Wheel stabilization structure capable of generating power by utilizing integrated kinetic energy in vehicle running

A technology for driving and stabilizing the structure of a vehicle, applied to vehicle components, auxiliary drive devices, elastic suspensions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

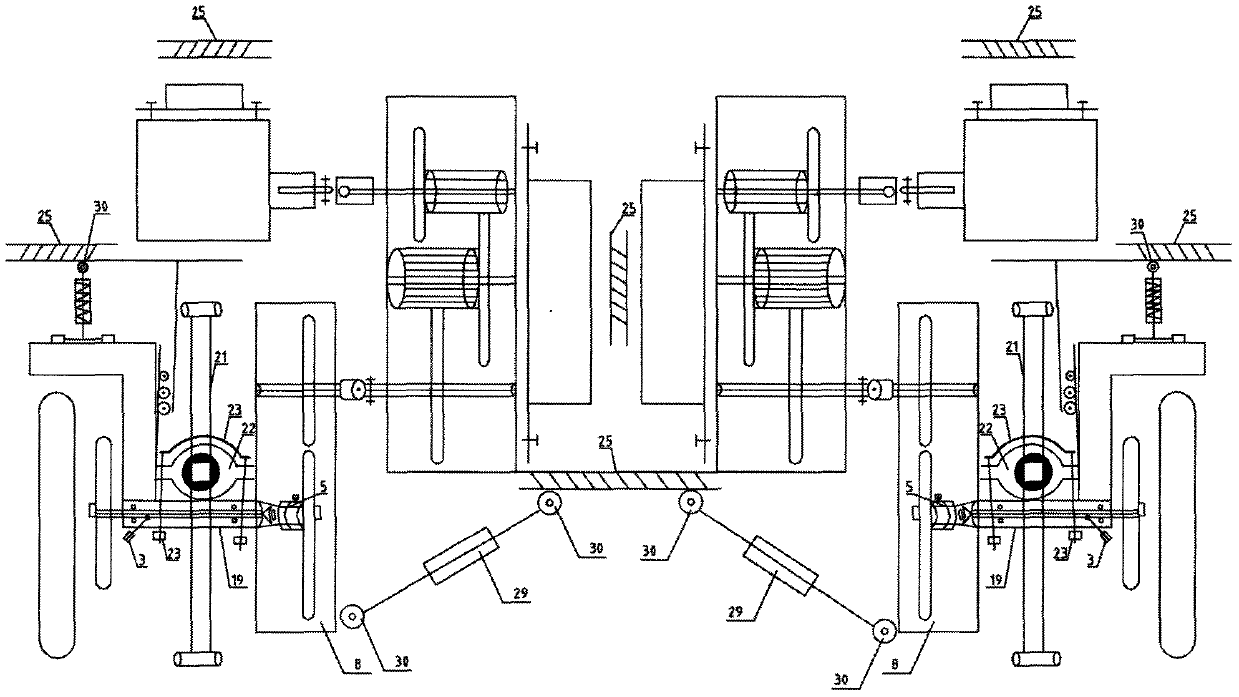

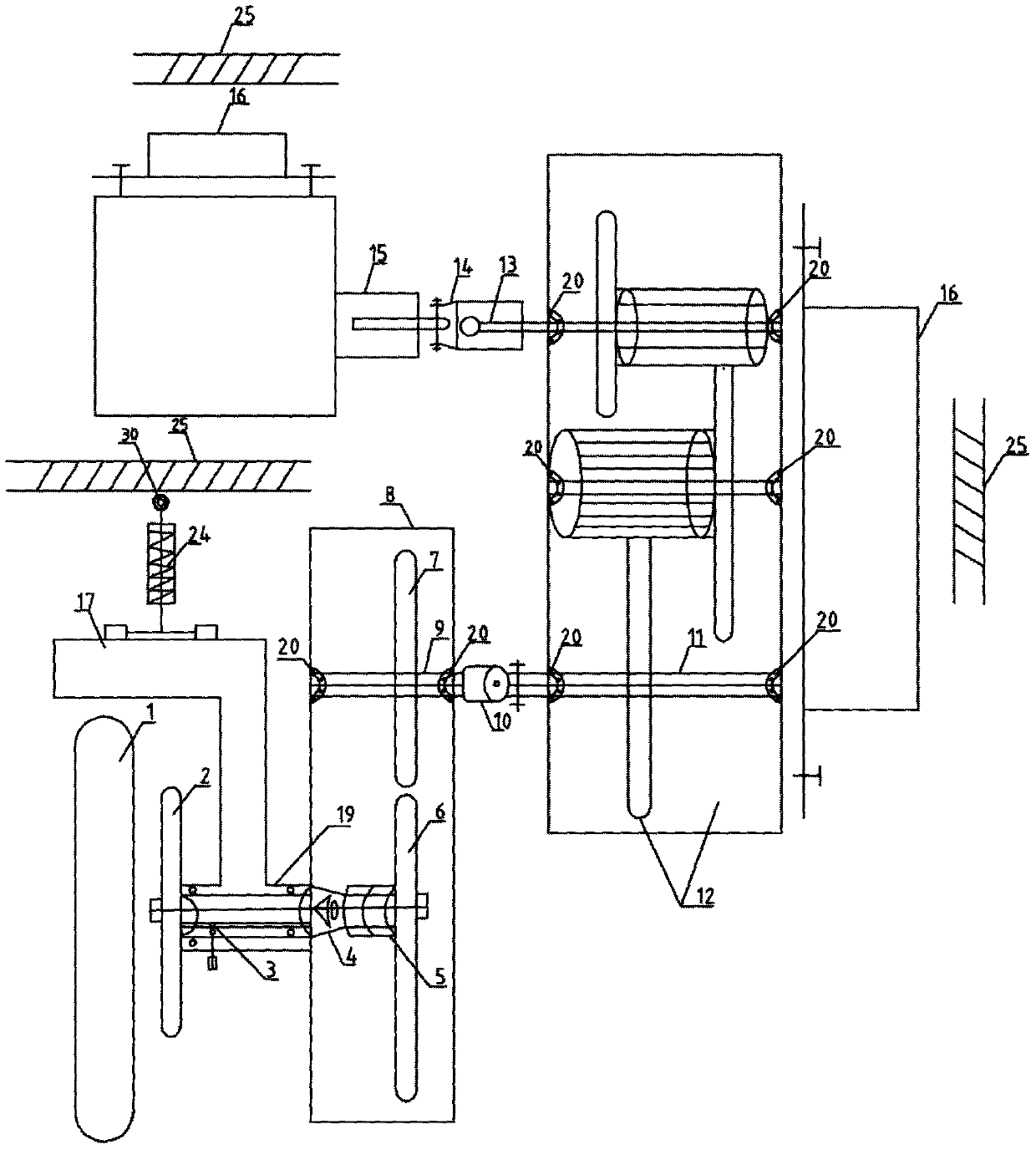

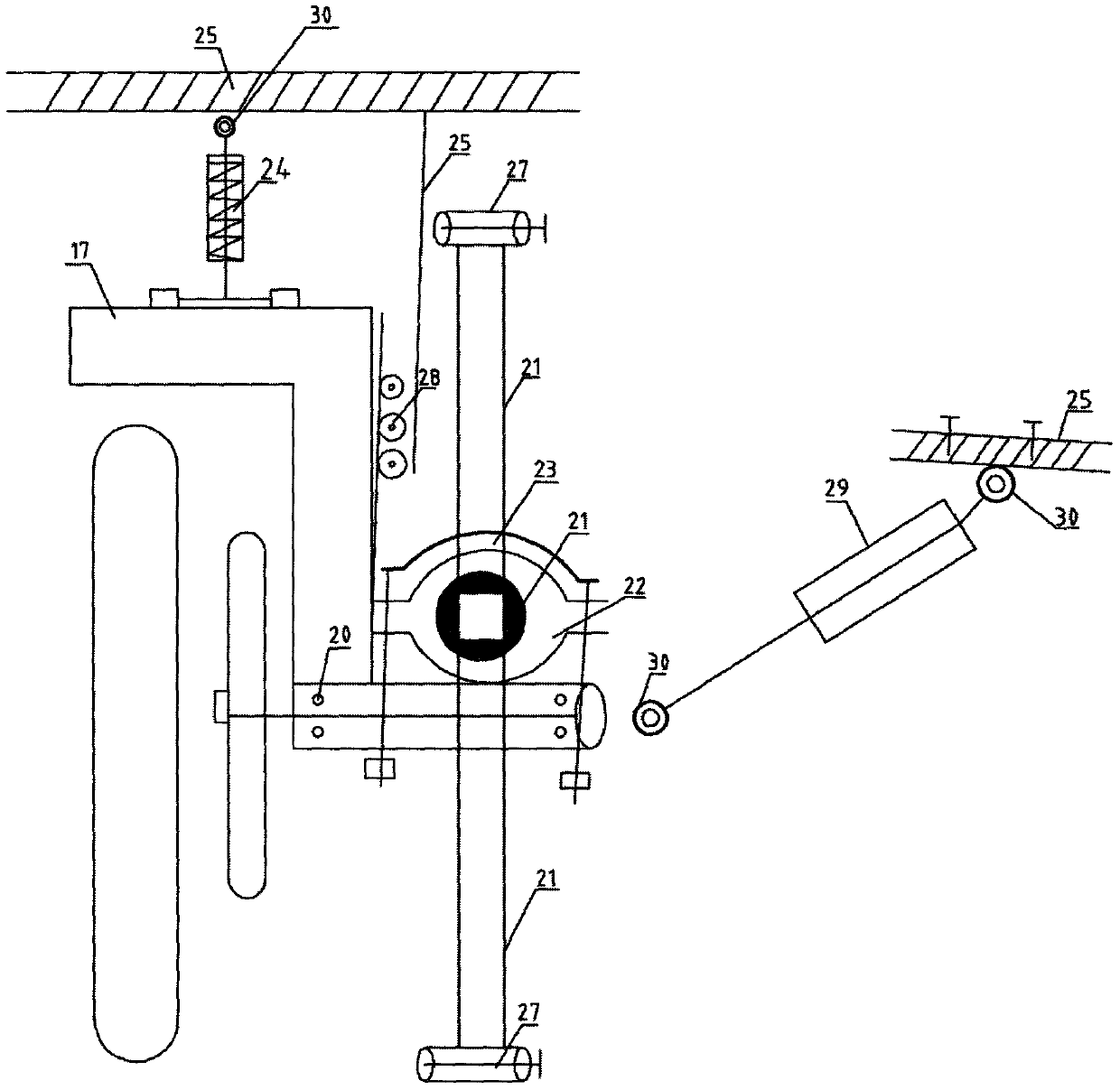

[0034] Such as Figure 1 to Figure 4 As shown, a structure using comprehensive kinetic energy power generation and wheel stabilization during vehicle running, and a structure utilizing comprehensive kinetic energy power generation and wheel stability during vehicle running, wherein the main components and connection methods of the comprehensive kinetic energy power generation structure