Method and device for heating flowing fluid as well as heating equipment applying same

A technology of flowing fluid and heating equipment, which is applied to fluid heaters, lighting and heating equipment, coil devices, etc., can solve the problems of high energy consumption, easy damage, and low thermal efficiency of the devices, and achieve long service life, fast heating speed, The effect of high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An electric heating device.

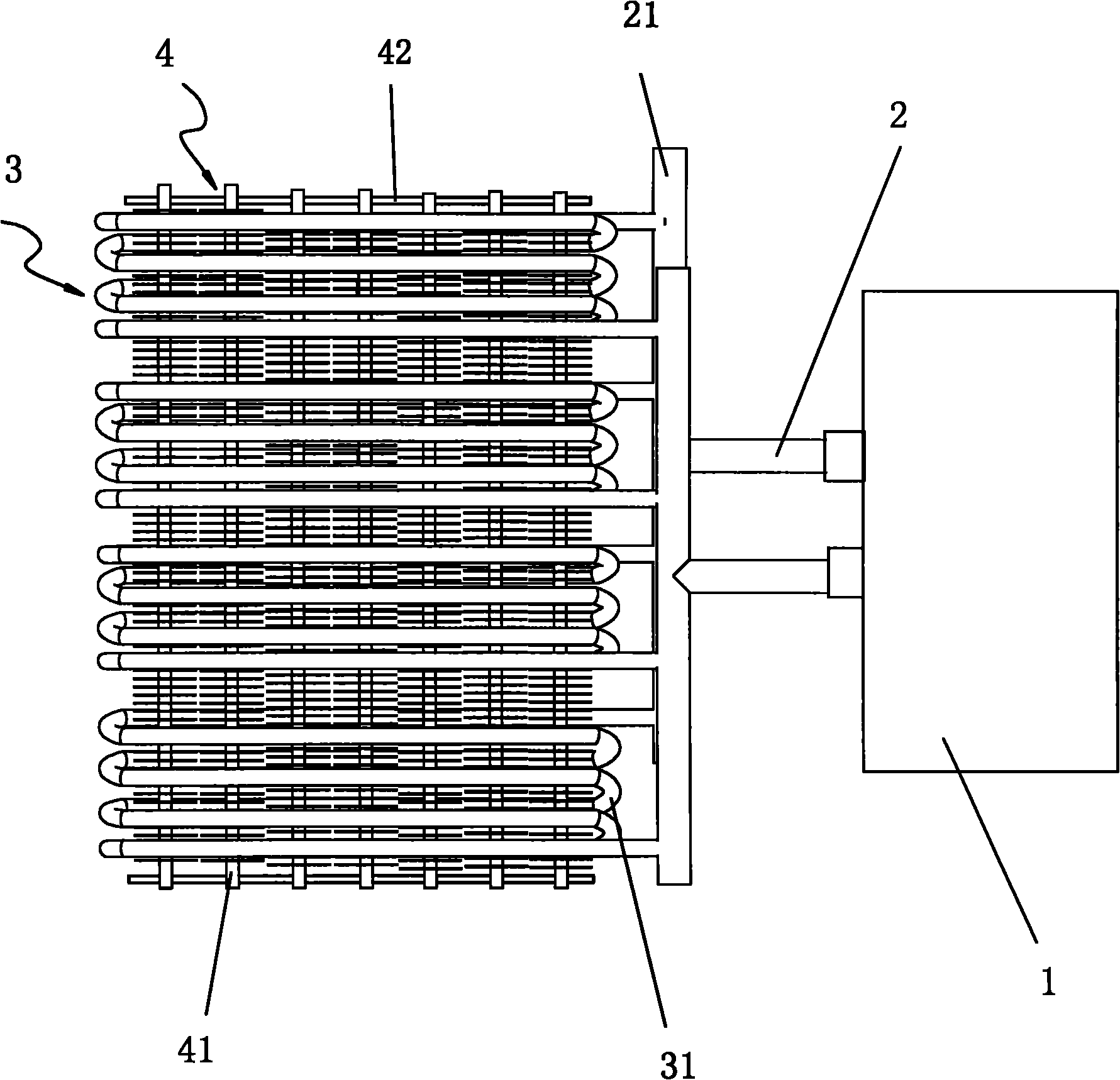

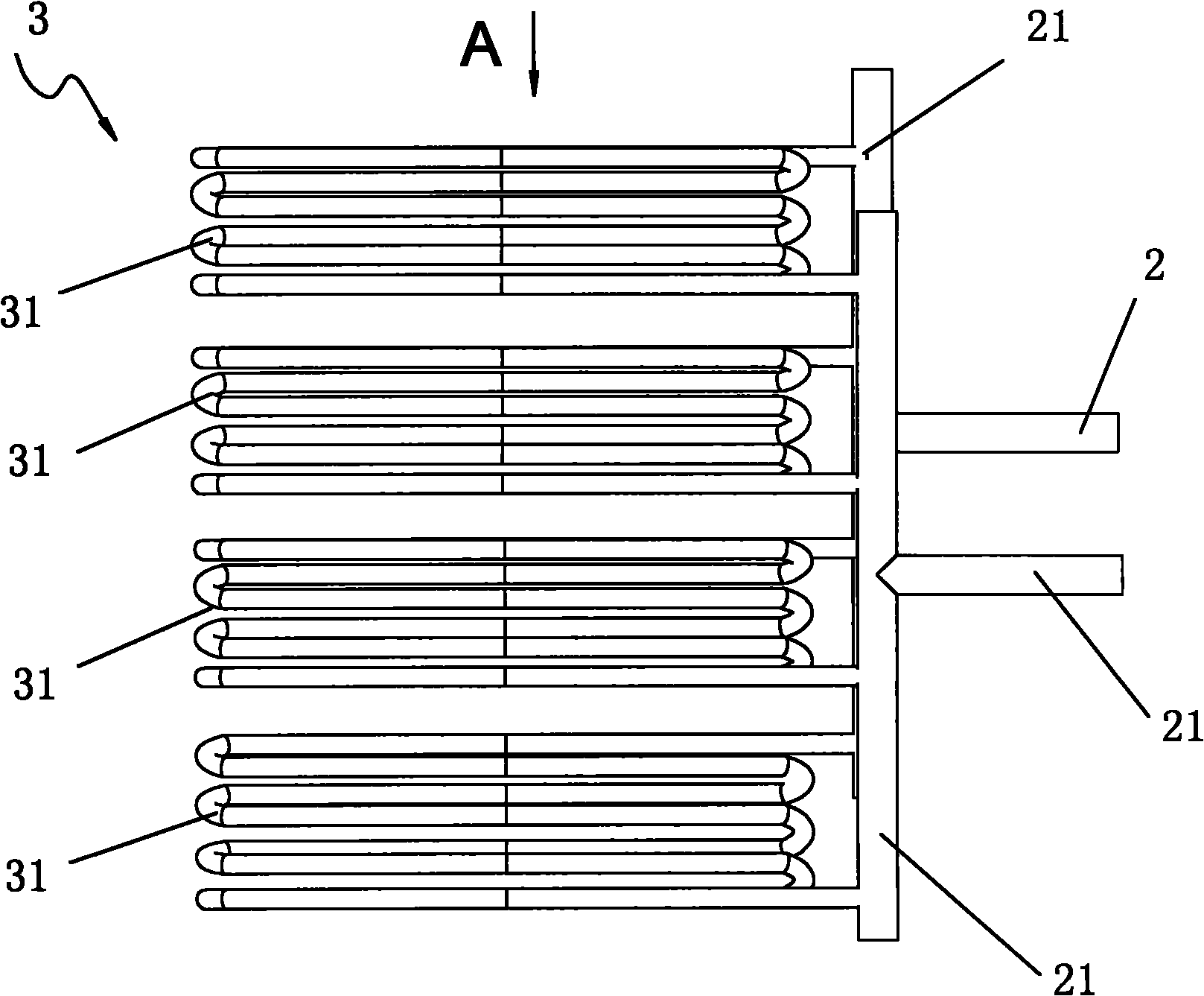

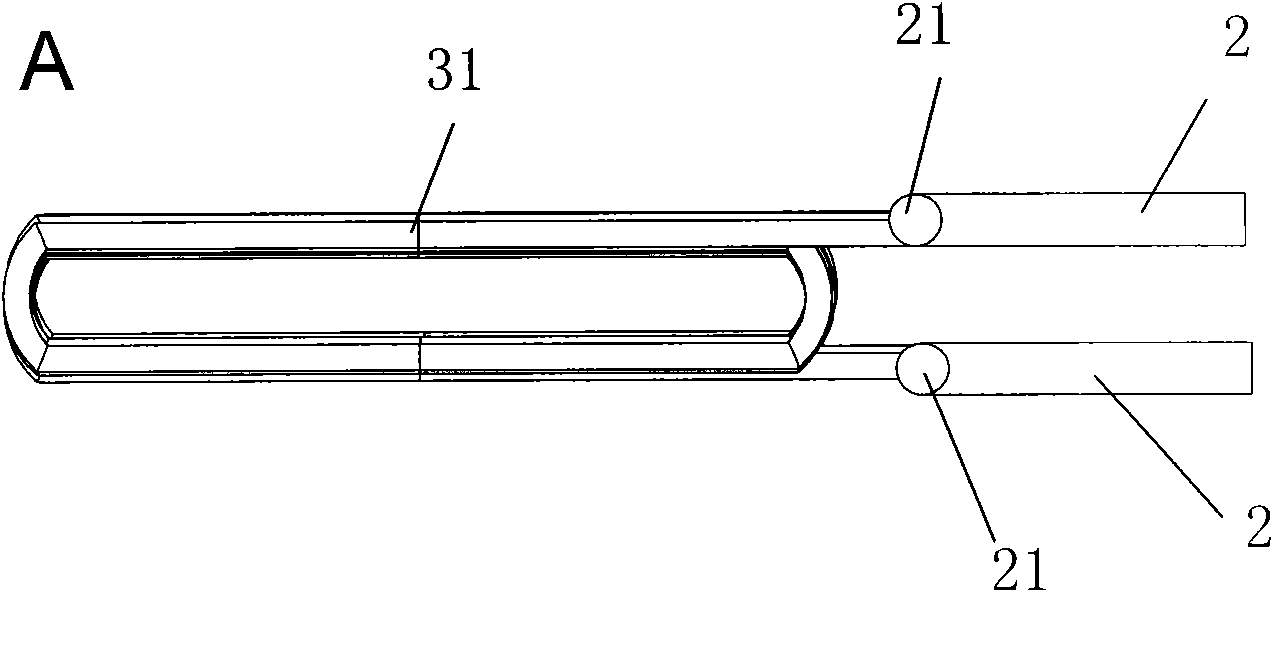

[0033] see Figure 1-3 The two high-frequency output terminals 2 of the high-frequency furnace are respectively connected to two conductive connecting rods 21 that are parallel to each other (or roughly parallel), and the high-frequency induction coil 3 is composed of several unit induction coils 