Patents

Literature

52results about How to "Solve the ignition problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

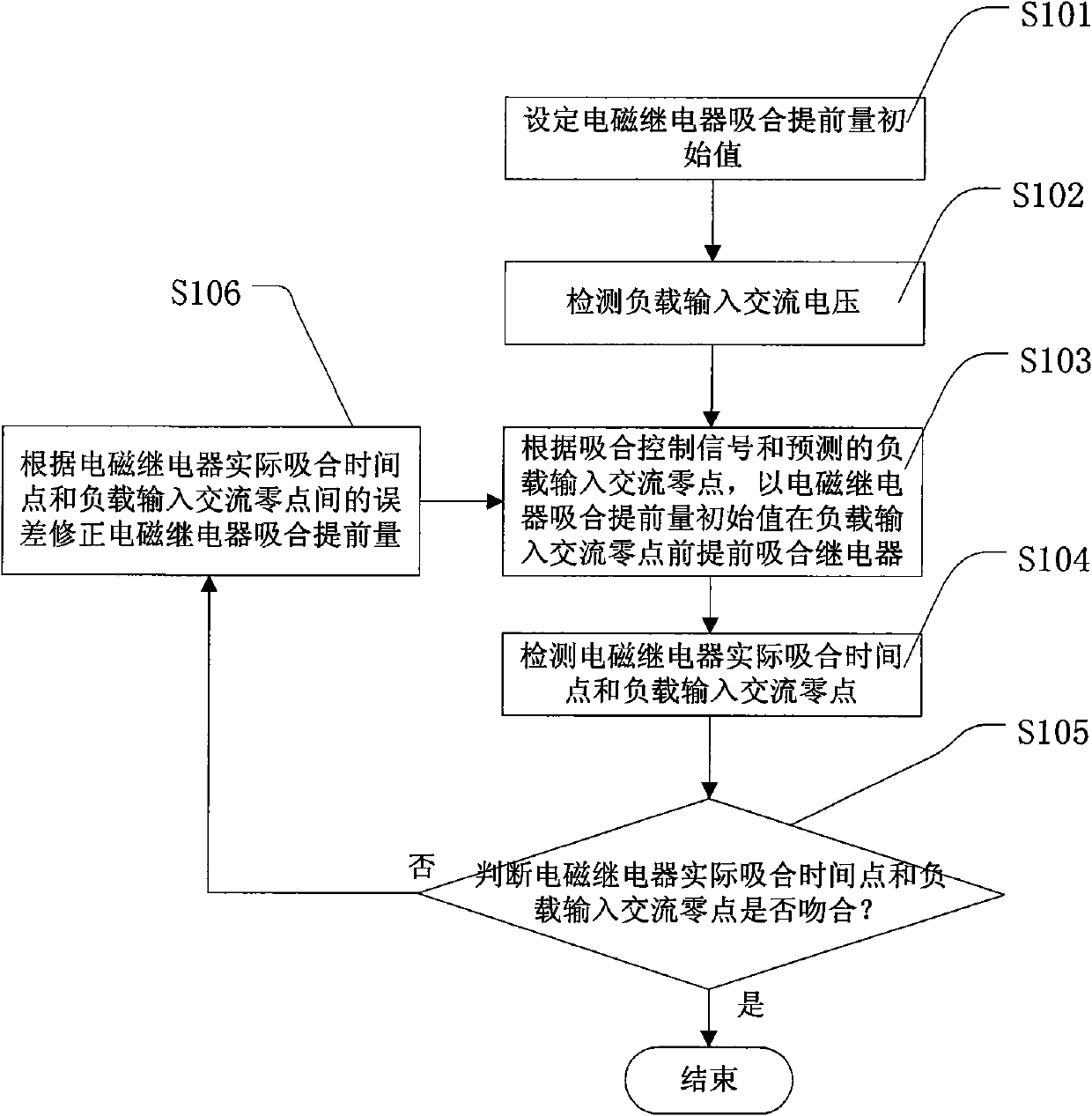

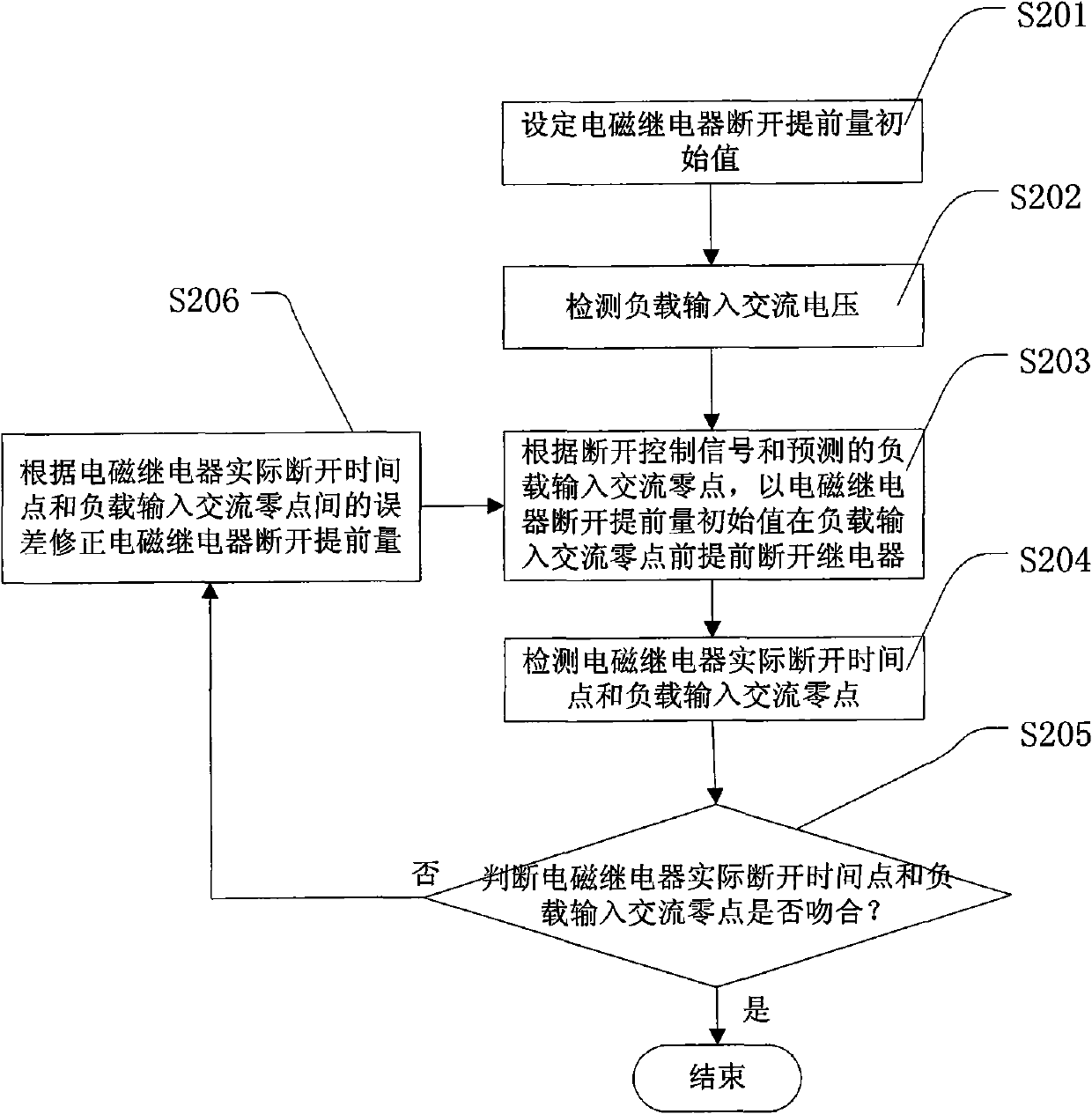

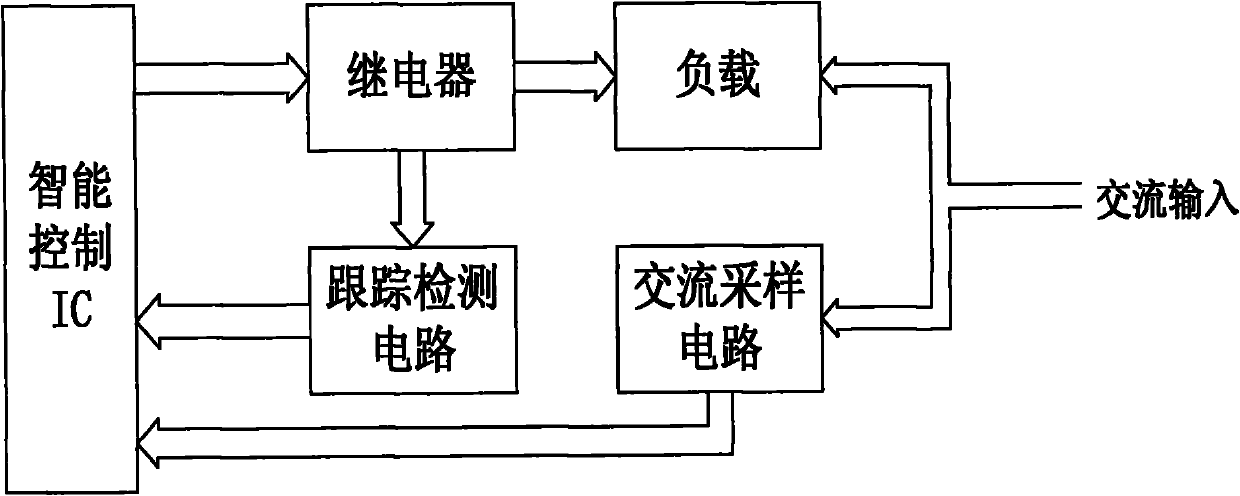

Method of zero passage switch of electromagnetic relay and circuit

ActiveCN101577192AReduce design and manufacturing costsSolve the ignition problemRelaysVoltageCircuit design

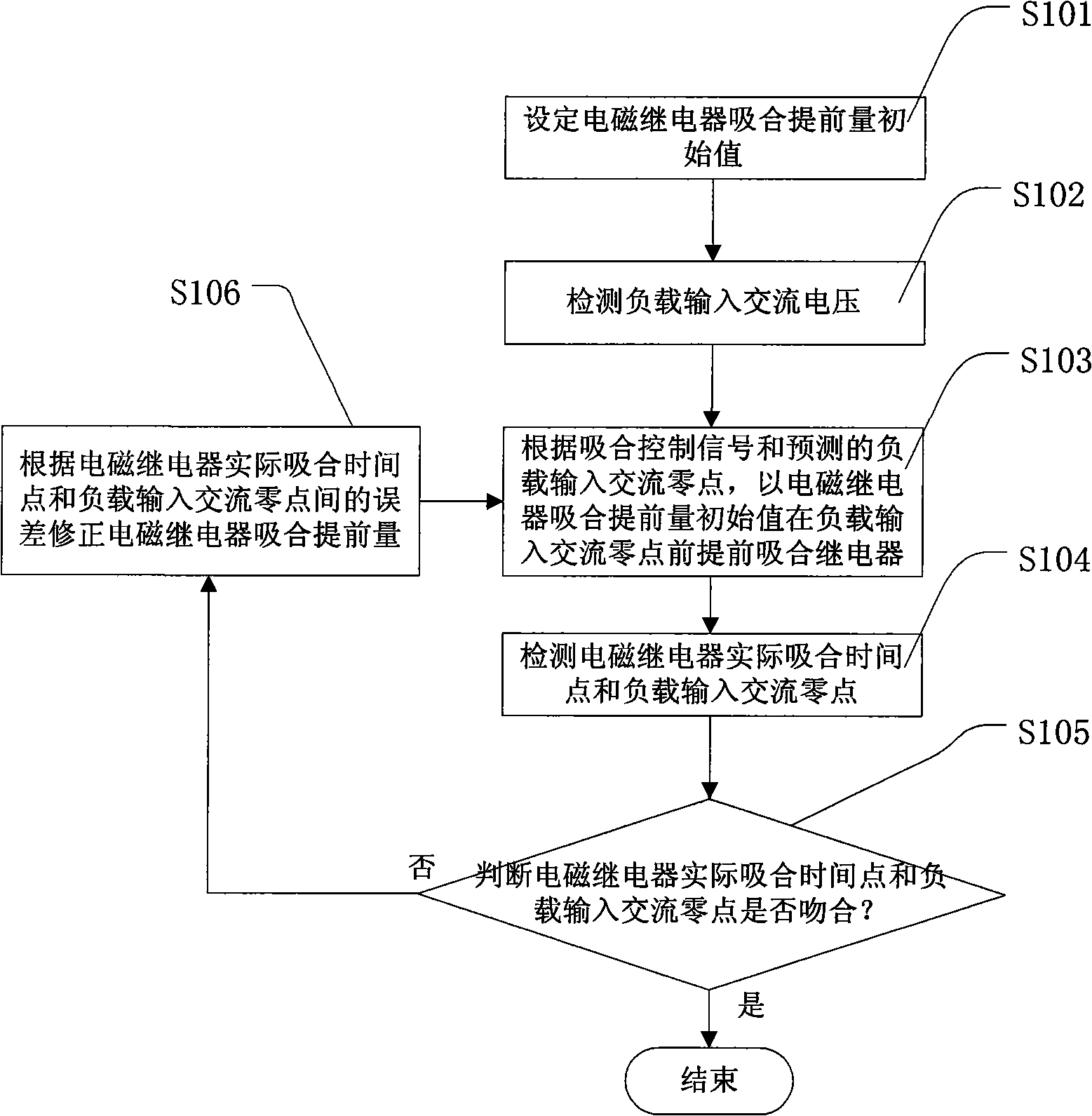

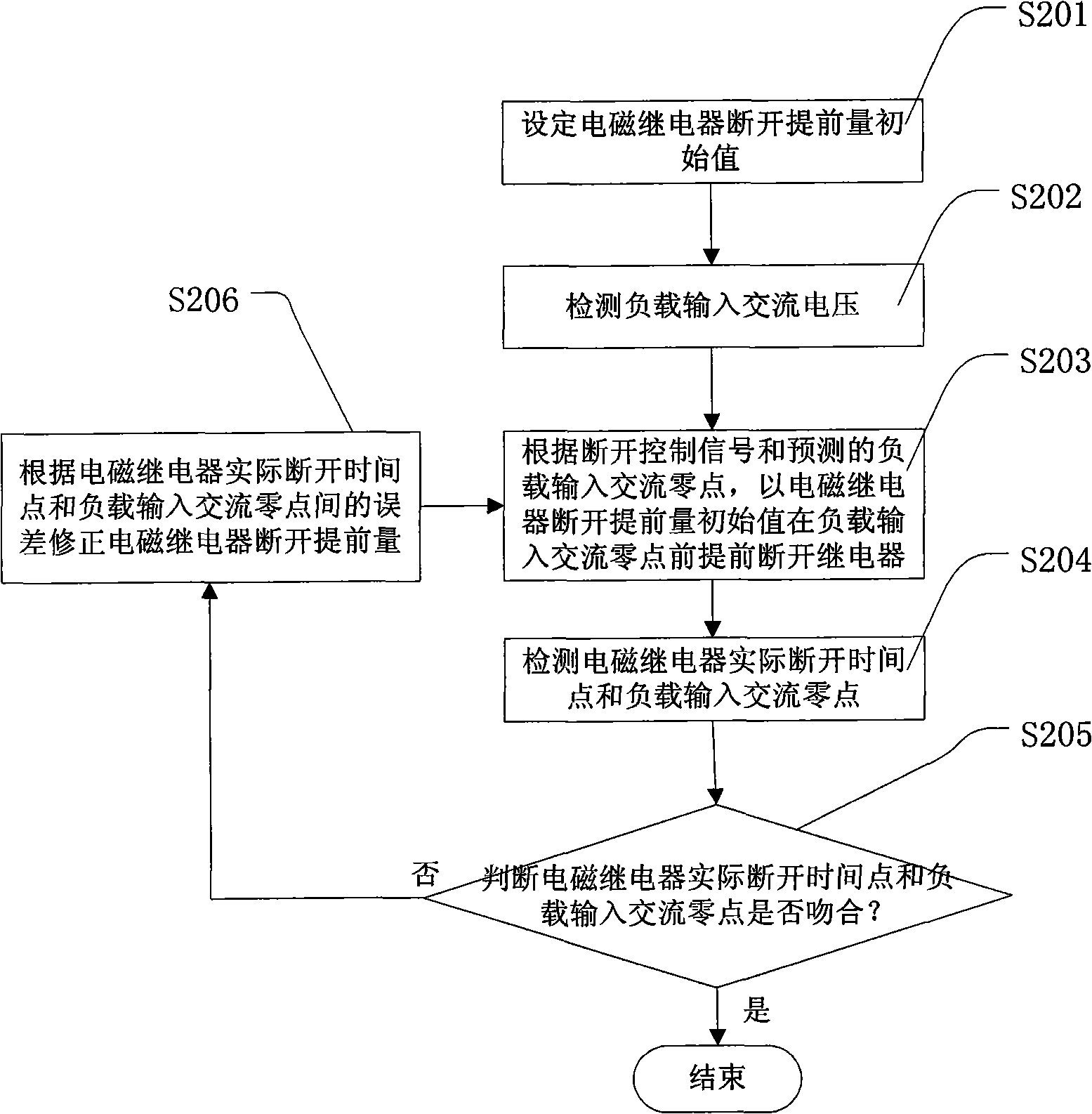

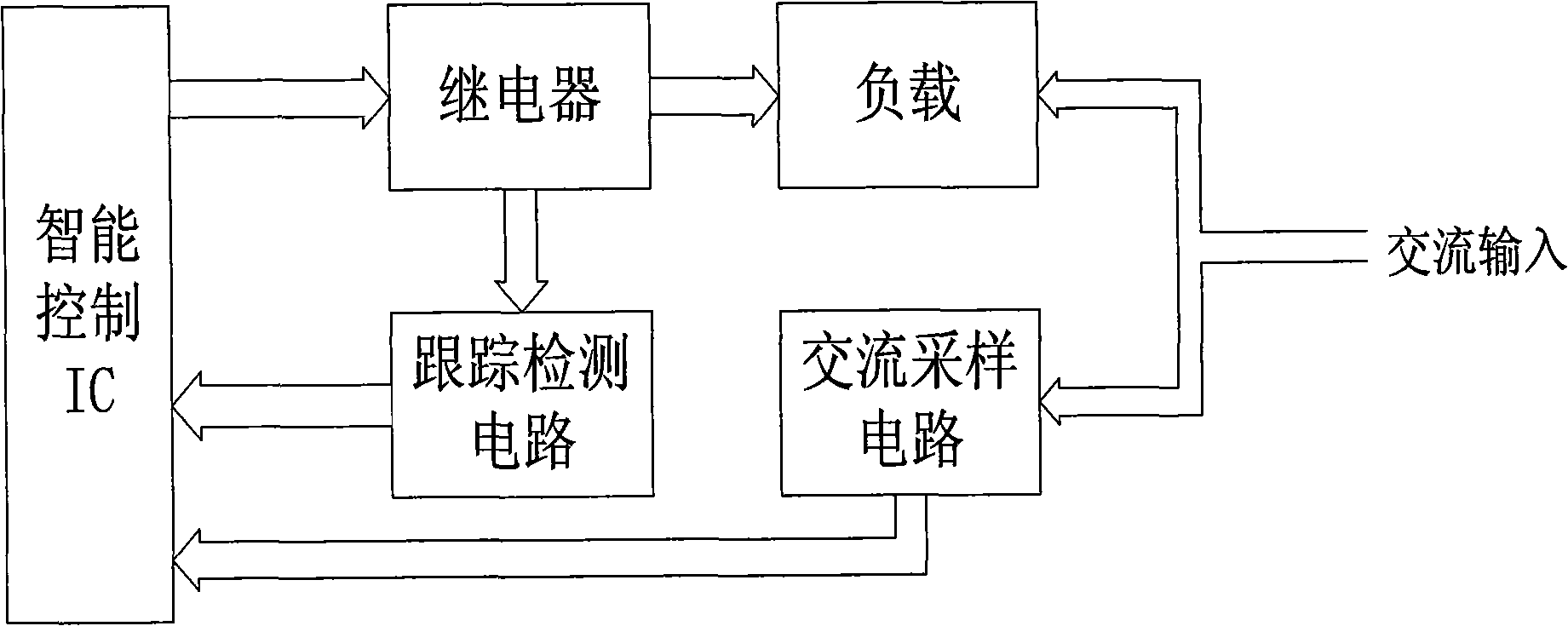

The invention discloses a method of a zero passage switch of an electromagnetic relay and a circuit, wherein an electromagnetic relay zero passage pull-in method comprises the following steps of: setting an initial value of the pull-in initial lead of the electromagnetic relay; detecting the input alternating voltage; pulling in the electromagnetic relay in advance before the input alternating zero point by the initial value of the pull-in initial lead of the electromagnetic relay according to pull-in control signals and the predicted input alternating zero point; detecting the actual pull-in time point of the electromagnetic relay and the input alternating zero point; if the actual pull-in time point of the electromagnetic relay and the input alternating zero point are identical, ending the detection; if not, modifying the pull-in initial lead of the electromagnetic according to the error between the actual pull-in time point of the electromagnetic relay and the input alternating zero point; and then repeatedly executing the steps. The invention solves the problems of striking fire of the electromagnetic relay and EMI by a circuit self-learning way, improves the service life of the relay, and reduces the manufacture cost of circuit design.

