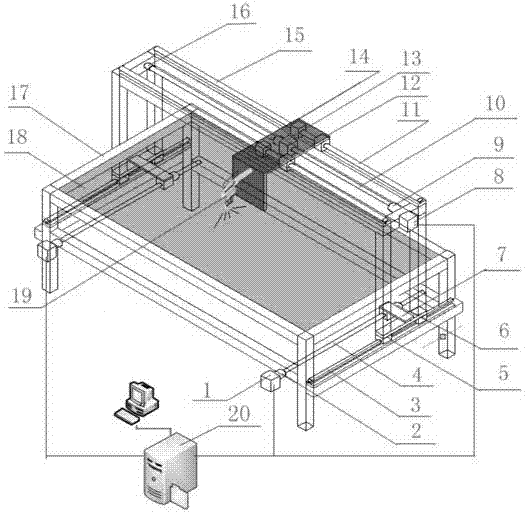

Intelligent nano anti-pollution coating spraying system

An anti-pollution, spray system technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems such as the limitation of the technical level of spraying quality operators, difficult control of stability, etc., and achieve the improvement of spraying efficiency, uniform moving speed and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

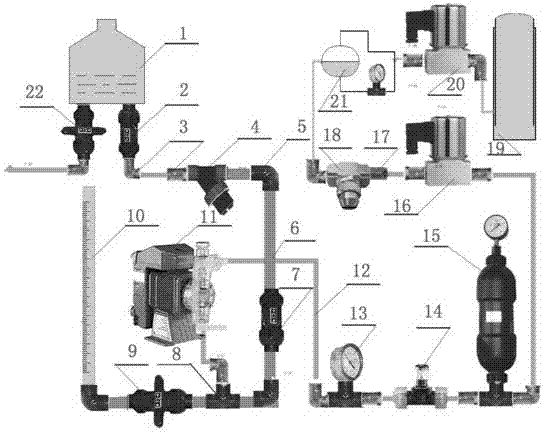

[0022] 1, figure 1 The nanometer anti-pollution coating in the Sinopolymer tank (1) is filtered by the filter (4) after the shut-off valve (2) is opened, and then enters the metering pump (11), then passes through the back pressure valve (14) and the damper (15) After obtaining a stable quantitative flow. After the electric valve (16) is opened, it is sprayed through the aerosol nozzle (18). At the same time, the compressed air in the air compressor (19) is supplied to the aerosol nozzle (18) through the voltage regulation of the pressure regulating valve (21) after passing through the electric valve (20). After atomization, it is sprayed with a stable fan-shaped mist, and is ready for uniform spraying of the object to be sprayed. The check valve (17) can prevent the compressed air from blowing back into the nanometer anti-pollution paint pipeline and prevent the nanometer anti-pollution paint from flowing back. A certain amount of nano-scale anti-pollution paint can be fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com