Flexible heat conduction/heat storage double-function composite material, method for manufacturing same and application of flexible heat conduction/heat storage double-function composite material

A technology of composite materials and phase-change heat storage materials, which is applied in the field of flexible heat conduction/heat storage dual-functional composite materials and their preparation, can solve the problems of inability to absorb or store heat, hinder the application of electronic equipment, and slow response time, etc., to achieve good results Cooling effect, prolonging service life, and reducing hot spot temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

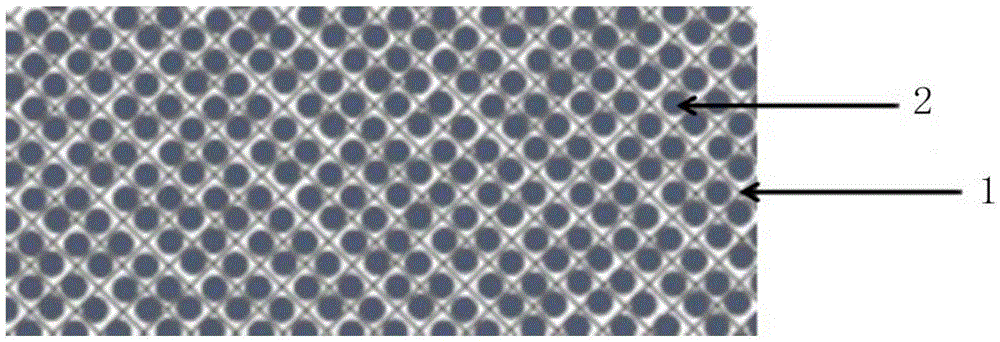

[0028] Disperse 40wt% sodium acetate trihydrate in the aqueous solution and stir evenly, then disperse 60wt% graphene in the solution and sonicate for 24 hours to obtain an aqueous solution of graphene-loaded sodium acetate trihydrate particles. The solution is dried and molded to prepare a flexible heat conduction / heat storage dual-functional composite material (film) with graphene as the matrix. Its structure is as figure 1 As shown, 1 is a three-dimensional network structure formed by a high thermal conductivity material, and 2 is a phase change heat storage material particle.

Embodiment 2

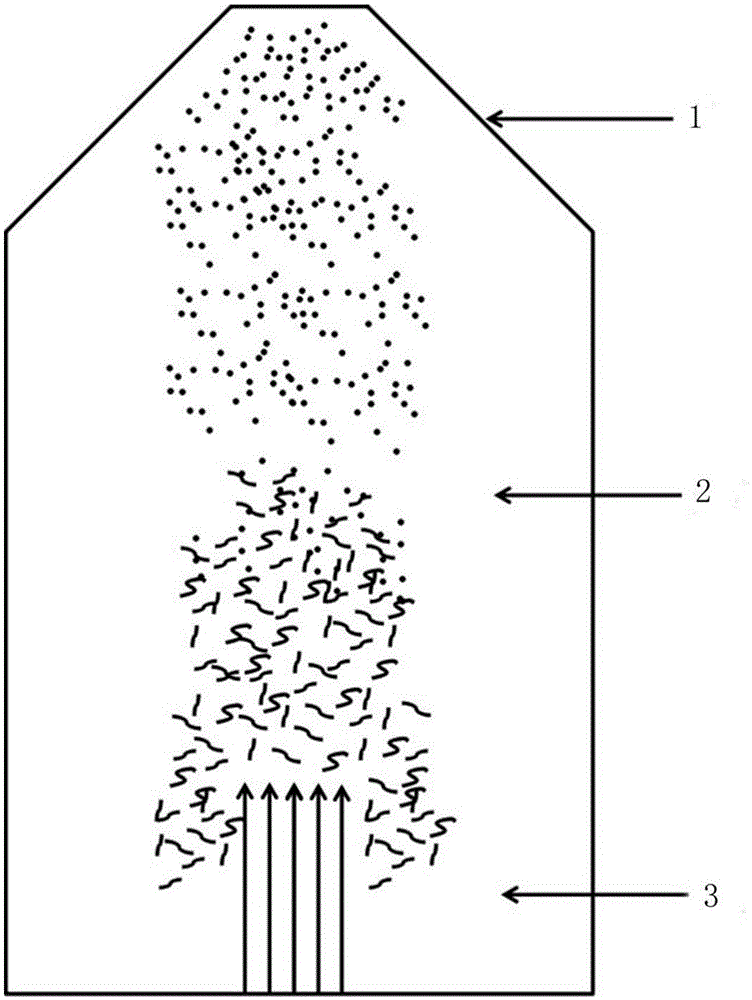

[0030] Such as figure 2 As shown, 20wt% of the paraffin is formed into micro-nano particles in the spray granulation zone 1 on the upper part of the furnace body through the process of spray granulation, and 80wt% of the nano-graphite flakes are blown by the airflow in the blowing zone 3 on the lower part of the furnace body. , the two materials meet in the loading zone 2 in the middle of the furnace body, the nano-graphite sheets loaded with paraffin particles will sink due to gravity, and finally obtain the powder of nano-graphite sheets loaded with paraffin particles. Roll molding of the powder can form a continuous flexible heat conduction / heat storage dual-functional composite material (film) with nano-graphite sheets as the matrix.

Embodiment 3

[0032] Disperse 33wt% calcium chloride hexahydrate in the aqueous solution and stir evenly, then disperse 67wt% carbon nanotubes in the solution and sonicate for 24 hours to obtain an aqueous solution of carbon nanotube-supported calcium chloride hexahydrate particles. The solution is dried and hot-pressed to prepare a flexible heat conduction / heat storage dual-functional composite material (film) with carbon nanotubes as the matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com