Feeding device having backdraft cutoff function and used for biomass fuel boiler

A technology of biomass fuel and feeding device, which is applied in the direction of supply configuration, fuel supply, combustion method, etc., can solve the problems of insufficient oxygen supply, high moisture content of biomass fuel, and affecting the use of boilers, so as to achieve sufficient combustion and high utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

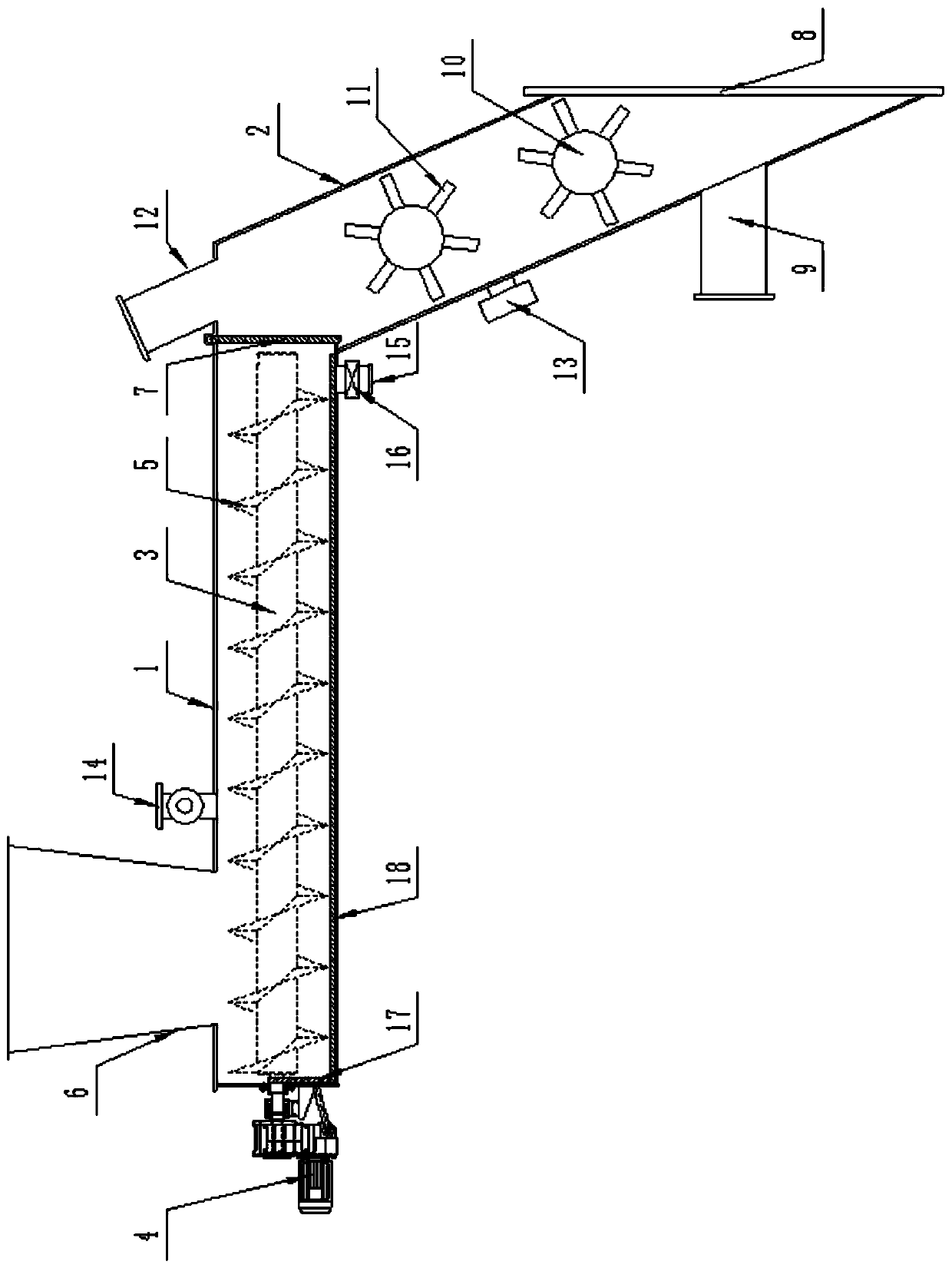

[0017] Such as figure 1 As shown, a feed device for blocking backburning of a biomass fuel boiler includes a screw conveying cylinder 1, one end of which is closed and the other end is open, and the open end of the screw conveying cylinder 1 is connected with an inclined Barrel 2, the conveying shaft 3 is arranged inside the screw conveying cylinder 1, and the conveying shaft 3 passes through the closed end of the spiral conveying cylinder 1 and is connected with a conveying motor 4, and the conveying shaft 3 is provided with conveying propeller blades 5. The top of the screw conveying cylinder 1 is provided with a feed inlet 6 near the closed end, and the top of the inner wall of the opening end of the spiral conveying cylinder 1 is rotated by a rotating shaft to install a flame-retardant self-closing plate 7, and the flame-retardant self-closing plate 7 The bottom covers the opening end of the screw conveying cylinder 1, and the bottom of the inclined lower material cylinder...

specific Embodiment 2

[0020] Such as figure 1 As shown, a feed device for blocking backburning of a biomass fuel boiler includes a screw conveying cylinder 1, one end of which is closed and the other end is open, and the open end of the screw conveying cylinder 1 is connected with an inclined Barrel 2, the conveying shaft 3 is arranged inside the screw conveying cylinder 1, and the conveying shaft 3 passes through the closed end of the spiral conveying cylinder 1 and is connected with a conveying motor 4, and the conveying shaft 3 is provided with conveying propeller blades 5. The top of the screw conveying cylinder 1 is provided with a feed inlet 6 near the closed end, and the top of the inner wall of the opening end of the spiral conveying cylinder 1 is rotated by a rotating shaft to install a flame-retardant self-closing plate 7, and the flame-retardant self-closing plate 7 The bottom covers the opening end of the screw conveying cylinder 1, and the bottom of the inclined lower material cylinder...

specific Embodiment 3

[0024] Such as figure 1 As shown, a feed device for blocking backburning of a biomass fuel boiler includes a screw conveying cylinder 1, one end of which is closed and the other end is open, and the open end of the screw conveying cylinder 1 is connected with an inclined Barrel 2, the conveying shaft 3 is arranged inside the screw conveying cylinder 1, and the conveying shaft 3 passes through the closed end of the spiral conveying cylinder 1 and is connected with a conveying motor 4, and the conveying shaft 3 is provided with conveying propeller blades 5. The top of the screw conveying cylinder 1 is provided with a feed inlet 6 near the closed end, and the top of the inner wall of the opening end of the spiral conveying cylinder 1 is rotated by a rotating shaft to install a flame-retardant self-closing plate 7, and the flame-retardant self-closing plate 7 The bottom covers the opening end of the screw conveying cylinder 1, and the bottom of the inclined lower material cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com