Welding gun moving apparatus of jackrod abrasion-proof belt welding machine

A wear-resistant band and welding machine technology, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of uneven thickness of wear-resistant band, poor welding quality, uneven movement, etc., and achieve good welding quality, The effect of uniform thickness and uniform axial movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

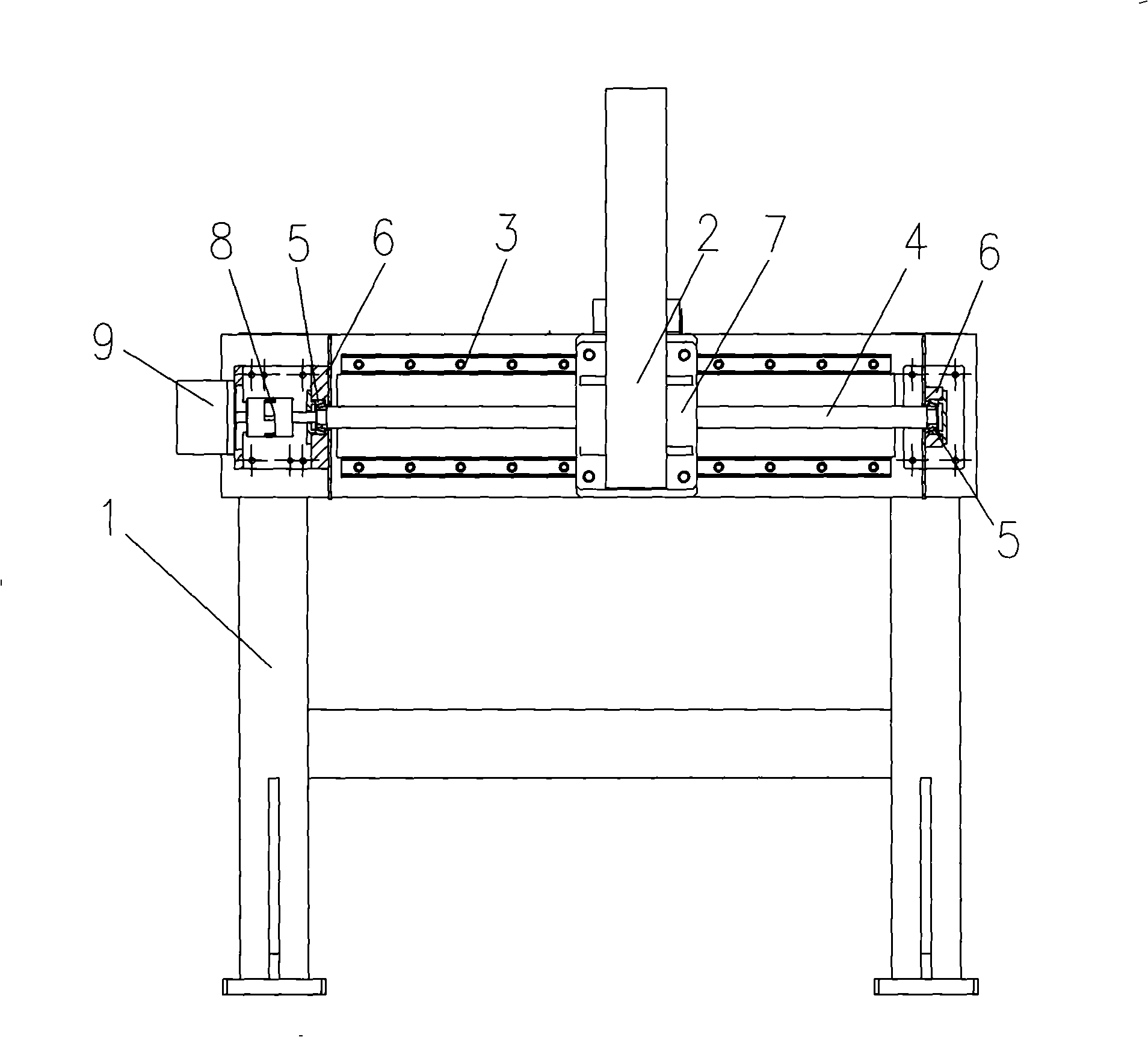

[0008] As shown in Figure 1, the welding torch moving device of a drill pipe wear-resistant band welding machine of the present invention includes: a mounting frame 1, a ball screw and a tubular moving column 2, a slide rail 3 is installed on the mounting frame, a ball screw The screw 4 in the ball screw is fixedly connected to the mounting frame 1 through the bearing 5 and the bearing seat 6, the tubular moving column 2 is fixedly connected to the nut in the ball screw through the slider fixedly connected to it, and the slider 7 is connected to the nut on the mounting frame 1. The slide rails 3 are connected, and the welding gun is connected to the tubular moving column 2; it is characterized in that one end of the lead screw 4 in the ball screw is connected with the stepper motor 9 through the coupling 8, and the stepper motor 9 is fixedly connected to the on the mounting bracket 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com