High-concentration odor combustion device with jacket cooling air

A technology of combustion device and cooling air, applied in gas fuel burners, burners, combustion methods, etc., can solve the problems of low safety factor, short service period, unstable combustion, etc., and achieve high safety factor, easy disassembly and Maintenance, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

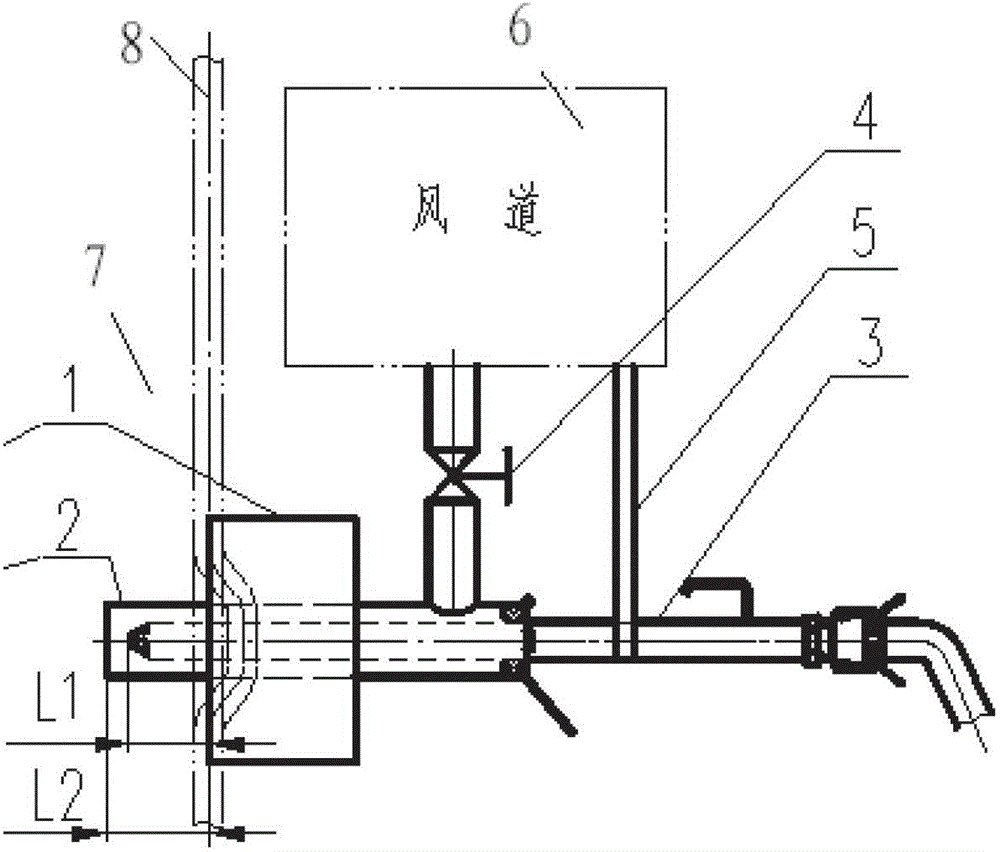

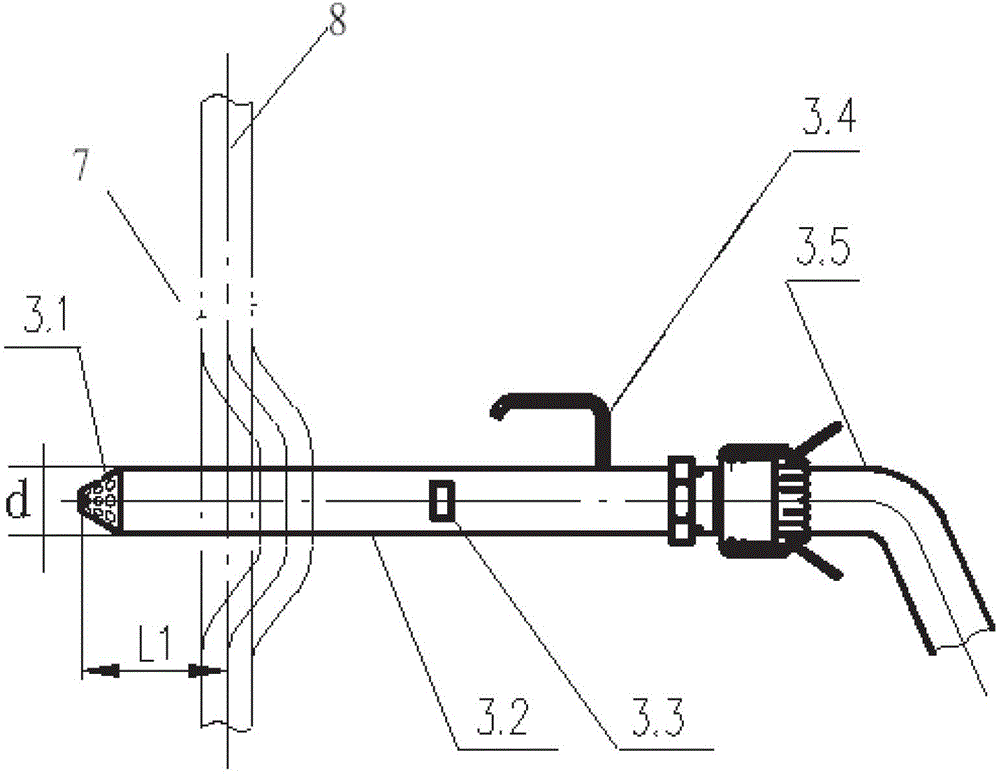

[0025] The specific implementation of the high-concentration odor combustion device with jacketed cooling air will be described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the connecting piece 1 is welded with the water-cooled wall 8 of the alkali recovery boiler, the