A thermal plasma arc flame generator

A thermal plasma and plasma technology, applied in the field of plasma, can solve the problems of low energy utilization rate, difficult ignition of the device, poor working stability, etc., and achieve the effects of improving working stability, large range and long length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

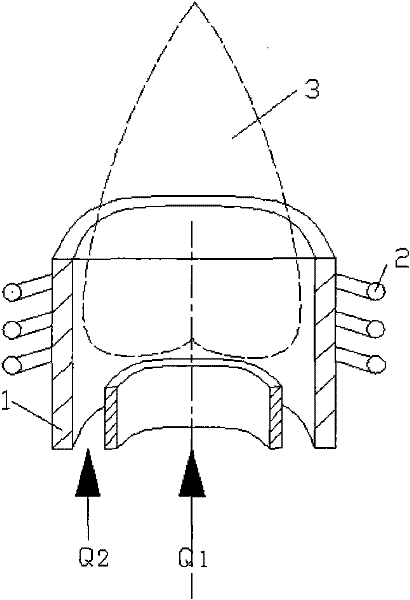

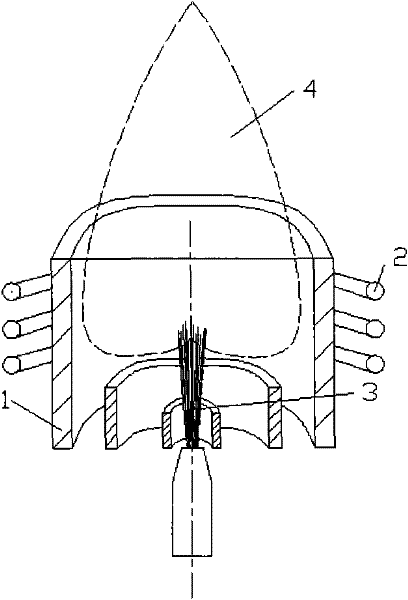

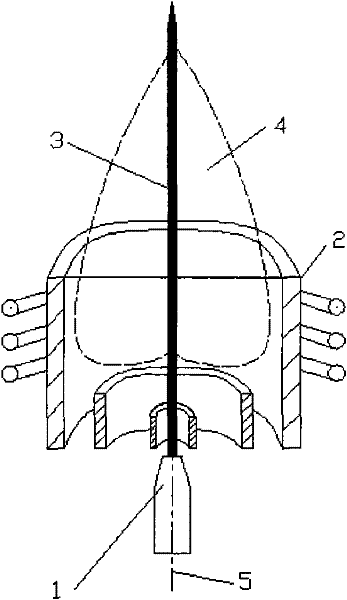

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

[0025] image 3 It is a schematic diagram of the principle of the present invention, and the thermal plasma arc flame generator of the present invention includes a high-frequency induction thermal plasma generator [2] and a laminar arc thermal plasma generator [1]. The central axis [5] of the laminar arc thermal plasma jet [3] and the high-frequency induction thermal plasma generator [2] coincides to guide the arc. The invention solves the problems of difficult ignition, cumbersome steps and easy arc breaking of the high-frequency induction thermal plasma generator, and greatly improves the working stability of the high-frequency induction thermal plasma generator. The laminar arc thermal plasma jet [3] is injected along the direction of the central axis [5] of the high frequency induction thermal plasma generator [2], and what is injected is the conductive arc plasma, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com