Ventilation and heat dispersion seat

A technology for ventilation, heat dissipation, and seats, which is applied to vehicle seats, seat heating/ventilation devices, and other seating furniture, etc., and can solve the problems of no direct ventilation, no heat dissipation, and no ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

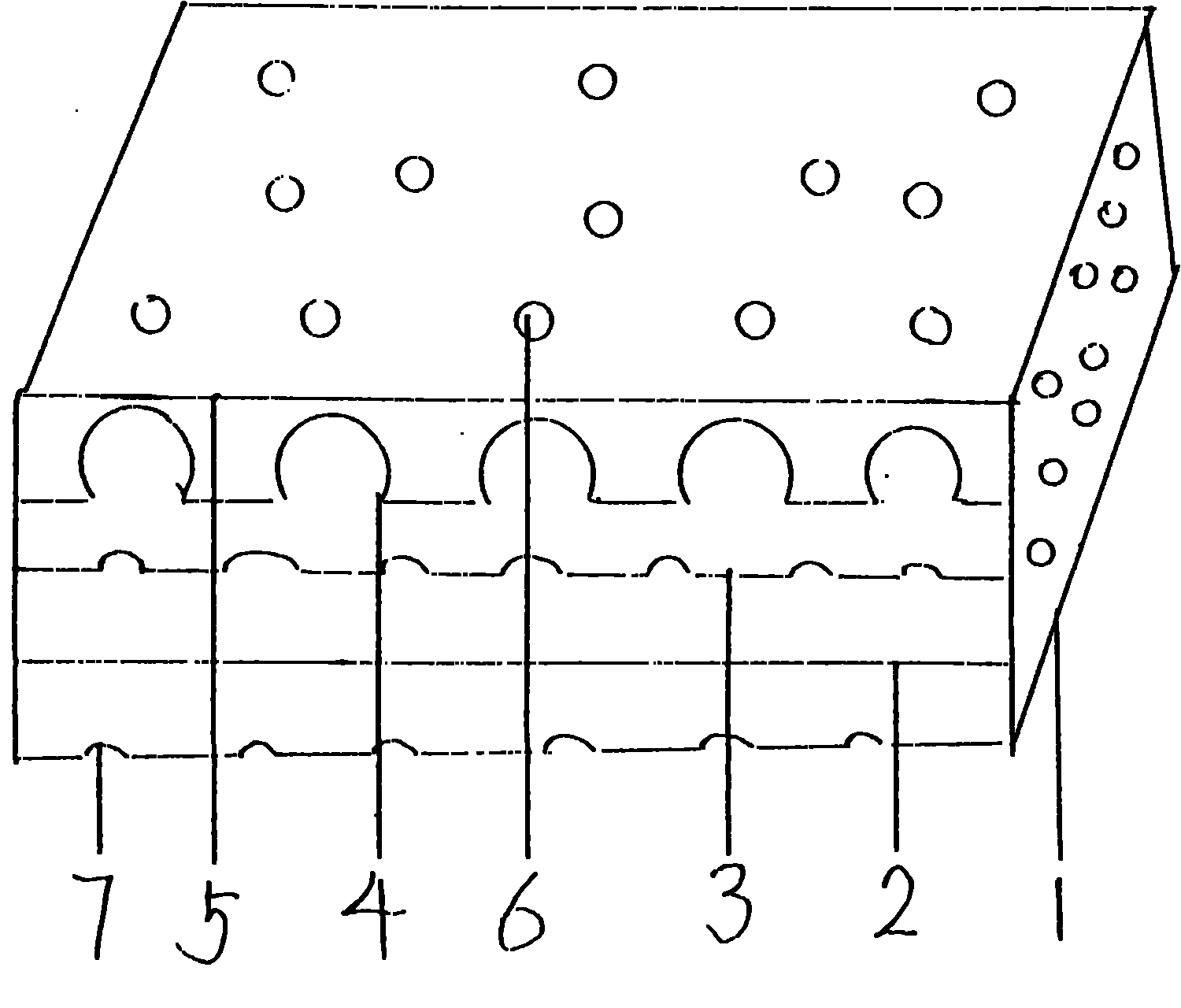

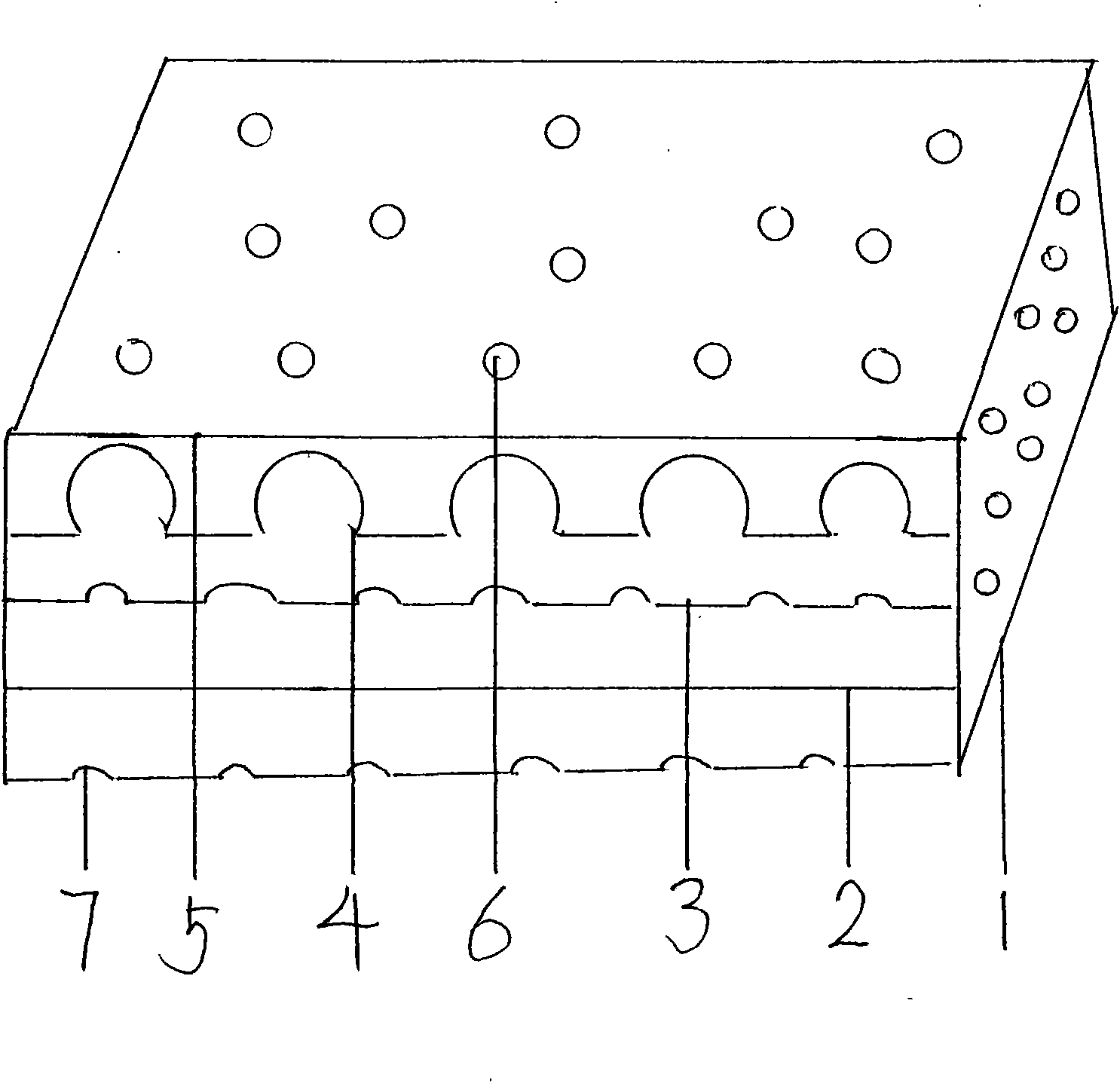

[0006] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. In the figure, the seat stool and the bottom surface of the backrest of the chair are formed and connected by a mold, and multiple vertical and horizontal ventilation grooves 7, or drilled and connected with multiple vertical ventilation holes 6 form the bottom plate 1, and the backrest of the seat stool can all be straight through. The air hole 6 or only the stool is the ventilation slot 7 or only the backrest is the ventilation slot 7. The bottom plate 1 is nailed or edge curled and contacted to connect the steel wire layer 2 with multiple crosses in the vertical and horizontal directions. On the steel wire layer 2, The sticking or contact connection or riveting connection corresponds to the bottom plate 1, and there are multiple straight ventilation holes 6 on the aluminum-plastic plate 3 or other material plates. How many adhesive or nail connections o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com