Continuous, quantitative and rotary feeder

A technology of rotary feeder and rotary block, which is applied in the direction of transportation, packaging, loading/unloading, etc. It can solve the problems of easy blockage of the screw, easy moisture of the medicine, and inaccurate measurement, so as to prevent moisture from entering the material bin and reduce costs. Inexpensive, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

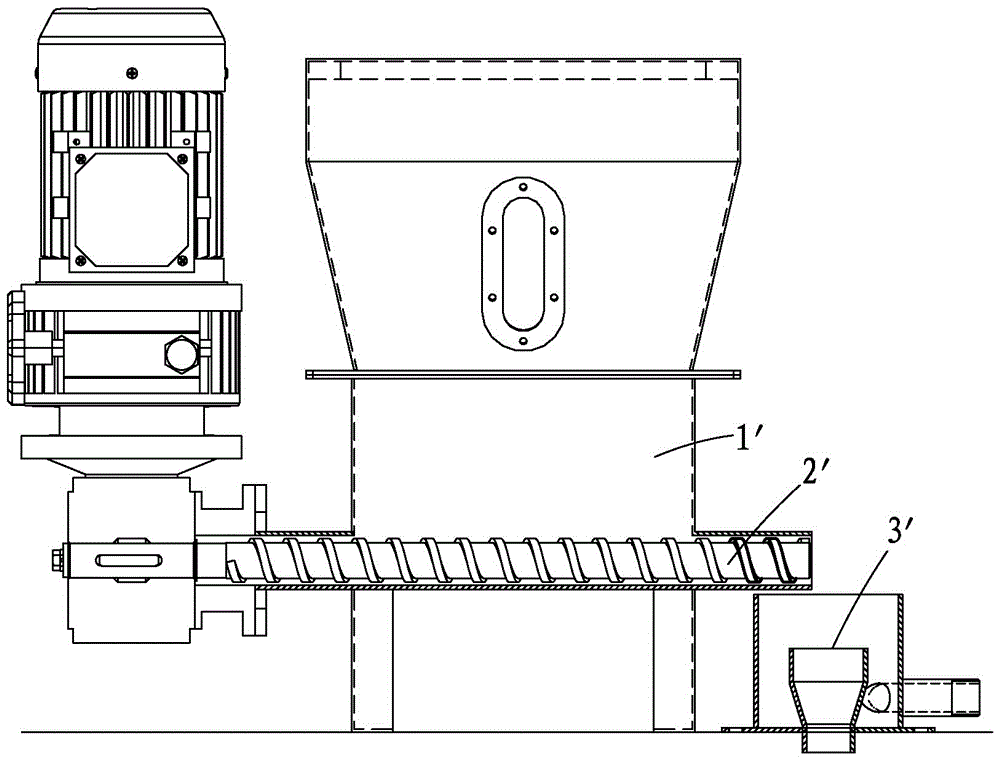

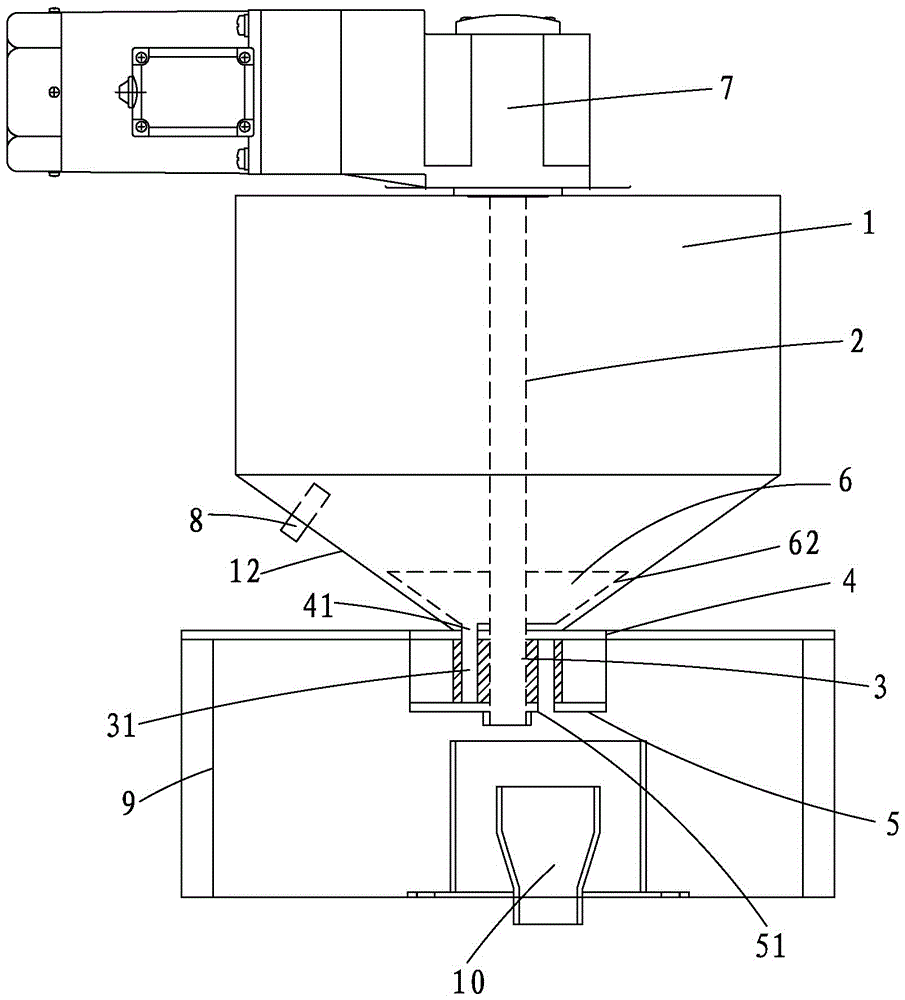

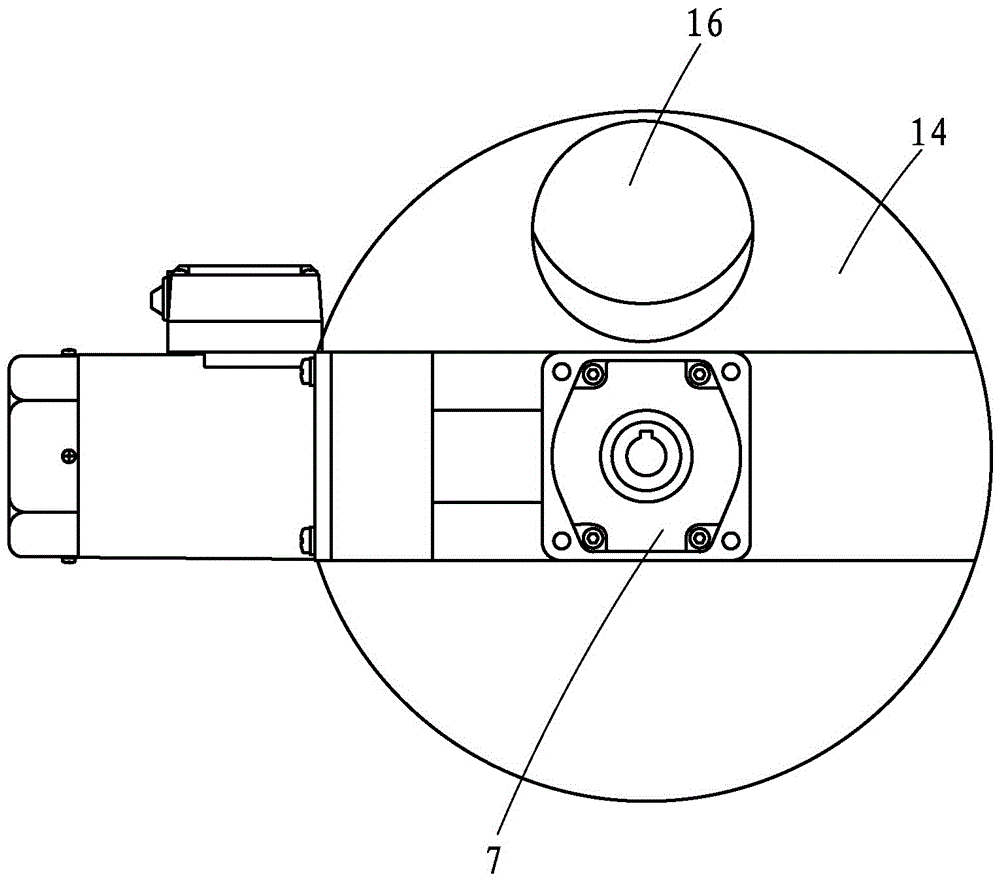

[0036] see Figure 2 to Figure 6 As shown, the continuous quantitative rotary feeder of the present invention includes a feed bin 1, a central shaft 2, a rotating block 3, an upper sealing plate 4, a lower sealing plate 5, a homogeneous stirring blade 6, a driving motor 7, and a material sensor 8. The bracket 9 and the material inlet 10.

[0037] The rotating block 3 is provided with quantitative holes 31 that are transparent up and down; the upper sealing plate 4 is provided with a feed port 41 and is located at the bottom of the silo 1; the lower sealing plate 5 is provided with a discharge port 51; The rotating block 3 is arranged between the upper sealing plate 4 and the lower sealing plate 5 and is driven to rotate by the central drive shaft 2, and during the rotating process of the rotating block 2, the quantitative holes 31 are only intermittently connected to the The feed port 41 or the discharge port 51, that is, when the feed port 41 is connected, the discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com