Frequency conversion motor and engineering machine with same

A technology of variable frequency motors and frequency converters, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of insufficient installation of motors and frequency converters, high motor power, and large frequency converter volume, etc., to achieve compact structure and energy saving Effects of cost and number of parts reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

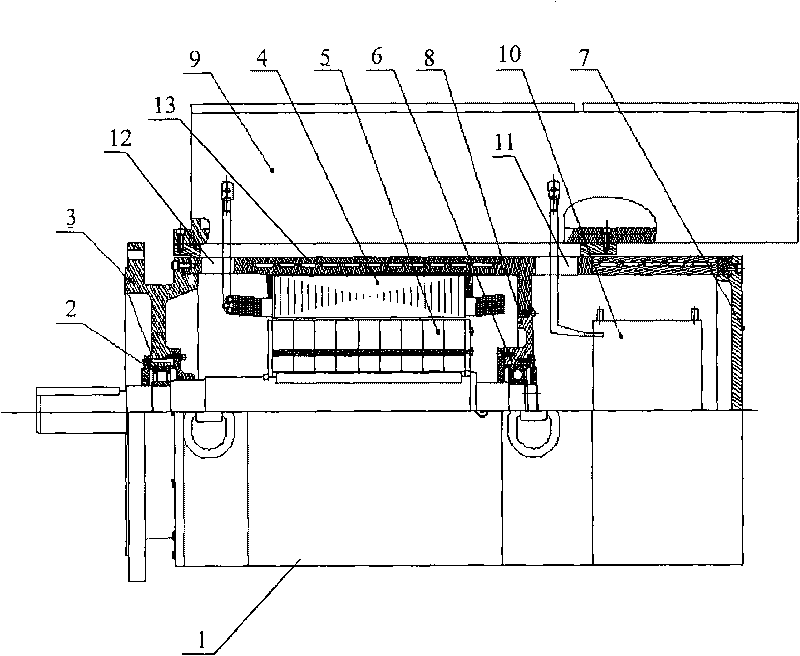

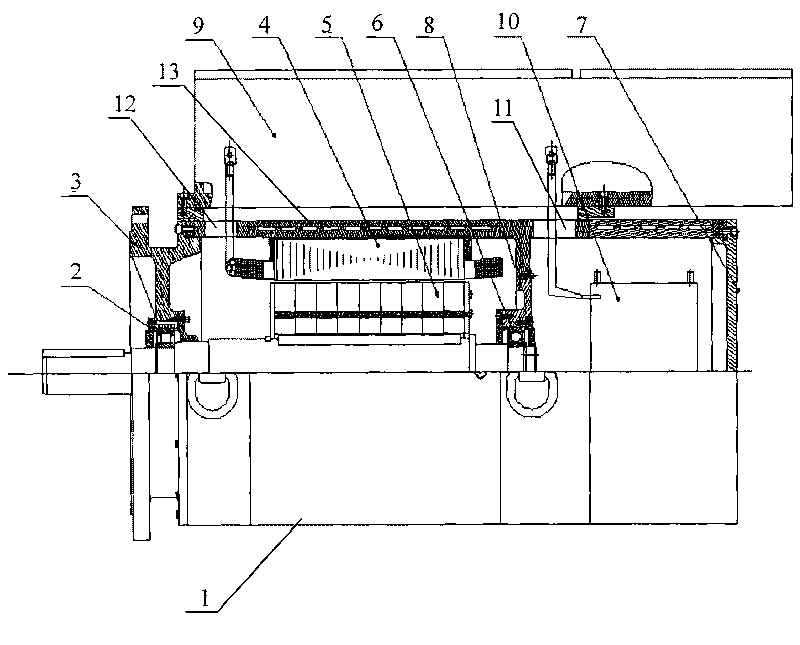

[0018] The only accompanying drawing of the present invention shows a cross-sectional view of a variable frequency motor according to a preferred design solution of the present invention.

[0019] from figure 1 As can be seen in , the frequency conversion motor includes a motor unit 1 and a frequency converter unit, wherein the motor unit 1 has a drive end bearing 2, a drive end cover 3, a stator 4, a rotor 5, a non-drive end bearing 6, and a non-drive end cover 7 and the non-drive end inner cover 8. The frequency converter unit has a frequency conversion control cabinet 9 and a line reactor 10 .

[0020] In this embodiment, the stator 4 includes a stator core and a machine base. The stator core is formed by laminating silicon steel sheets. The pressure plates are installed at both ends of the core. Weld with the pressure plate. The winding of the stator 4 is a loose-embedded winding, and the corona-resistant enameled wire with an insulation grade of H is used for the loose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com