Anti-corrosion oil jetting tool for inner cavity of wind power pre-buried screw sleeve

An anti-corrosion oil and pre-embedded technology, which is applied in the direction of spraying devices, can solve the problems of multi-coating or missed coating, uneven anti-corrosion oil spraying, low efficiency, etc., and achieve the effect of consistent moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is further described in detail through specific implementation methods:

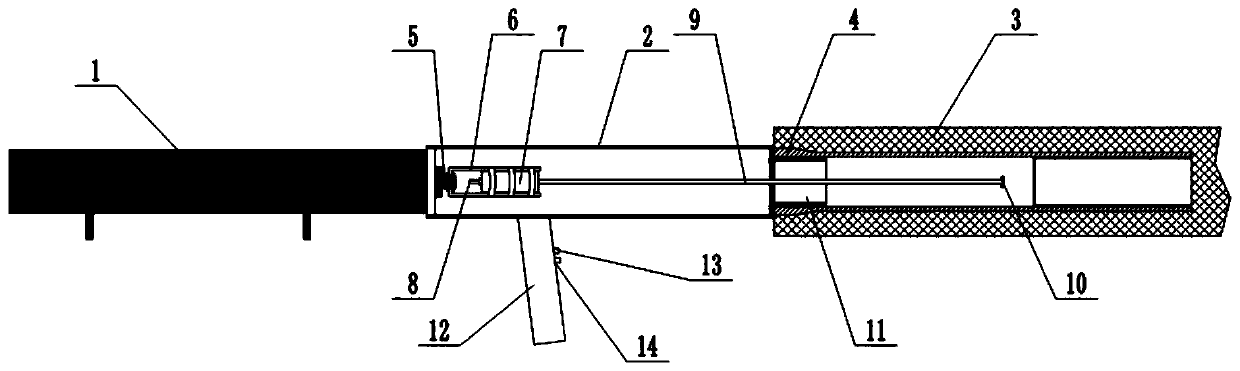

[0014] The reference signs in the drawings of the description include: cylinder 1, main frame 2, wind turbine blade 3, embedded screw sleeve 4, telescopic rod 5, fixed block 6, handle of spray gun 7, air cap 8, gun nozzle 9, nozzle 10 , a positioning block 11, a tooling handle 12, a "forward" button 13, and a "backward" button 14.

[0015] The embodiment is basically as attached figure 1 Shown: a wind power pre-embedded screw sleeve inner cavity anti-corrosion oil injection tooling, including the driving part, the main frame 2, the spray gun, the positioning block 11 and the control assembly, the spray gun is horizontally connected to the inside of the main frame 2, the driving part in this implementation Adopt cylinder 1, cylinder 1 is fixed on the main frame 2, is fixed with fixed block 6 outside the handle 7 of spray gun, and fixed block 6 is fixed with the telescoping link 5 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com