A kind of automatic production equipment of high-performance instant glue powder

A technology of instant gel powder and production equipment, applied in the direction of dissolution, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased burden on enterprises, high labor costs, and reduced product quality, so as to reduce the content of fine dust, Improving the environmental quality and ensuring the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

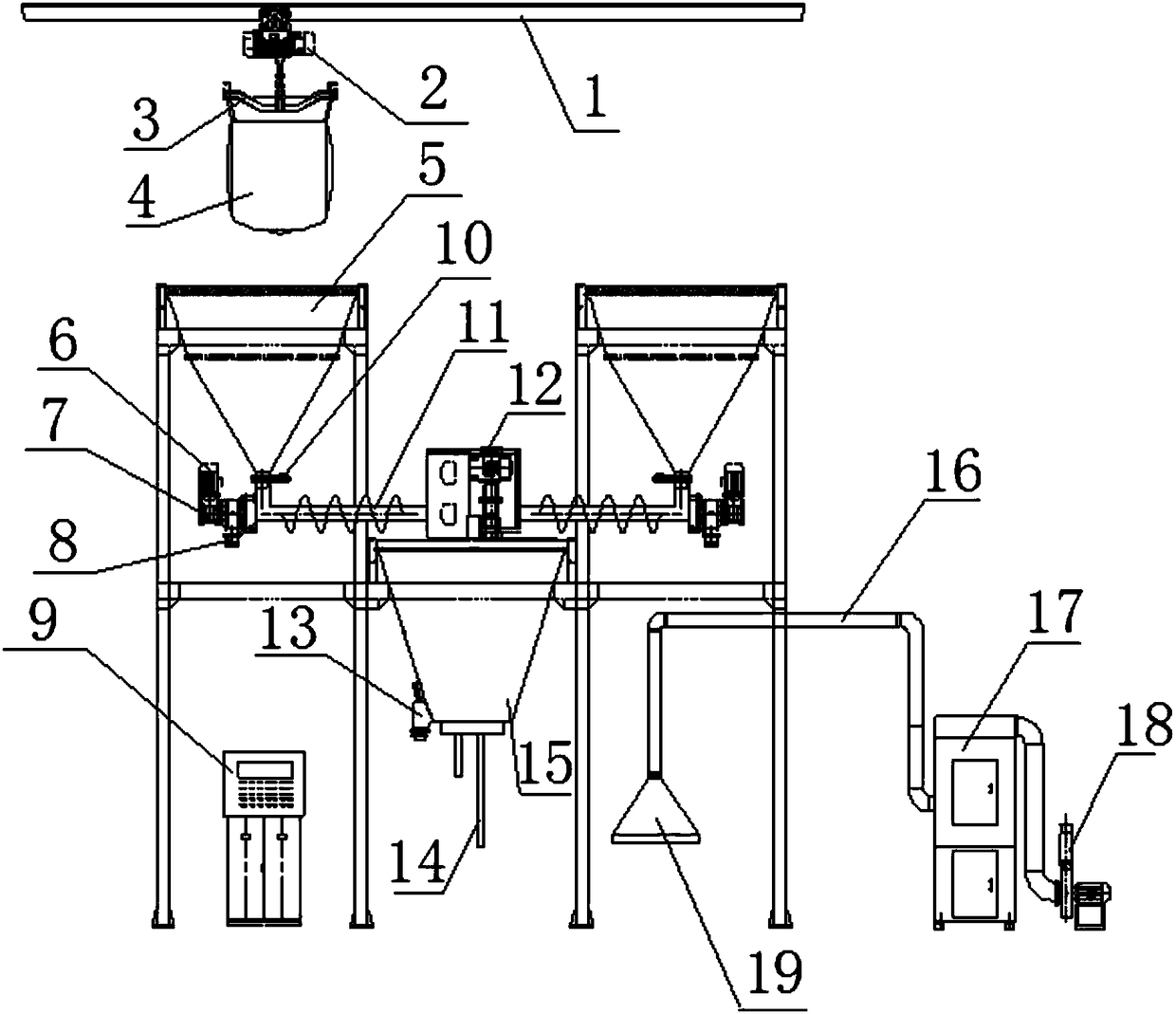

[0043] A kind of automatic production equipment of high-performance instant glue powder, such as figure 1As shown, it includes two material bins 5 and a reactor 15. The two material bins 5 are respectively used to hold main materials and auxiliary materials. The material bin 5 is a funnel-shaped structure fixed on a bracket. The bracket structure can ensure that the material bin 5 The opening is open to the top. The two material bins 5 are respectively connected to the reactor 15 through the feeding pipe 11. The feeding screw rod is provided in the feeding pipe 11. The feeding screw rod is connected to the motor 6 through the reducer 7, and the motor 6 drives the feeding screw rod to rotate. , to realize the feeding of the main material or auxiliary material, and the speed reducer 7 is also connected with the rotational speed measuring device 8 . The rotational speed measuring device 8 can measure the rotational speed of the feed screw rod, and the speed of the feed screw rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com