Six-degree-of-freedom self-reconfigurable parallel spray painting robot

A spraying robot, self-reconfiguration technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of heavy robot mechanism, bulky whole mechanism, complex internal structure, etc., and achieve compact structure, good dynamic response, and spraying speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

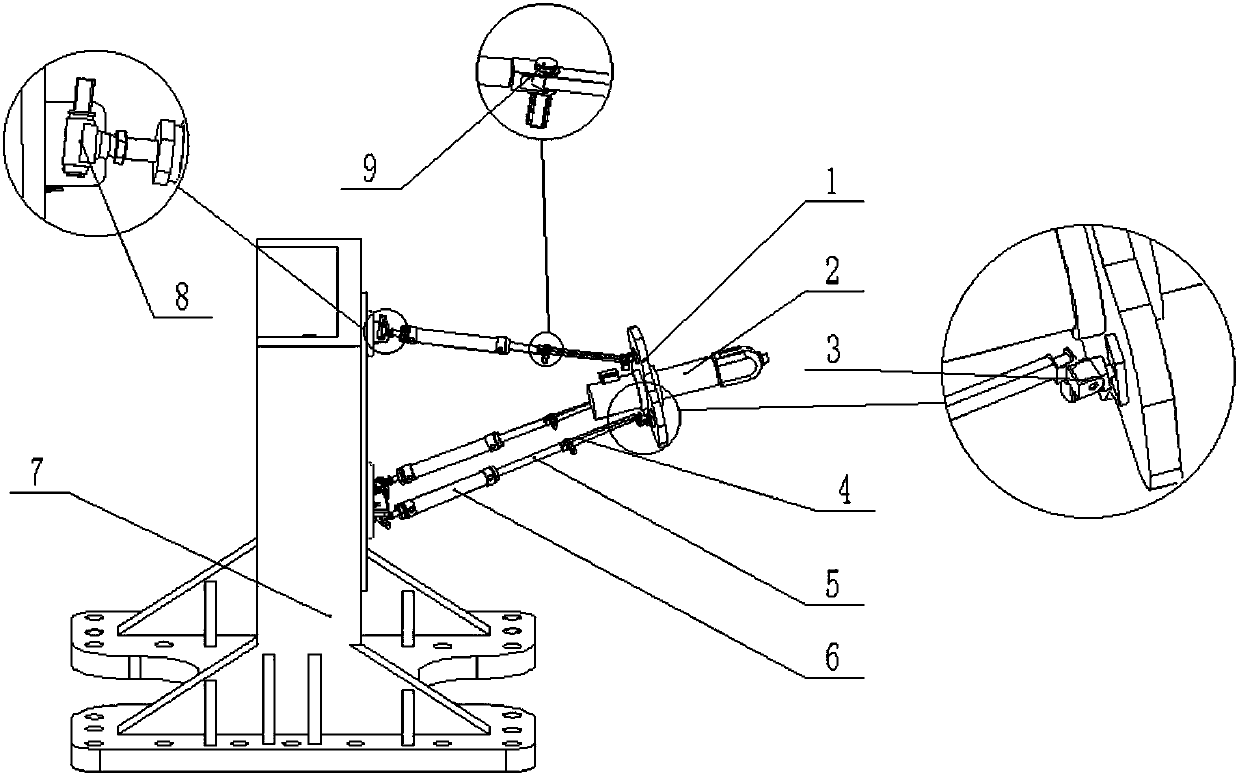

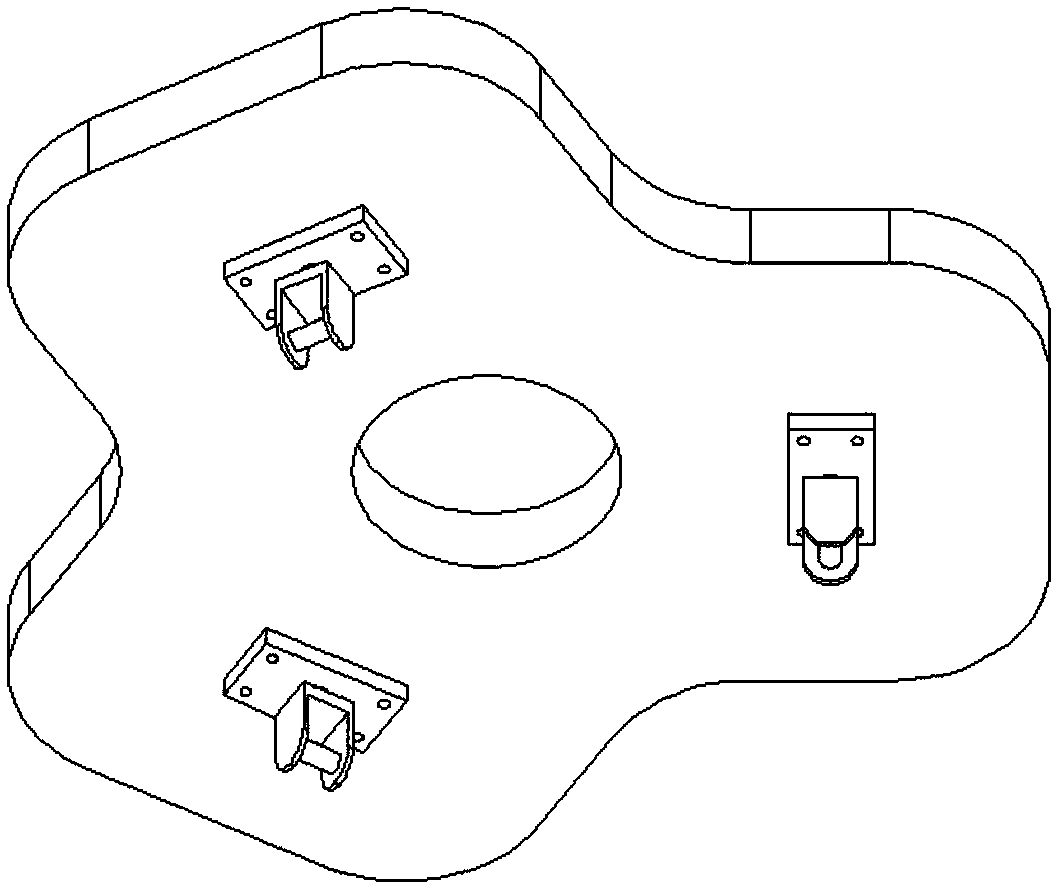

[0028] Such as Figure 1 to Figure 9 As shown, the six-degree-of-freedom self-reconfiguration parallel spraying robot of the present invention consists of a nozzle 2, a nozzle support platform 1, three nozzle hinges 3 with identical