during vehicle running include wheel and fasteners 1, brake disc and fasteners 2, transmission shaft and transmission shaft lock pin 3, overrunning clutch 4, overrunning clutch sleeve 5, driving gear and fixing piece 6, driven gear with one-way pulley and Fixing part 7, driving and driven gear box 8, driven gear output shaft 9, telescopic universal joint coupling and fixing part 10, input shaft of variable speed torque converter 11, gear of variable speed torque converter And gear box 12, output shaft 13 of speed-regulating torque converter, universal coupling and fixing parts 14, generator and ...

Embodiment 2

[0047] This embodiment is further limited on the basis of Embodiment 1: as a simple and easy-to-implement technical solution, the driven gear with a one-way pulley and the driven gear output shaft 9 are the driven gear and the single There is an interference fit to the pulley or a fastener for the connection between the two. The interference fit between the one-way pulley and the output shaft of the driven gear makes the two form an assembly. The two ends of the output shaft head Bearings, limiters and fixing parts are set separately, and the output end is an external spline shaft, which is used to connect with the spline sliding telescopic sleeve in the expansion joint of the universal joint, so that the two shafts can reach the two shafts due to the contraction and extension of the suspension. It can transmit power smoothly when the axes cross and the mutual position changes frequently.

[0048] As a simple and easy-to-implement technical solution, the bearing, bearing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com