Output power control method of combustion apparatus

A combustion device and output power technology, applied in the direction of combustion method, combustion control, fuel supply regulation, etc., can solve problems such as polluting the environment, inability to achieve full combustion, and extinguishing the flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

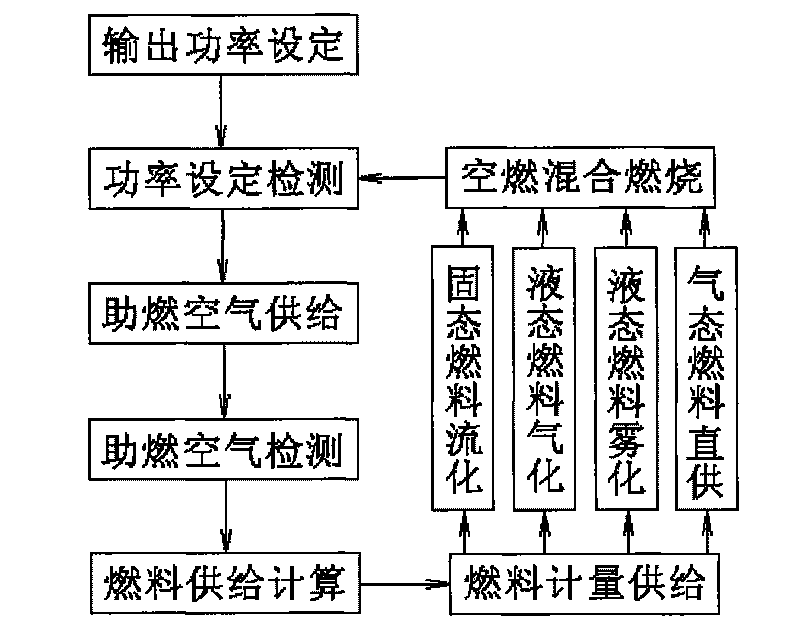

[0015] figure 1 Among them, the present invention follows the output of the fuel with the combustion-supporting air flow rate or air mass flow rate detected by the combustion device; the follow-up of the fuel output is a control method, which is based on the combustion-supporting air volume detected by the combustion device, according to The requirement of the best "air-fuel ratio" is metered, and the fuel is provided by the fuel supply device to participate in the combustion, so that the amount of fuel supplied changes simultaneously with the amount of combustion-supporting air, satisfying sufficient and stable combustion under the condition of the best "air-fuel ratio". The adjustment of the output power of the combustion device in the present invention is realized by adjusting the amount of combustion-supporting air provided by the air supply device, which can be adjusted continuously or in sections within the specified output power range, and can be completed by one key or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com