structures, three identical long poles 4, a brake 9, three It consists of a cylinder 6 of the same specification, three support hinges 8 with the same structure and a frame 7. The specific structure and connection relationship are as follows:

[0029] The nozzle 2 and the nozzle support platform 1 are fixedly connected together, and the two are relatively stationary, and the side of the nozzle support platform 1 close to the frame 7 is connected with three nozzle hinges 3;

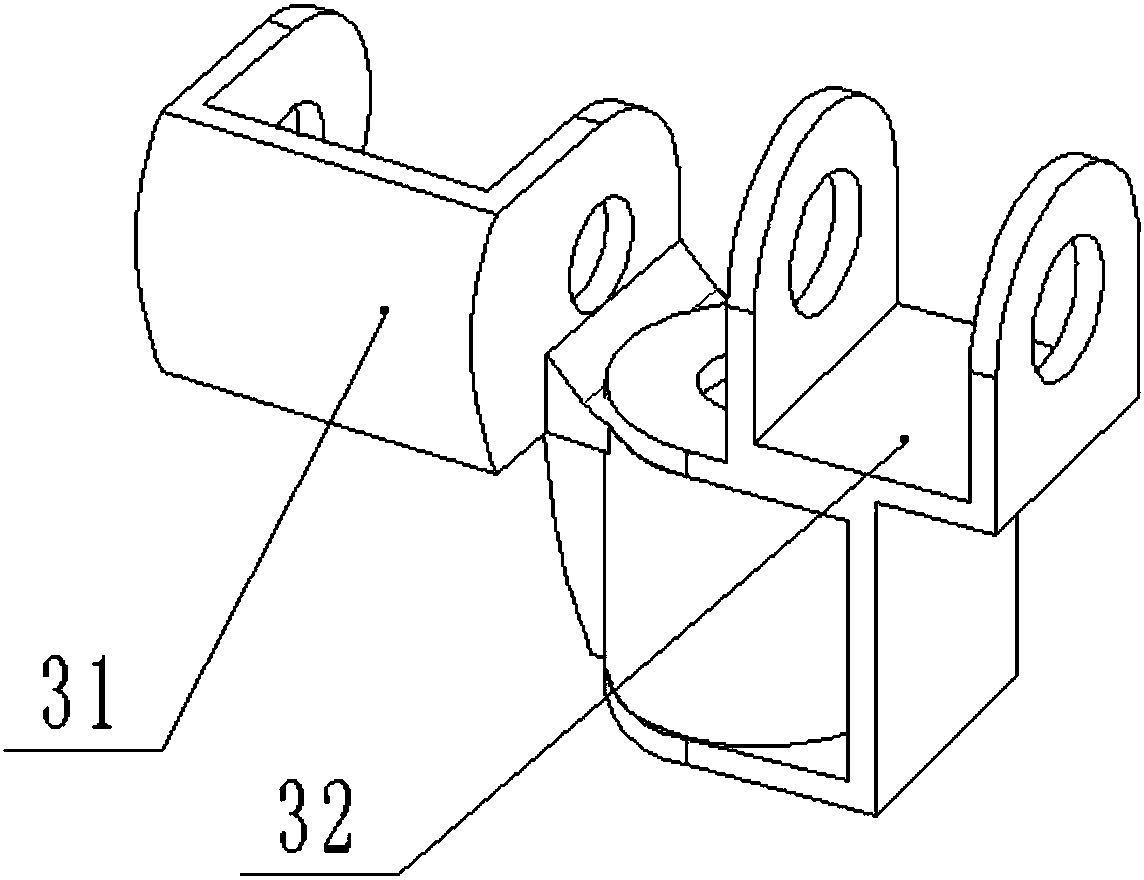

[0030] The three nozzle hinges 3 with identical structures are all composed of a rotating head 31 and a rotating sleeve 32, one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com