Automobile torsion rod spring rolling straightening quenching equipment

A technology of torsion bar springs and quenching equipment, applied in the direction of quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of different cooling capabilities of workpieces, uneven hardness of workpieces, hardening of the core, etc., to achieve small deformation and uniform quenching , the effect of uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

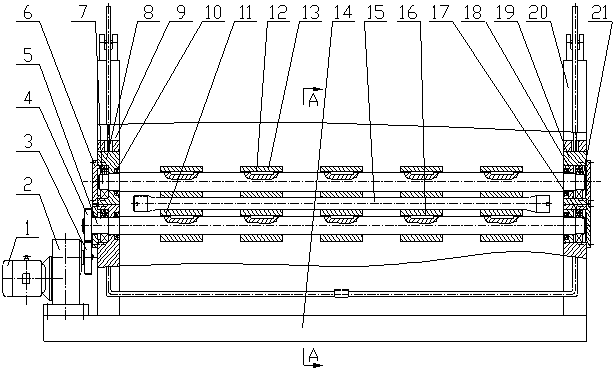

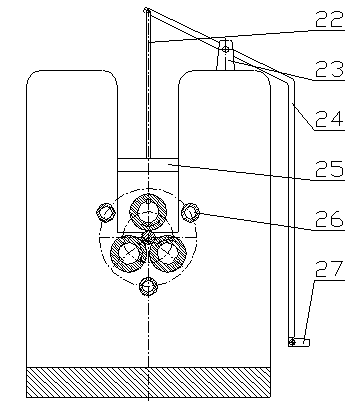

[0021] Such as Figure 1 to Figure 2 As shown, the automobile torsion bar spring rolling straightening quenching equipment includes motor 1, gearbox 2, driving gear 3, driven gear 4, driving shaft 5, end cover 6, driven shaft 7, slider 8, bed 9, U Type sealing ring 10, driving wheel 11, flat key 12, driven wheel 13, base 14, torsion bar spring 15, flat key 16, bearing 17, U-shaped sealing ring seat 18, slider 19, bed 20, shaft elastic Back-up ring 21, steel wire rope 22, lever support 23, lever 24, counterweight 25, water spray pipe 26, pedal 27.

[0022] The motor 1 is directly connected with the gearbox 2, and the driving gear 3 on the gearbox 2 is connected with the passive gear 4 on the two driving shafts 5 at the same time. Bearings 17 and U-shaped sealing rings 10 are installed at both ends of the driving shaft 5, the bearings 17 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com