Owner:PERICOM TECH (SHANGHAI) CO LTD

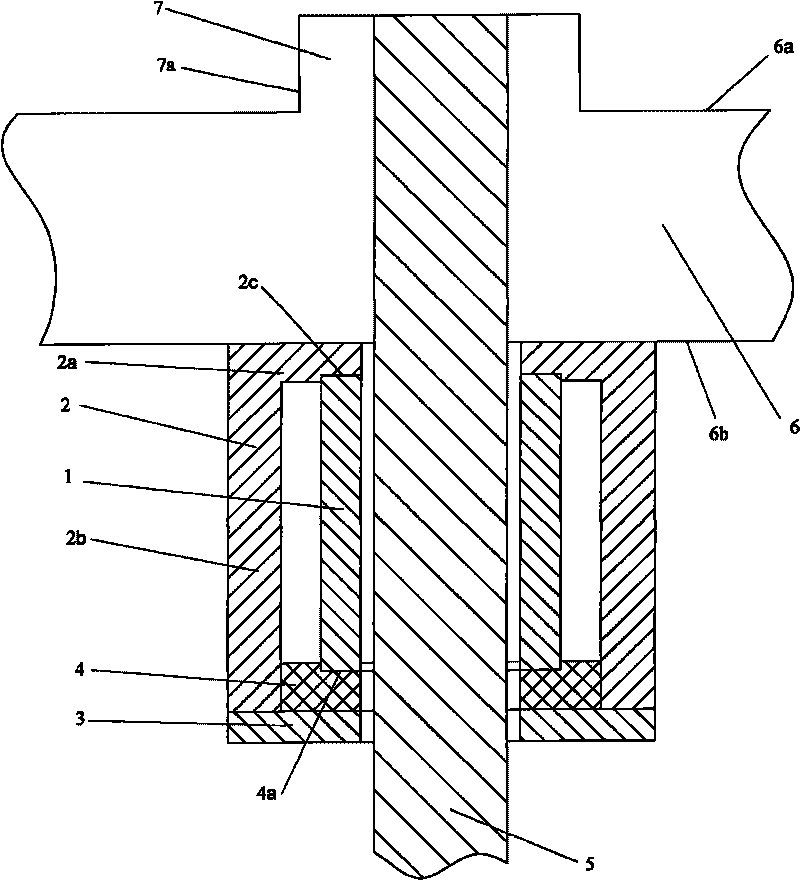

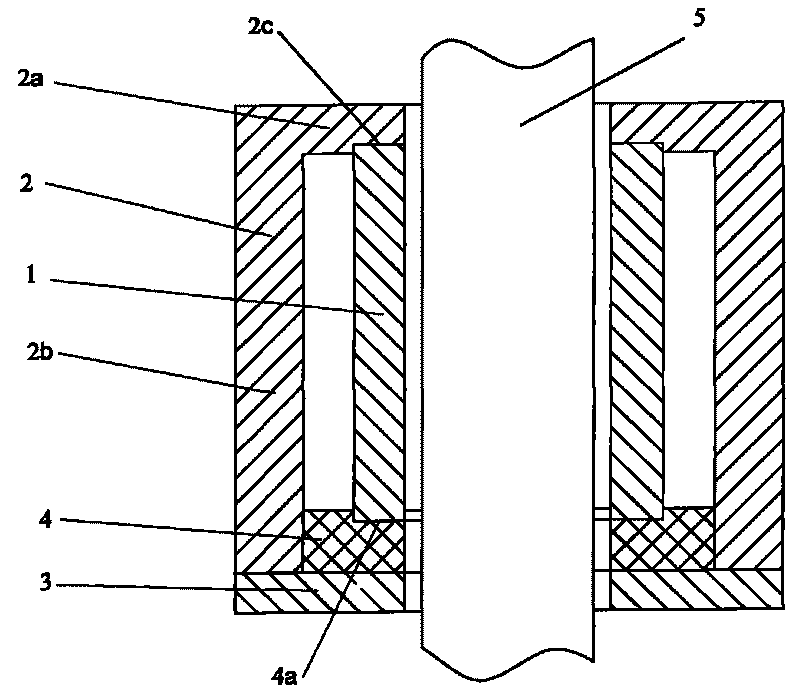

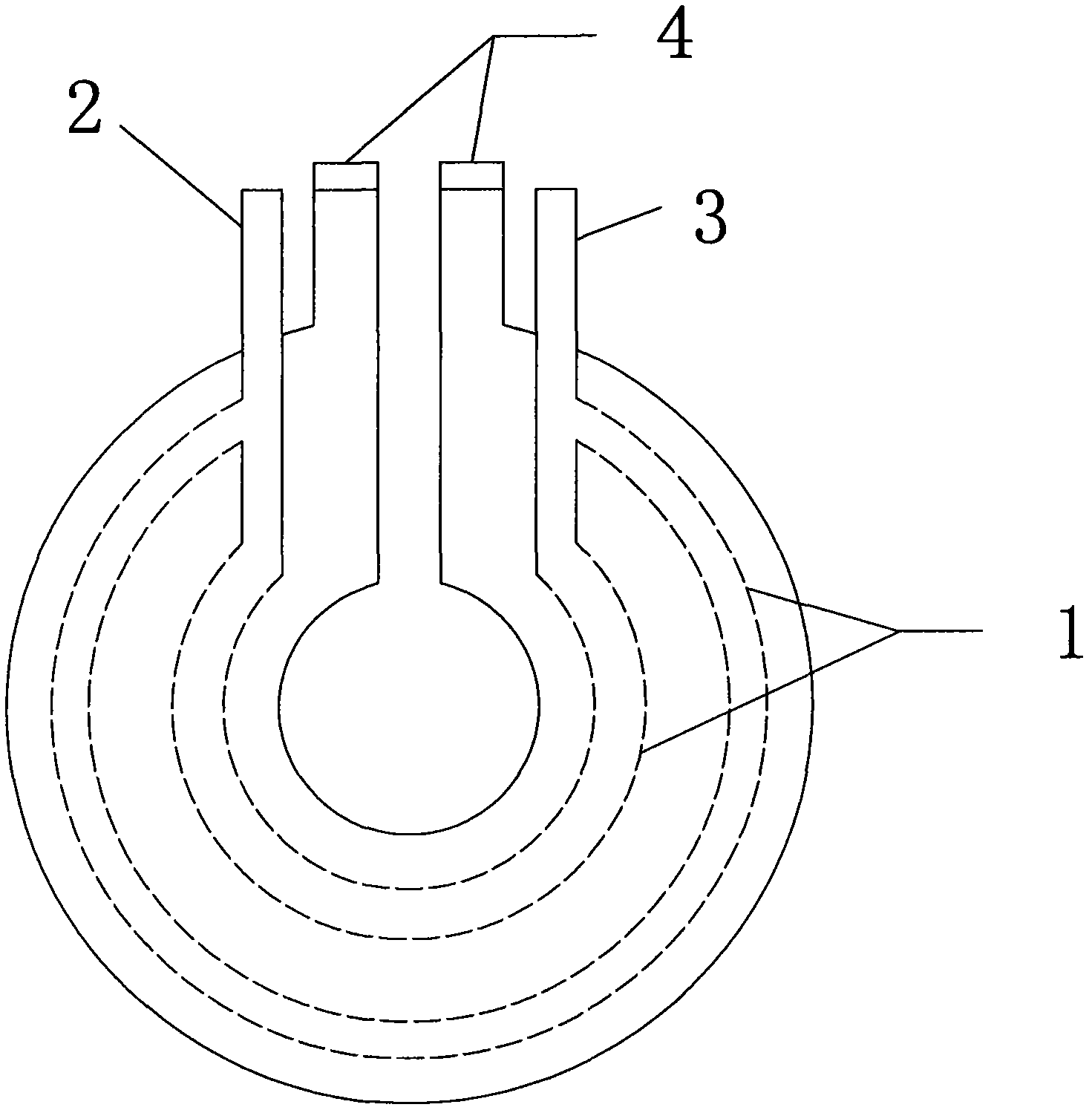

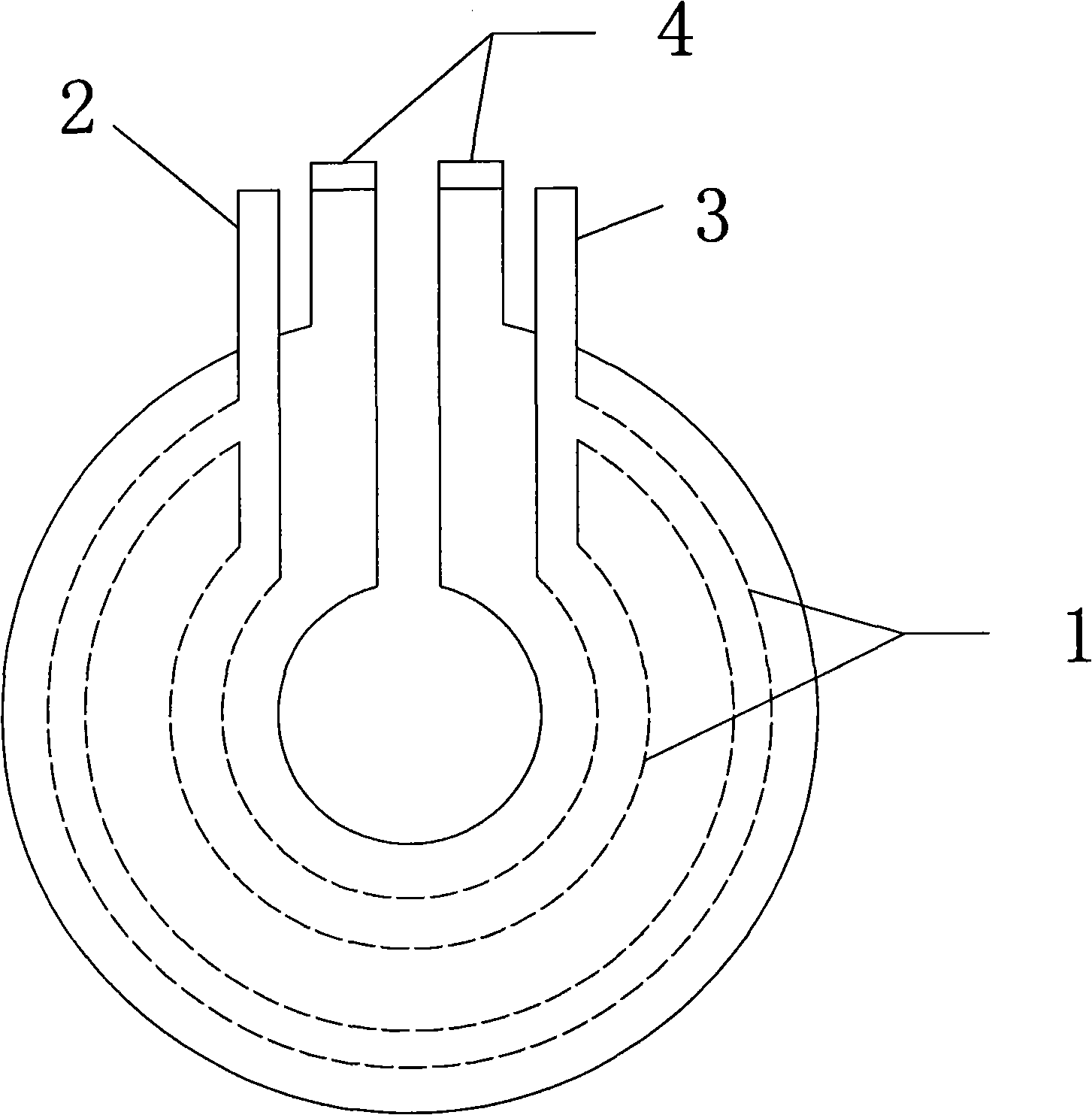

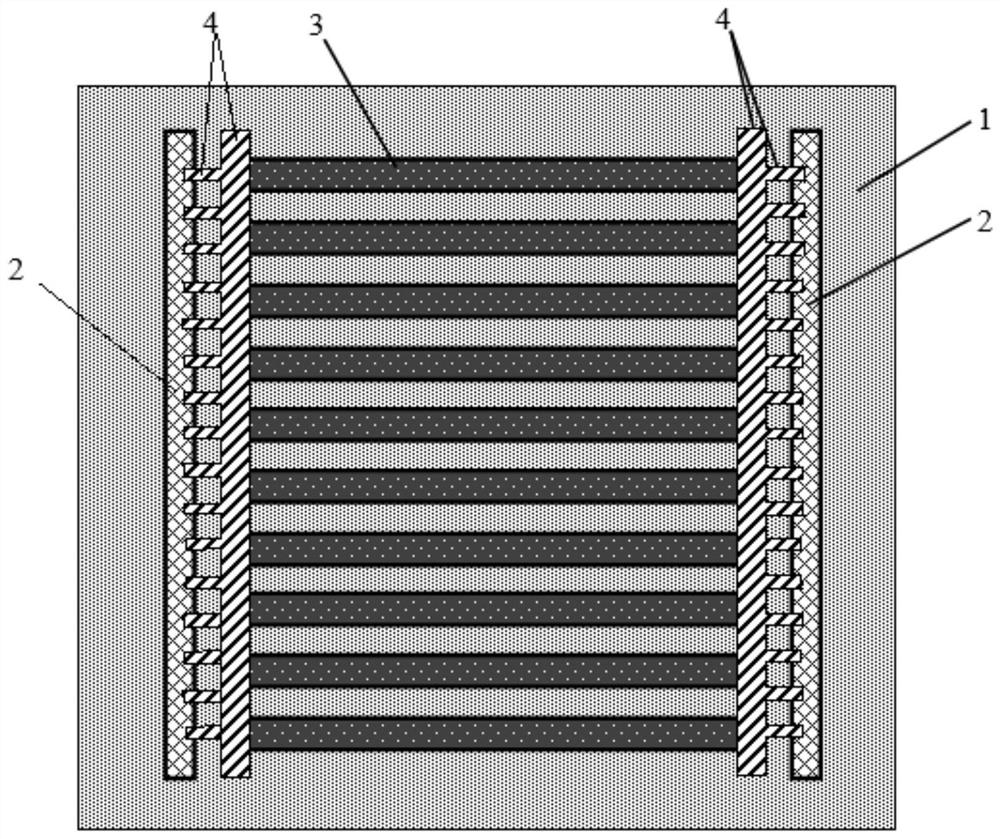

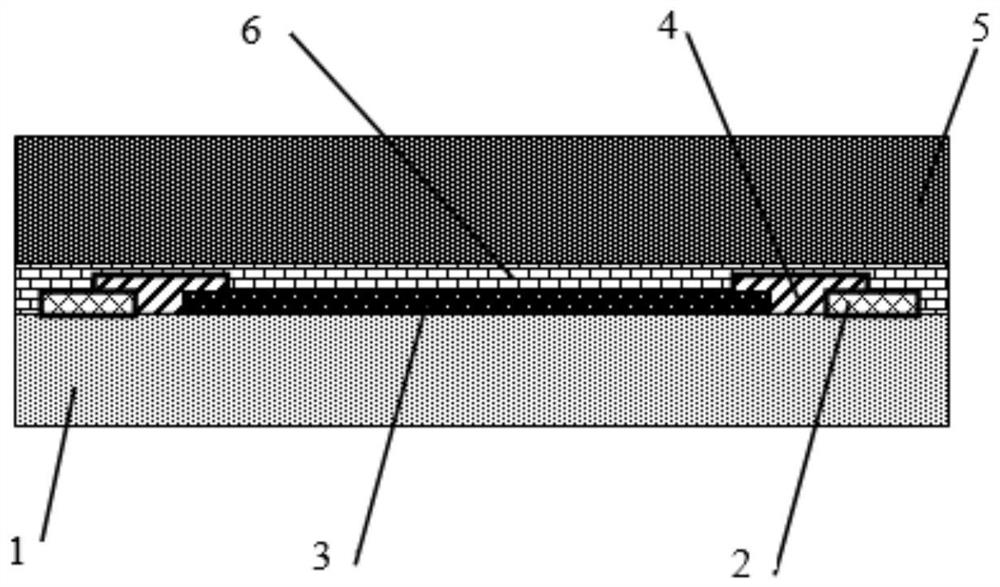

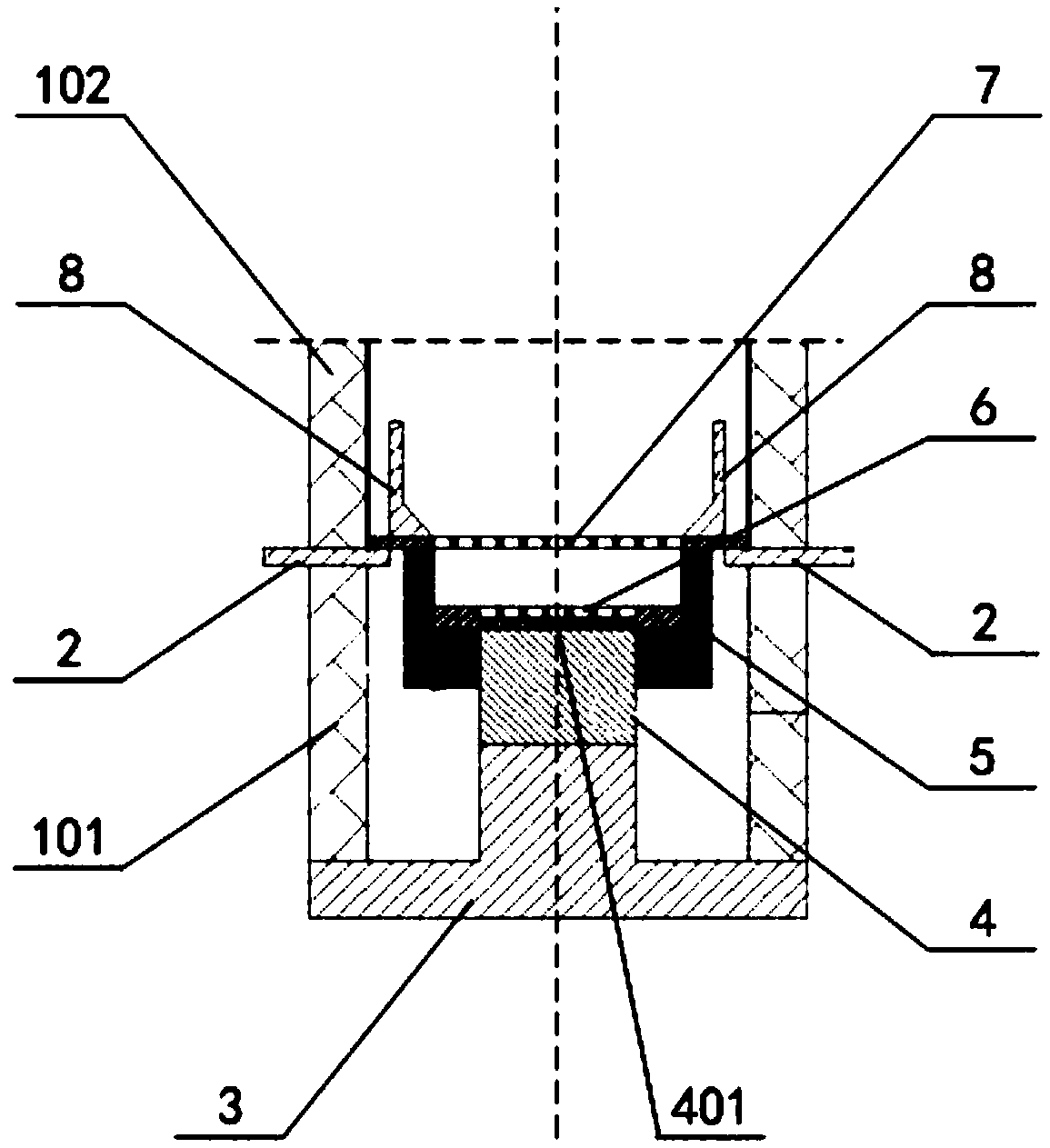

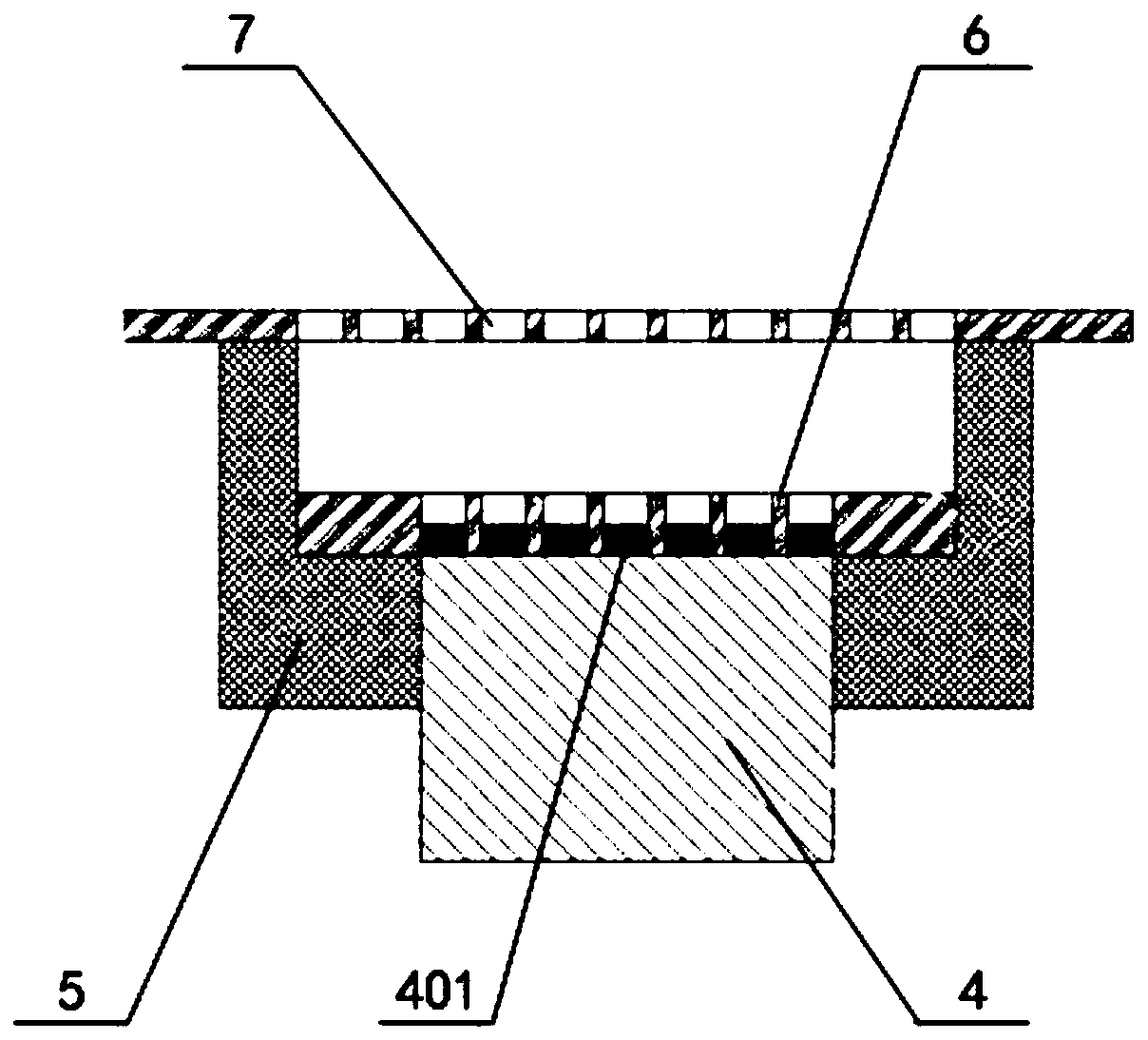

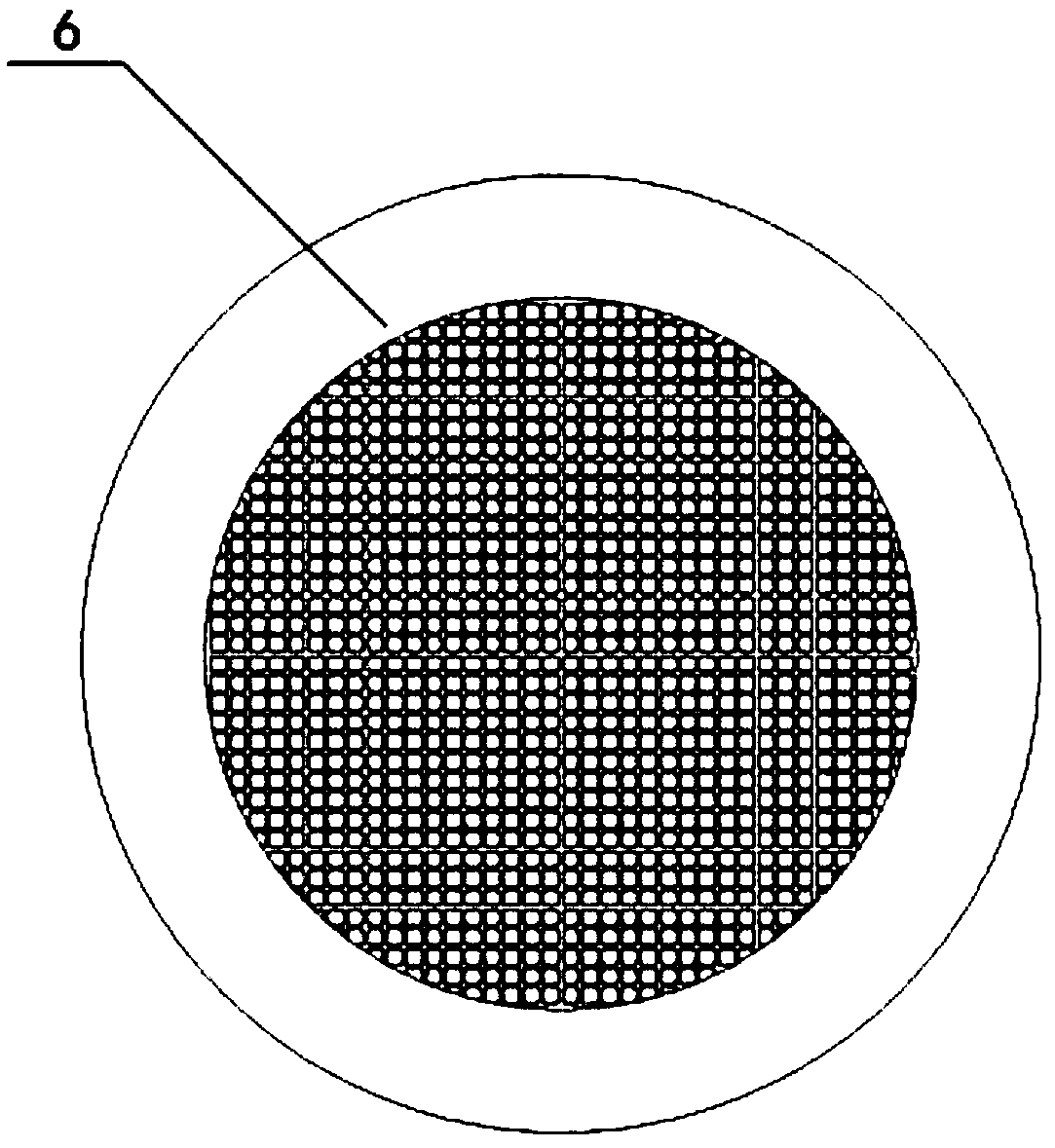

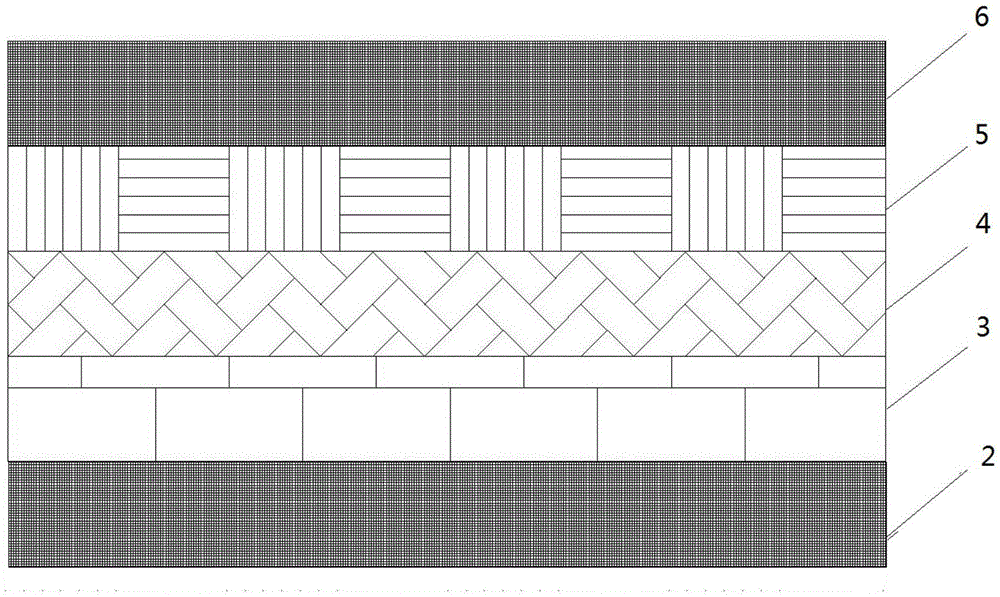

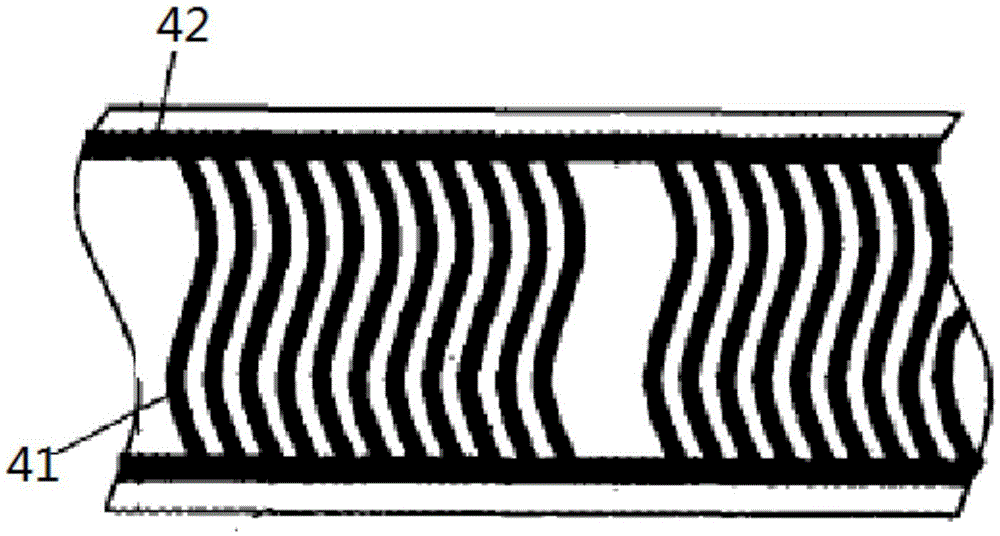

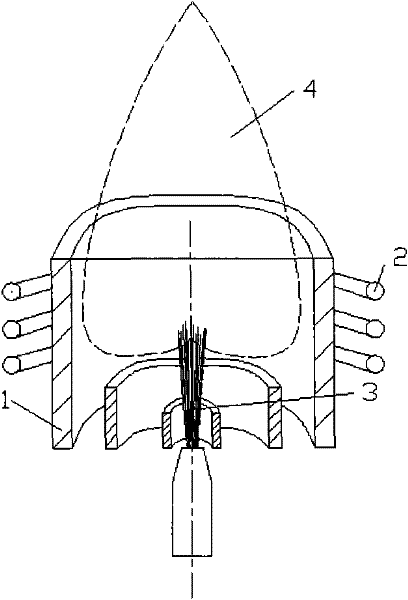

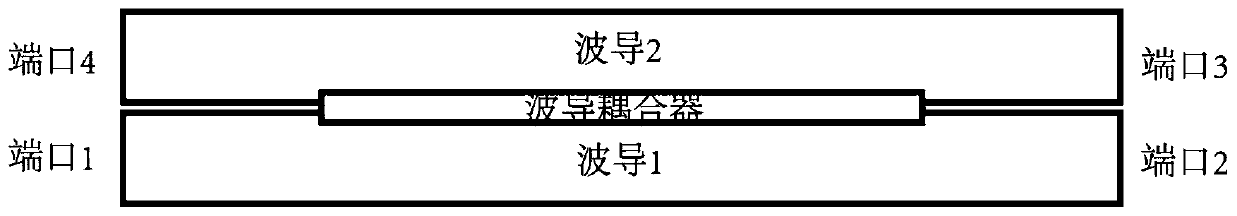

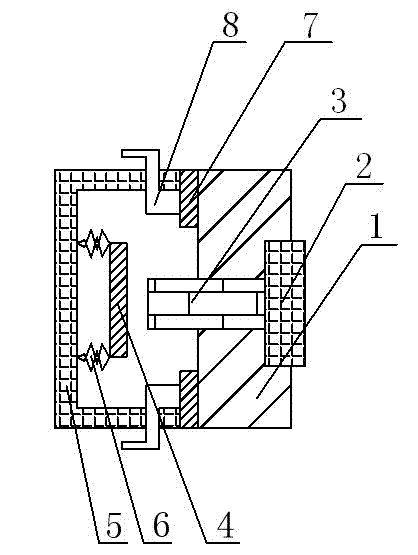

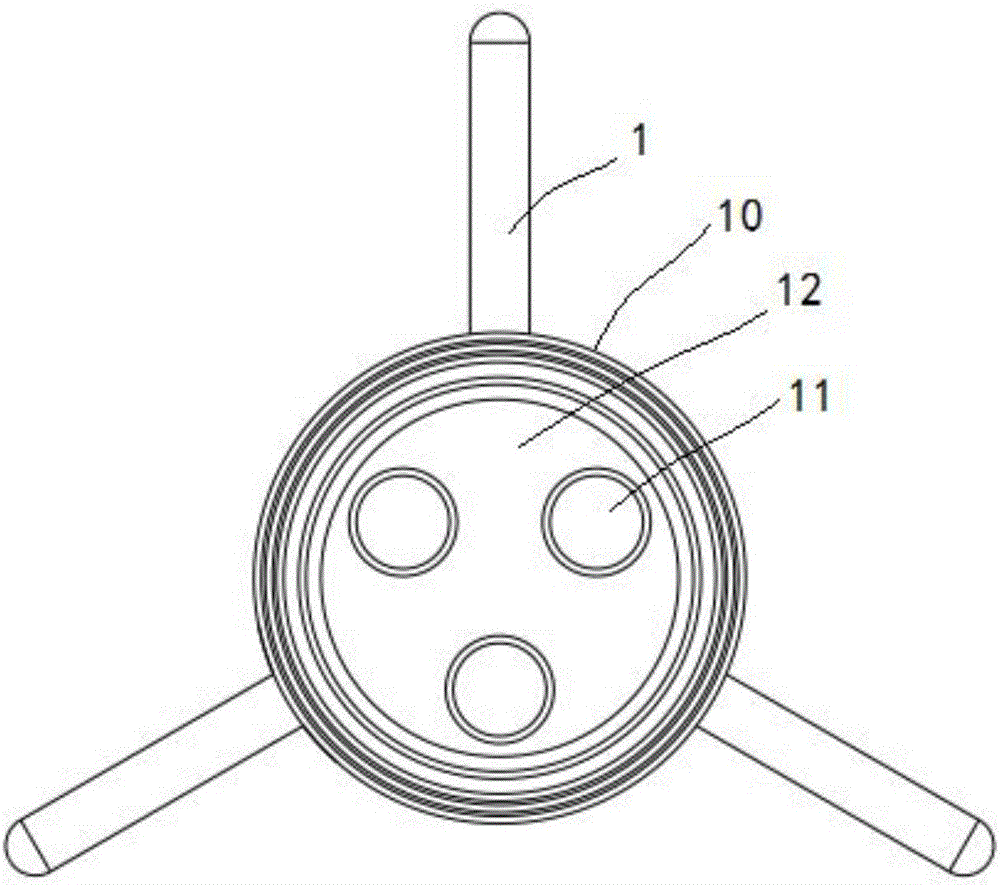

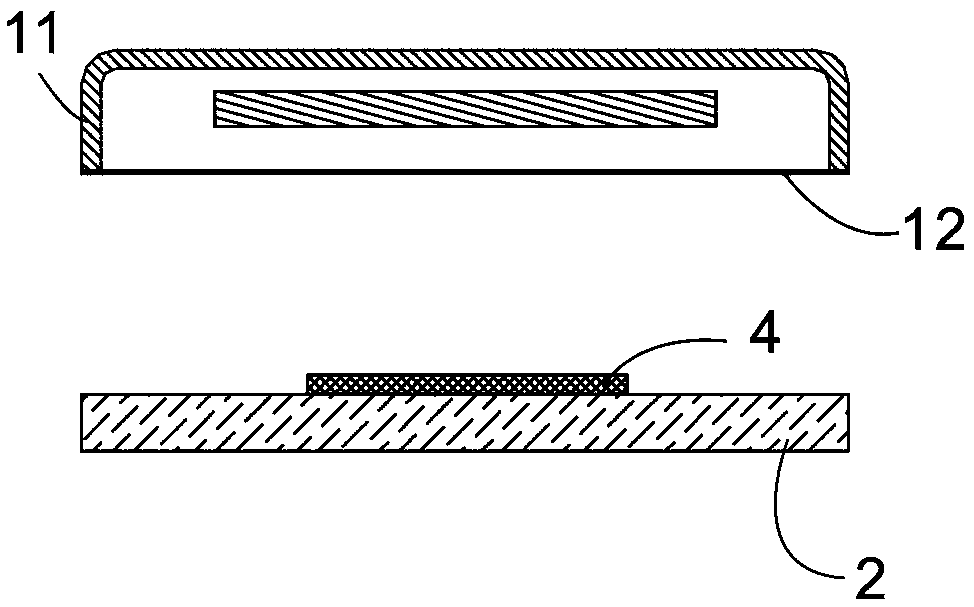

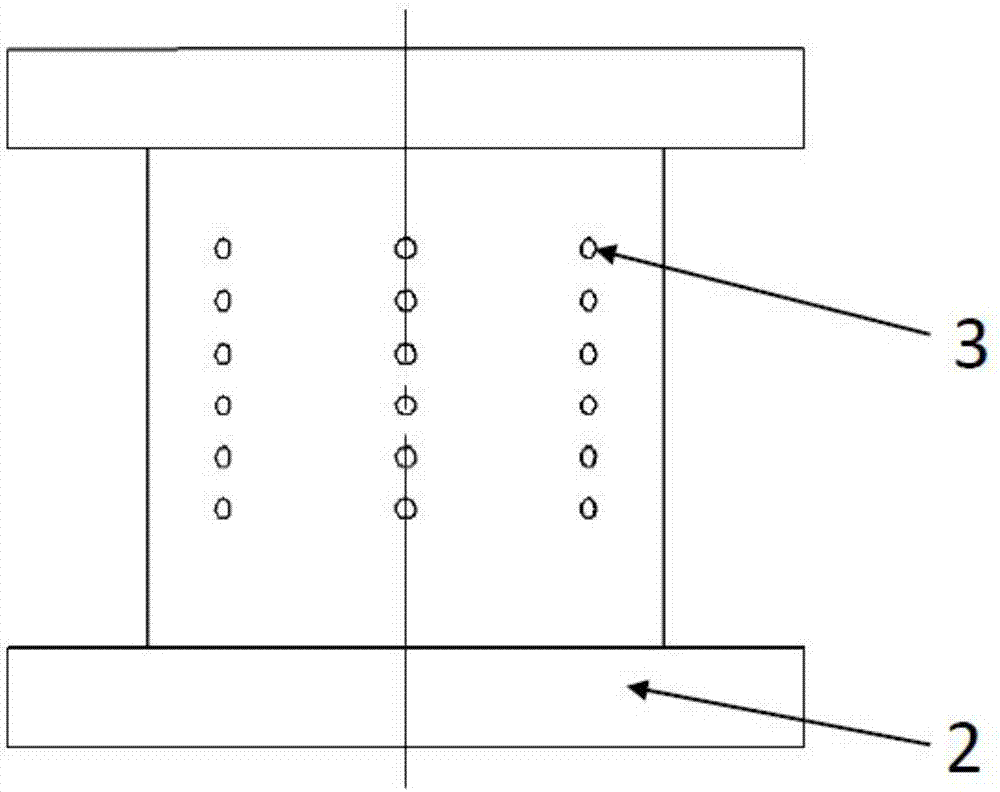

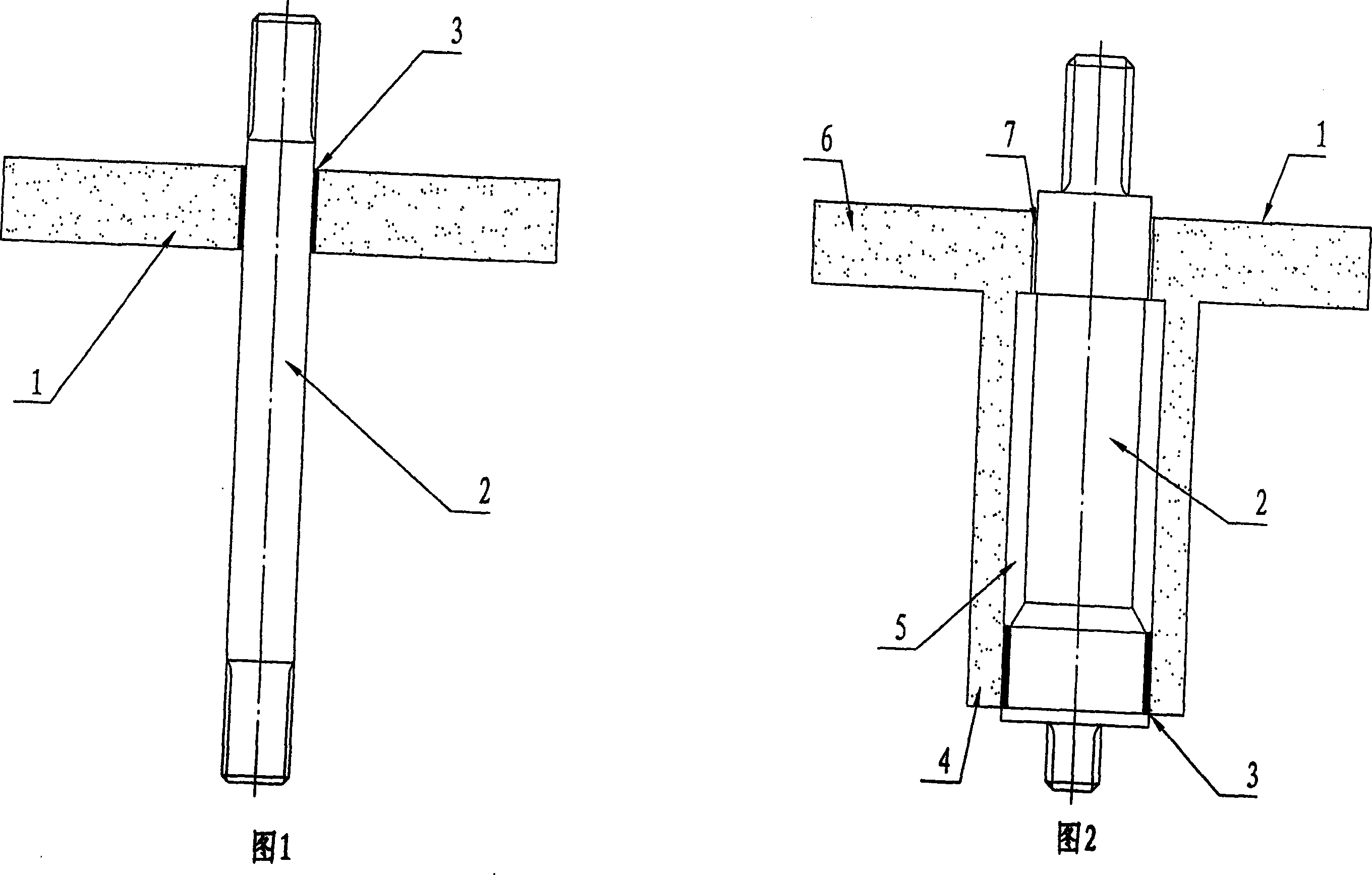

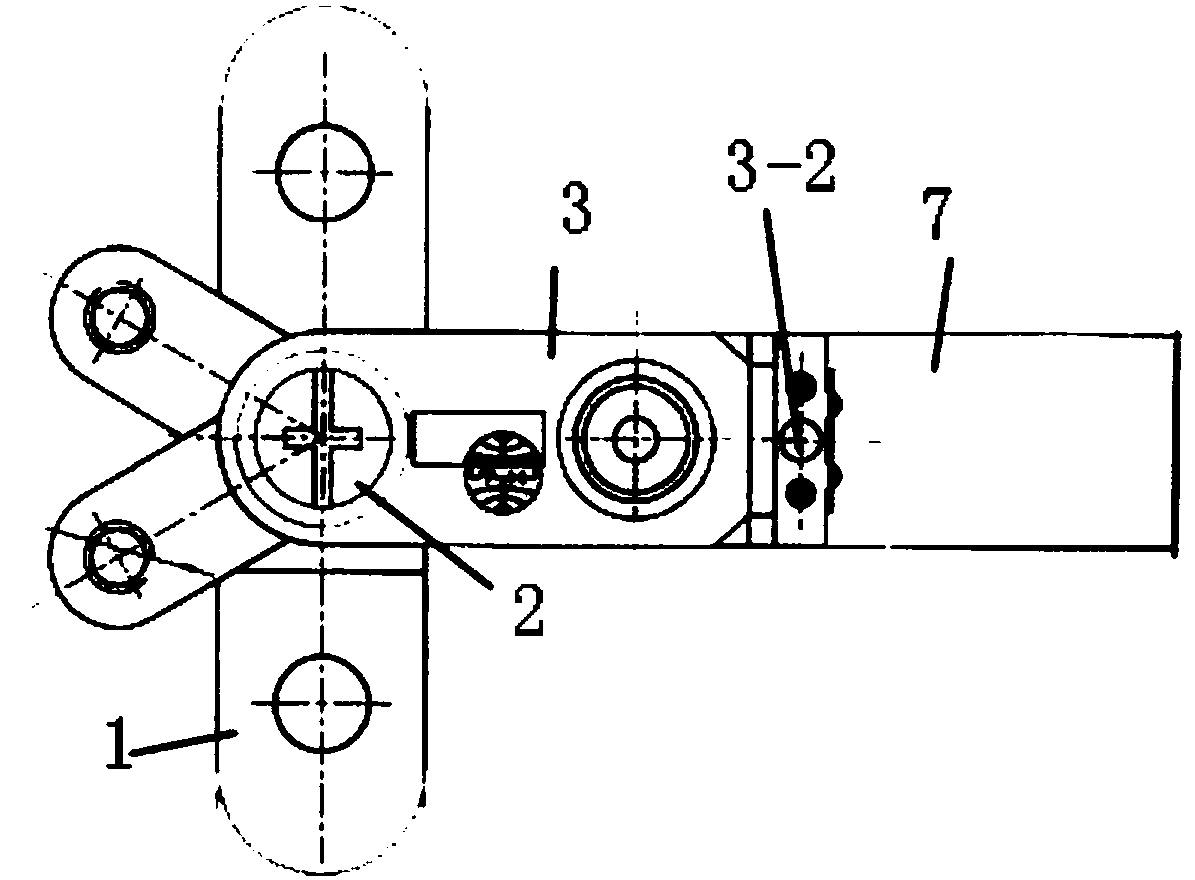

Minitype broadband throttling device used for transmission shaft in guided wave system

InactiveCN101702456AAvoiding Concentricity RequirementsSolve the ignition problemMicrowave heatingWaveguide type devicesFrequency bandBroadband

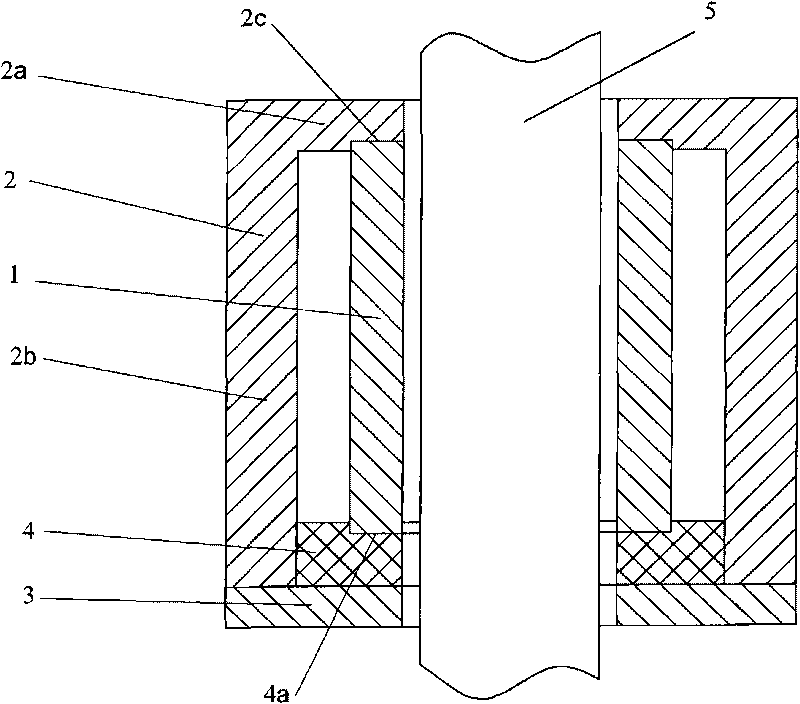

The invention provides a minitype broadband throttling device used for a transmission shaft in a guided wave system, which comprises an inner wall 1, a casing 2, a base 3 and a medium gasket 4 of the throttling device, wherein the top of the inner wall 1 of the throttling device is connected with the casing 2 of the throttling device, and the casing 2 of the throttling device is connected with the base 3 of the throttling device; the inner wall 1 of the throttling device is positioned by the medium gasket 4; and a transmission shaft 5 is positioned in the center of the throttling device, and the transmission shaft 5 and the throttling device are coaxial. The throttling device has small volume, light weight, easy processing, wide frequency band and little microwave leakage, and is suitable for an occasion that a mechanical transmission device is introduced into the guided wave system when a microwave system and a mechanical transmission system work synergically.

Owner:SOUTHWEST JIAOTONG UNIV

Method for producing gas phase heavy phosphorus-doped float zone silicon single crystal

ActiveCN101979719AAvoid problems that damage coilsSolve the ignition problemPolycrystalline material growthBy zone-melting liquidsChemical reactionGas phase

