A pressure-suppressing pulse type fire extinguishing method and its fire extinguishing device

A pulse type, fire extinguishing agent technology, applied in fire rescue and other fields, can solve the problems of low fire extinguishing efficiency and slow spraying speed of fire extinguishing materials, and achieve the effect of accelerating spraying speed and improving fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

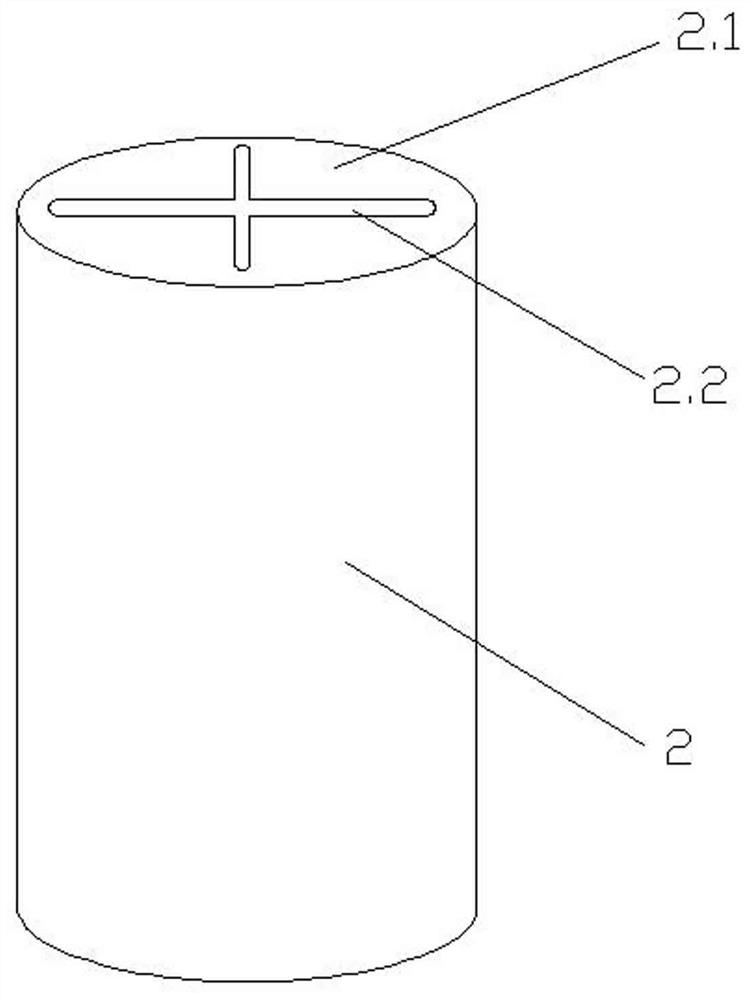

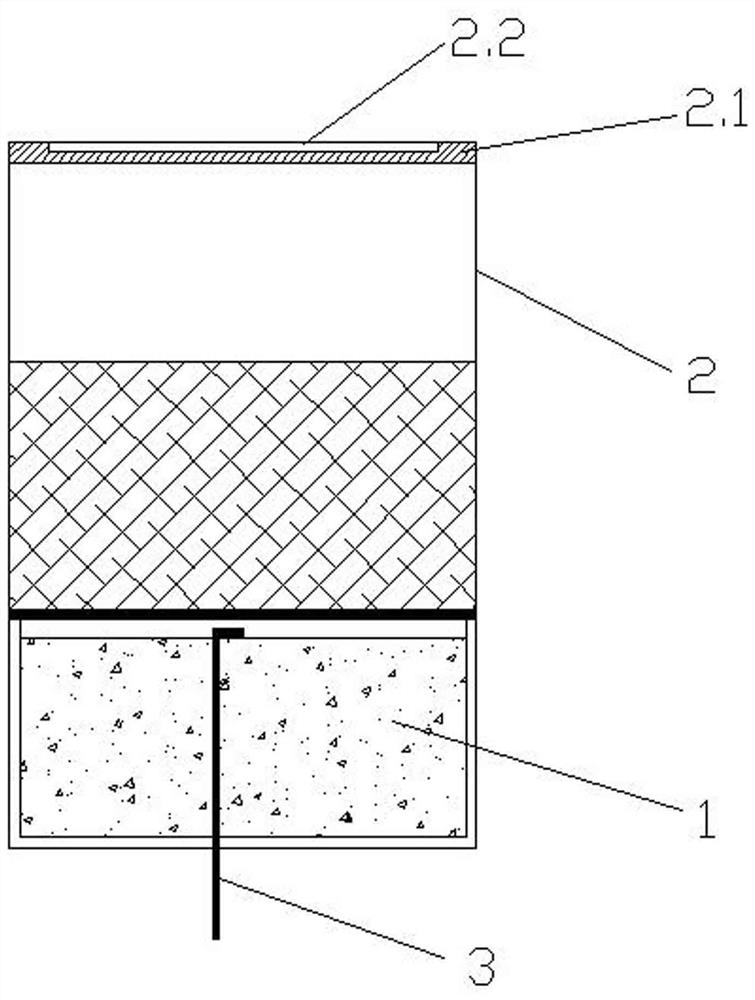

[0045] Embodiment 1: as figure 1 and 2 , this embodiment discloses a pressure-suppressed pulse type fire extinguishing device using the above-mentioned fire extinguishing method, which includes a closed container 2, a fire extinguishing agent 1 is arranged in the closed container 2, and a spray nozzle is installed on the cover 2.1 of the closed container 2. Putting the groove 2.2, the depth of the spraying groove 2.2 is less than the thickness of the cover body 2.1. As shown in the figure, when the fire extinguishing agent 1 in the airtight container 2 is ignited and the fire extinguishing substance is released, the pressure in the airtight container 2 gradually increases. Since the depth of the discharge groove 2.2 is smaller than the thickness of the cover body 2.1, when the critical pressure is reached , the position where the spraying groove 2.2 is located will be broken first, so that the fire extinguishing material is quickly sprayed out from the cracked gap.

Embodiment 2

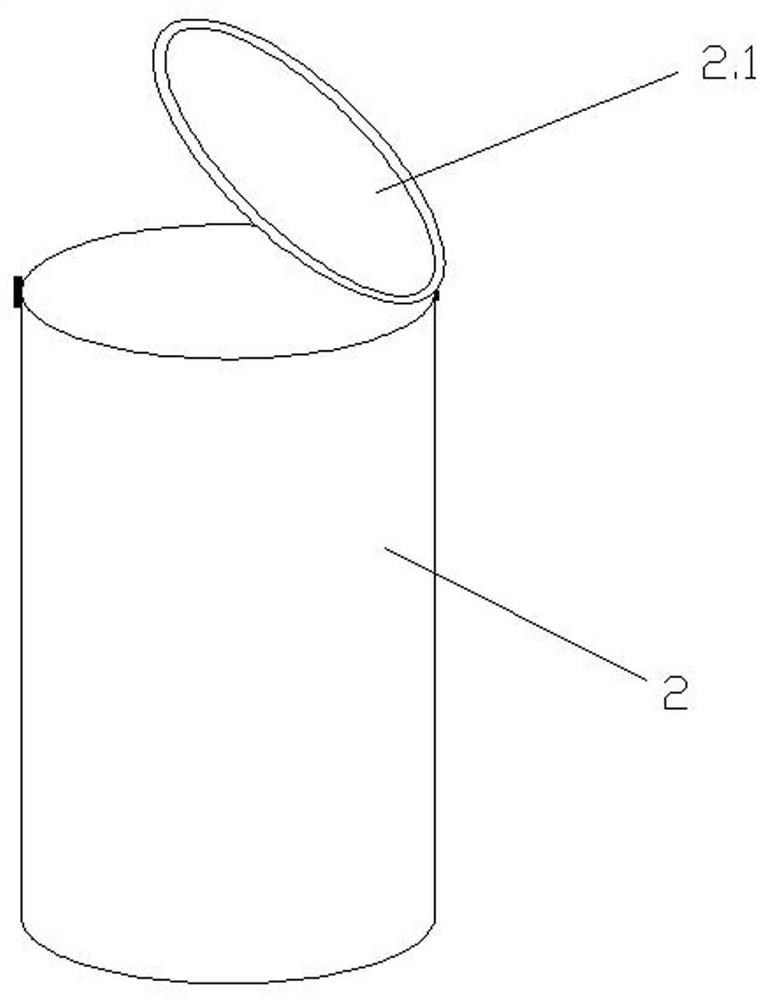

