Fuel oil combustion treatment method for thermal desorption remediation of polluted soil

A technology of polluted soil and thermal desorption, applied in the field of fuel combustion treatment, can solve the problems of high cost of desorption waste gas treatment, high safety risk, limitation of steam injection heating desorption technology, etc., and achieve high energy utilization efficiency and fuel saving. Use, secondary pollution controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

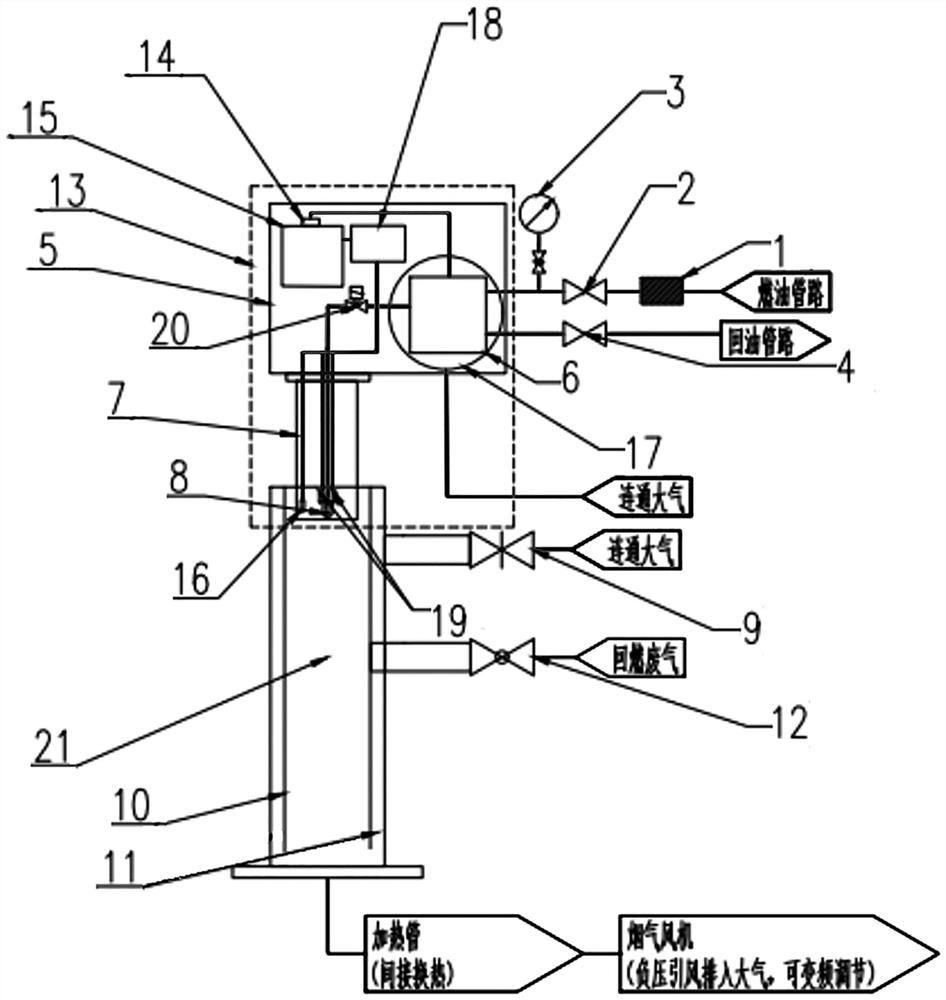

[0042] A fuel combustion treatment method for thermal desorption restoration of polluted soil, the fuel is atomized in the fuel burner 13 and then mixed with combustion-supporting air, ignited by the ignition electrode 19 and continuously and stably burned in the combustion chamber 10 to generate high temperature The flue gas is sent to the thermal desorption repair system for conduction heat exchange; the desorbed organic waste gas generated by the thermal desorption repair system is sent to the combustion chamber 10 through the back-burning waste gas introduction unit for thermal combustion treatment.

[0043] This method is mainly carried out by an integrated machine composed of a fuel supply unit, a secondary air supply unit, a backfire exhaust gas introduction unit, a fuel burner 13 and a combustion chamber 10 .

[0044] The fuel supply unit is connected with the fuel burner 13 and sends the fuel into the fuel burner 13; the combustion chamber 10 is arranged under the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com