The invention relates to a method for producing a gas phase heavy phosphorus-doped float zone silicon single crystal. The method comprises float zone gas phase heavily doping and crystal pulling processes. In the process, a water-cooled electromagnetic copper coil with double waterways is adopted so that the temperature of the coil can be controlled between 10 and 20 DEG C; therefore, the coil is prevented from being damaged by a chemical reaction of phosphorus and the copper coil at a high temperature; and simultaneously the problem of a coil spark caused by thermal ionization of phosphorus impurities near the coil is solved. The gas phase heavy phosphorus-doped float zone silicon single crystal produced by the method has the characteristics of: oxygen content below 1ppm, axial resistivity uniformity of within + / -10 percent and resistivity of 0.002 Ohm.cm, well meets the strict requirement of a transient voltage suppressor (TVS) on a silicon substrate material, and meets the requirement of a TVS device on the silicon substrate material.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

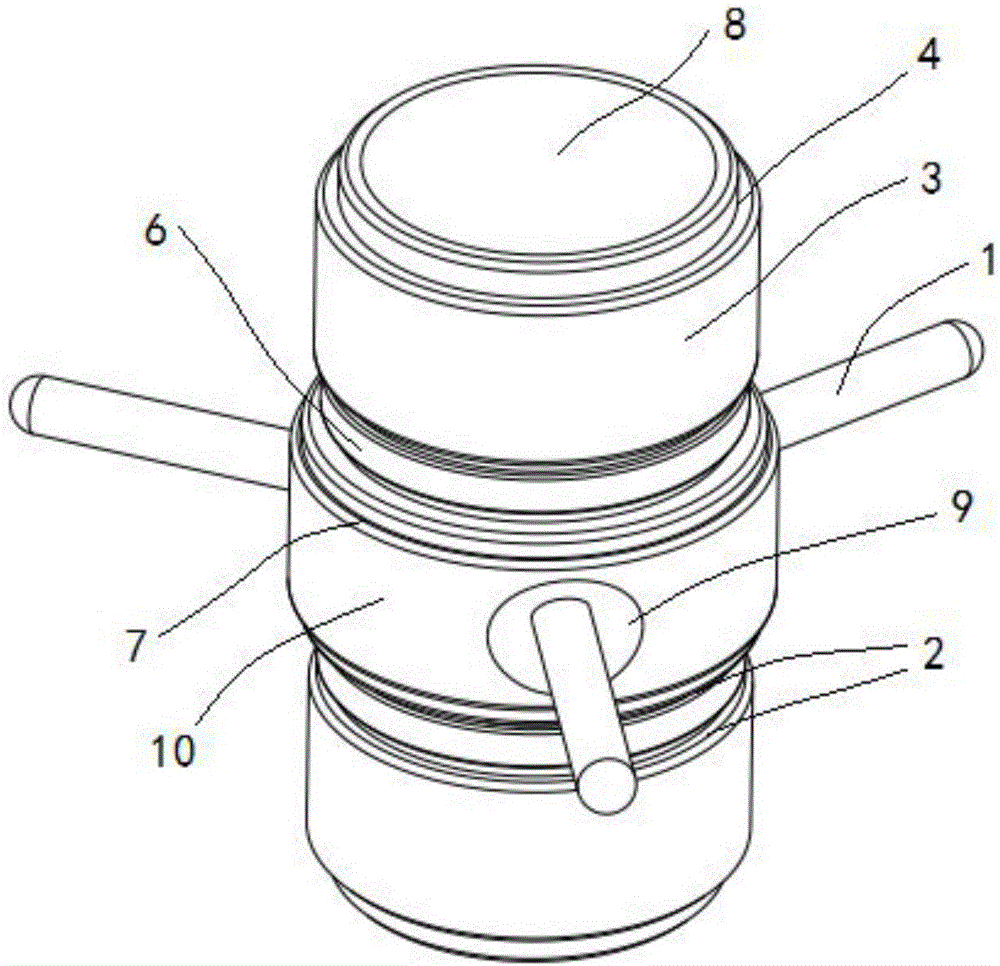

High-voltage coaxial cable joint

ActiveCN109546492ASolve the ignition problemInhibit local contactEngagement/disengagement of coupling partsCoupling contact membersElectrical conductorCoaxial cable

The invention discloses a high-voltage coaxial cable joint and aims to solve the problem that an existing high-voltage coaxial cable joint is likely to cause sparks when large current flows and is inaccurate to connect and position. The high-voltage coaxial cable joint consists of a cable male connector and a cable female connector. The connection reliability is improved by disposing a metal spring on the contact surface of the cable male connector and the cable female connector. The positioning accuracy is improved by installing an auxiliary positioning ring on the outer insulator of a high-voltage coaxial cable. Thus, the overall connection effect of the high-voltage coaxial cable joint is improved. The high-voltage coaxial cable joint realizes the high-voltage potential contact betweenthe inner conductor connecting body and the female connecting body of the cable male connector, and the elastic connection of the ground potential contact between a male connector nut and a female connector flange, so as to avoid partial contact in case of eccentric installation . The high-voltage coaxial cable joint solves the sparks when the pulsed large current flows, enhances a connection effect, and is suitable for high-voltage coaxial cables of different radial sizes, and is improved in universality.