combustion device is fixed on the water-cooled wall, and the inside of the connecting piece is filled with refractory castable; the casing 2 is fixed on the connecting piece 1 by welding; the combustion gun 3 and the casing The 2 phases are connected, and the heat-resistant rubber 2.3 is used to seal between them; the casing 2 is connected with the air duct through the valve 4, and the valve 4 plays the role of opening and closing; the support and hanger 5 is used to fix the combustion gun 3, prevent the combustion gun 3 from shaking, support and hang The frame is fixed on the air duct or the water cooling wall.

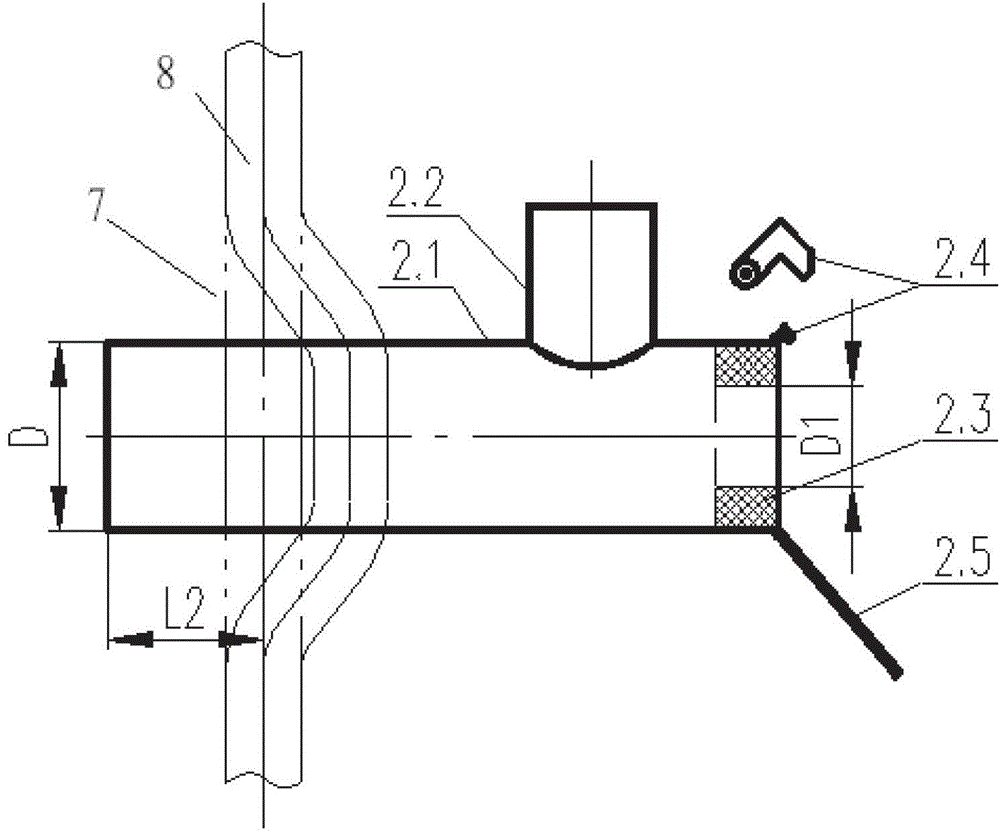

[0027] Such as figure 2 As shown, the casing 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com