Energy-saving belt type sludge low-temperature drying device

An energy-saving, sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problem that the heat pump cannot be coupled, and achieve the effect of safe system operation, saving processing cost and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

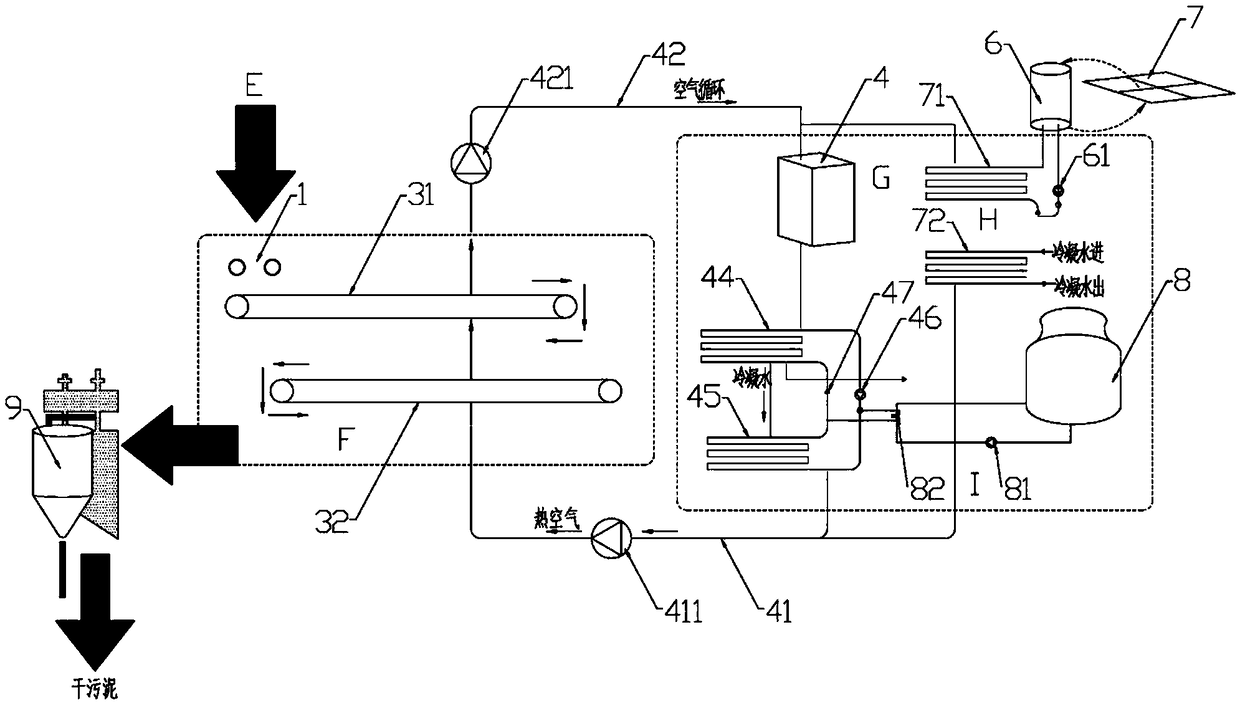

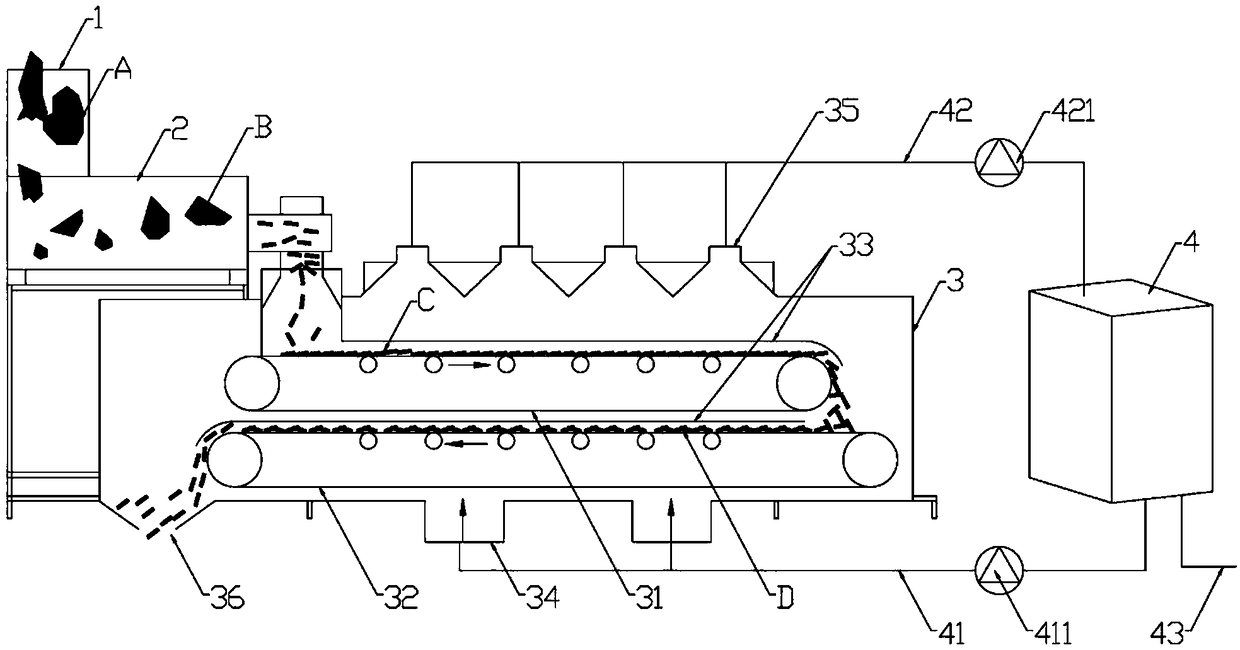

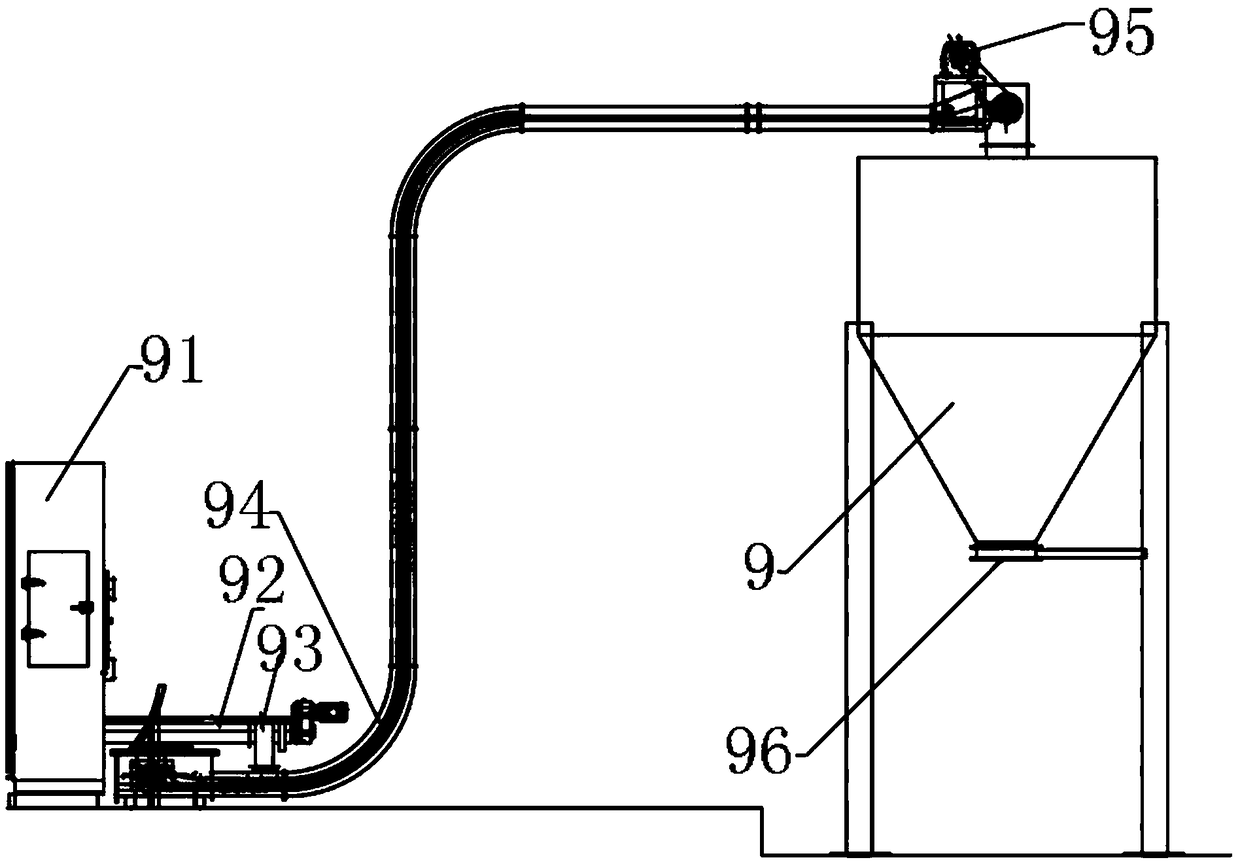

[0030] In this embodiment, the energy-saving belt-type sludge low-temperature drying device is combined with figure 1 , including the mud feeding forming area E, the drying area F, the circulation condensation area I and the heating area formed by the heat pump heating area G and the clean energy heating area H, the mud feeding forming area E is provided with a sludge inlet 11, and the sludge mechanical The sludge with a water content of about 80% produced by the dehydrator is irregular in shape, and it is sent into the mud forming area E, and formed into a strip, cake or pancake shaped sludge A through the mud forming machine 1. The shaped sludge A can be evenly spread on the conveyor belt in the drying area, which is an important part of the sludge dehydration process; the shaped sludge A enters the refinement zone 2 through the sludge inlet 11, and is refined in the refinement zone 2 into the pulverized filter cake B with a particle size of 5-8mm, and the pulverized filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com