Owner:NAT UNIV OF DEFENSE TECH

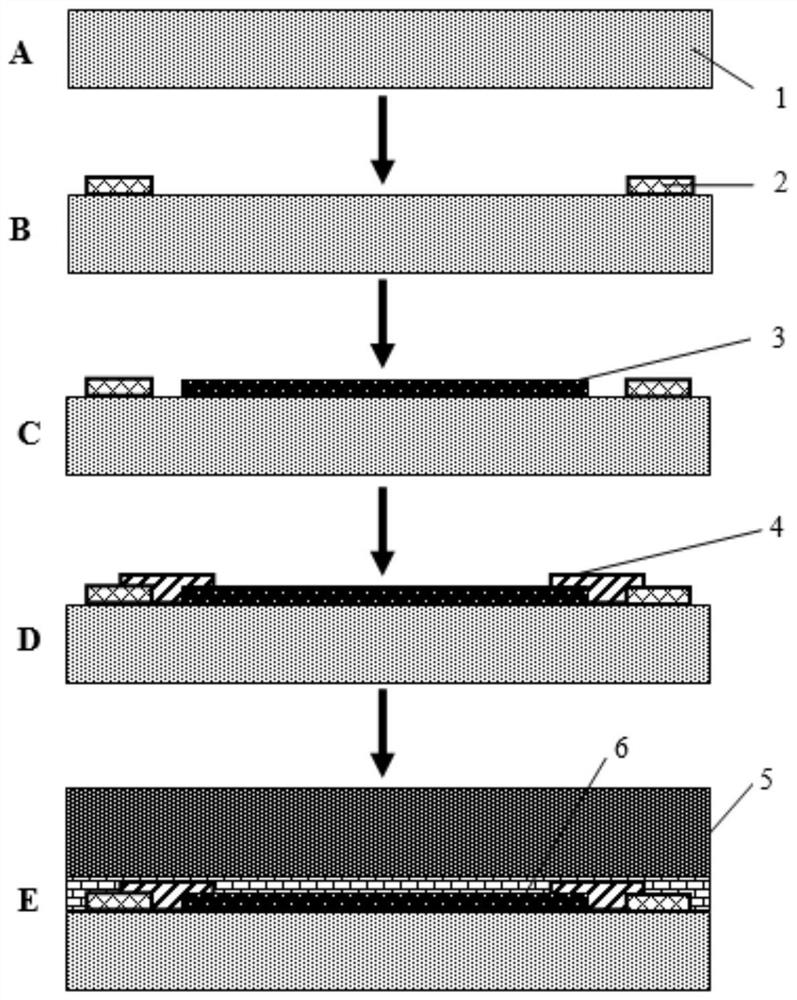

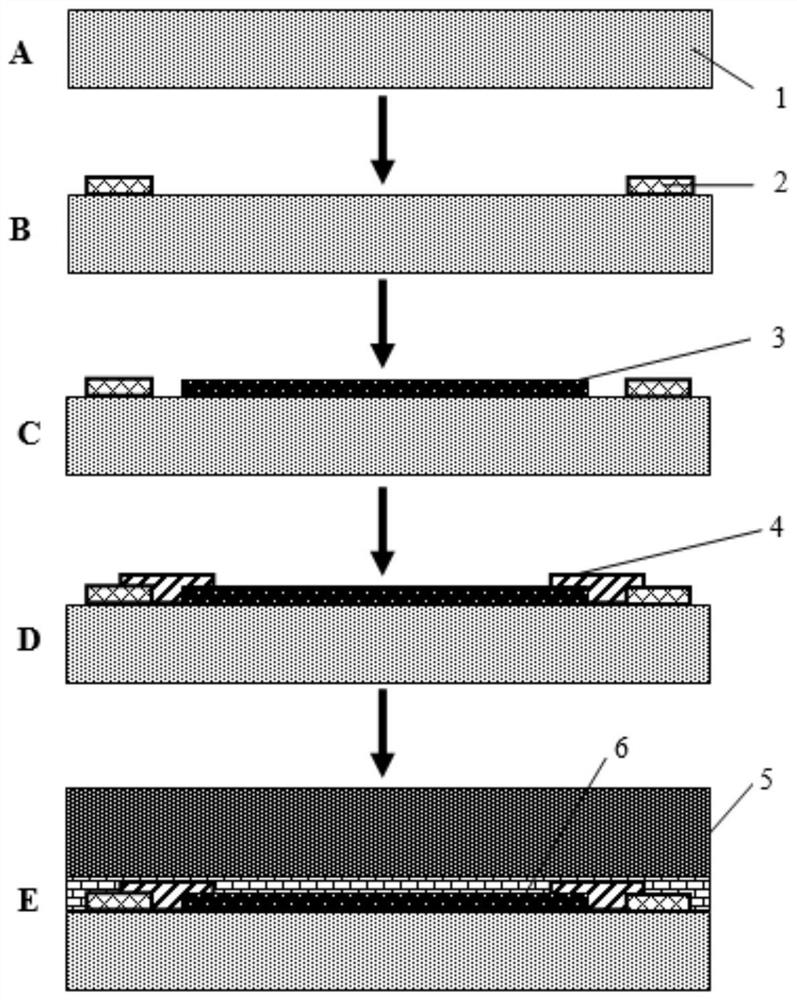

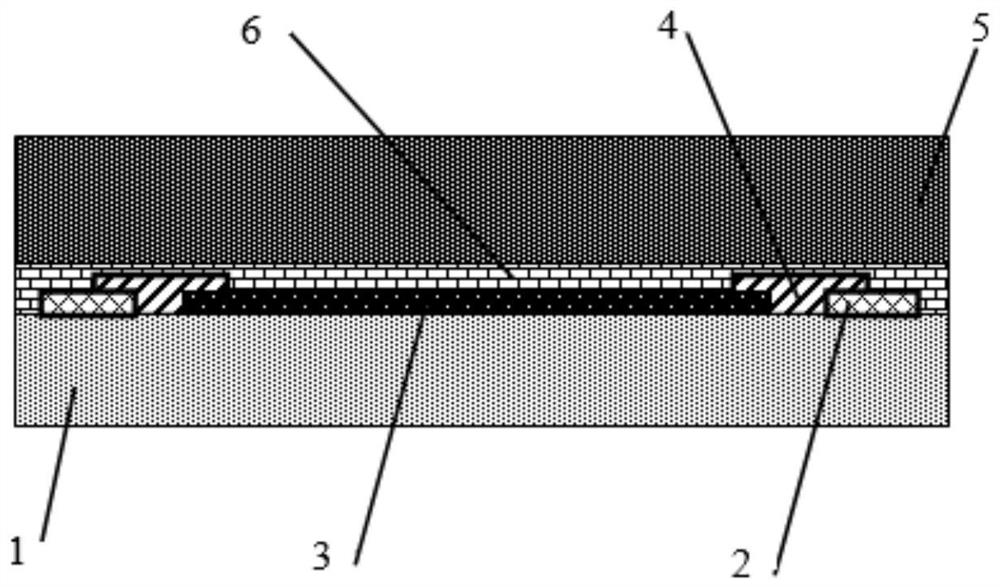

Graphene electrothermal film for floor heating

PendingCN111712001AStrong adhesionReliable electrical connectionLamination ancillary operationsSynthetic resin layered productsFlexible circuitsCopper electrode

The invention discloses a graphene electrothermal film for floor heating, which is prepared according to the following steps: coating a graphene heating film on the surface of an insulating substrateof the electrothermal film, and implanting copper electrodes into two opposite sides of the graphene heating film; printing bridging electrodes on the surfaces of the graphene heating film and the copper electrode; and then covering and packaging the second insulating substrate to form the flexible circuit board. The heating body of the graphene electrothermal film for floor heating is in good contact with the bridging electrode and the copper electrode. The bridging electrode completely coats the copper electrode. The contact resistance between the bridging electrode and the surface of the copper current-carrying electrode is obviously reduced. The graphene electrothermal film has the advantages that the the peeling resistance is improved, the risk of fire caused by edge sparking of the heating body is effectively solved, the energy utilization rate is increased, the whole-process automatic production is more favorably realized, and the problem that the copper electrode compounding process is easy to be abnormal and cannot be automatically connected with the front-end process in the traditional production process is completely eradicated.

Owner:安徽宇航派蒙健康科技股份有限公司

A double-grid controlled cold cathode electron gun and a preparation method thereof

ActiveCN109065428ASimple processExtended service lifeTransit-tube electron/ion gunsCold cathodesHigh densityElectron radiation

The invention relates to the technical field of vacuum electronic devices, and discloses a double-grid control type cold cathode electron gun and a preparation method thereof. In accordance with the present invention, A simple, a new type of electron gun with long service life and excellent performance is provided, the cold cathode is used as the emission source of the vacuum electronic device, Asurface of the cold cathode is arrayed by a cathode grid, which can effectively weaken the electrostatic shielding effect of electron emitted by large area cold cathode material, the emission currentof large area cold cathode material is increased, At the same time, the surface of the cathode substrate is designed as a whole plane so as to not only avoid machining burr and other problems, improveedge effect and spark phenomenon, but also make the electric field distribution on the surface of cathode substrate flat, which is conducive to improving the uniformity of emission current density and achieving the purpose of large current emission, so the electron gun can be used in vacuum electron radiation components or devices that generate large current and high density electron beam.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

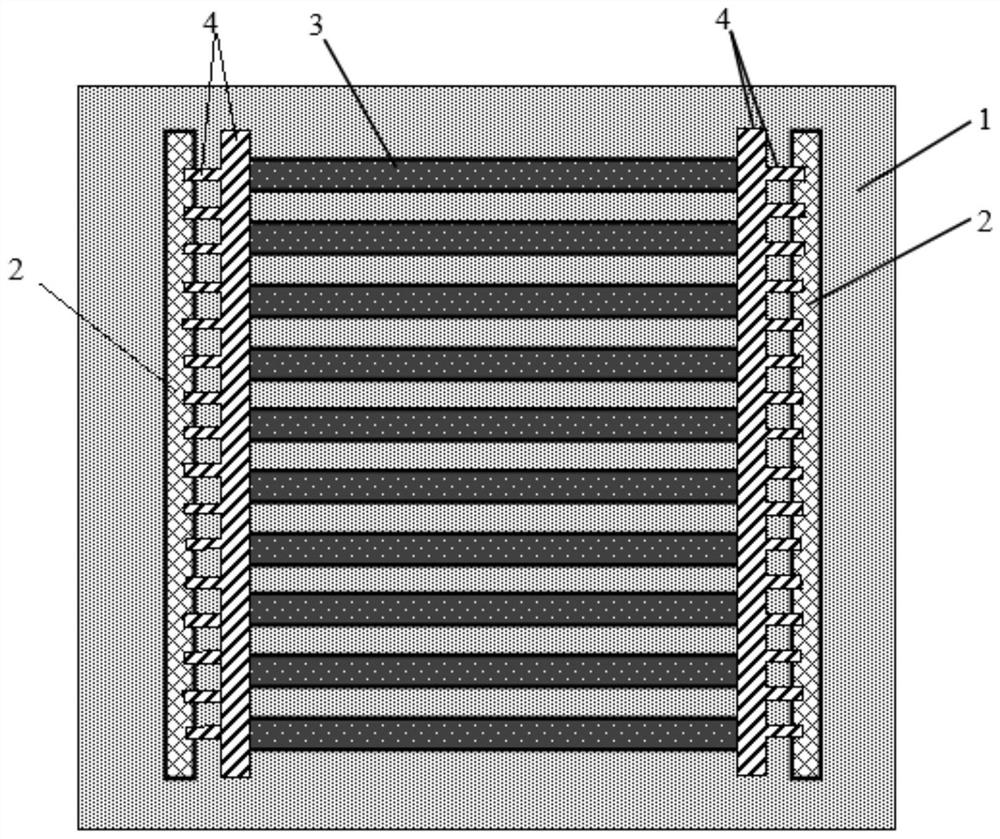

Mica high temperature resistant electrothermal film and preparation method thereof

ActiveCN105554925AFacilitated DiffusionSolve the short circuitHeating element materialsAlloyMetal electrodes

The invention provides a mica high temperature resistant electrothermal film and a preparation method thereof. The mica high temperature resistant electrothermal film comprises a metal electrode, and a first mica layer, a first heat conduction film, a metal heating layer, a second heat conduction film and a second mica layer which are successively stacked from bottom to top; the first heat conduction film is evenly coated on the upper surface of the first micro layer; the metal heating layer is arranged on the upper surface of the first heat conduction film; a plurality of conductive alloy bars are evenly distributed on the metal heating layer; the metal electrode is electrically connected with the metal heating layer; the second heat conduction film is evenly coated on the upper surface of the metal heating layer; the second mica layer is arranged on the upper surface of the second heat conduction layer; the main components of the first heat conduction film and the second heat conduction are silicon carbide; and the mass fraction of the silicon carbide is more than or equal to 50 %. According to the mica high temperature resistant electrothermal film and the preparation method thereof, the use security and service life problems resulted from partial over heat of the micro electrothermal film can be effectively solved.

