Device for measuring rotational inertia and friction moment of ball screw

A technology of ball screw and friction torque, applied in the direction of measuring device, static/dynamic balance test, torque measurement, etc., can solve the problem of no ball screw, etc., achieve reliable measurement results, simple structure, and improve sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

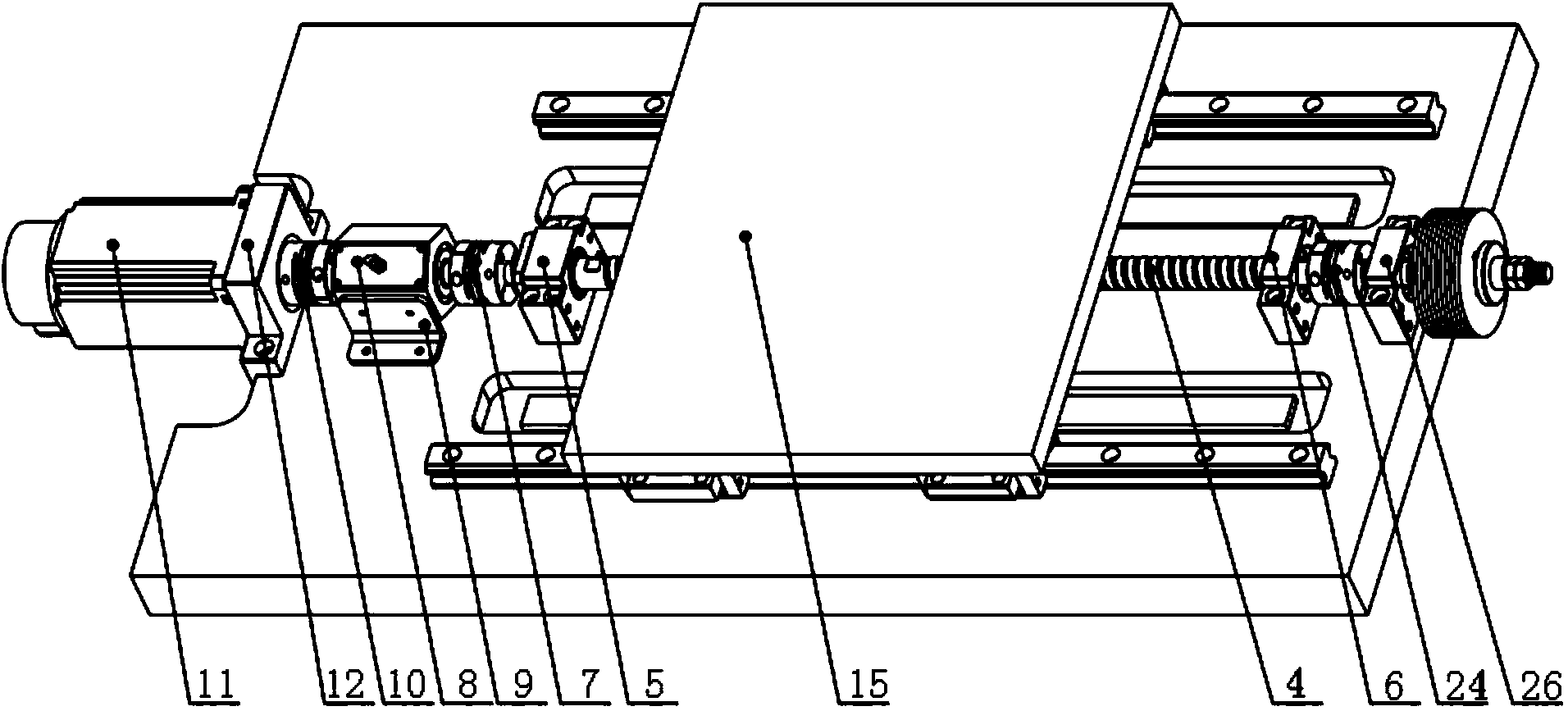

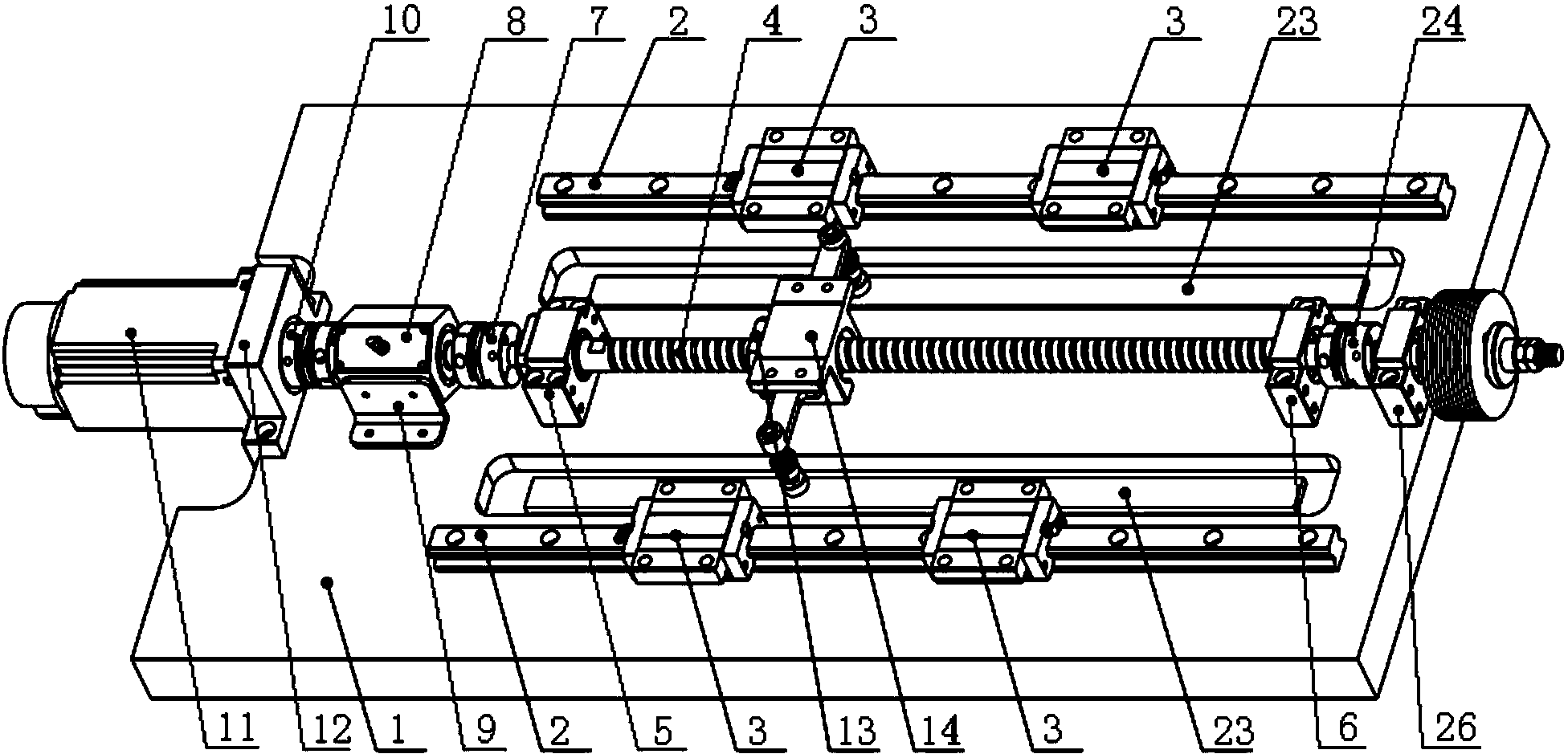

