Intelligent combustion treatment integrated machine used for thermal desorption remediation of contaminated site

A technology of thermal desorption and integrated machine, which is applied in the restoration of polluted soil, etc., can solve the problems of limitation, difficulty in large-scale power consumption, and high energy cost for heating, so as to achieve good energy saving and consumption reduction, economical use, and improved The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

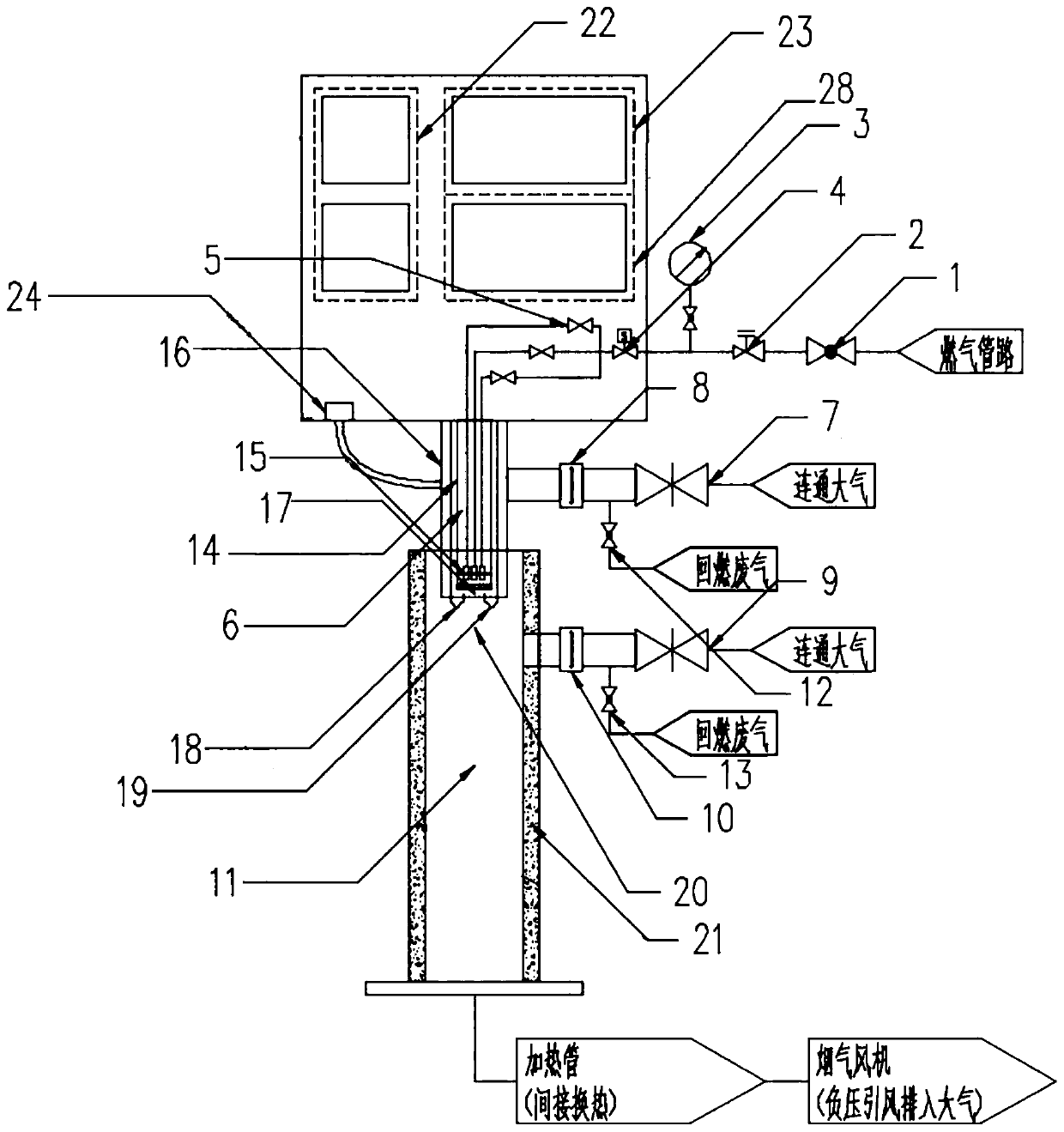

[0036] An intelligent combustion treatment integrated machine for thermal desorption restoration of polluted sites, mainly composed of a gas supply unit, a combustion air supply unit, a backburning exhaust gas introduction unit, a burner 6, a combustion chamber 11, a control cabinet and other facilities.

[0037] (1) Gas supply unit.

[0038] The gas is delivered from the gas supply pipeline to the intelligent combustion processing integrated machine successively through the gas shut-off valve 1, the pressure reducing regulating valve 2, the gas pressure gauge 3, the automatic shut-off valve 4 in the control cabinet and the manual shut-off valve 5 of the gas supply branch. The gas cut-off valve 1 is manually operated, normally open during operation, and kept closed during system shutdown or maintenance, and cut off the connection with the gas supply pipeline; the gas pressure is adjusted to a reasonable range through the pressure reducing regulating valve 2, and the pressure va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com