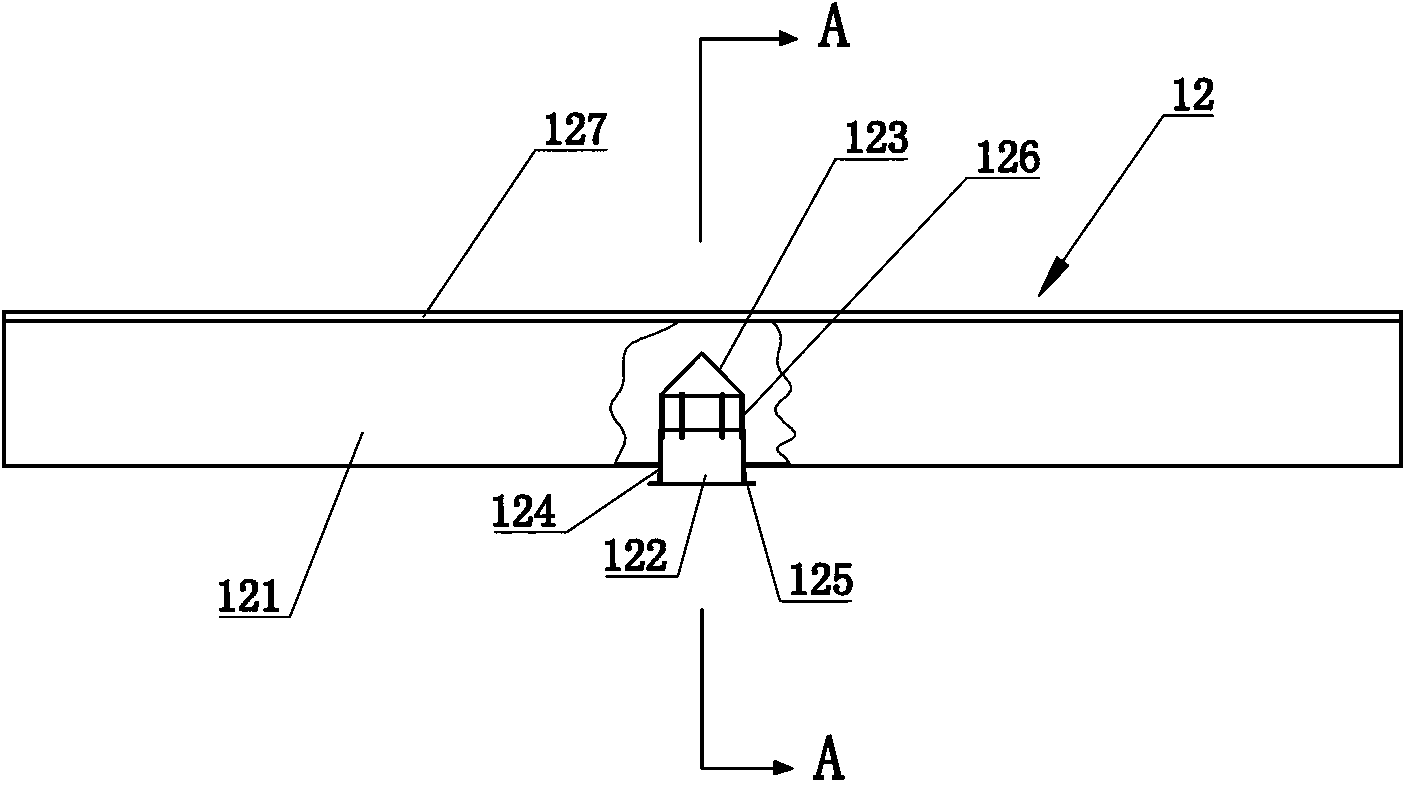

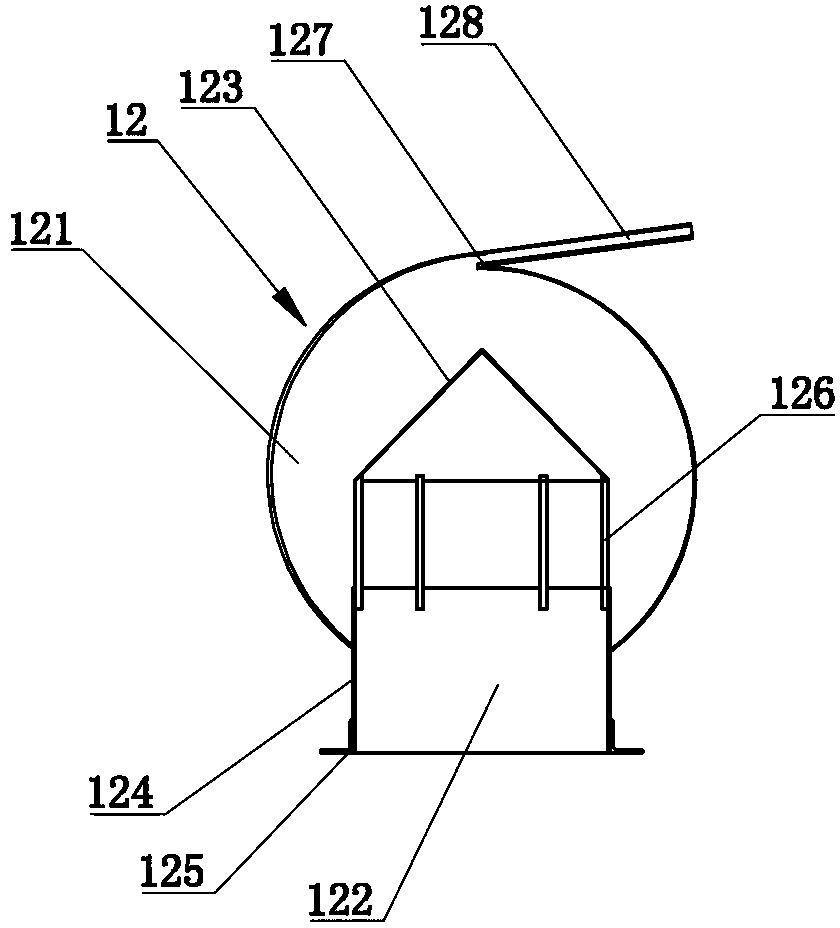

[0024] figure 1 It is a structural schematic diagram of the poisonous and harmful gas treatment equipment in the workshop of the present invention; figure 2 Yes figure 1 Schematic diagram of the structure of the air curtain tube in ; image 3 Yes figure 2 A-A sectional enlarged schematic diagram of ; Figure 4 Yes figure 1 Schematic diagram of the connection between the induced draft fan and the plenum box; Figure 5 Yes figure 1 Schematic diagram of the structure of the wind collecting hood; refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the poisonous and harmful gas treatment equipment in the workshop of the present invention comprises the air supply system 1, the air suction system 2 and the treatment discharge system 3 arranged in sequence; Connected to the air inlet 122 of the air curtain tube, the air outlet 127 of the air curtain tube extends along the axial direction of the air curtain tube 12 and is located above the toxic and harmfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com