W-type combustion boiler with thermal power flexibility adjusting function and adjusting method of boiler

An adjustment method and flexible technology, which is applied in the direction of combustion method, fuel supply adjustment, and the combustion of block fuel and liquid fuel, etc., can solve the problems of furnace fire extinguishing, sacrificing boiler efficiency, easy flameout, etc., and achieve load response The effect of increasing the speed and speed, improving the flexibility of peak shaving, and increasing the temperature of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

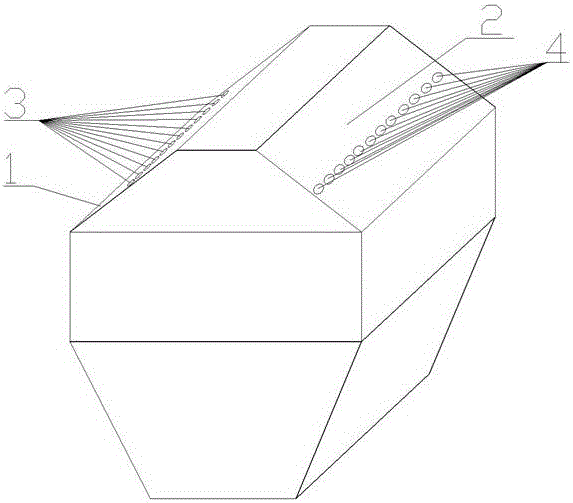

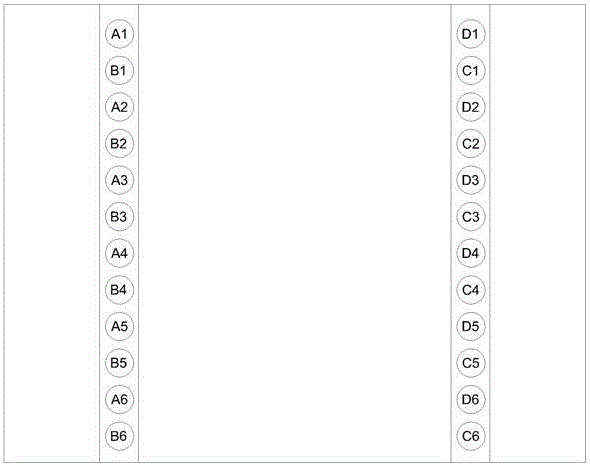

[0053] Embodiment one, combine figure 1 and figure 2 It can be seen that a W-shaped combustion boiler with thermal power flexibility adjustment function, the W-shaped combustion boiler is divided into front arch 1 and rear arch 2, and the burner can be divided into front arch burner 3 and rear arch burner according to the installation position 4. It is characterized in that: the front arch burner 3 can be divided into the front arch common burner and the front arch peaking burner according to the category, and the rear arch burner 4 can be divided into the rear arch ordinary burner and the rear arch peaking burner according to the category , the front arch peaking burner and the rear arch peaking burner are internal combustion burners, which can ignite coal powder inside the burner and burn stably; the front arch ordinary burner and the rear arch ordinary combustion The burner is an internal combustion burner or an external combustion burner. The W-type combustion boiler re...

Embodiment 2

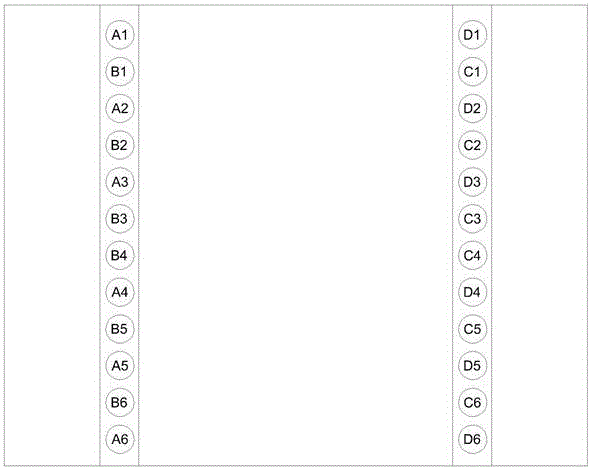

[0077] Embodiment two, combining figure 1 and image 3It can be seen that the boiler structures of Embodiment 1 and Embodiment 2 are the same, the difference lies in the distribution positions of the peaking burners and ordinary burners, and the front arch burners 3 are set at intervals of one or two front arch ordinary burners. One or two front arch peaking burners; one or two rear arch peaking burners are arranged at intervals of one or two rear arch common burners in the rear arch burner 4; and the rear arch peaking burner and the front arch Ordinary burners correspond, and the rear arch ordinary burners correspond to the front arch peaking burners; that is to say, one or two different numbers of adjustable peaking burners and ordinary burners can be distributed arbitrarily, as long as it can meet and The rear arch peak-shaving burner is corresponding to the front arch common burner, and the rear arch common burner is corresponding to the front arch peak-shaving burner suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com