Owner:BIHE ELECTRIC TAICANG CO LTD

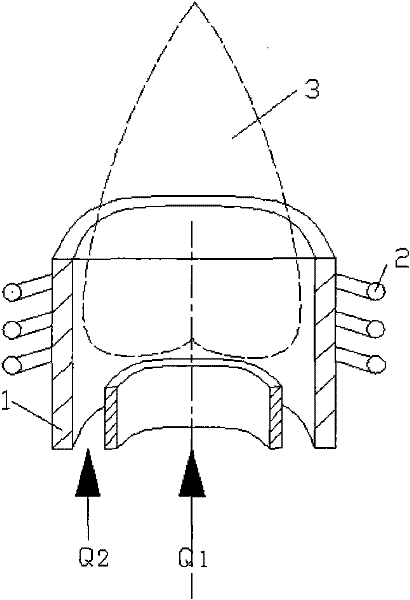

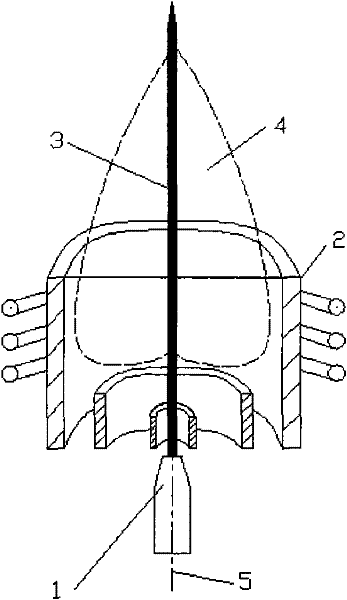

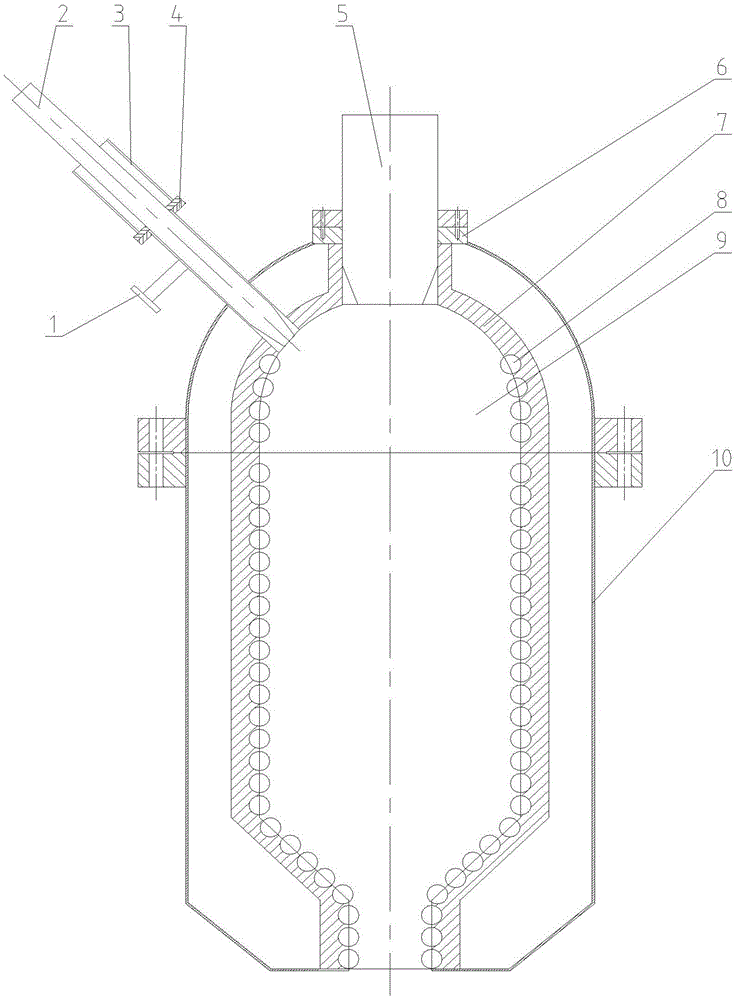

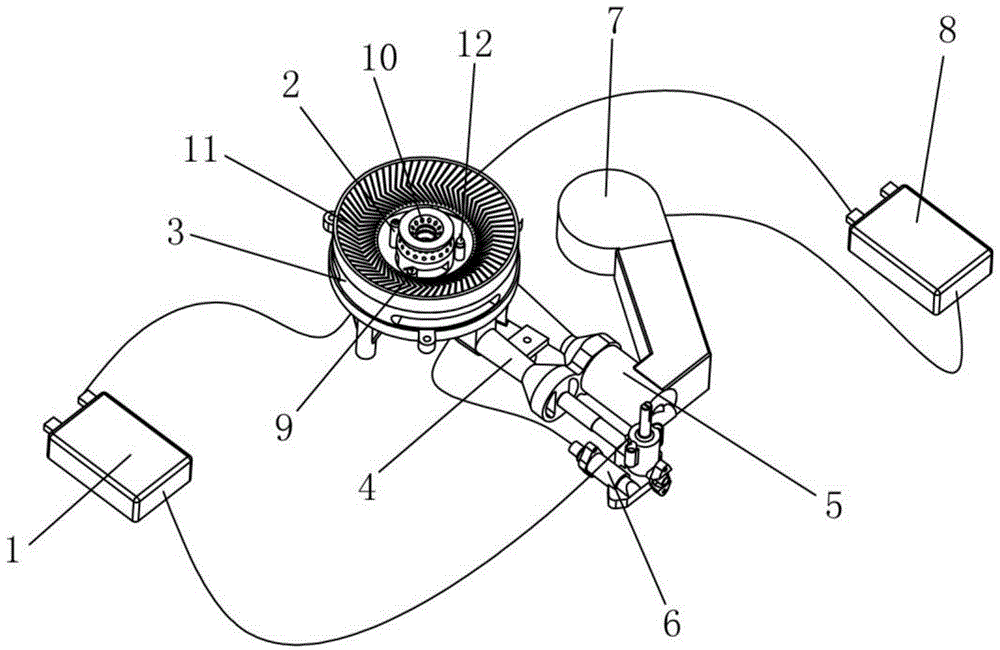

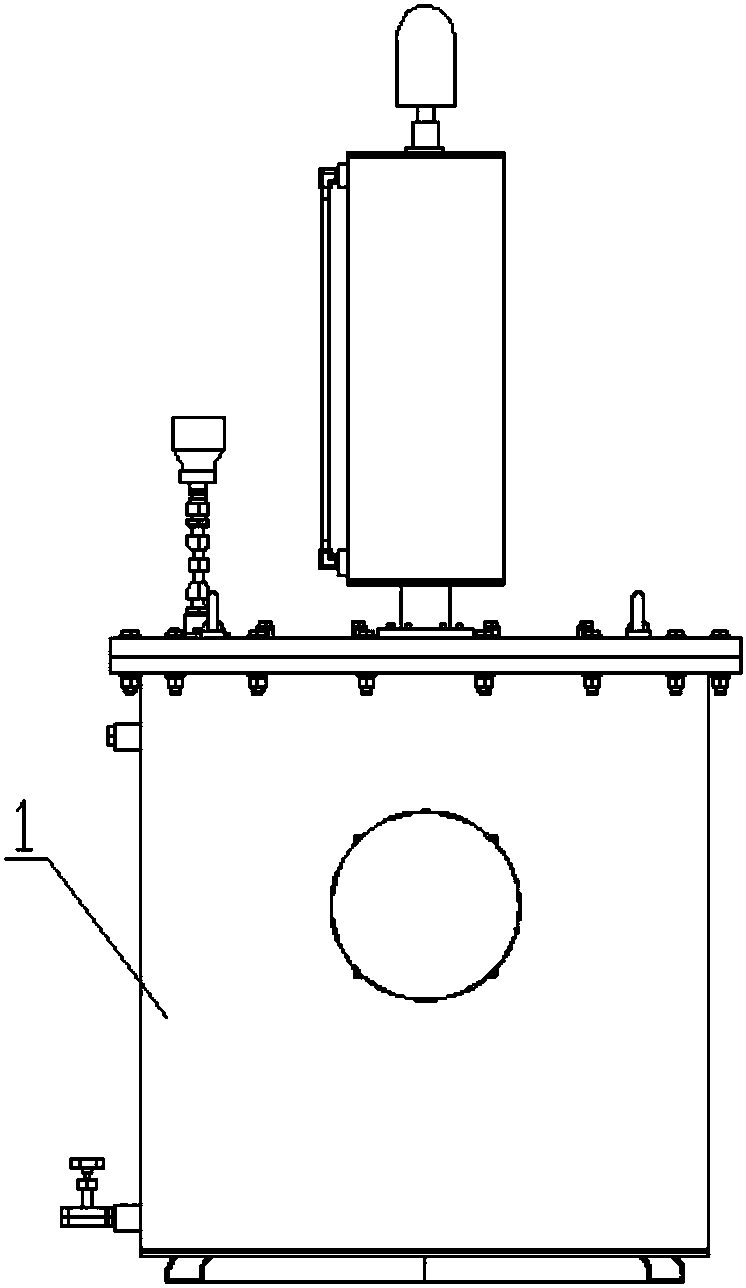

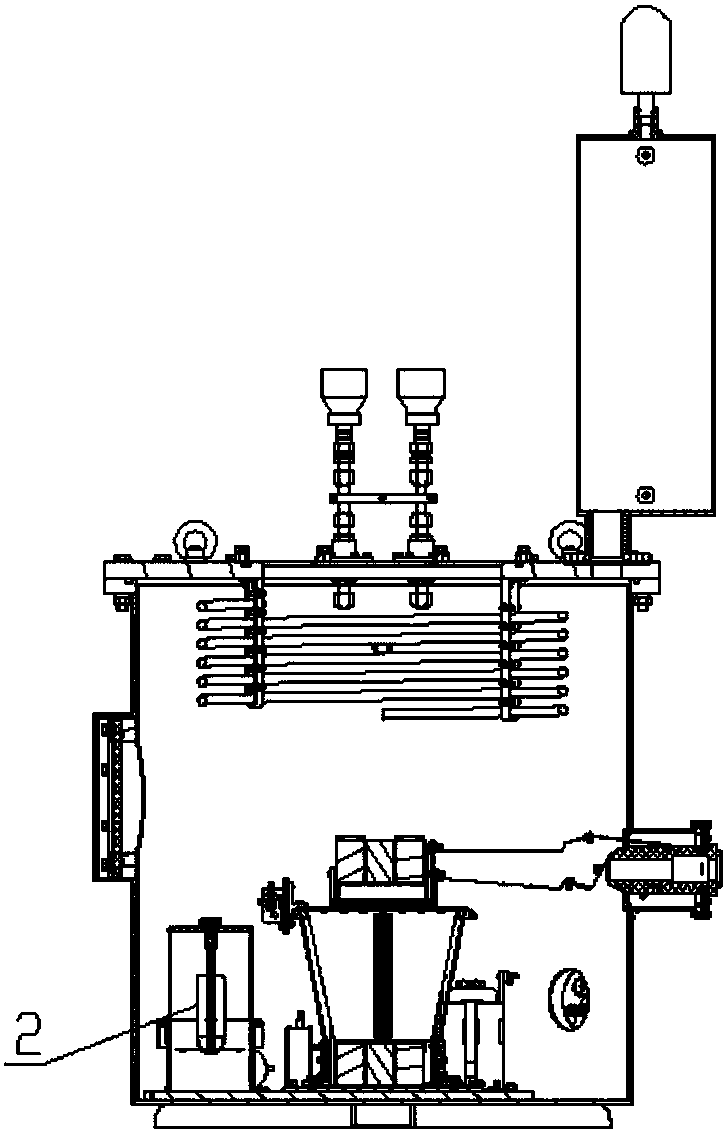

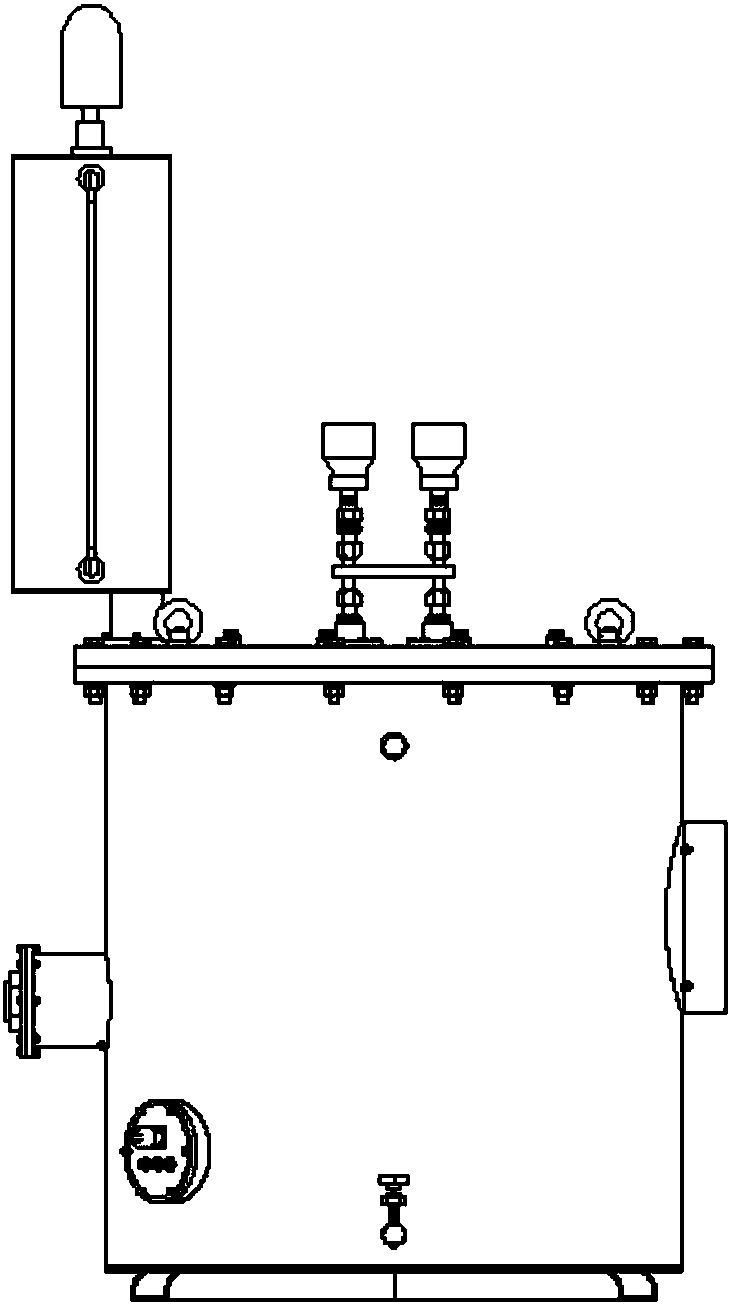

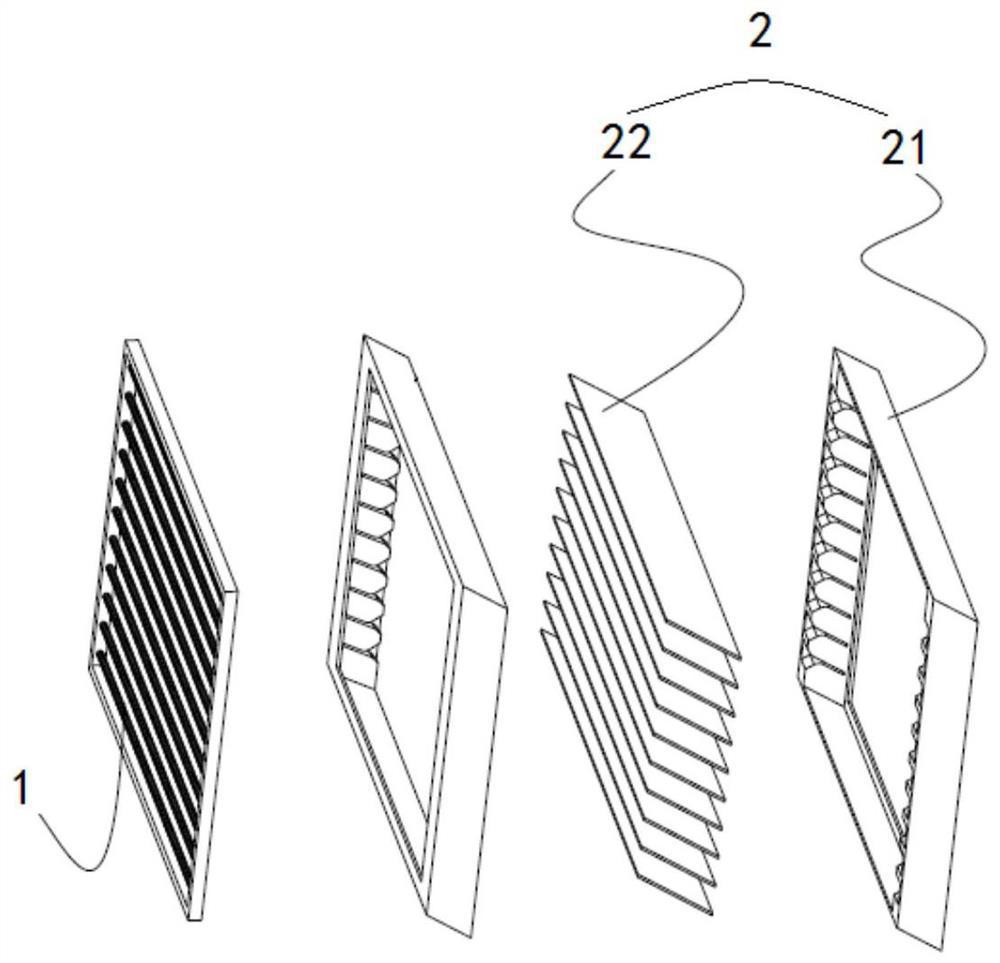

A thermal plasma arc flame generator

InactiveCN102271452AGood induction arc guidanceSimplify ignition stepsPlasma techniqueHeat flowElectric arc

The invention belongs to the technical field of high-frequency induction thermal plasma. Aiming at the problems existing in current high-frequency induction thermal plasma generation devices, such as difficulty in ignition, poor working stability, high arc maintenance power, and low efficiency, the invention provides a thermal plasma arc flame generator. The present invention includes a laminar arc thermal plasma generator [1] and a high-frequency induction thermal plasma generator [2], which is characterized in that it is injected along the central axis [5] of the high-frequency induction thermal plasma generator [2] The laminar arc thermal plasma jet [3] plays the role of arc guidance, arc maintenance and induction enhancement of the high-frequency induction thermal plasma flame [4]. The laminar arc thermal plasma jet [3] has the advantages of long jet length, small fluctuation of flow field parameters, almost no entrainment of ambient gas, long length of high temperature zone, and small axial gradient of parameters such as temperature. Adopting the technical scheme of the present invention can solve the problems of difficult ignition and easy arc breaking of the high-frequency induction thermal plasma generator, reduce the operating frequency and arc maintenance power of the high-frequency induction thermal plasma generator, and increase the Efficiency facilitates the development of higher power high-frequency induction thermal plasma generators.

Owner:四川金虹等离子技术有限公司

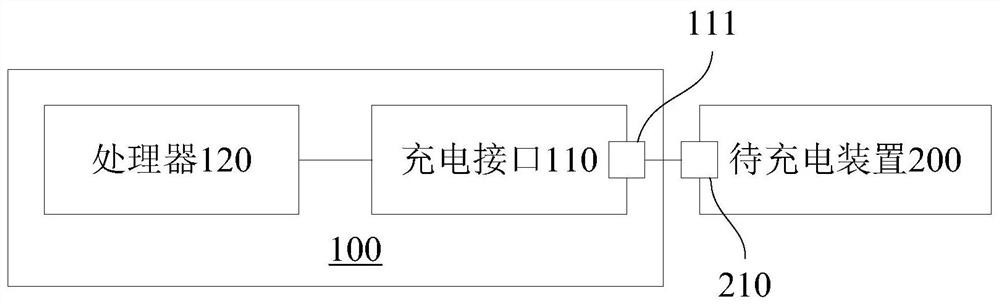

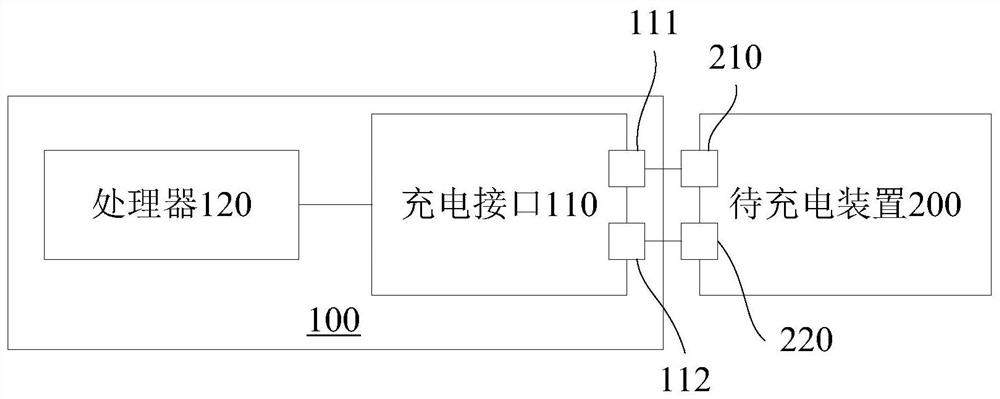

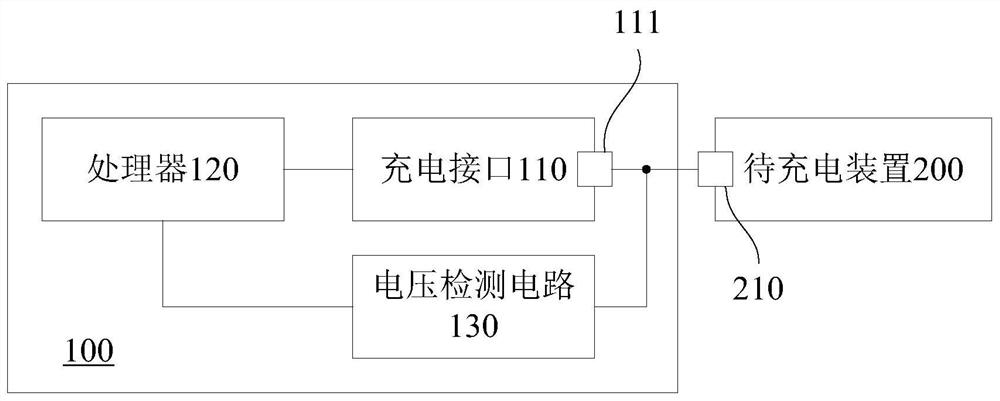

Charging device and charging control method and device

PendingCN112689935ASolve the ignition problemAchieving a soft startBatteries circuit arrangementsSecondary cells charging/dischargingCharge controlElectrical connection

The present invention relates to a charging device and a charging control method and device. The charging device (100) comprises a charging interface (110) and a processor (120), the charging interface comprises a power supply output end, and the power supply output end can be electrically connected with the power supply end of the device (200) to be charged. The processor is electrically connected with the charging interface and is used for acquiring real-time voltage of a power supply end of the to-be-charged device when the to-be-charged device is inserted into a charging interface of the charging device; determining the output voltage of the power supply output end according to the real-time voltage and a gradient threshold value, so as to charge the to-be-charged device through the output voltage; and repeating the steps until the output voltage is increased to the full charge voltage of the to-be-charged device. According to the invention, soft start in the charging starting process is realized, the problem of sparking phenomenon caused by hot plug in the charging process is solved, and the problems of surge current and sparking caused by high voltage difference at the moment when the to-be-charged device is inserted into the charging device are solved at the same time.

Owner:SZ DJI TECH CO LTD

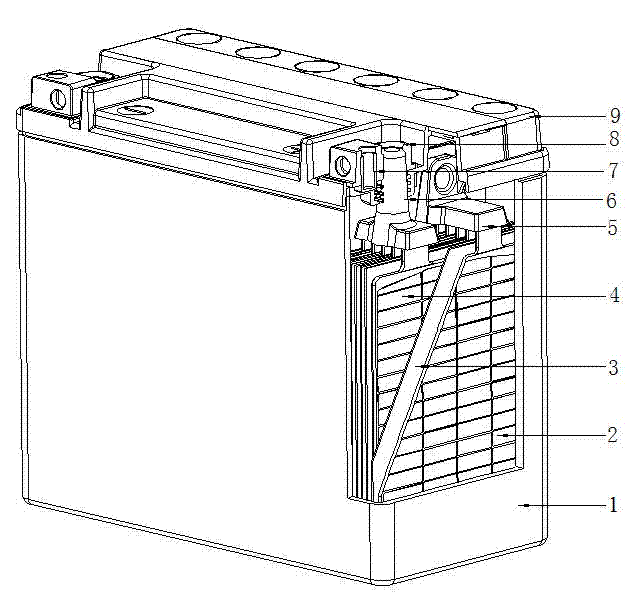

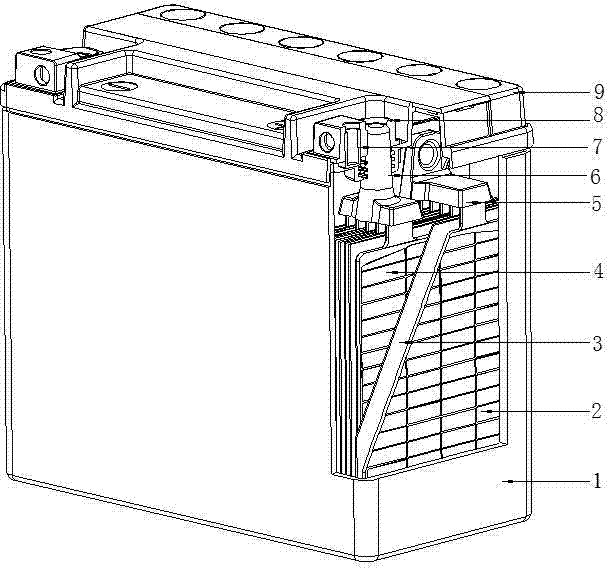

Manufacturing method of maintenance-free motorcycle battery lead terminal structure

InactiveCN102244228ASolve the wiring methodEasy to operateCell component detailsElectrical batteryMechanical engineering

The invention discloses a manufacturing method of a maintenance-free motorcycle battery lead terminal structure, which comprises the following steps of: firstly, fixing a nut (7) in a lead terminal die cavity and directly pouring lead liquid molten at a high temperature into the lead terminal die cavity for carrying out casting molding to form a lead terminal (8); then fixing the lead terminal in a battery cover die cavity and carrying out high-temperature injection molding to form a battery cover (9); secondly, arranging and cast-welding a negative plate (2), a separator (3) and a positive plate (4) at intervals into a pole group and welding a bus bar (5) on the pole group; cast-welding on the bus bar (5) to directly form a pole (6); thirdly, carrying out heat seal on a battery case (1) and a battery cover (9) so that the pole (6) is matched with the lead terminal (8), welding the pole (6) with the lead terminal (8) together in an acetylene welding manner; and finally, pouring an electrolyte to form a battery. According to the manufacturing method, the production operating process is reduced, the production fraction defective is reduced and the appearance quality of the battery is improved, but also the problem of wiring mode of the motorcycle battery is solved, the motorcycle battery is convenient to operate and is easy to install and the problem of acid creeping at the lead terminal of the battery is avoided.

Owner:JIANGSU LEOCH BATTERY

Preparation method of graphene electrothermal film for floor heating

PendingCN111669846AReliable electrical connectionEnhanced resistance to peelingLighting and heating apparatusElectric heating systemHeating filmCopper electrode

The invention discloses a preparation method of a graphene electrothermal film for floor heating, which comprises the steps of coating the surface of an insulating base material of the electrothermalfilm with a graphene heating film, implanting copper electrodes into two opposite sides of the graphene heating film, and arranging the graphene heating film and the copper electrodes at intervals; and printing a bridging electrode on the surfaces of the graphene heating film and the copper electrodes. A heating body of the graphene electrothermal film for floor heating prepared by the method is in good contact with the bridging electrode and the copper electrodes; the bridging electrode completely coats the copper electrodes; the contact resistance between the bridging electrode and the surface of the copper current-carrying electrode is obviously reduced; and the peeling resistance is improved, the risk of fire caused by edge sparking of the heating body is effectively solved, and the energy utilization rate is increased. In addition, the whole-process automatic production is more favorably realized, and the problem that the copper electrode compounding process is easy to be abnormaland cannot be automatically connected with the front-end process in the traditional production process is completely eradicated.

Owner:安徽宇航派蒙健康科技股份有限公司

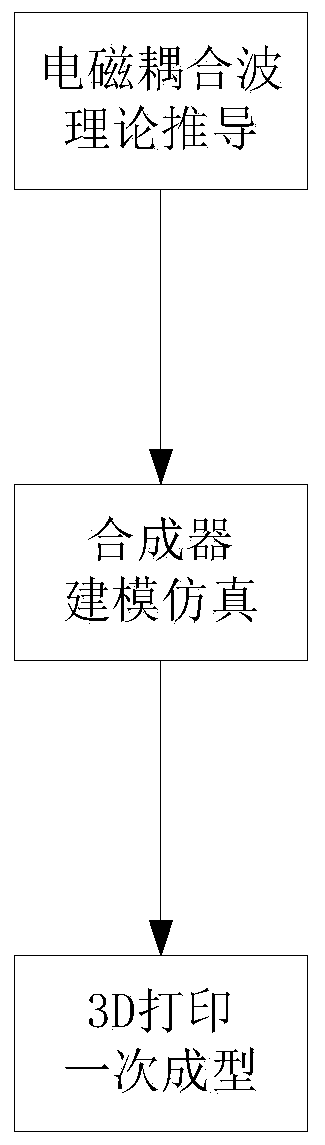

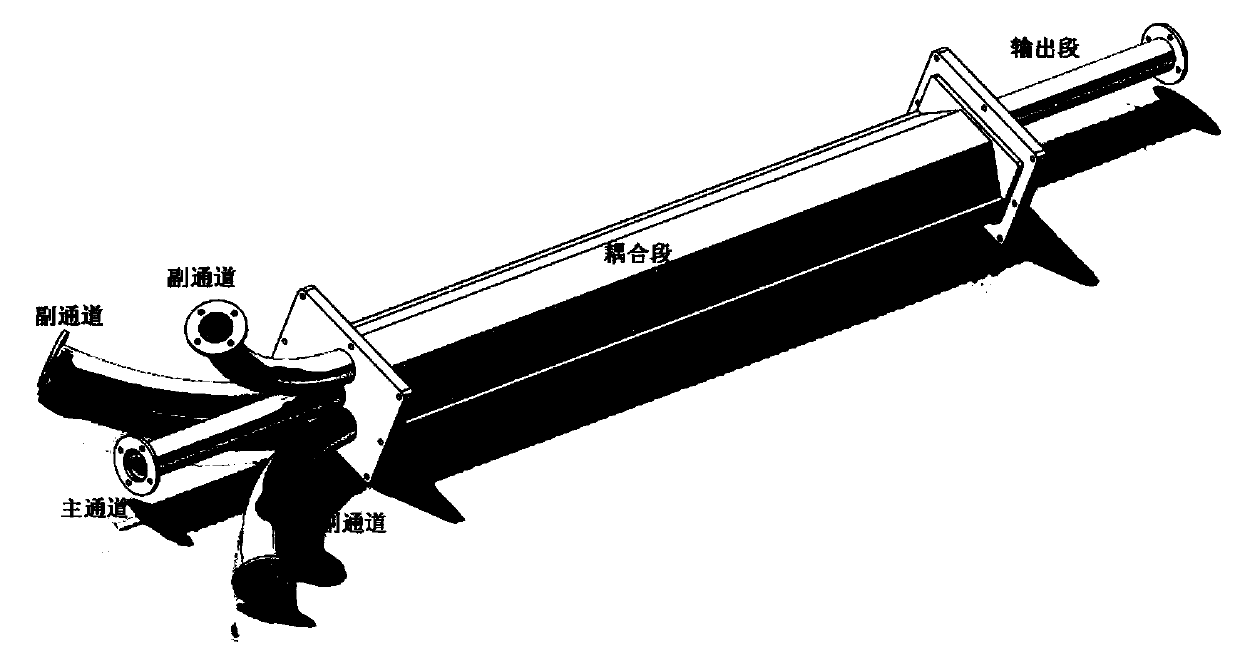

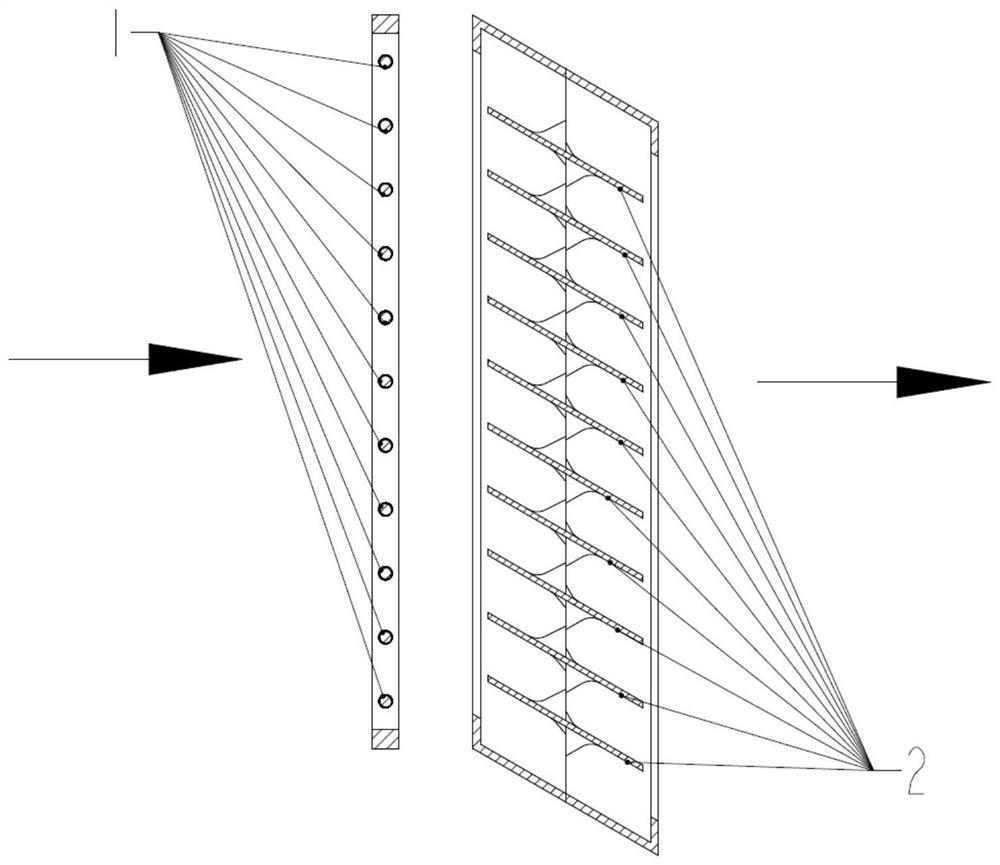

Four-path high-power microwave synthesizer manufacturing method based on 3D printing and synthesizer

ActiveCN110875507AHigh synthesis efficiencyIncrease powerWaveguide type devicesTime domainElectromagnetic coupling

Owner:CHINA SHIP DEV & DESIGN CENT

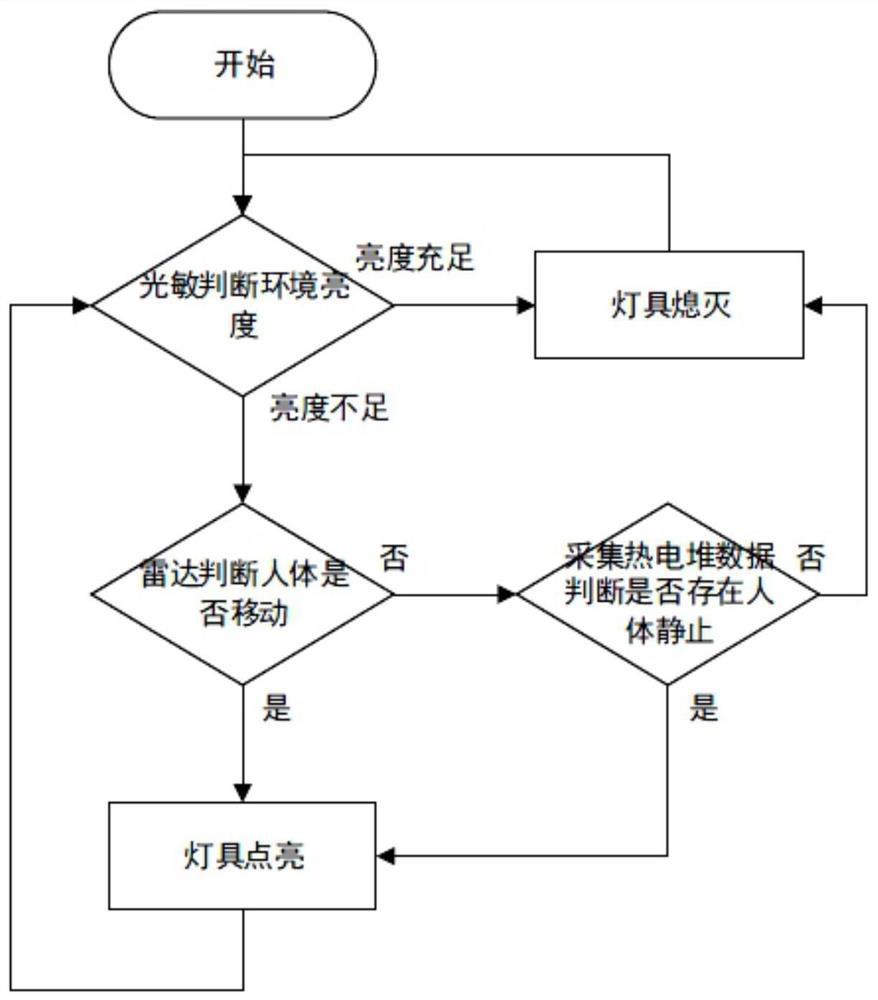

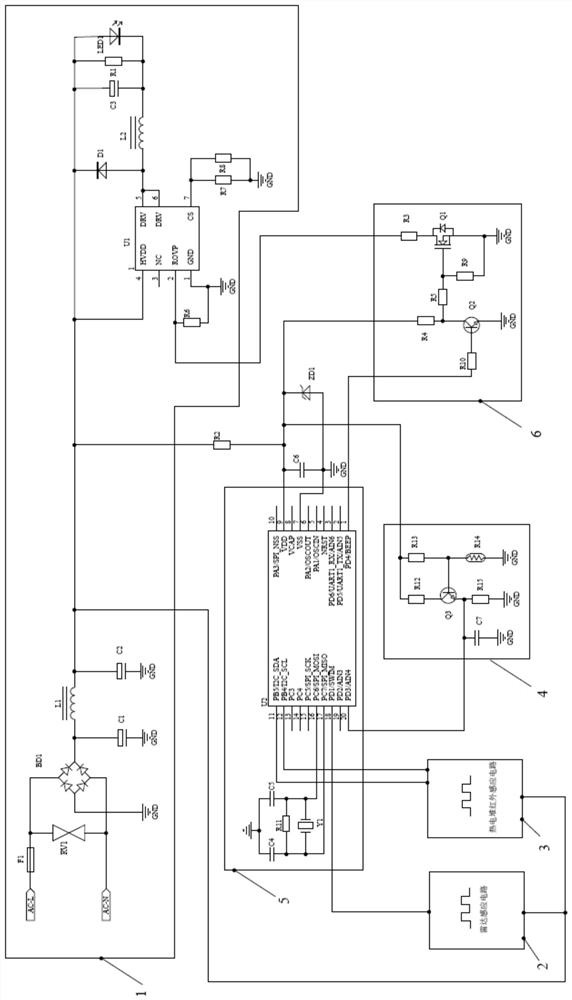

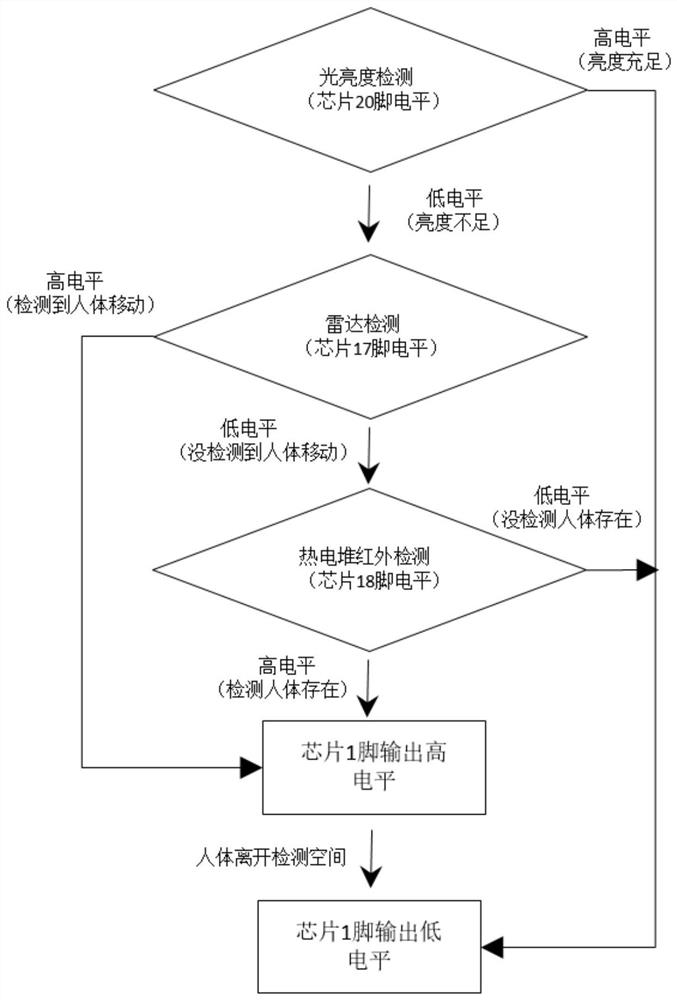

Intelligent lamp circuit

PendingCN111800907ATurn on and offExtend your lifeElectrical apparatusEnergy saving control techniquesSignal processing circuitsTelecommunications