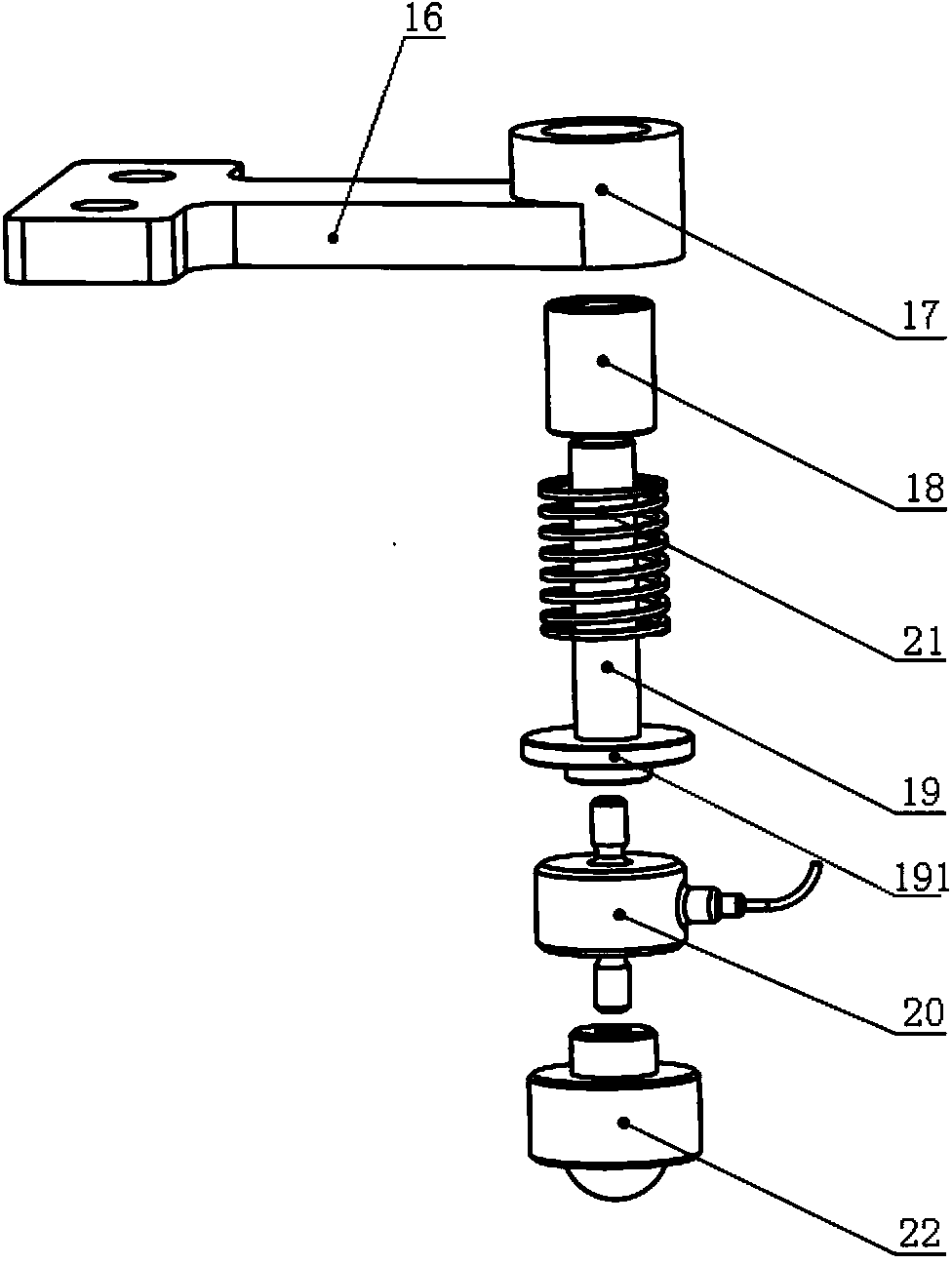

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a bottom plate 1, two linear guide rails 2 are arranged in parallel at intervals on the top surface of the bottom plate 1, and two sliders 3 are respectively arranged on each linear guide rail 2. In the middle of the two linear guide rails 2, a ball screw 4 is installed in parallel. One end of the ball screw 4 is rotatably supported on a fixed support seat 5, and the other end is rotatably supported on a floating support seat 6 (a ball screw here). Conventional setting when the bar 4 is installed, that is, in the two support seats, one of them is immovable with the ball screw 4 in the axial direction, and the other is slidable with the ball screw 4 in the axial direction). Both the fixed support base 5 and the floating support base 6 are fastened to the bottom plate 1 . On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com