Pipe cooling type fuel gas premixing ultra-low nitrogen combustor and premixing method

A low-nitrogen burner and gas premixing technology, applied in combustion methods, gas fuel burners, burners, etc., can solve the problems of complex structure, large volume, and difficulty in miniaturization, and achieve less NOX generation and mixing uniformity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

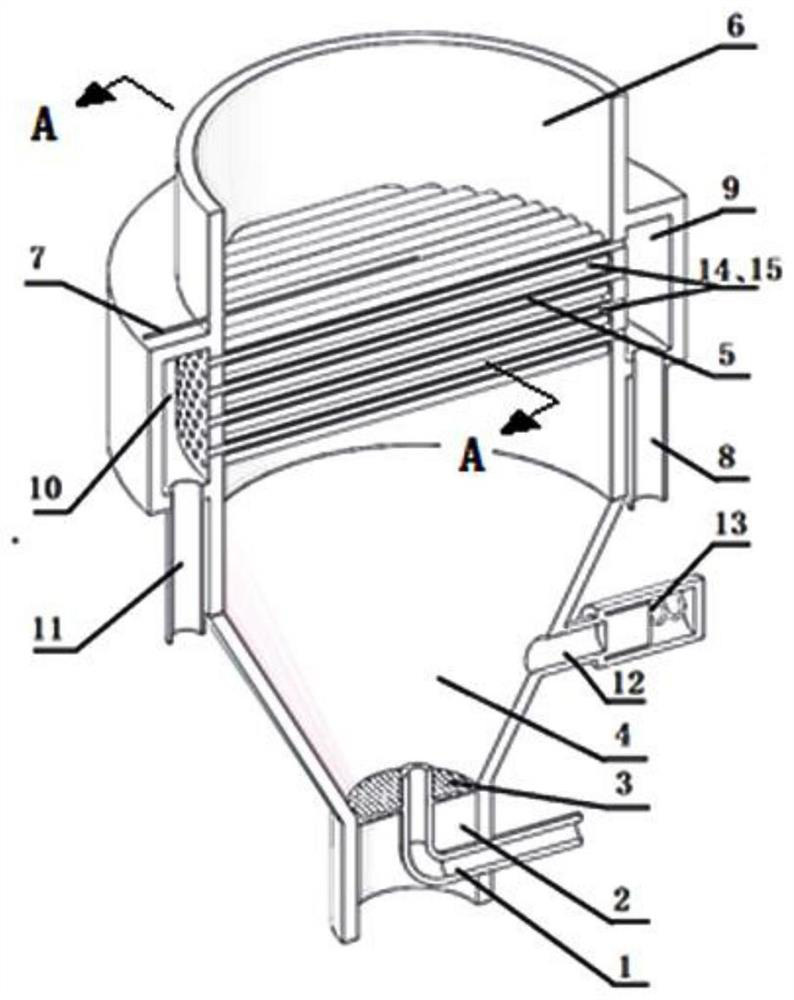

[0042] Such as figure 1 As shown, this embodiment is a tube-cooled gas premixed ultra-low nitrogen burner according to the present invention, which includes a burner body. The burner body is provided with a gas inlet 1 and an auxiliary gas inlet 2. The burner body There is an inner cavity inside, and the inner cavity is divided into a premixing chamber 4, a tube-cooled mixing chamber 5 and a combustion chamber 6 in sequence along the airflow direction; the gas inlet 1 and the auxiliary gas inlet 2 are respectively connected with the premixing chamber 4, and the auxiliary gas inlet 2 There is a flow equalizing plate 3 inside, the flow equalizing plate 3 closes the gas-supporting gas inlet 2, and a number of flow-balancing holes are arranged on the flow-balancing plate 3, and the flow-balancing holes pass through the gas-supporting gas inlet 2 and the premixing chamber 4; the premixing chamber 4 is provided with A safety valve interface 12, the safety valve interface 12 is conne...

Embodiment 2

[0048] Such as figure 1 As shown, this embodiment is a tube-cooled gas premixed ultra-low nitrogen burner according to the present invention, which includes a burner body. The burner body is provided with a gas inlet 1 and an auxiliary gas inlet 2. The burner body There is an inner cavity inside, and the inner cavity is divided into a premixing chamber 4, a tube-cooled mixing chamber 5 and a combustion chamber 6 in sequence along the airflow direction; the gas inlet 1 and the auxiliary gas inlet 2 are respectively connected with the premixing chamber 4, and the auxiliary gas inlet 2 There is a flow equalizing plate 3 inside, the flow equalizing plate 3 closes the gas-supporting gas inlet 2, and a number of flow-balancing holes are arranged on the flow-balancing plate 3, and the flow-balancing holes pass through the gas-supporting gas inlet 2 and the premixing chamber 4; the premixing chamber 4 is provided with A safety valve interface 12, the safety valve interface 12 is conne...

Embodiment 3

[0054] Such as figure 1 As shown, this embodiment is a tube-cooled gas premixed ultra-low nitrogen burner according to the present invention, which includes a burner body. The burner body is provided with a gas inlet 1 and an auxiliary gas inlet 2. The burner body There is an inner cavity inside, and the inner cavity is divided into a premixing chamber 4, a tube-cooled mixing chamber 5 and a combustion chamber 6 in sequence along the airflow direction; the gas inlet 1 and the auxiliary gas inlet 2 are respectively connected with the premixing chamber 4, and the auxiliary gas inlet 2 A flow equalizer 3 is provided inside, and the flow equalizer 3 closes the gas-supporting gas inlet 2, and a number of flow-uniform holes are arranged on the flow uniformity plate 3, and the flow uniformity holes penetrate through the gas-supporting inlet 2 and the premixing chamber 4; the premixing chamber 4 is provided with There is a safety valve interface 12, and the safety valve interface 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com