The invention relates to an intelligent lamp circuit which comprises a brightness detection circuit, a radar induction circuit, an infrared thermopile induction circuit, a signal processing circuit, an electronic switch circuit, an LED lamp circuit and a power supply circuit. The power supply circuit provides power; the brightness detection circuit, the radar induction circuit and the infrared thermopile induction circuit are connected with the input terminal of the signal processing circuit. The electronic switch circuit is connected with the signal processing circuit, and the electronic switch circuit is connected with the LED lamp circuit; the signal processing circuit sends a switching signal to the electronic switch circuit, so that the electronic switch circuit sends an electric control signal to the LED lamp circuit, and the LED lamp circuit controls an LED lamp to be turned on or turned off. Radar, infrared and brightness detection technologies are adopted and comprehensively applied, detection of movement and stillness of a human body in the daytime and at night is achieved, and the sparking problem is solved through an electronic switch without a mechanical contact.

Owner:昇辉控股有限公司

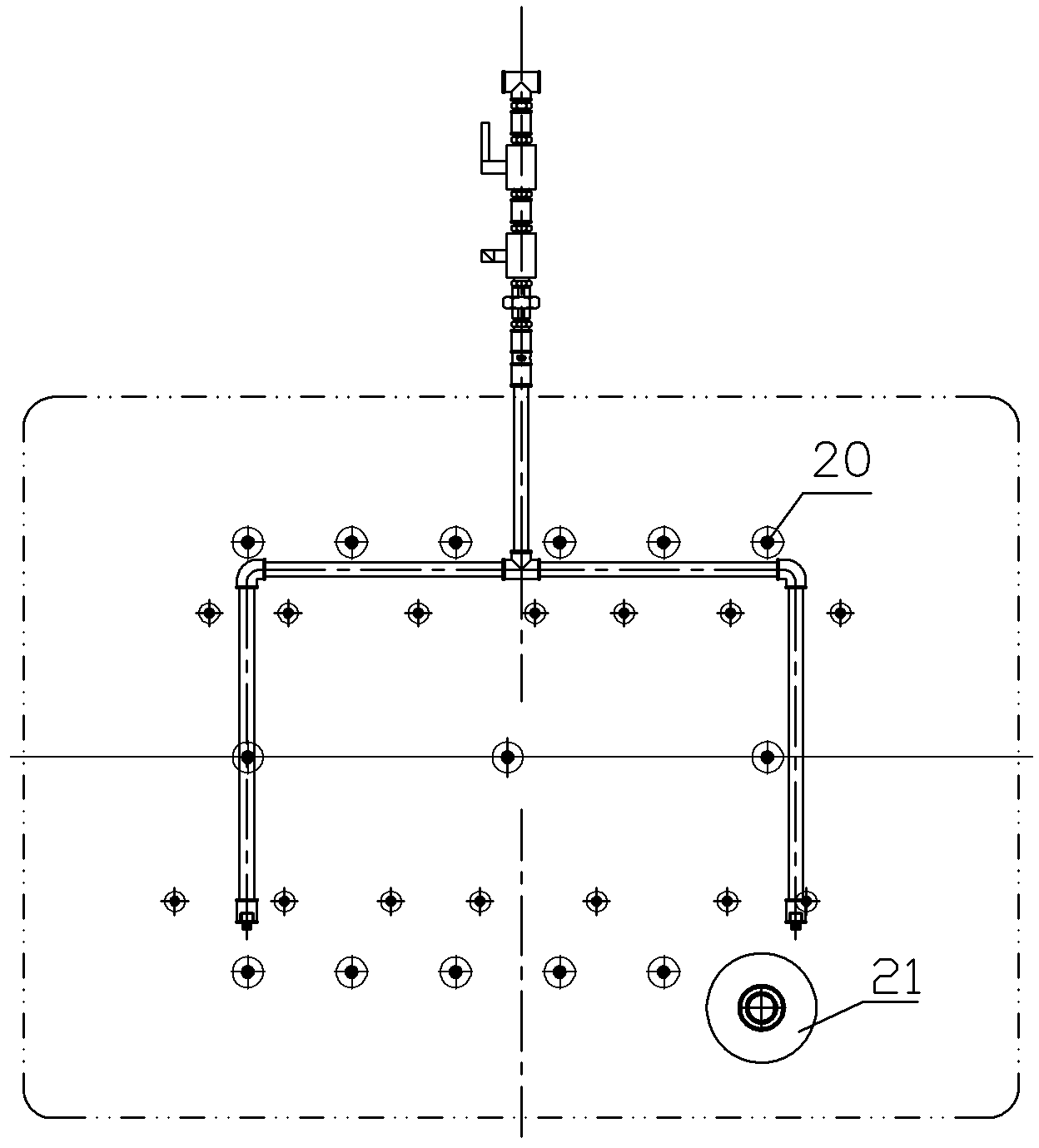

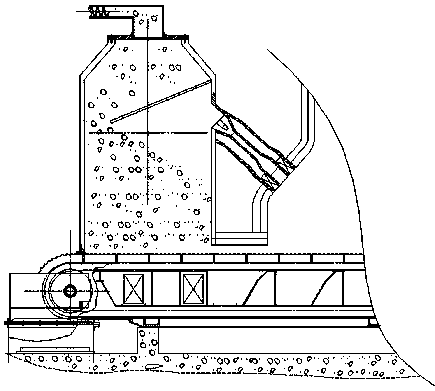

Ignition device of water-coal slurry cold wall gasifier

InactiveCN105647586ASolve the ignition problemWork lessGasification processes detailsGasification apparatus detailsSystem transformationCoal slurry

The invention discloses an ignition device of a water-coal slurry cold wall gasifier. The ignition device comprises the water-coal slurry cold wall gasifier and a hearth arranged in the water-coal slurry cold wall gasifier in a nested mode. A chamber for water-coal slurry and oxygen combustion is formed in the hearth, a guide opening is formed in the end of the hearth and connected with a water-coal slurry process burner, and the water-coal slurry process burner is fixed to the water-coal slurry cold wall gasifier through a water-coal slurry burner connector. The ignition device further comprises a guide channel. The guide channel penetrates through the water-coal slurry cold wall gasifier and the inner wall of the hearth in sequence and is communicated with the chamber formed in the hearth, and an ignition startup burner is arranged in the guide channel in a nested mode and moves freely in the guide channel. According to the ignition device, ignition operation is simple, system transformation is small, cost is low, stability is good, and the service life of the burners is long.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

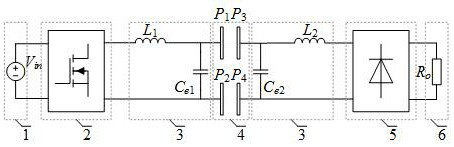

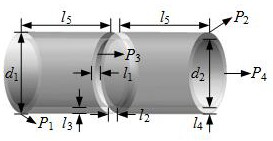

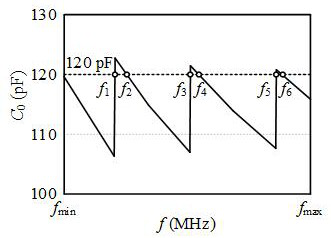

Bilateral LC compensation type CPT system and parameter design method thereof

ActiveCN113258687AConducive to development needsReduce voltage stressGeometric CADEfficient power electronics conversionCapacitanceCapacitive coupling

The invention discloses a bilateral LC compensation type CPT system and a parameter design method thereof. Under the size limitation of any given output power Po, output load Ro and capacitive coupling mechanism, the bilateral LC compensation type CPT system can simultaneously realize the minimum voltage stress, the optimal AC-AC efficiency and the minimum number of capacitors, and facilitates the development demand of the CPT system in a miniaturized application occasion. According to the parameter design method, the resonant frequency is designed, the voltage stress of the capacitive coupling mechanism is limited within a reasonable design range, and the sparking problem caused by air breakdown between metal polar plates is avoided while the power transmission capacity is ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Domestic gas blasting stove with safety control system

ActiveCN104315553AImprove combustion thermal efficiencySolve the ignition problemBurner safety arrangementsDomestic stoves or rangesCombustorControl system

The invention discloses a domestic gas blasting stove with a safety control system. The domestic gas blasting stove comprises an igniter, a combustor, at least two injection pipes communicated with the combustor, and a valve for controlling the injection pipes to open and close, wherein an ignition needle connected with the igniter is arranged on the combustor; at least one of the injection pipes is a natural air inlet type injection pipe, and at least one of the injection pipes is a blasting injection pipe; the domestic gas blasting stove also comprises a blasting device, a controller and an induction needle; the induction needle is used for inducing the gas combustion state; the blasting device is used for inputting air into the blasting injection pipe; and the controller is respectively connected with the induction needle and the blasting device and controls the blasting device to start, stop and regulate the air according to an induction signal of the induction needle. According to domestic gas blasting stove disclosed by the invention, the potential safety hazard problems caused by ignition difficulty and floating flames or blow-off of the domestic gas blower are effectively solved.

Owner:宁波丹沃思厨卫科技有限公司 +1

Improved explosion-proof switch button

The invention discloses an improved explosion-proof switch button. The improved explosion-proof switch button comprises a panel. The improved explosion-proof switch button is characterized in that a switch button is arranged in the panel; the switch button is connected with a conductive sheet at the back surface of the panel through a pin body; the conductive sheet is arranged inside a junction box at the back surface of the panel; the conductive sheet is connected with the junction box through springs; a plurality of conductive contacts are arranged between the junction box and the panel; and the conductive contacts are connected with wiring columns. According to the improved explosion-proof switch button of the invention, a point-pressing switch-on and switch-off mode is adopted, and therefore, problems of poor contact, arcing and explosion can be effectively solved, and personal safety and the safety of electric equipment can be ensured.

Owner:启东恒瑞防爆通讯电气有限公司

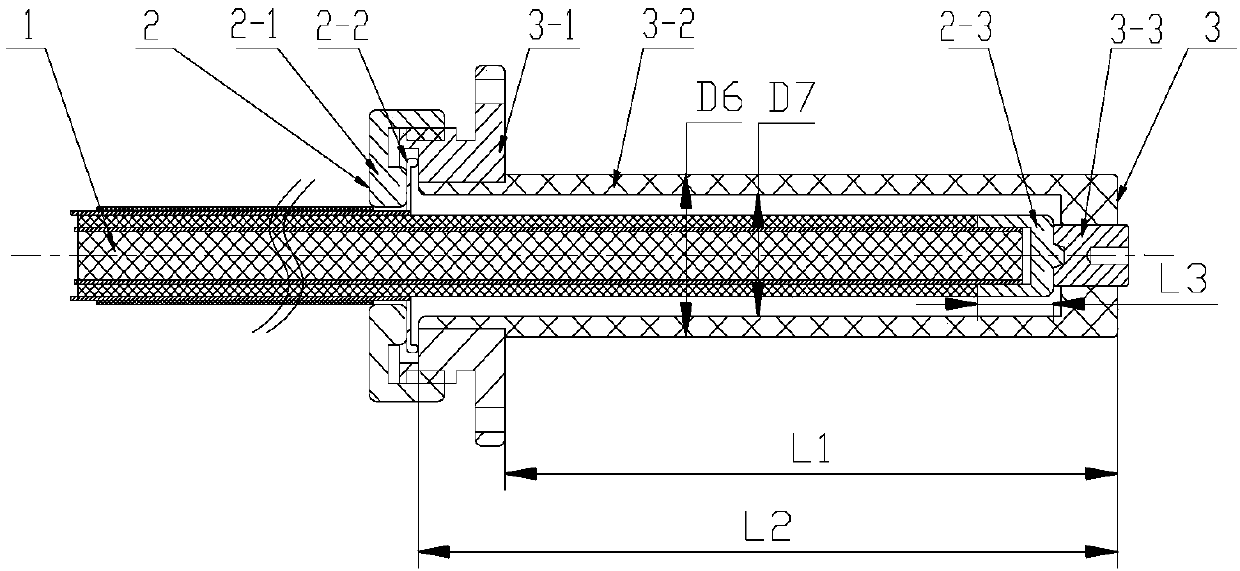

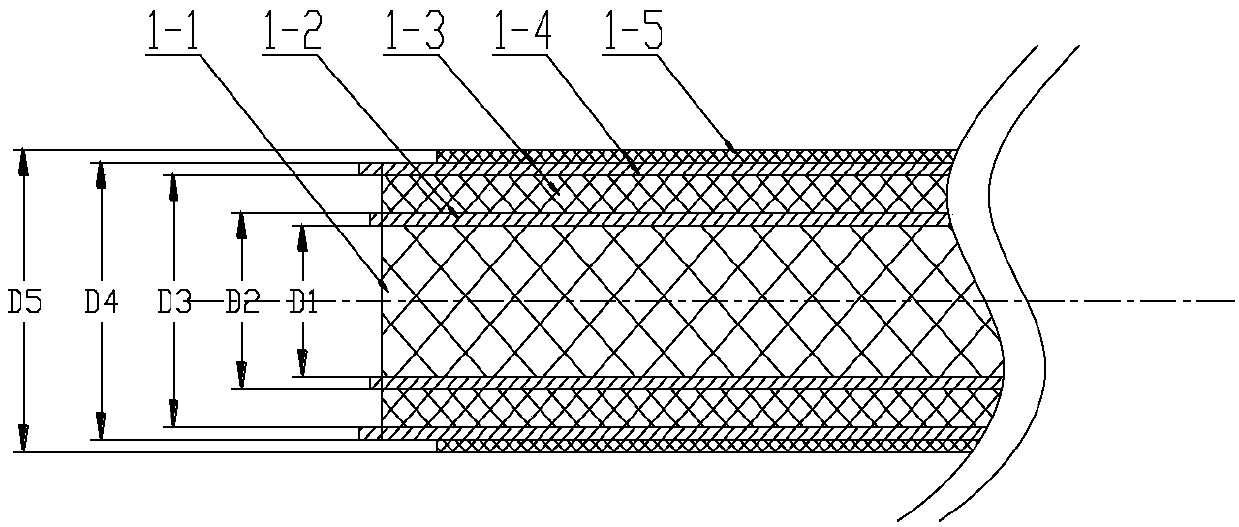

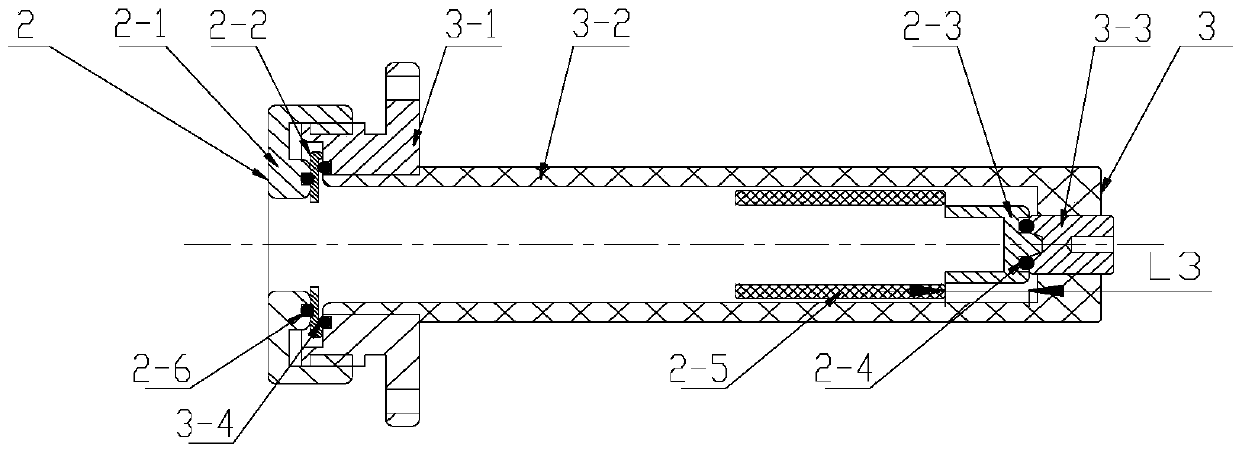

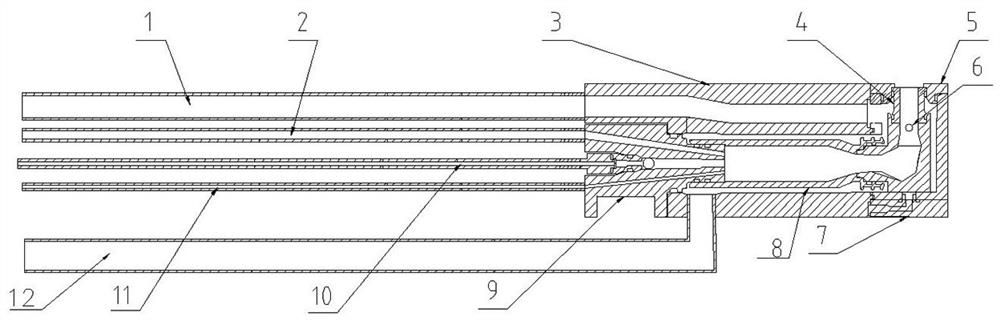

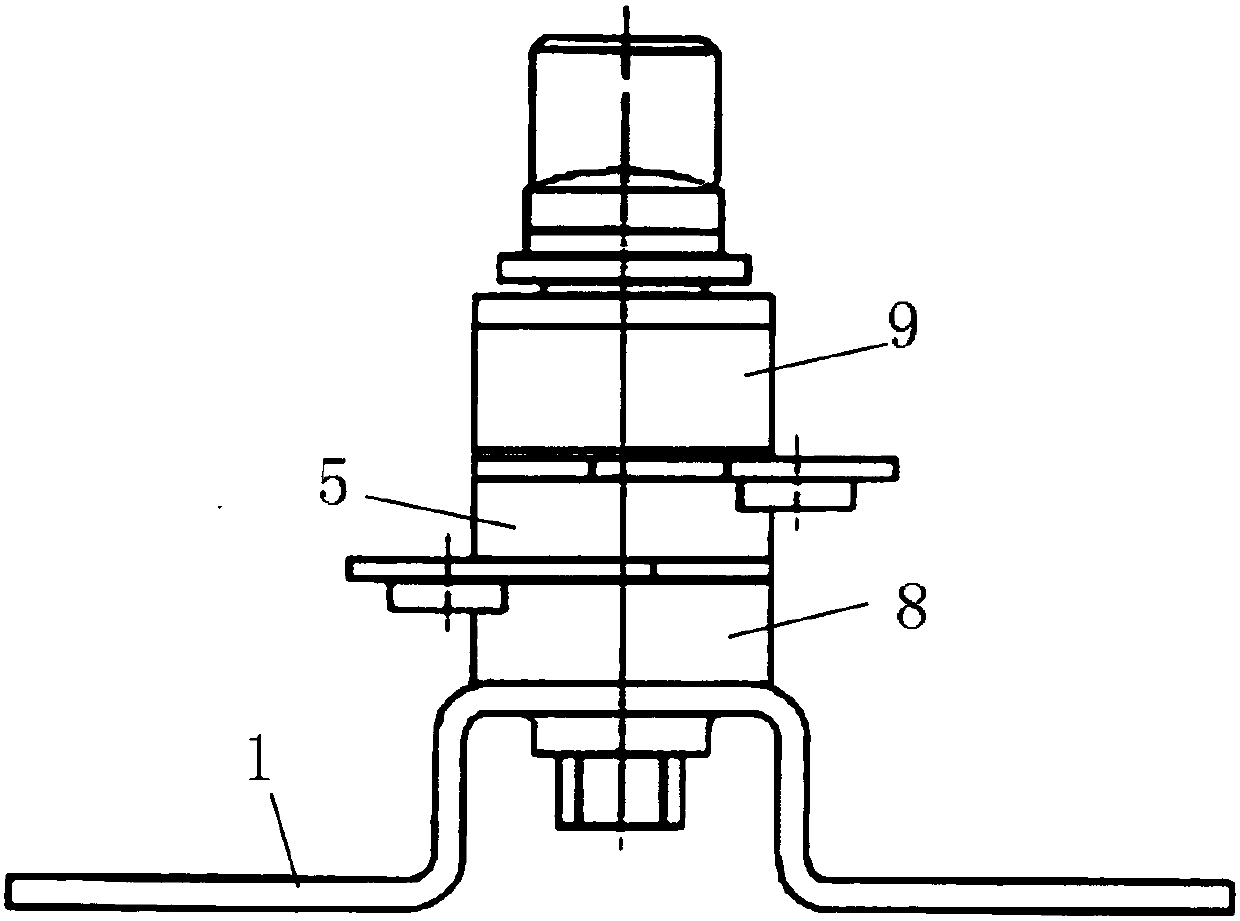

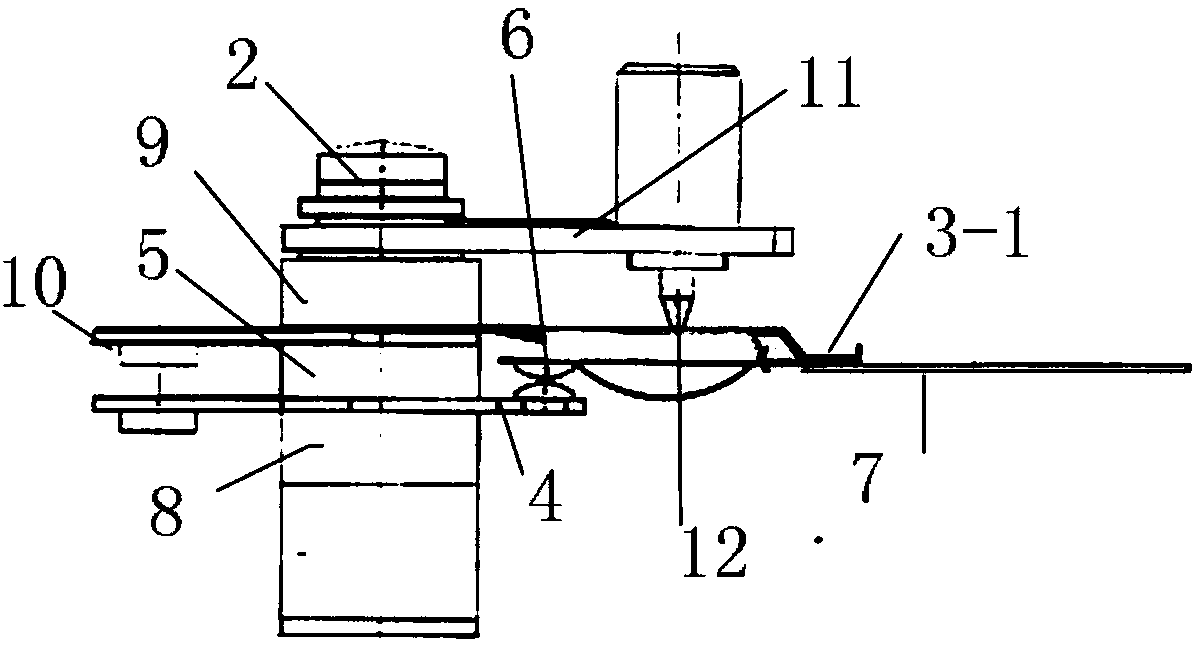

Fast joint for compact superconductive cyclotron's high frequency resonator coaxial waveguide