31, and each unit induces The coil is provided with several coils of induction coils, and its two ends are electrically connected to two parallel conductive connecting rods 21, so that the unit induction coil is connected between the two conductive connecting rods, and the high-frequency induction coil 3 is formed in parallel. A metal induction body 4 electrically isolated from the induction coil is fixed in the cavity connected with the inner cavity in a straight line.

[0034] Usually, each unit induction coil 31 can be provided with 3-5 coils respectively, and the number of high-frequency induction coils should match the number of transformer c...

Embodiment 2

[0039] An electric heating device.

[0040] see Figure 7-8 The difference from Embodiment 1 is that in this example, each unit induction coil 31 forming the high-frequency induction coil 3 is a single-turn U-shaped coil body, and the U-shaped coil bodies are equidistantly spaced and arranged along the direction of the conductive connecting rod 21 , the two ends of each U-shaped coil body 31 are electrically connected with two conductive connecting rods 21 respectively, and are connected between the two conductive connecting rods. of).

Embodiment 3

[0042] An electric heating device.

[0043] see Figure 9 , Figure 10 , different from Embodiment 1, the cross-section of the cavity surrounded by the high-frequency induction coil 3 in this example is circular, and the metal induction body 4 is arranged in a cylindrical shape by a number of surrounding circular cavities. There are hollow or solid metal rods 41 with gaps between them. Both ends of each metal rod 41 are relatively fixed to the ring-shaped fixing strips 42 located at the longitudinal ends of the high-frequency induction coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com