Centrifugal feeding machine

A centrifugal and feeder technology, applied in the field of feeder, can solve the problems of loud noise, inability to adjust, and inability to replace the structure, and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

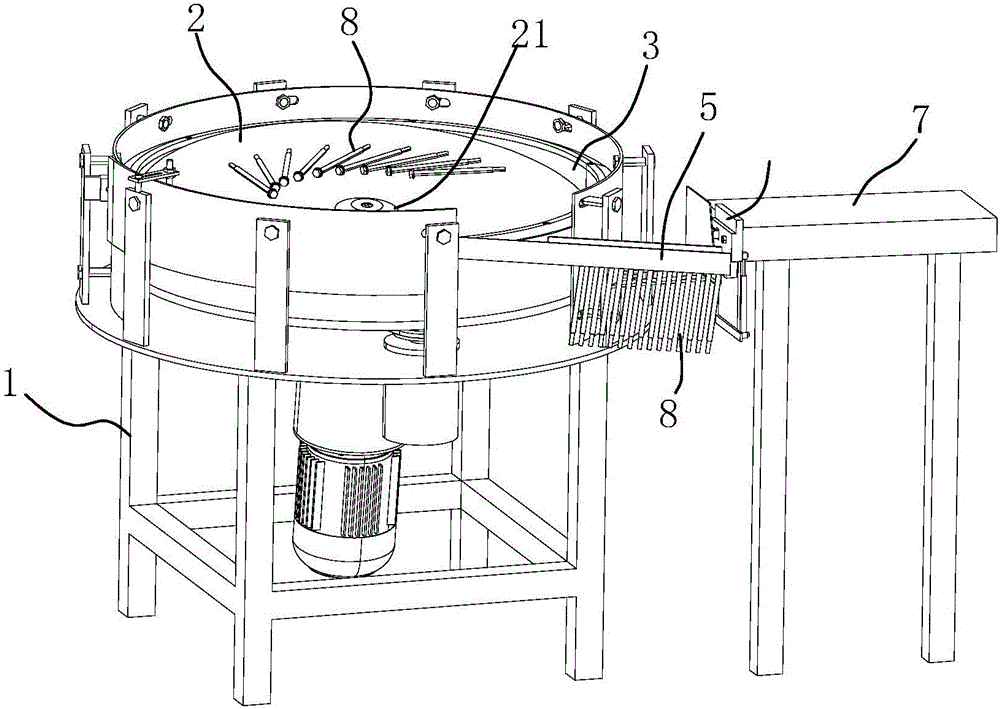

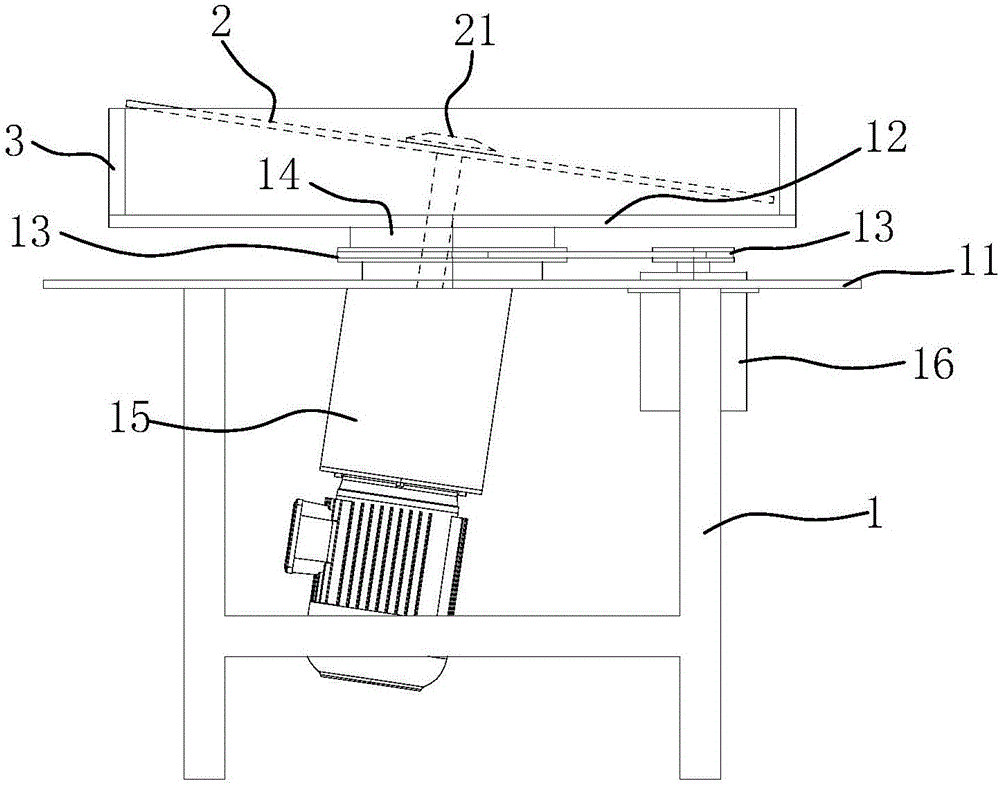

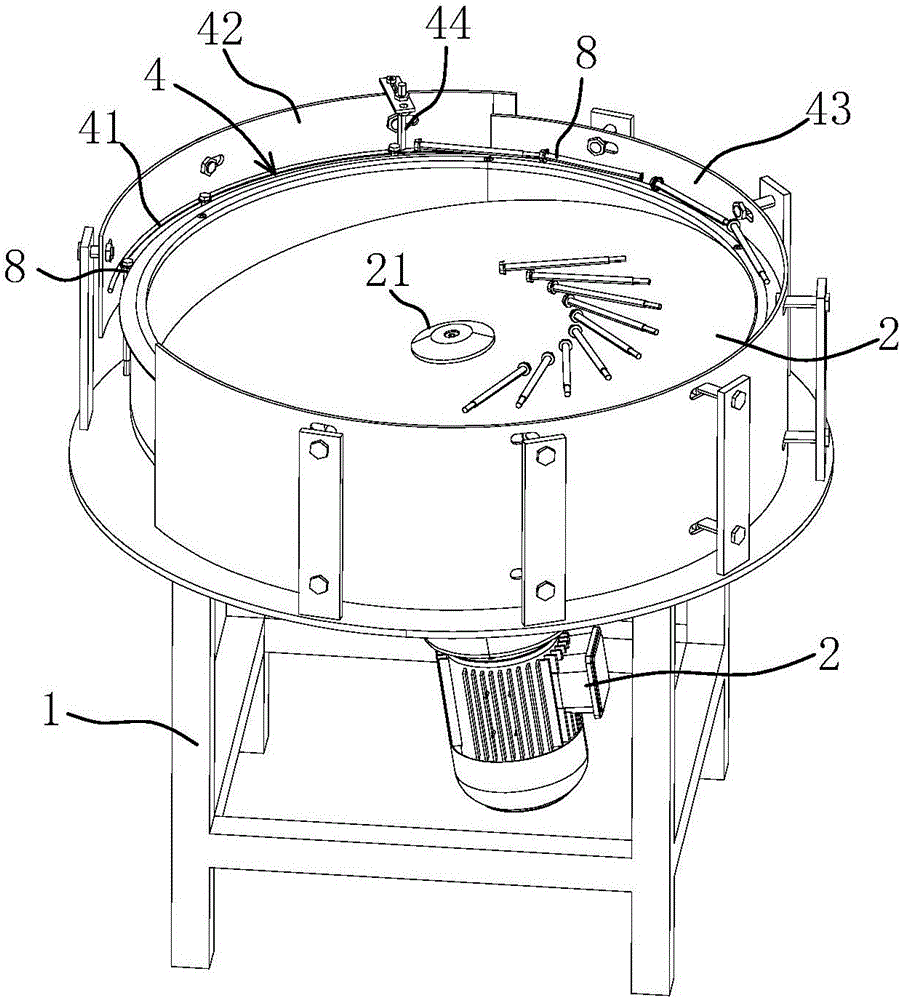

[0034] Please refer to the attached figure 1 , a centrifugal feeding machine, suitable for feeding scattered rod-shaped parts 8, such as fasteners that have not been threaded, including a frame 1, an inner turntable 2 is arranged above the frame 1, and An outer turntable 3 is arranged outside the turntable 2, wherein the inner turntable 2 and the outer turntable 3 are driven by independent motors, and a discharge track 4 is arranged outside the outer turntable 3, wherein unsorted fasteners are placed The centrifugal force is provided after the inner turntable 2 realizes the rotation, and the centrifugal force drives the fasteners into the discharge track 4, and is sent out along the discharge track 4 under the drive of the outer turntable 3, and enters the undetermined track 5, and is clamped The piece 6 is clamped into the straight feed channel 7 to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com