ActiveCN106329034AImprove sealingEasy to updateCoupling devicesElectrical conductorCoaxial waveguides

The invention discloses a fast joint for compact superconductive cyclotron's high frequency resonator coaxial waveguide. The fast joint comprises an internal conductor and insulation supports. The internal conductor is of a cylindrical shape; the outer side wall of the internal conductor is provided with a middle section as well as spiral joint sections at two sides of the middle section. The outer side walls of the internal conductor among the middle section and the spiral joint sections are provided with two anti-current grooves. A circumferential protrusion part is arranged between the two anti-current grooves. The circumferential side wall of the middle section is provided with three installation holes. Each installation hole is provided with an insulation support. The insertion end of each insulation support is in threaded connection with a spring. The spring is fixedly connected to the installation hole. The outer end of the insulation support undergoes a fillet processing. The two end faces of the middle section are provided with a first step respectively. The outer end faces of the two spiral joint sections are provided with second steps. Simple in structure and small in size, the fast joint enables the convenient and rapid installation, maintenance and replacement of a coaxial waveguide.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

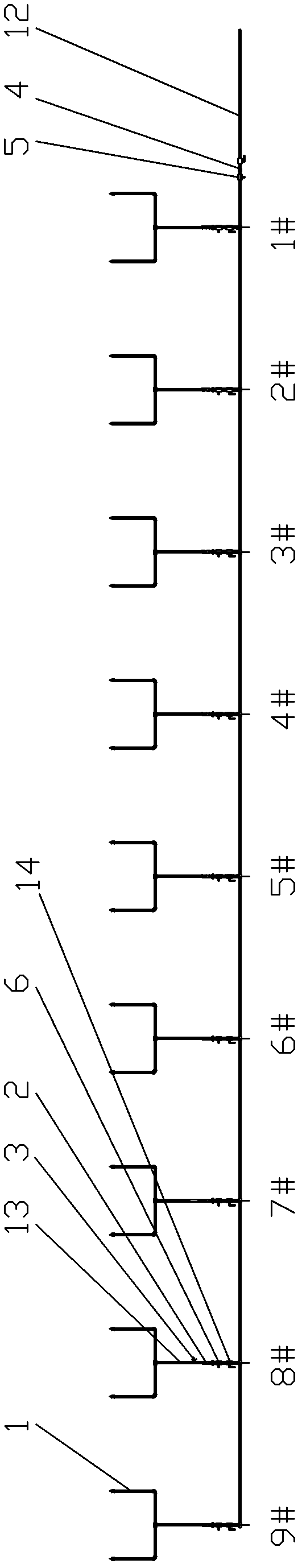

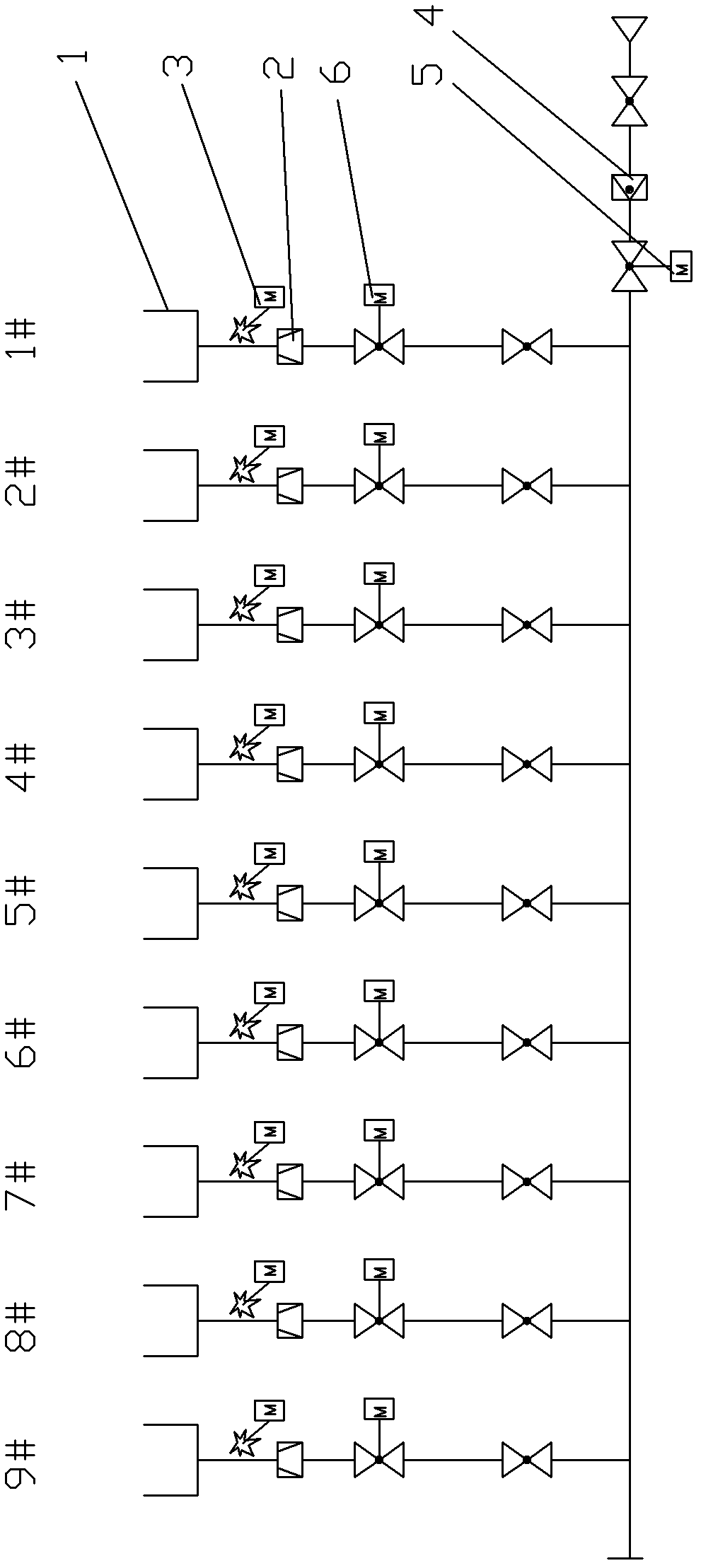

Automatic ignition and air entraining device and method for full automatic casting machine

InactiveCN102554211AReduce defectsTimely and accurate ignitionCasting apparatusSolenoid valveProgrammable logic controller

The invention discloses an automatic ignition and air entraining device for a full automatic casting machine, which comprises a main gas inlet pipe for natural gas and a group of parallel sub-gas inlet pipes for natural gas; a pressure regulating valve and a main solenoid valve are arranged at a front pipeline positioned on the sub-gas inlet pipes on the main gas inlet pipe; each sub-gas inlet pipe is provided with a sub-solenoid valve, a combustion nozzle and an electronic ignition device sequentially; the end part of each sub-gas inlet pipe is connected with an ignition pipe; the ignition pipe is provided with a group of obliquely downward gas outlet holes; the main solenoid valve and each sub-solenoid valve are connected to a PLC (Programmable Logic Controller). When the casting is started, the main solenoid valve and the sub-solenoid valve of the natural gas of a casting box position are opened; the electronic ignition device is used for automatically igniting mixed natural gas of the ignition pipe of the box position and accordingly igniting combustible gas discharged from a cavity and each gas hole of a sand core; the gas discharge of the cavity is accelerated; and then, the solenoid valves of the natural gas are closed. The automatic ignition and air entraining device for the full automatic casting machine is timely and accurate in ignition and air entraining, the defects of casting gas holes are reduced, the labor cost is saved, and the personal safety accidents are avoided.

Owner:CHINA NAT HEAVY DUTY TRUCK GRP HANGZHOU ENGINE

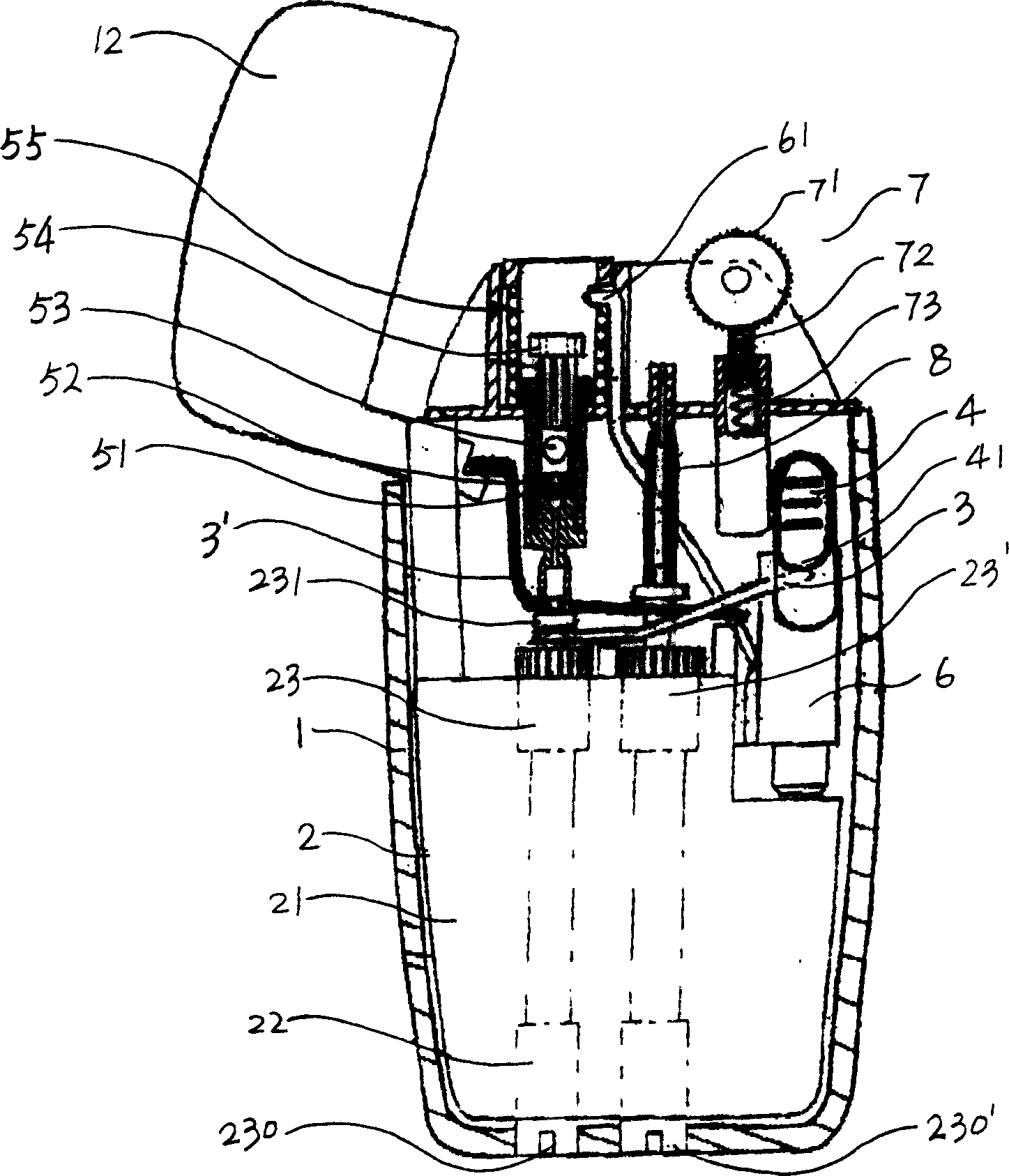

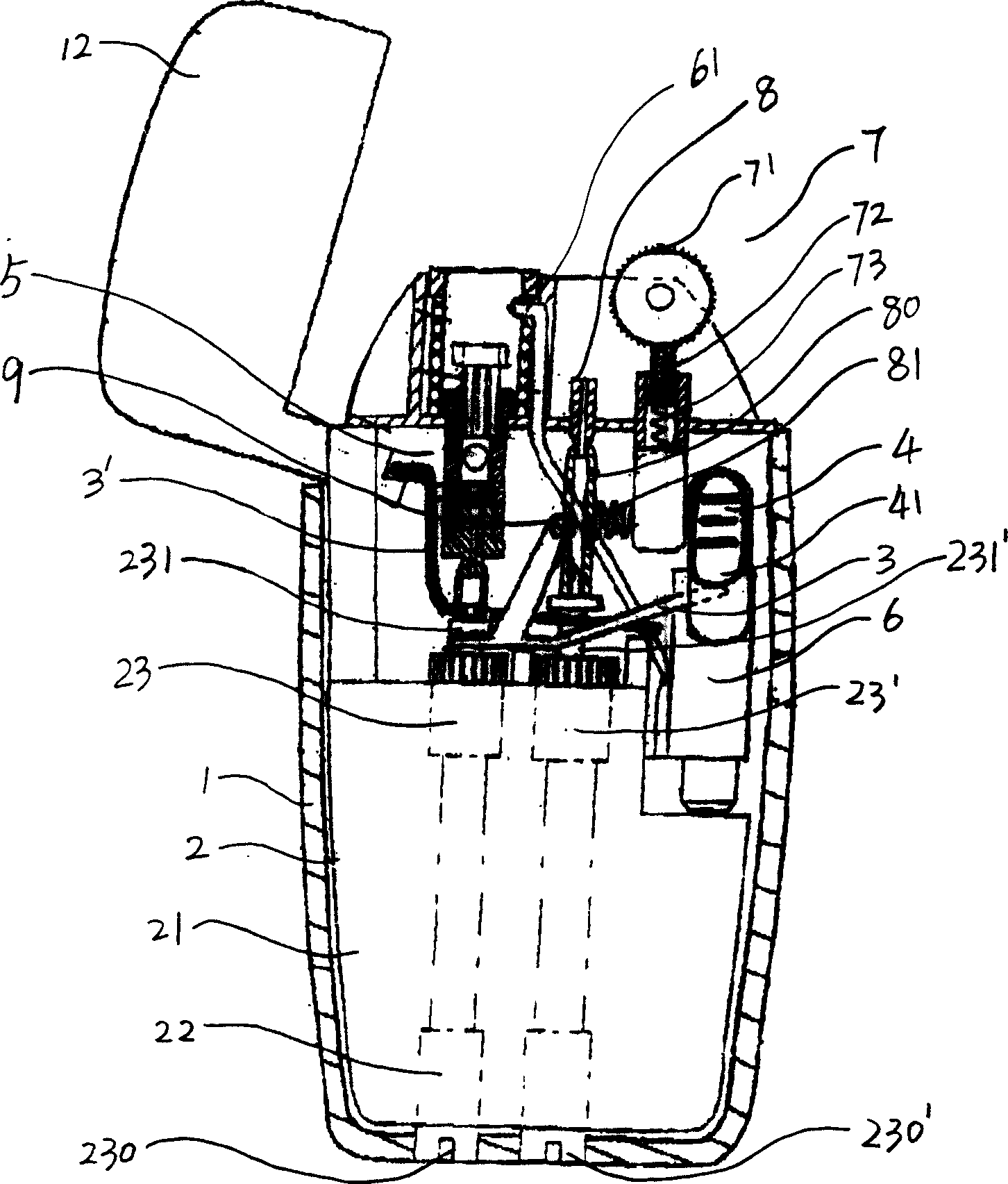

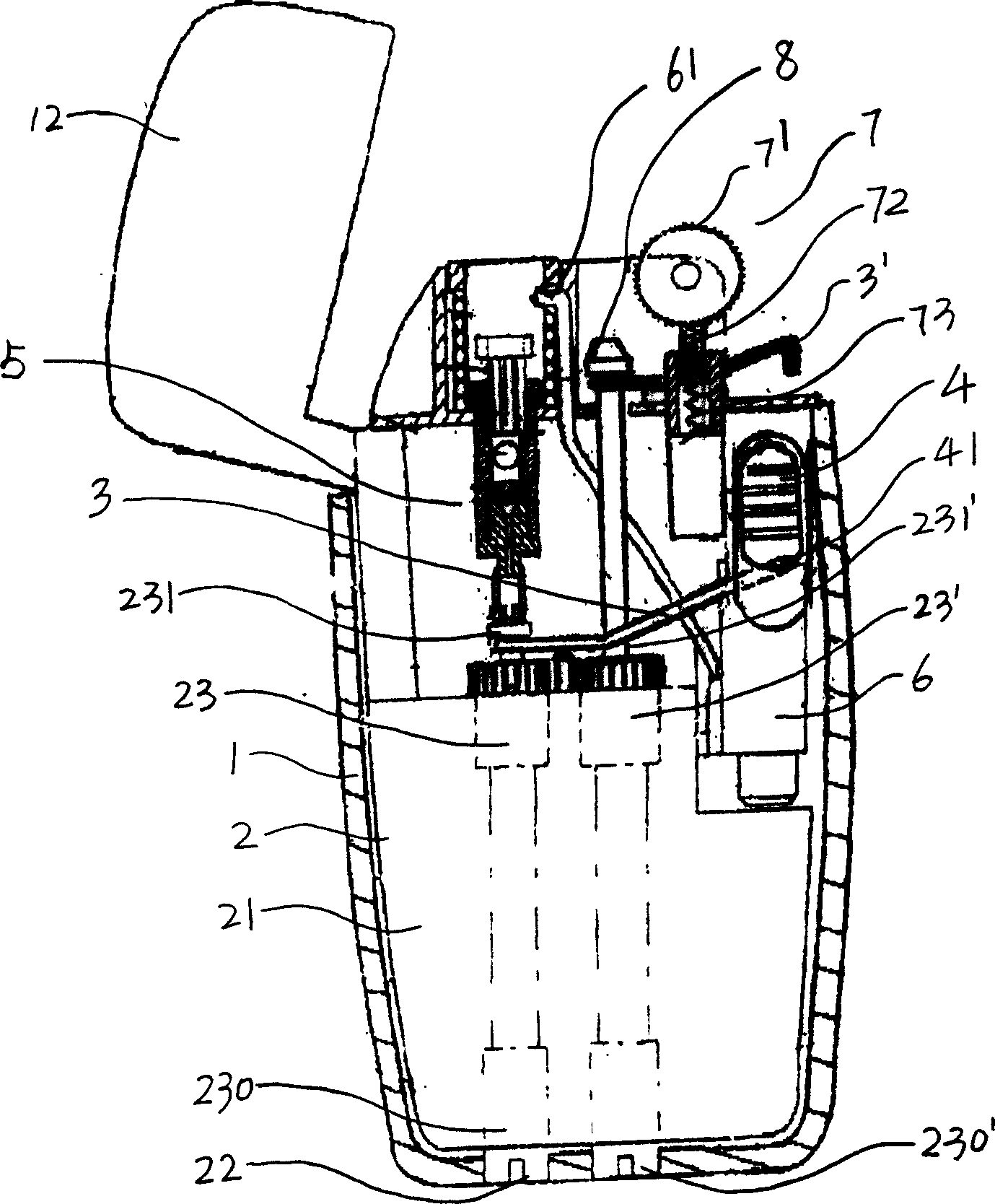

Multiple-flame lighter

InactiveCN1690518AStrong windproof effectNot easy to heat and service lifeFuel lightersIgnition controlMechanical engineering

The invention relates to a multi-flame lighter, comprising a casing; a storage including air tank, air outlet valve and an air inlet valve; an air outlet control lever; a wind-proof assembling units; and an ignition control unit including an electronic igniter, a flint ignition device and a pull button, wherein, said electronic igniter mounted under the pull button which is exposed partly to the surface of the one side of casing. It is characterized in that: the storage has a second outlet valve, which has a candlepower outlet pipe. The invention integrates the advantages of lighter and the wind-proof lighter, meeting the requirement of wind-proof and using for longtime, improving the service life of lighter significantly. And it has simple and reasonable structure with simple operation, while realizing the selection of two flames without increasing the volume of the lighter.

Owner:王良 +1

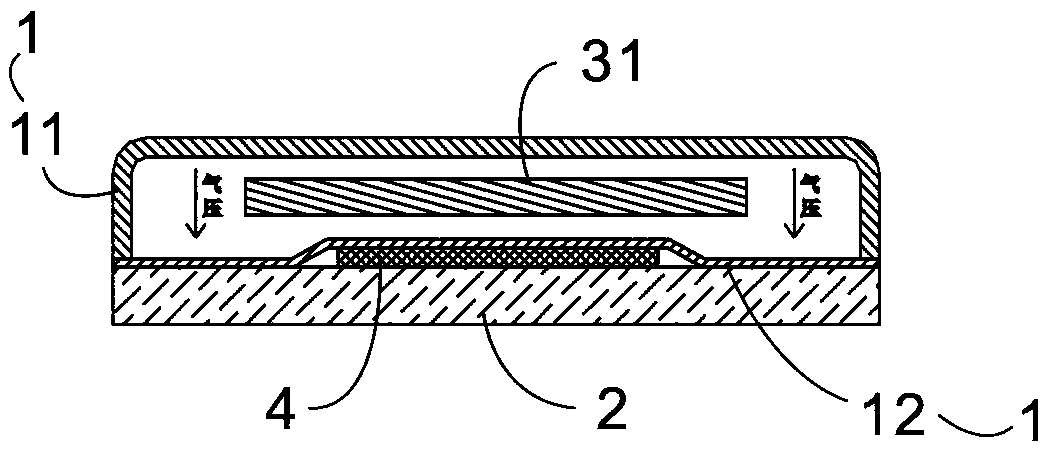

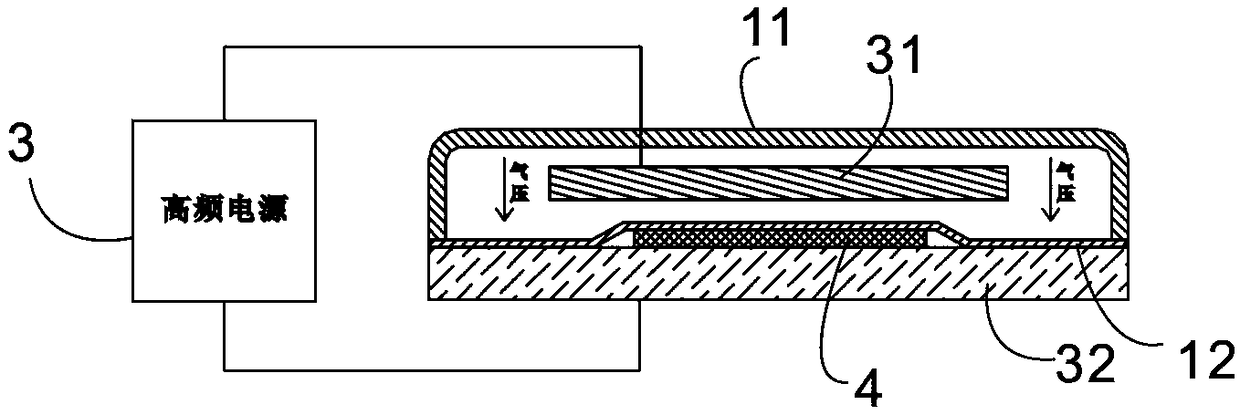

Method and device of free-stitching shoe face air-isolation fusion welding pressurization

PendingCN108839348AWon't overflowGood weldabilityShoemaking devicesDomestic articlesEngineeringSilica gel

The invention discloses a method and a device of free-stitching shoe face air-isolation fusion welding pressurization. The method comprises the following steps that S1. a to-be-processed shoe face isplaced on a working table, wherein the to-be-processed shoe face is formed by laminating a plurality of layers of shoe face materials; S2, a pressurization cover is arranged, and the pressurization cover and the working table are oppositely closed and tightly compressed, wherein the pressurization cover comprises an airtight cover and a silica gel membrane, the airtight cover is connected with a non-contact heating device, and the silica gel membrane covers the to-be-processed shoe face; and S3, air is inflated into the pressurization cover, so that the silica gel membrane is made to form a coated pressurization pressure on the to-be-processed shoe face; and the heating device is used for carrying out non-contact fusion welding processing on the to-be-machined shoe face; and the pressurization cover, the working table and the heating device are correspondingly arranged according to the method by the device. According to the method and the device, a pressure applying limit with maxim ofonly 0.1 MPa of the vacuum coating is overcome; and the ionization breakdown voltage of an air medium when high-frequency fusion welding is performed can be greatly improved, an optimal fusion welding effect can be obtained, and the product quality is improved.

