Carbon deposits removal method for internal combustion engine

A technology for internal combustion engines and carbon deposition, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as industrial safety, unsafety, and increased operating costs, and achieve good combustion characteristics, anti-knock properties, and good anti-riot properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

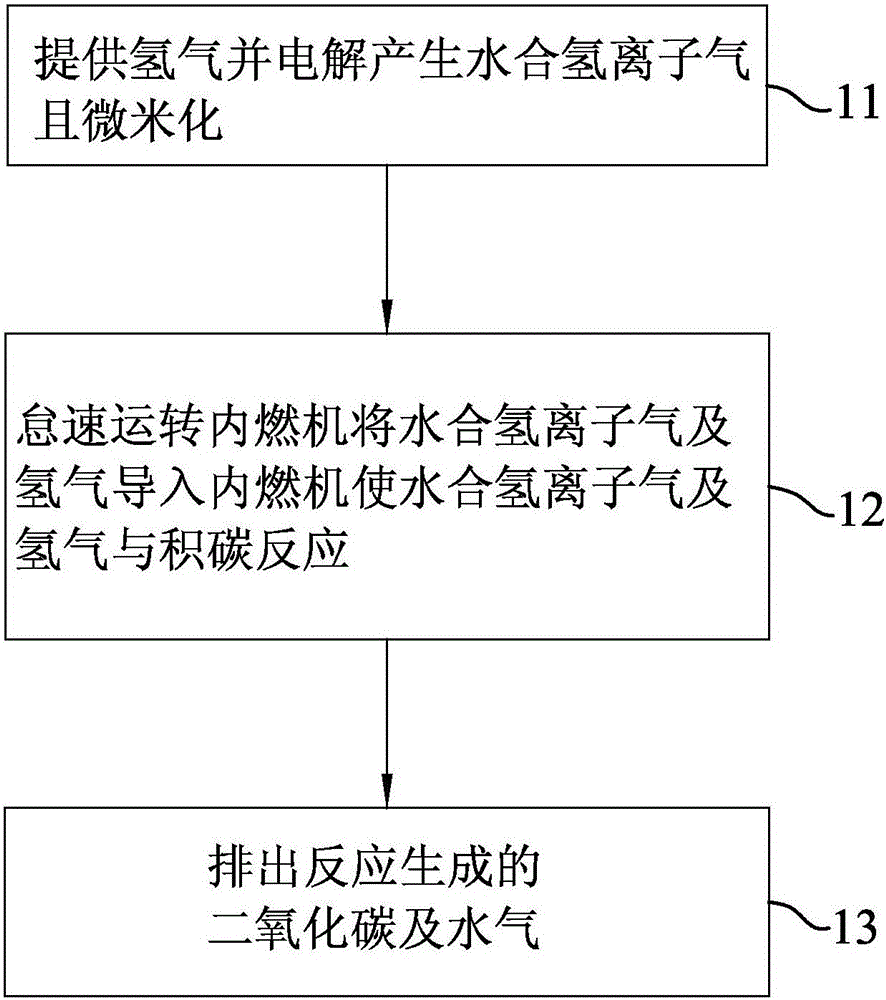

[0036] refer to figure 1 , an embodiment of the internal combustion engine carbon deposit removal method of the present invention is used to remove carbon deposits in an internal combustion engine with a displacement of 3000cc, and includes a step 11 of providing hydronium ion gas and hydrogen gas, an introduction reaction step 12, and a Drain step 13.

[0037] In the step 11 of providing hydronium ion gas and hydrogen gas, the acetic acid aqueous solution is electrolyzed at 55° C. with a direct current of 9 volts. The acetic acid aqueous solution will produce a hydronium ion mixed solution after electrolysis. The hydronium ion mixture will be sprayed to a thinning interference plate at a flow rate of 0.5m per second, so that the gas and liquid of the hydronium ion mixture will be separated to generate hydronium ion gas with a smaller size. The thin interference plate has several interference holes each with a diameter of 1 mm per unit square centimeter area.

[0038] The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com