Non-flour dust overflow environment friendly intelligent fluidized bed airflow ultramicro crushing apparatus

A kind of airflow ultra-fine grinding and intelligent technology, which can be used in combination devices, chemical instruments and methods, grain processing, etc., and can solve problems such as harm to human health, harmful health, and flying dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

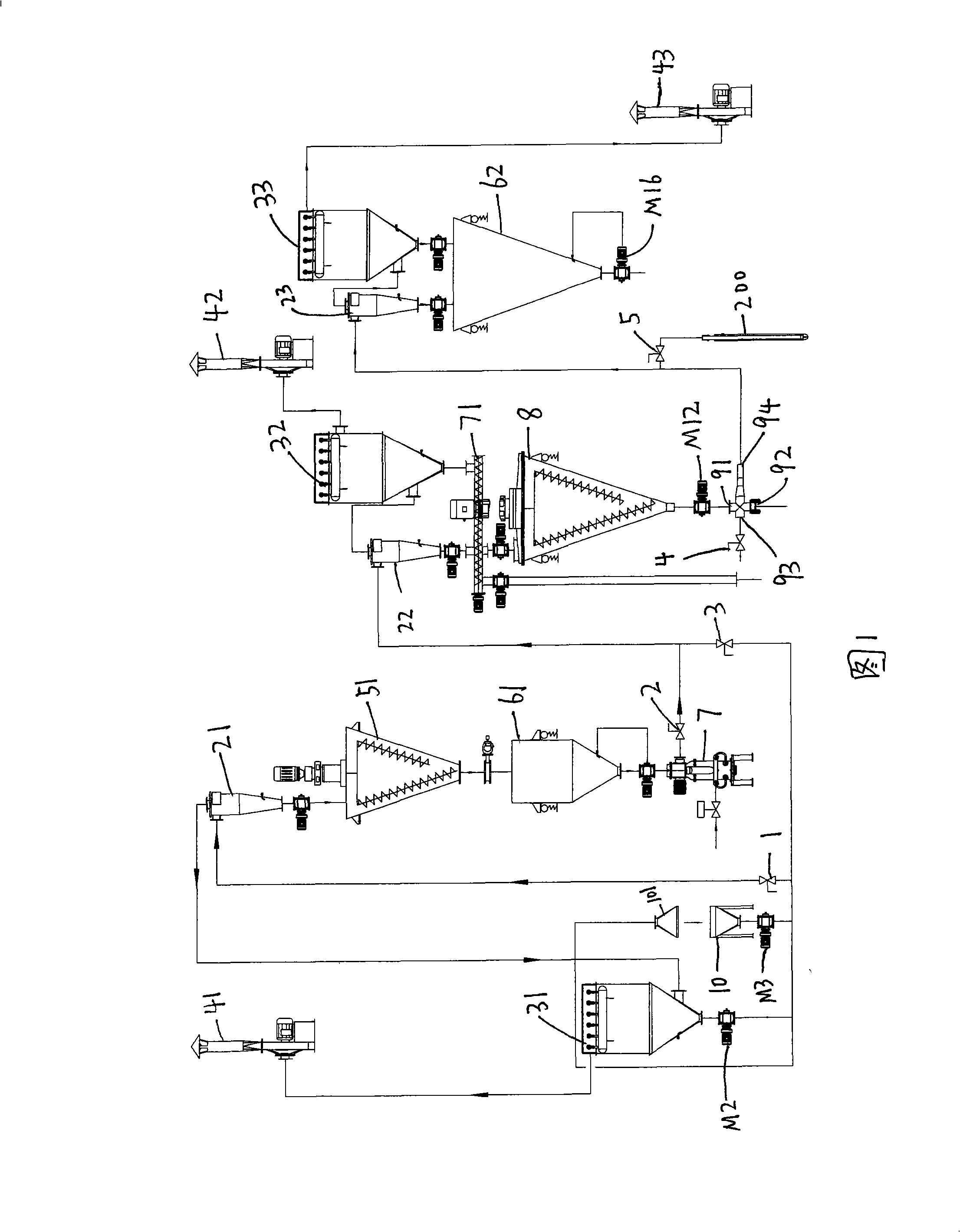

[0008] Embodiment: A dust-free, environmentally friendly, and intelligent fluidized bed airflow ultrafine pulverization device. The lower outlet of the feeding hopper 10 passes through the first rotary valve M3 and the first manual valve 1 in sequence, and then enters the upper end of the first cyclone separator 21. The material port is connected, and the lower discharge port of the hopper passes through the first rotary valve M3 and the third manual valve 3 at the same time, and then communicates with the upper end of the second cyclone separator 22. The outlet communicates with the feed port of the first pulse bag filter 31, the upper air outlet of the first pulse bag filter communicates with the first induced draft fan 41, and the material outlet at the lower end of the first pulse bag filter passes through the second rotary valve M2 and the second rotary valve M2 in turn. A manual valve 1 communicates with the feed inlet at the upper end of the first cyclone separator 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com