Owner:FUZHOU SANJU MECHANICAL & ELECTRICAL EQUIP CO LTD

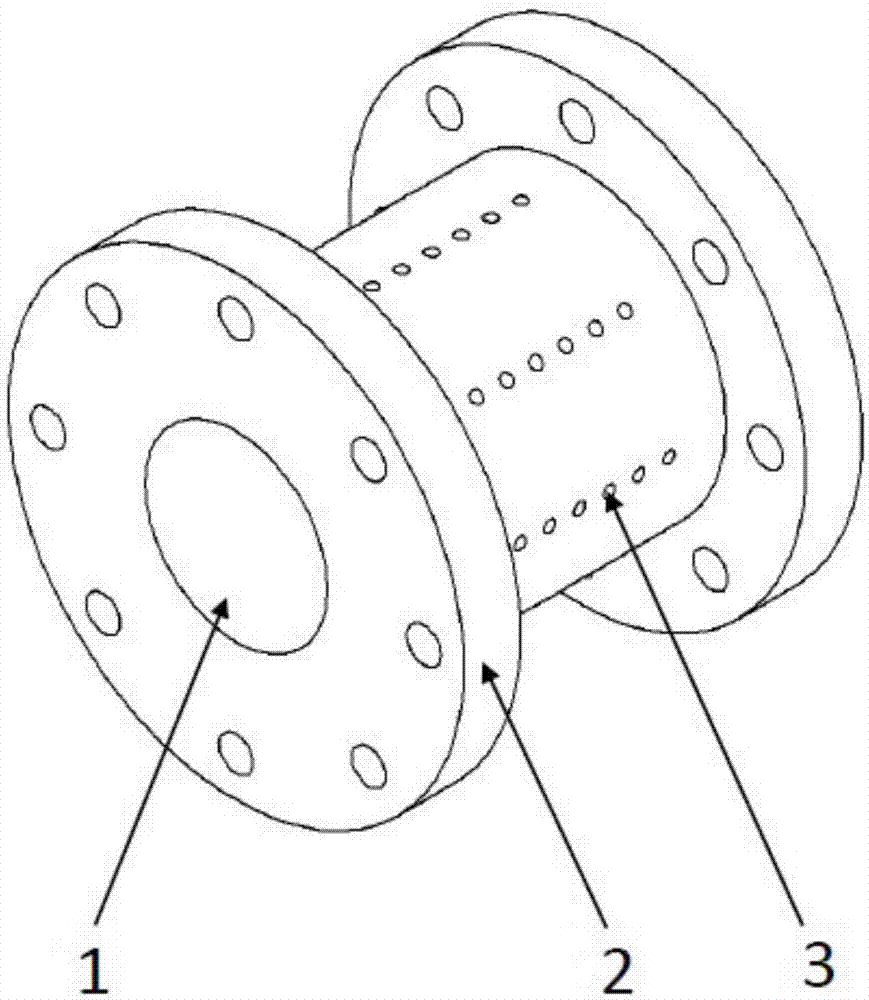

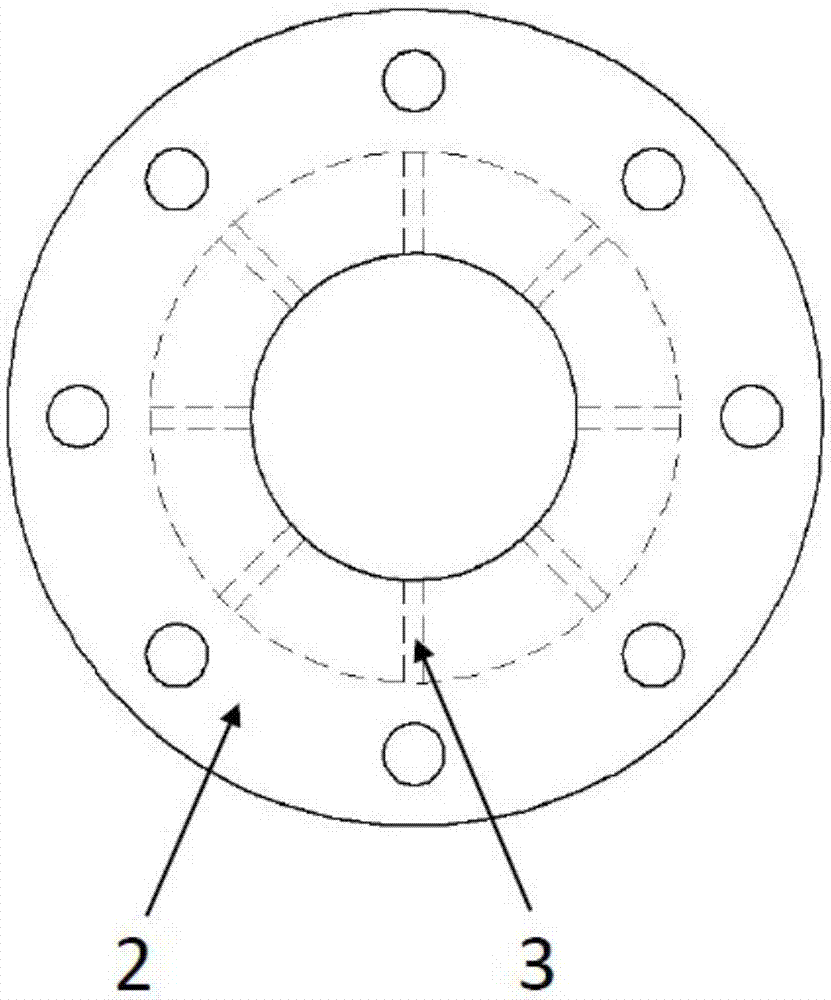

Novel multi-hole ventilation circular waveguide for transmitting high power microwave and millimeter waveguide

The invention discloses a novel multi-hole ventilation circular waveguide for transmitting high power microwave and millimeter wave, and belongs to the technical field of high power microwave and millimeter wave devices. The structure of the novel multi-hole ventilation circular waveguide for transmitting high power microwave and millimeter wave is characterized in that a plurality of rows of circular ventilating holes are arranged on a waveguide wall of the circular waveguide in parallel at intervals. The ventilating holes enable the air in the waveguide to communicated with the external atmosphere for realize ventilation. After the ventilation environment of the waveguide is improved, air flow in the waveguide is improved, thus improving the convection heat loss capability of the surface of the output window of a large power vacuum device so as to achieve the aim of improving the power capacity of the output window, and reducing the ignition probability of microwave in the waveguide, and also improving the power threshold value of the output window damage caused by rising of air pressure because microwave breaks down ignition to cause air expansion, and indirectly improving the power capacity of the output window.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

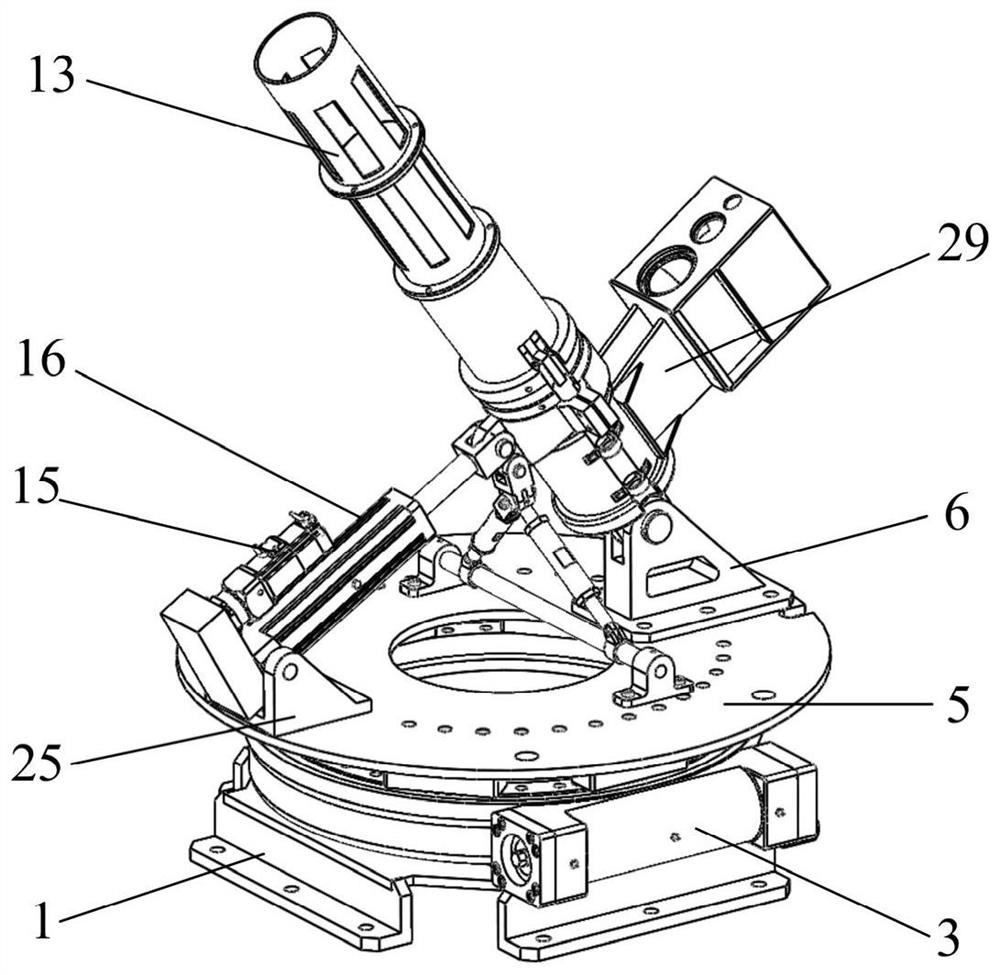

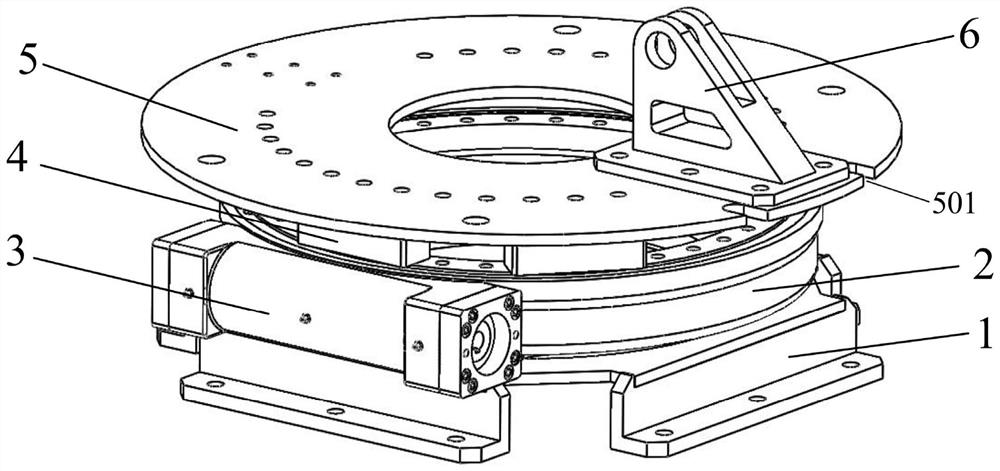

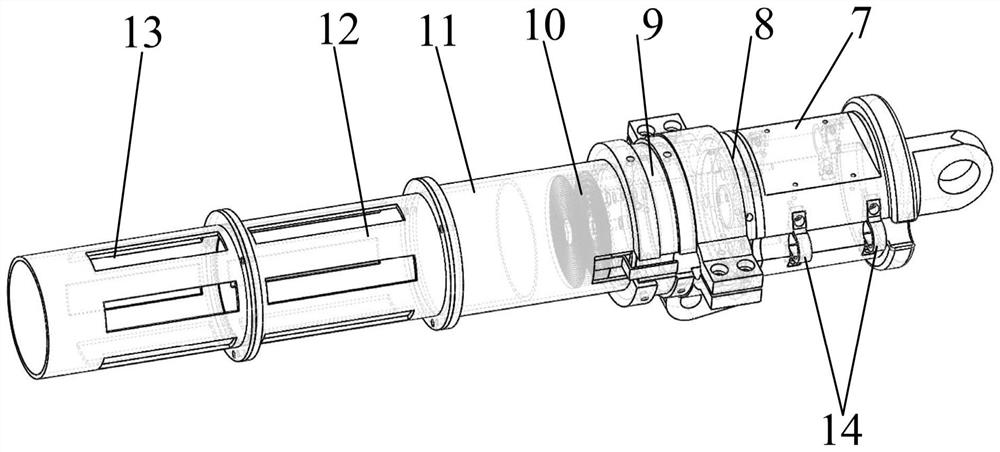

Coil bottom pushing type electromagnetic gun and pitching adjusting device thereof

PendingCN114034208AEfficient launchEasy to adjustElectromagnetic launchersSighting devicesElectric machineControl theory

The invention discloses a coil bottom pushing type electromagnetic gun and a pitching adjusting device thereof, and belongs to the technical field of electromagnetic launching. An active driving mechanism in the pitching adjusting device can control the change of the pitching angle of a gun barrel on one hand, and can be matched with a follow-up supporting mechanism to jointly support the gun barrel on the other hand; furthermore, three-point support is formed on the gun barrel with the fixed base, so that the influence of the shaking of the gun barrel on the launching precision is avoided; a rotating motor and a servo motor are matched for use, so that the gun barrel can be quickly aligned to a striking direction to enter a combat state; the coil bottom pushing type electromagnetic gun is integrated with an aiming system, a rough aiming module and a fine aiming module are used in cooperation, a hit target can be rapidly located, meanwhile, the fine aiming module has a distance measuring function, the distance between the electromagnetic gun and a hit point at present can be measured while imaging is achieved, and the hit point can be located through an infrared aiming system at night or under the condition of low visibility; and combat requirements in all-weather and complex environments are met.

Owner:SHAANXI DAGONG XUHANG ELECTROMAGNETIC TECH CO LTD

A super high voltage pulse transformer

ActiveCN105489356BFix damageSolve assembly problemsTransformers/inductances coolingTransformers/inductances coils/windings/connectionsCapacitanceUltra high voltage

The invention discloses an ultra-high voltage pulse transformer, which comprises a transformer component and an oil cylinder, wherein the transformer component is connected with the oil cylinder in a rapid connecting manner of a socket and a plug; the transformer component comprises a main transformer, a bias inductor, a capacitive voltage divider, a current transformer and an equipotential capacitor, which all are arranged on a semicircular bottom plate to be conveniently and quickly installed and maintained; the main transformer is formed by combining multiple groups of iron cores which are rectangular cutting iron cores in parallel; and corners of all iron cores are rounded. According to the ultra-high voltage pulse transformer, multiple problems that a traditional ultra-high voltage pulse transformer is huge in volume, heavy, not beautiful in appearance, complicated in structure, difficult to produce, assemble and maintain, too long in pulse rising time and the like, and the problem that surroundings and operators are harmed due to the fact that the radiation dose of dangerous rays exceeds the standard in online charging work are solved; the production cost is reduced; and the production efficiency is improved.

Owner:GLORYMV ELECTRONICS

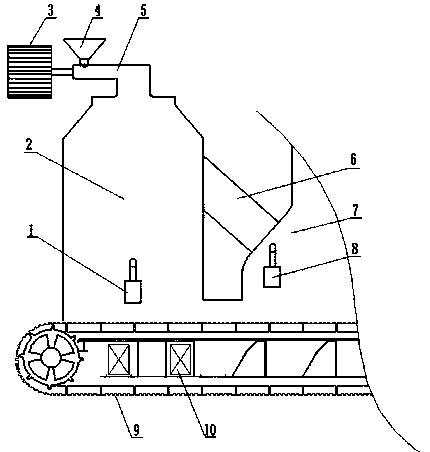

Biomass gasification and combustion boiler with secondary ignition device

PendingCN108800103ASolution to low furnace temperatureSolve the ignition problemSolid fuel combustionAir/fuel supply for combustionCombustion chamberFuel gasification

The invention provides a biomass gasification and combustion boiler with a secondary ignition device, belongs to the technical field of boiler combustion, and solves the problem that by adoption of aconventional biomass boiler, the boiler temperature is low at the beginning of ignition, the ignition is difficult, black smoke is generated, and the combustion is unstable. According to the biomass gasification and combustion boiler, a primary ignition device is positioned at the lower end of a biomass gasifier and used for the ignition for biomass fuel gasification; and the secondary ignition device is positioned at the outlet of a connecting device arranged between a biomass gasification chamber and a combustion chamber, and used for the ignition of biomass gasification gas. The working process of the two ignition devices comprises the following steps: biomass fuel enters the biomass gasification chamber through a feeding screw conveyor, the primary ignition device is started, and the biomass gasification gas generated from the biomass gasification chamber enters the combustion chamber through the connecting device; at the time, the boiler temperature is low at the beginning of ignition and the secondary ignition device is started; and when the boiler temperature meets the temperature demand of the combustion chamber, the secondary ignition device is stopped. By adoption of thebiomass gasification and combustion boiler provided by the invention, the flame stabilization of the biomass combustion chamber can be guaranteed, and the incomplete combustion, caused by the low boiler temperature at the beginning of ignition, of biomass gasification gas can be effectively avoided.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Gas ignition type inner hole supersonic spray gun

PendingCN112695267AImproves sprayabilityAchieve axial rotationMolten spray coatingCombustion chamberCombustible gas

The invention discloses a gas ignition type inner hole supersonic spray gun which comprises a gun body, a gun barrel, a pressure stabilizer, a combustion chamber and a connector. An igniter and three gas channels are arranged on the pressure stabilizer; inlets of the three gas channels are communicated with an oxygen conveying pipeline, a fuel oil conveying pipeline and a fuel gas conveying pipeline respectively; outlets of the three gas channels are respectively communicated with an inlet of the combustion chamber; a cooling water channel is arranged on the gun body and is communicated with a cooling water inlet pipe; and a gap is arranged between the combustion chamber and the gun body, and is respectively communicated with the cooling water channel and a cooling water outlet pipe to form cooling water circulation. According to the gas ignition type inner hole supersonic spray gun provided by the invention, combustible gas is firstly introduced for primary ignition, and fuel oil is introduced for secondary combustion after flame is introduced into the combustion chamber, so that the aim of igniting the spray gun to form high-speed flame flow is fulfilled, and the ignition problem of an external ignition type spray gun is solved.

Owner:ZHENGZHOU LIJIA THERMAL SPRAYING MACHINERY CO LTD

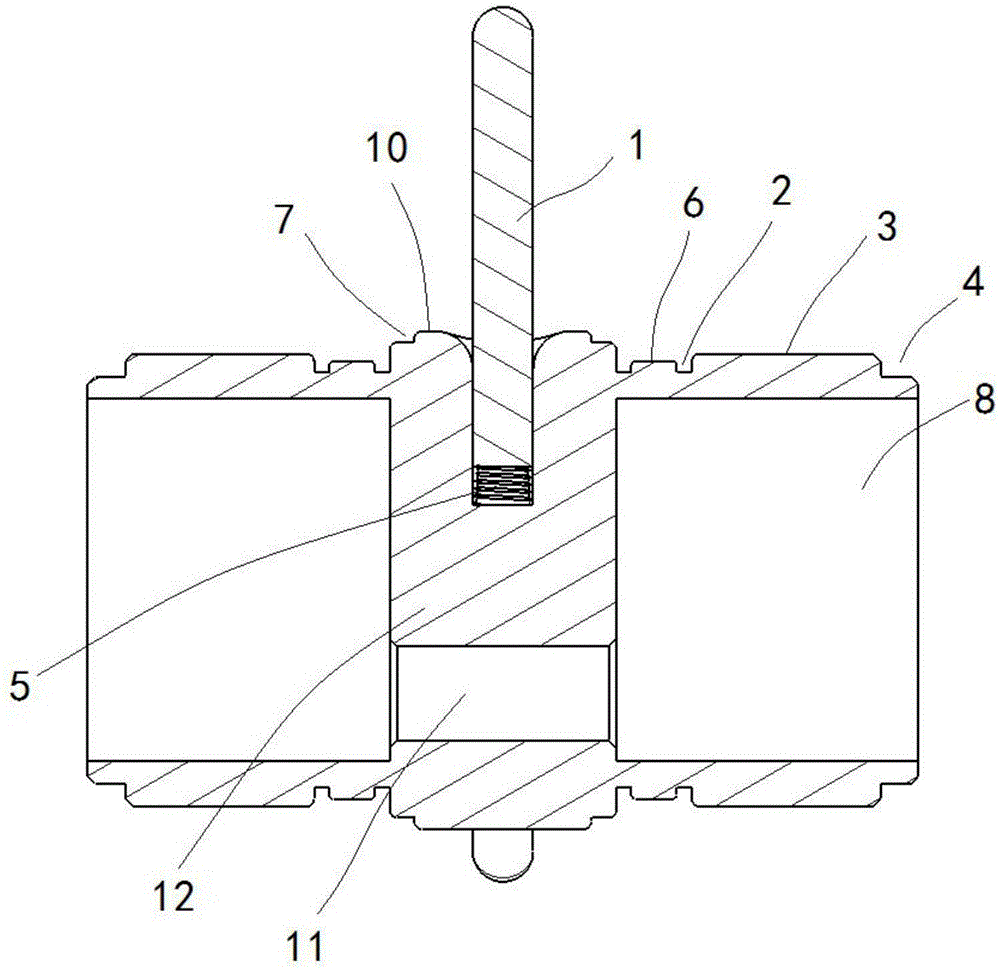

High-tension ceramics lead wire lever being resistant to high power radio frequency pulse peak power

InactiveCN101222107ASolve the ignition problemIncrease pressureLaser constructional detailsCircular discPulse energy

The present invention relates to a high-voltage ceramic wire leading rod which is resistant to high-power RF pulse peak power and used for RF slab CO2 lasers, which comprises a ceramic part (1) and a wire leading rod (2). The ceramic part (1) is in a T-shaped structure, which is an integral structure formed by a ceramic disk (6) with a center hole (7) and a ceramic cylinder (4) extending downwards from the lower surface of the ceramic disk (6); the wire leading rod (2) passes through an inner hole (5) and the center hole (7) of the ceramic part (1); the wall of the inner hole (5) at the lower end of the ceramic cylinder (4) is provided with a metal layer (3); the ceramic cylinder (4) is welded with the lower part of the wire leading rod (2) through the metal layer (3); a clearance is arranged between the wall of the center hole (7) of the ceramic disk (6) and the outer edge of the wire leading rod (2); a clearance is arranged between the wall of the inner hole (5) of the ceramic cylinder (4) and the outer edge of the wire leading rod (2) as well. Under the conditions of guaranteeing no change on the prior overall dimension of a laser shell, the present invention can prevent the surface of the wire leading rod from striking fire when the RF pulse energy with identical average power, identical frequency and exponentially increased pulse peak power is input.

Owner:江苏新潮创新投资集团有限公司

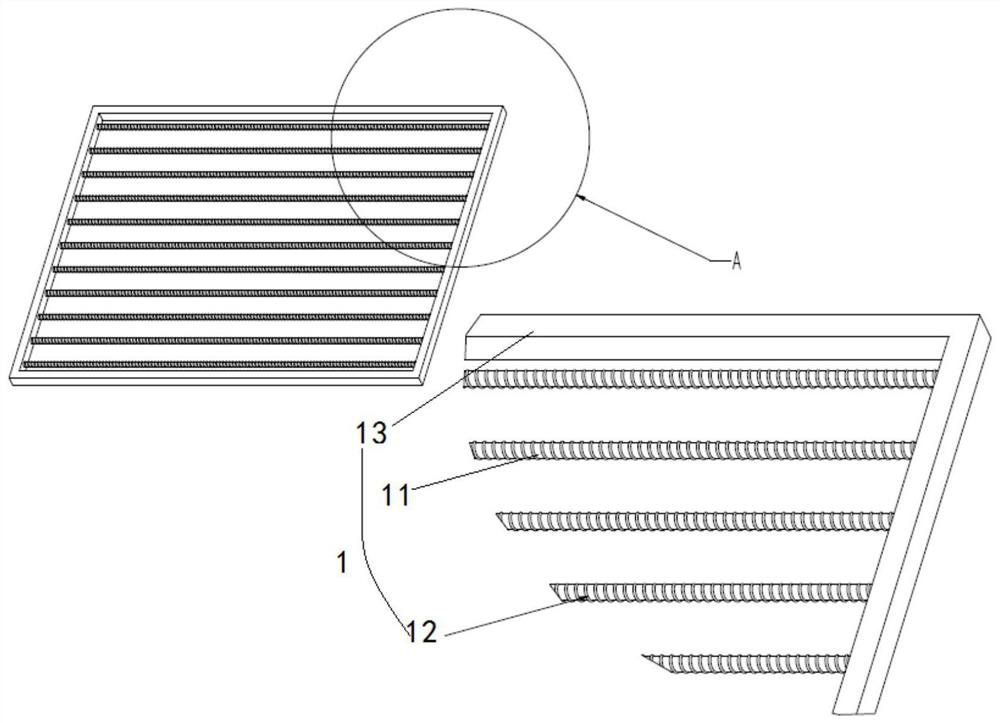

Electric purification assembly and air purification equipment

PendingCN112254261ALower ionization voltageSolve creepage and ignition problemsMechanical apparatusSpace heating and ventilationPhysicsChemistry

The invention relates to the technical field of household appliances, in particular to an electric purification assembly and air purification equipment. The electric purification assembly comprises adischarge electrode and a dust collection electrode corresponding to the discharge electrode. The discharge electrode comprises a base body and at least one discharge body spirally arranged on the base body. According to the electric purification assembly, the density of ionized plasmas can be greatly improved by adopting the spiral discharge bodies, and meanwhile, the discharge bodies are spirally designed, so that the discharge volume is reduced; and furthermore, the discharge bodies are spirally fixed to a bracket, do not need to be tensioned by a spring, so that a thinner ionization wire is selected, an ionization voltage can be further reduced, the problems that creepage and sparking are prone to being caused by high existing ionization voltage are solved, and the ozone of ionizationdischarge is reduced.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Adjustable electric cooker contact switch

InactiveCN107680845ASolve the ignition problemImprove reliabilityContact driving mechanismsCooking vesselsFastenerCooker

The invention discloses an adjustable electric cooker contact switch. The adjustable electric cooker contact switch is characterized by comprising a contact holder, a screw set on the contact holder,and an upper fixing sheet and a lower fixing sheet which are mutually spaced. The upper fixing sheet and the lower fixing sheet are separated by a first ceramic washer and are fixed on the contact holder through the screw. A leaf spring is connected with the upper fixing sheet through a fastening element. Mutually corresponding contacts are set on the lower fixing sheet and the leaf spring. The adjustable electric cooker contact switch is simple in structure, convenient in usage and adjustment and high in stability.

Owner:肇庆金雅乐电器有限公司

Method of zero passage switch of electromagnetic relay and circuit

ActiveCN101577192BReduce design and manufacturing costsSolve the ignition problemRelaysControl signalControl theory

Owner:PERICOM TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com