[0046] Embodiment 2: as image 3 and 4 , this embodiment discloses a pressure-suppressed pulse type fire extinguishing device for extinguishing fires using the above-mentioned fire extinguishing method, including an airtight container 2, a fire extinguishing agent 1 is arranged in the airtight container 2, a cover body 2.1 of the airtight container 2 and an airtight container 2 The top is detachably attached. As shown in the figure, when the fire extinguishing agent 1 in the airtight container 2 is ignited and the fire extinguishing substance is released, the pressure in the airtight container 2 gradually increases. Since the cover 2.1 of the airtight container 2 is detachably connected to the top of the airtight container 2, when After reaching the critical pressure, the cover body 2.1 will be separated from the top of the airtight container 2, so that the fire extinguishing material can be sprayed out from the top of the airtight container 2 quickly. Specifically, there ar...

Embodiment 3

[0047] Embodiment 3: as Figure 5 and 6 , this embodiment discloses a pressure-suppressed pulse type fire extinguishing device using the above-mentioned fire extinguishing method for extinguishing fires, including an airtight container 2, in which a fire extinguishing agent 1 and a coolant 5 are sequentially arranged from bottom to top, and the surface of the airtight container 2 is opened There is a discharge hole 2.3, and a diaphragm 2.4 is arranged at the position of the discharge hole 2.3. In this embodiment, the diaphragm 2.4 can adopt an aluminum film structure or an explosion-venting diaphragm structure. When the fire extinguishing agent 1 in the airtight container 2 is ignited, the fire extinguishing substance is released, and the pressure in the airtight container 2 increases gradually. When the pressure reaches a critical After the value is set, the diaphragm 2.4 is broken through under pressure, and the fire extinguishing substance is ejected from the discharge hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com